High peeling strength polysulfide sealant and sealing method

A polysulfide sealant and high-peeling technology, which is applied in the direction of chemical instruments and methods, adhesives, non-polymer adhesive additives, etc., can solve the problem of increased viscosity of sealant, decreased performance of use process, and improved peel strength. Problems, achieve the effect of improving adhesive performance, improving flexibility, and improving peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation of component A and component B is mixed with a three-roll mill, and each component is weighed according to the proportion, then roughly mixed and then mixed with a three-roll mill for 3 times before use;

[0018] Component A and Component B are kept separately.

[0019] The preparation method of the acrylic end-blocking modified polysulfide rubber in the high peel strength polysulfide sealant as described above is characterized in that: the acrylic end-blocking modified polysulfide rubber is composed of liquid polysulfide rubber and acrylic acid The acrylic compound is obtained by reacting with a free radical initiator at a temperature of 70°C to 80°C for 4 to 6 hours, wherein the acrylic compound has the following structure: R 1 CH=CR 2 COOR 3 , where: R 1 and R 2 is H, CH 3 、CH 2 CH 3 or CH 2 CH 2 CH 3 One of them, considering the activity of the reaction, R 1 and R 2 Preferably H; R 3 is H or (CH 2 ) n CH 3 One of them, n=0~5, preferab...

Embodiment 1

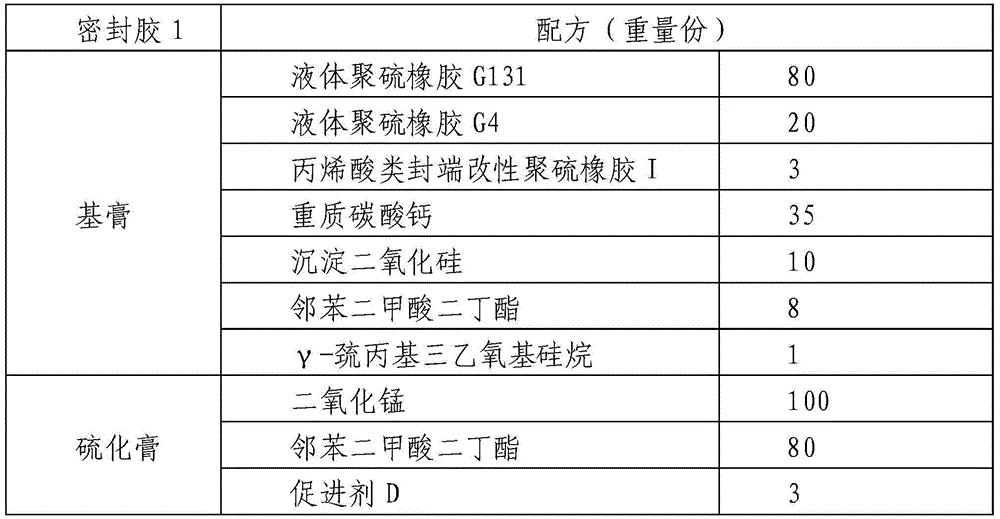

[0021] Embodiment 1: Sealant 1 is a kind of sealant used for oil tank sealing. It is composed of component A base paste and component B vulcanized paste, component A is base paste, and component B is vulcanized paste. Its composition formula is as follows Table 1 shows:

[0022] Formulation composition of table 1 sealant 1

[0023]

[0024] Among them, the synthesis steps of acrylic acid end-capped modified polysulfide rubber I are as follows: 100 parts by weight of liquid polysulfide rubber G44 with a number average molecular weight of 1000 and a crosslinking degree of 0.5%, and 14.4 parts by weight of acrylic acid are put into a reaction bottle , heated in an oil bath to 70°C, added 0.05 parts by weight of azobisisobutyronitrile, stirred and reacted for 6 hours, and cooled to obtain modified polysulfide rubber I;

[0025] Both the base paste and the vulcanizing paste are prepared by mixing with a three-roll mill, then weighed according to a weight ratio of 100:10, mixed ...

Embodiment 2

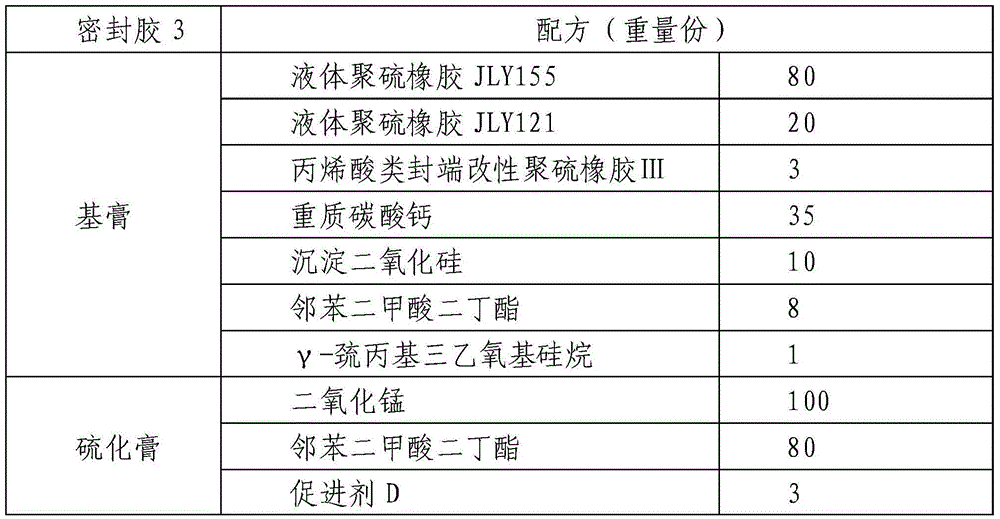

[0026] Embodiment 2: Sealant 2 is a sealant used for anti-corrosion sealing of bridges, consisting of component A base paste and component B vulcanized paste, component A is base paste, and component B is vulcanized paste, its composition Formula is as shown in table 2:

[0027] Formulation composition of table 2 sealant 2

[0028]

[0029] Among them, the synthesis steps of acrylic acid end-capped modified polysulfide rubber II are as follows: 100 parts by weight of liquid polysulfide rubber LP33 with a number average molecular weight of 1000 and a degree of crosslinking of 0.5%, and 17.2 parts by weight of methacrylic acid are put into the reaction In the bottle, heat the oil bath to 80°C, add 0.05 parts by weight of isobutyl peroxybenzoate, stir and react for 6 hours, and cool to obtain modified polysulfide rubber II;

[0030] Both the base paste and the vulcanizing paste are prepared by mixing with a three-roll mill, then weighed according to a weight ratio of 100:10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com