Low-crystallization-degree coating material and preparation method thereof, anode material and lithium battery anode

A technology of negative electrode material and crystallinity, applied in the field of materials, can solve problems such as affecting the first charge and discharge efficiency of graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

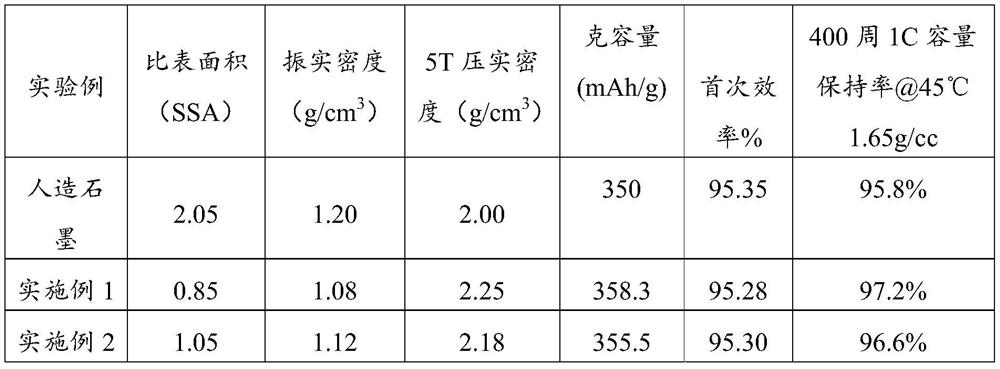

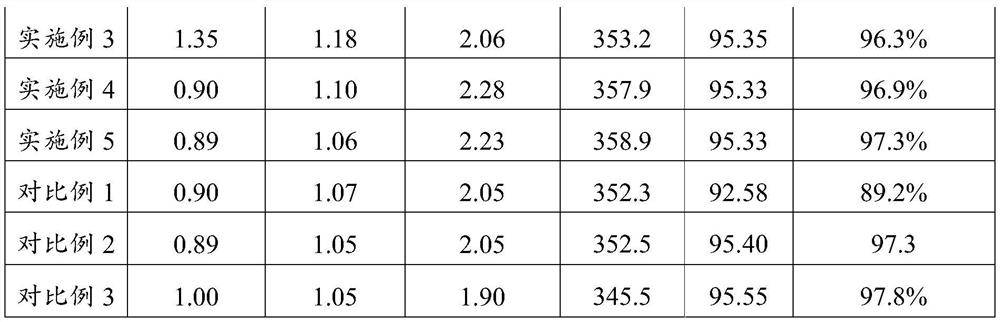

Examples

preparation example Construction

[0033] The application provides a method for preparing a coating material with low crystallinity, which mainly includes:

[0034] mixed Al 2 o 3 Nanoparticles and pitch, heat treatment to carbonize the pitch.

[0035] Will Al 2 o 3 Nanoparticles are mixed with pitch, and the pitch is carbonized by heat treatment to form a microcrystalline structure, Al 2 o 3 The nanoparticles can prevent the further fusion and expansion of the microcrystalline structure, and obtain a coating material with a lower crystallinity; the crystallinity of the coating material is lower than that of conventional soft carbon. Using the coating material to coat graphite can obtain more lithium intercalation sites, which is beneficial to improving the energy density of the material.

[0036] In some embodiments of the present application, Al with a particle size of 20nm-200nm is used 2 o 3 Nanoparticles; within this particle size range, a coating material with a lower degree of crystallization can...

Embodiment 1

[0062] This embodiment provides a negative electrode material, which is mainly prepared through the following steps:

[0063] Artificial graphite, pitch, Al with a particle size of 20-50nm 2 o 3 Mix according to the mass ratio of 92:8:0.7, put the mixed material in the reaction kettle, heat and stir under the protection of inert gas, raise the temperature to 500°C at 5°C per minute, keep warm for 6H, and discharge the material to obtain graphite-coated materials .

[0064] The graphite coating material and sodium alginate aqueous solution were put into the kneading pot, and the mass ratio of graphite coating material to sodium alginate was 97.5:2.5. The mixture was stirred at room temperature for 30 min, and then kneaded in an inert atmosphere at 100-120° C. to remove moisture to obtain a negative electrode material.

Embodiment 2

[0066] This embodiment provides a negative electrode material, which is mainly prepared through the following steps:

[0067] Artificial graphite, pitch and Al with a particle size of 50-80nm 2 o 3 Mix at high speed according to the mass ratio of 95:5:0.26, put the mixed material in the reaction kettle, heat and stir under the protection of inert gas, raise the temperature to 600°C at 5°C per minute, keep it warm for 4H, and discharge the material to obtain a graphite-coated material .

[0068] The graphite coating material and chitosan aqueous solution were put into the kneading pot, and the mass ratio of graphite coating material to chitosan was 98.5:1.5. The mixture was stirred at room temperature for 30 min, and then kneaded in an inert atmosphere at 100-120° C. to remove moisture to obtain a negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com