Enameled inner container for water heater and enameling glaze powder

An enamel glaze, water heater technology, applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of easy occurrence of tiny cracks or silver streaks, shortened life of enamel liner, corrosion and perforation of liner, etc., so as to reduce fish scale-like substances. and gray cracking phenomenon, improve surface finish and texture hardness, reduce the effect of sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

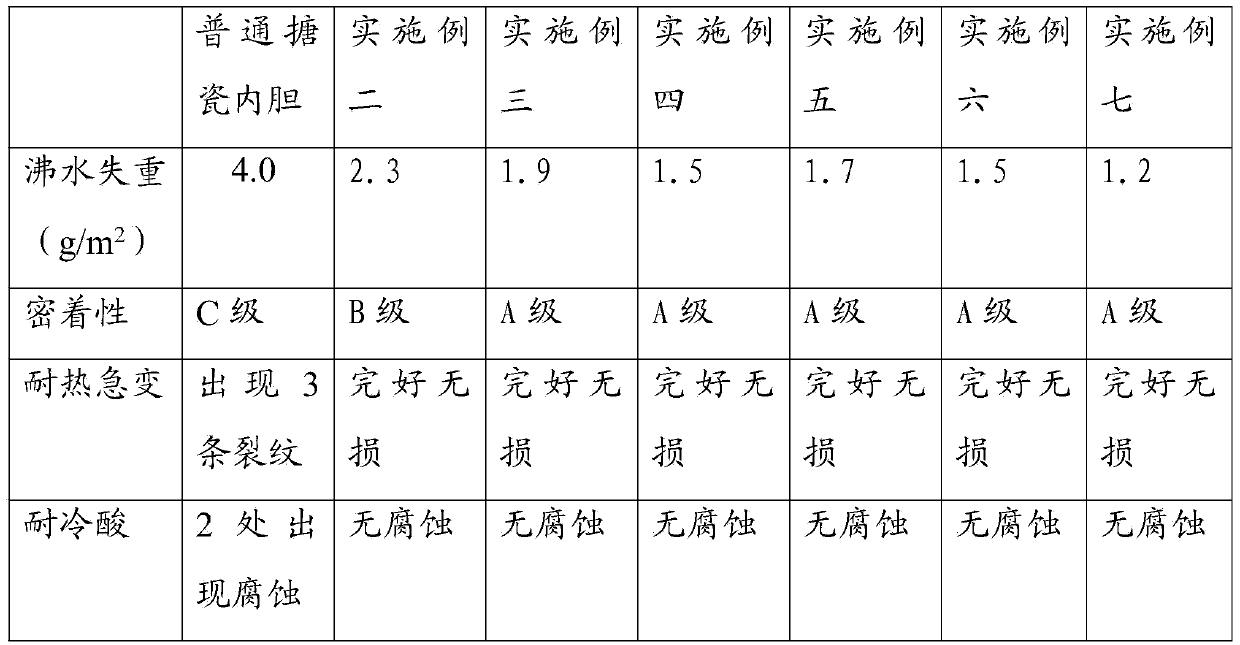

Examples

Embodiment 1

[0017] This embodiment proposes a kind of water heater enamel liner, and this liner is made according to the following method:

[0018] Step 1: The steel plate is processed into an inner tank blank, that is, a steel plate layer through shearing, stamping, stretching, welding and other processes, and the thickness of the steel plate layer is preferably 0.8-3.5mm.

[0019] Step 2: Clean, degrease, pickle, neutralize, dry, etc. the surface of the inner wall of the blank of the liner before enamel treatment, so as to facilitate the adhesion of the enamel glaze layer.

[0020] Step 3: Prepare the enamel glaze powder according to the following weight percentages:

[0021] 40-55% SiO 2 , 5-10% Na 2 O, 5-15% of B 2 o 3 , 5-7% Al 2 o 3 , 0.05~0.2% Fe 2 o 3 , 3~6% K 2 O, 5-23% ZrO 2 , 3~7% CaF 2 , 2.5-4% NaF, 3-10% Co 3 o 4 , 2~10% CoO, 0.2~0.5% MnO 2 , 2~4% Li 2 o 2 , 3 to 10% SiC.

[0022] Step 4: Apply the prepared enamel slurry on the inner wall of the blank of the ...

Embodiment 2

[0035] Based on Example 1, this example uses a steel plate with a carbon content of 0.07%, a titanium content of 0.06%, an aluminum content of 0.0001%, a manganese content of 0.28%, a sulfur content of 0.02%, and a silicon content of 0.37%.

[0036] The percentage of each component in the enamel glaze powder is: 49% SiO 2 , 5% Na 2 O, 8% of B 2 o 3 , 5.5% Al 2 o 3 , 0.2% Fe 2 o 3 , 4% K 2 O, 7% ZrO 2 , 5% CaF 2 , 2.8% NaF, 3% Co 3 o 4 , 3% CoO, 0.5% MnO 2 , 2% Li 2 o 2 , 5% SiC.

Embodiment 3

[0038] Based on Example 1, this example uses a steel plate with a carbon content of 0.07%, a titanium content of 0.06%, an aluminum content of 0.0001%, a manganese content of 0.28%, a sulfur content of 0.02%, and a silicon content of 0.37%.

[0039] The percentage of each component in the enamel glaze powder is: 48% SiO 2 , 5% Na 2 O, 5% B 2 o 3 , 5% Al 2 o 3 , 0.1% Fe 2 o 3 , 3% K 2 O, 8% ZrO 2 , 4% CaF 2 , 2.7% NaF, 5% Co 3 o 4 , 5% CoO, 0.2% MnO 2 , 3% Li 2 o 2 , 6% SiC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com