Method for mfg. nano alumina

A kind of technology of aluminum oxide and nanometer, applied in chemical instruments and methods, aluminum oxide/aluminum hydroxide, colloid chemistry, etc., can solve problems such as uncontrollable and wide gel particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

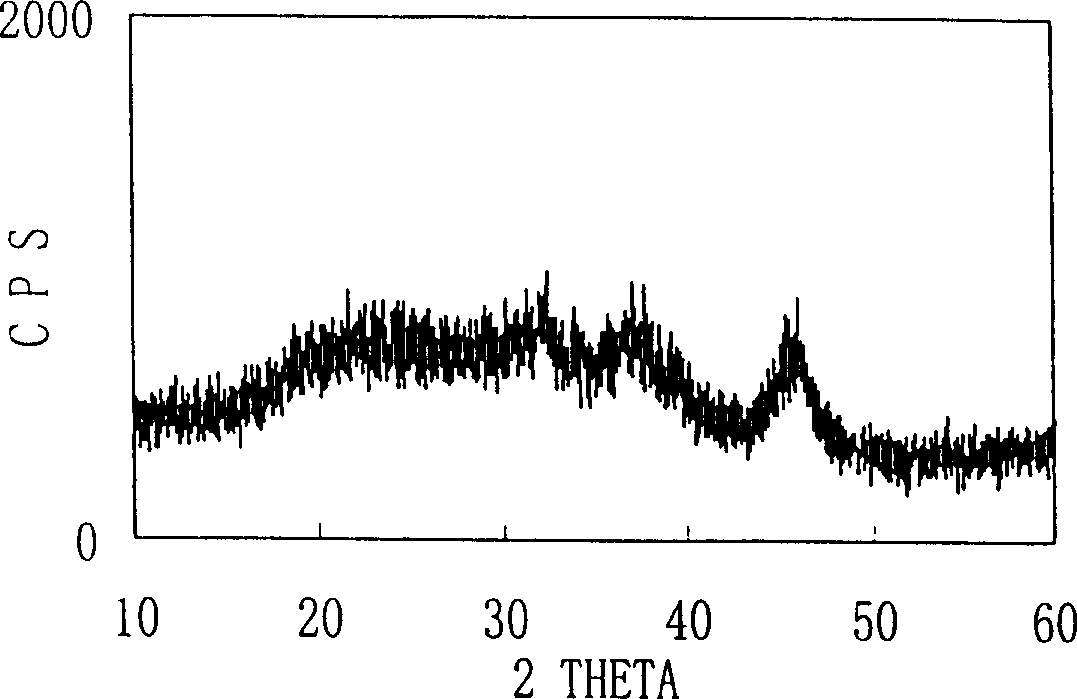

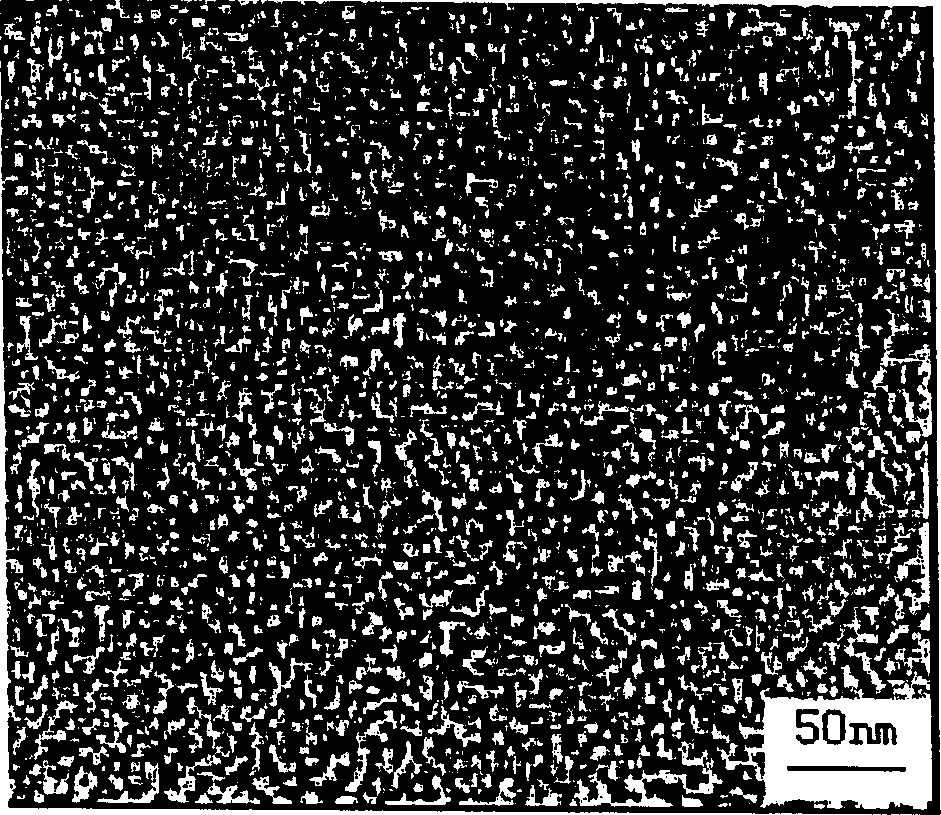

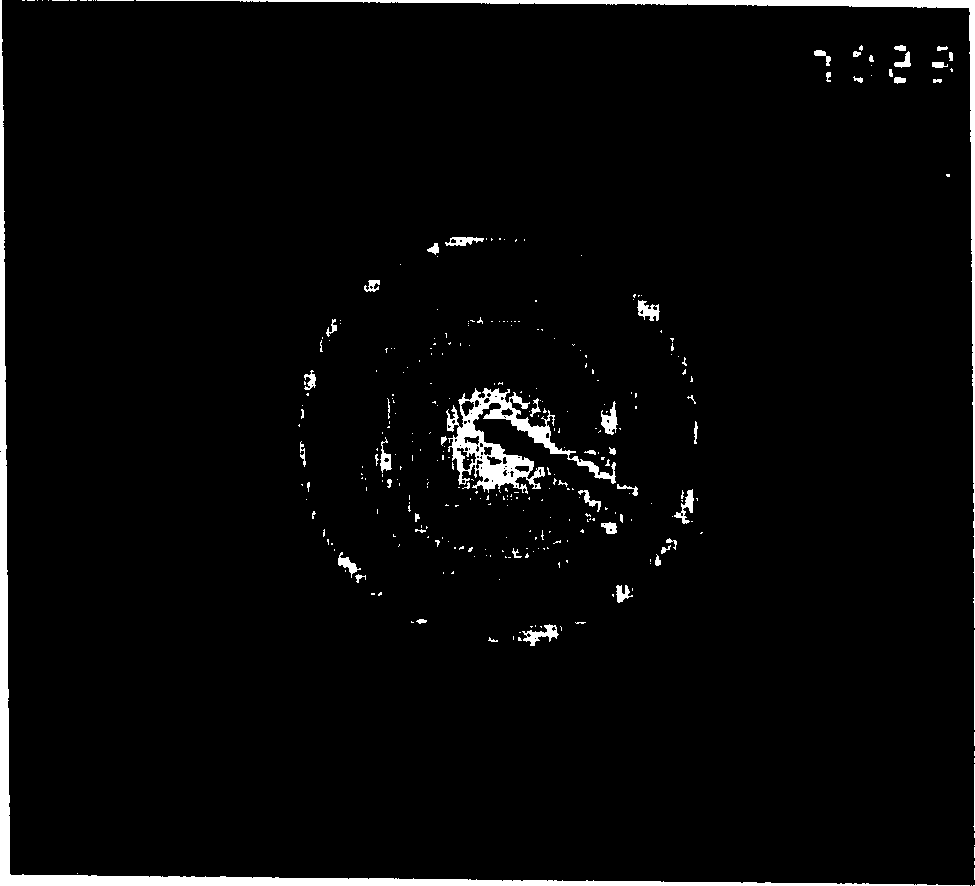

Embodiment 1

[0012] Embodiment 1: raw material is aluminum ammonium sulfate, the soluble aluminum salt concentration that is mixed with is 0.1mol / L, and precipitant concentration is ammoniacal liquor: water=1: 3, gets 400ml precipitant, adds emulsifying agent triton 100 respectively, its The addition amount is 0.05vol%, and the additive polyethylene glycol 200 is added at 2.5vol%, vigorously stirred at 40°C for 15 minutes, and 1000ml of soluble aluminum salt solution is added dropwise to obtain a hydrated alumina gel solution, the pH of which is between 9- Between 12; the prepared gel is aged in the mother liquor, the aging time can be 12-24 hours, the present embodiment is aged for 18 hours and then suction filtered, washed 8-10 times with deionized water, washed with anhydrous The water in the gel is exchanged with ethanol several times, dried by supercritical fluid drying method, and the ultrafine particles obtained after drying are calcined at 900°C for 2 hours to obtain nanometer γ-Al ...

Embodiment 2

[0013] Example 2, the raw material is aluminum nitrate, the concentration of the prepared soluble aluminum salt solution is 0.3mol / L, Triton X-155 is added respectively in the precipitation, the addition amount is 0.1vol%, and the additive polyethylene glycol 1540 is added 0.5vol%, stirred vigorously at 40°C for 10 minutes, and added dropwise 1000ml of soluble aluminum salt solution to obtain a hydrated alumina gel solution, the pH of which was between 9-12; roasted at 900°C for 4 hours. All the other are with embodiment 1.

Embodiment 3

[0014] Embodiment 3, the raw material is aluminum trichloride, the concentration of the soluble aluminum salt prepared is 0.2mol / L, Triton X-200 is added respectively in the precipitation, its addition is 0.13vol%, additive polyethylene glycol 1540, Added as 1.5vol%. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com