Epoxy resin composition for prepreg, carbon fiber prepreg and carbon fiber compound material

A technology of epoxy resin and prepreg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Pour 100g of epoxy resin E-51 into the speed-adjustable disperser, add 10g of carboxy-terminated polynitrile liquid rubber, 10g of modified epoxy resin, and 10g of dicyandiamide in turn, stir and disperse evenly, and then add 35g of aromatic amines The curing agent was dispersed for 30 minutes to obtain an epoxy resin composition;

[0067] The prepared epoxy resin composition is evenly coated on the release paper, and then the epoxy resin composition is heated and melted to impregnate the carbon fiber material to obtain a carbon fiber prepreg, and the epoxy resin content in the prepreg is 50%.

[0068] The carbon fiber prepreg was cured in a molding machine at 165°C for 60 minutes to obtain a carbon fiber composite material.

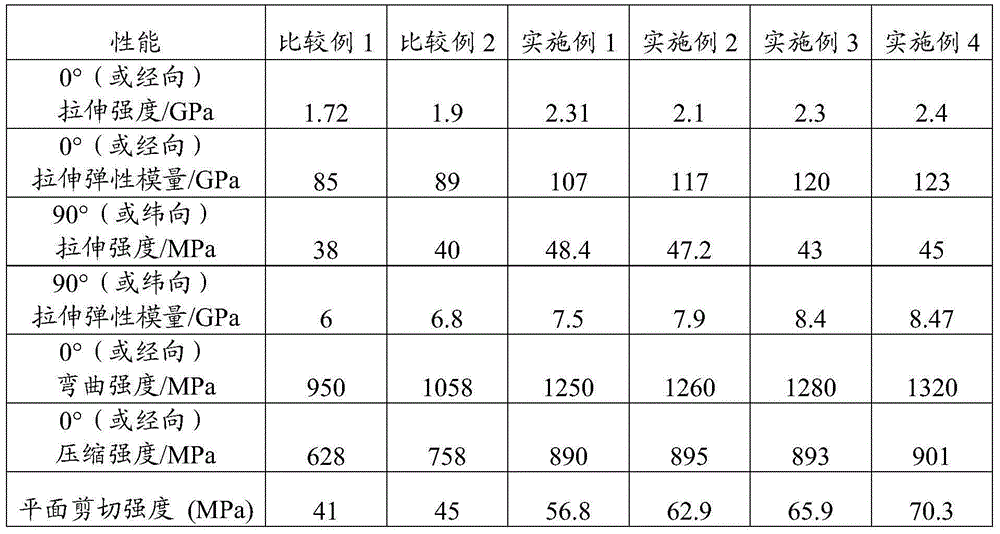

[0069]The present invention tests the tensile properties, flexural strength, compressive strength and plane shear strength of carbon fiber composite materials according to "GB / T 28461-2012 Carbon Fiber Prepreg Standard", and the results are shown ...

Embodiment 2

[0071] Pour 100g of epoxy resin E-51 into the speed-adjustable disperser, add 10g of carboxy-terminated polynitrile liquid rubber, 10g of modified epoxy resin, and 10g of dicyandiamide in turn, stir and disperse evenly, and then add 30g of polyetheramine D-2000 and 15g polyetheramine D-400 were dispersed for 30 minutes to obtain an epoxy resin composition;

[0072] The prepared epoxy resin composition is evenly coated on the release paper, and then the epoxy resin composition is heated and melted to impregnate the carbon fiber material to obtain a carbon fiber prepreg, and the epoxy resin content in the prepreg is 30%.

[0073] The carbon fiber prepreg was cured in a molding machine at 165°C for 60 minutes to obtain a carbon fiber composite material.

[0074] The present invention tests the tensile properties, flexural strength, compressive strength and plane shear strength of carbon fiber composite materials according to "GB / T 28461-2012 Carbon Fiber Prepreg Standard", and th...

Embodiment 3

[0076] Pour 70g of epoxy resin E-51 and 30g of epoxy resin F-51 into the adjustable speed disperser, add 10g of carboxy-terminated polynitrile liquid rubber, 10g of modified epoxy resin, and 10g of dicyandiamide in order to stir and disperse evenly , and then add 30g polyetheramine D-2000 and 15g polyetheramine D-400 to disperse for 30min to obtain an epoxy resin composition;

[0077] The prepared epoxy resin composition is evenly coated on the release paper, and then the epoxy resin composition is heated and melted to impregnate the carbon fiber material to obtain a carbon fiber prepreg, and the epoxy resin content in the prepreg is 35%.

[0078] The carbon fiber prepreg was cured in a molding machine at 165°C for 60 minutes to obtain a carbon fiber composite material.

[0079] The present invention tests the tensile properties, flexural strength, compressive strength and plane shear strength of carbon fiber composite materials according to "GB / T 28461-2012 Carbon Fiber Prepr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com