Cementation type polysulfide sealant

A sealant and vulcanizing agent technology, applied in the chemical field, can solve the problems of hydrocarbon solvent resistance, poor atmospheric aging resistance, harsh use environment requirements, and no flame retardant effect, and achieves the effect of a simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] Below in conjunction with embodiment the present invention is further described.

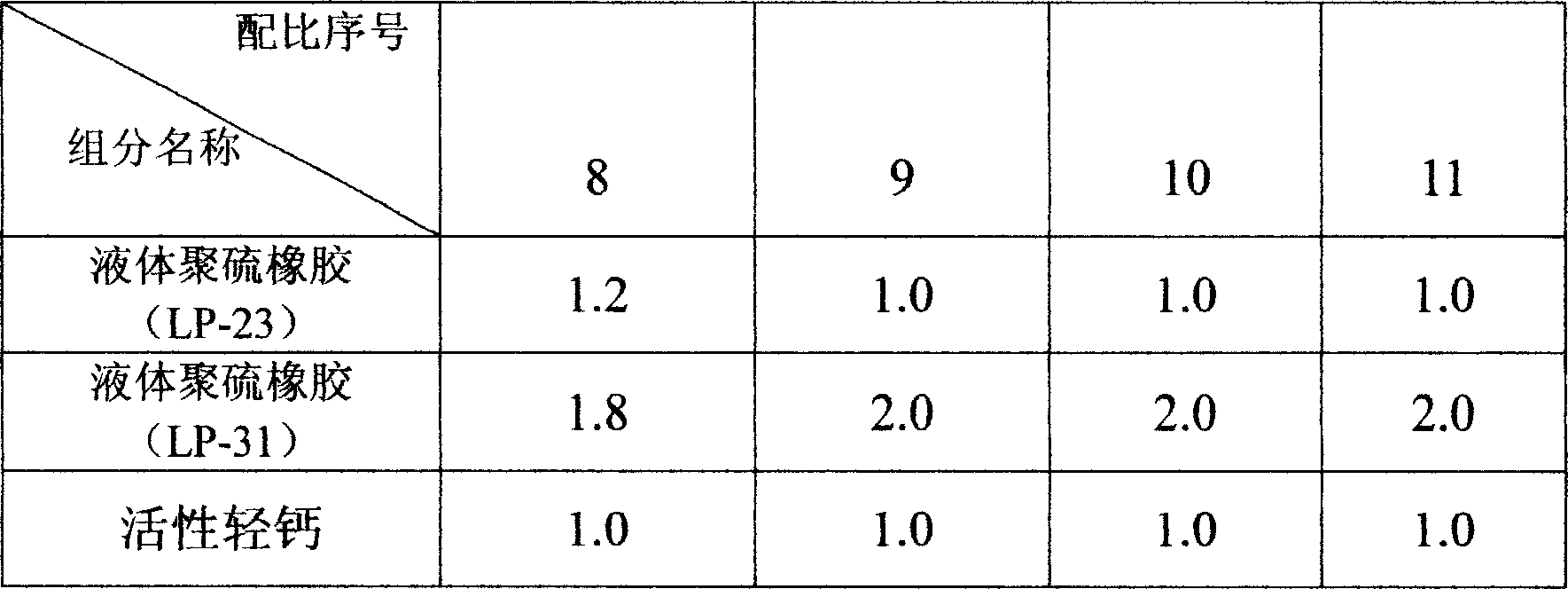

[0093] The adhesive polysulfide sealant of the present invention was prepared according to the preparation method specified in the present invention by adopting the 4 formulations in Table 1.

[0094] 1. The base paste (component A) and vulcanized paste (component B) are prepared and mixed (closed) separately.

[0095] 2. When weighing the base paste raw materials, first weigh the solid material, then weigh the liquid material; after weighing a small dose of liquid material, mix it with a large dose of liquid material, and then mix it with the solid material to fully moisten it.

[0096] 3. When preparing vulcanized paste, first weigh manganese dioxide and phthalic anhydride, then weigh chlorinated paraffin and mix well, then weigh other components and mix well to fully moisten.

[0097] 4. The components of manganese dioxide, diphenylguanidine and phthalic anhydride can be properly adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com