Epoxy anti-corrosive paint used for underwater concrete

A technology of epoxy anti-corrosion coatings and underwater concrete, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., and can solve the problems of low volume shrinkage, easy damage, and incomplete curing of cured products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

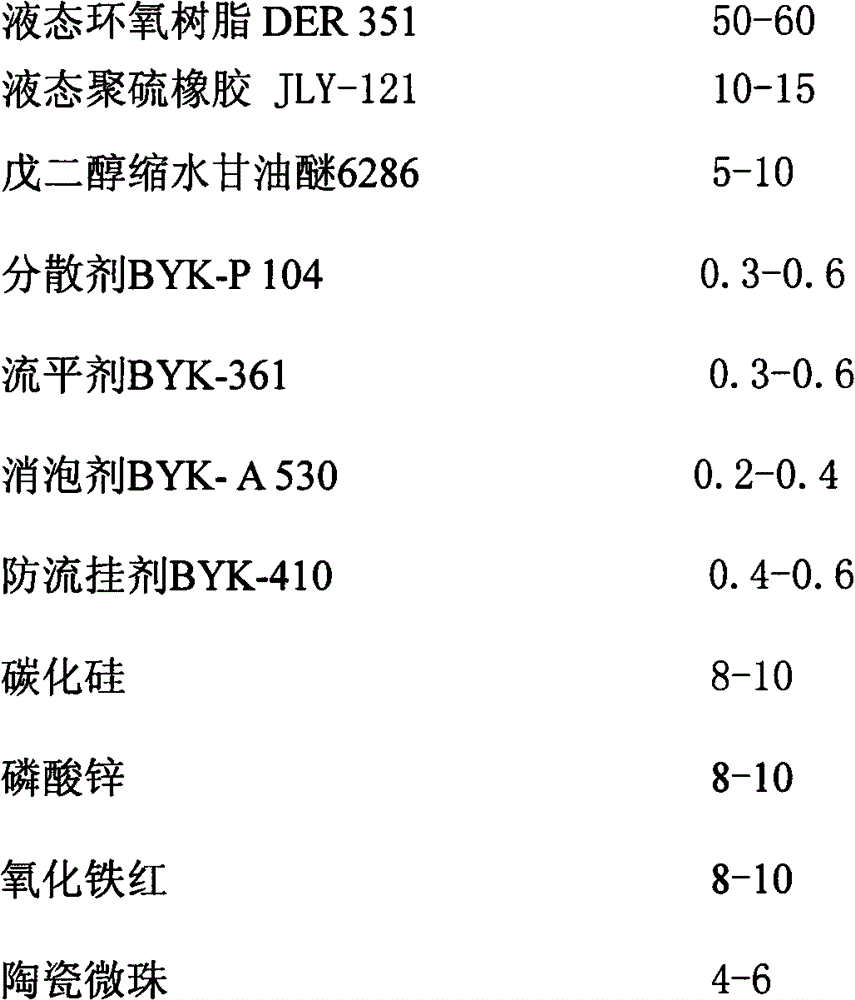

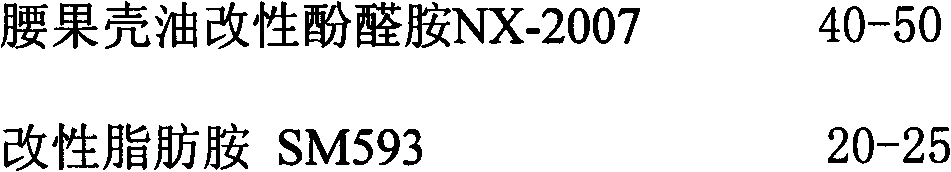

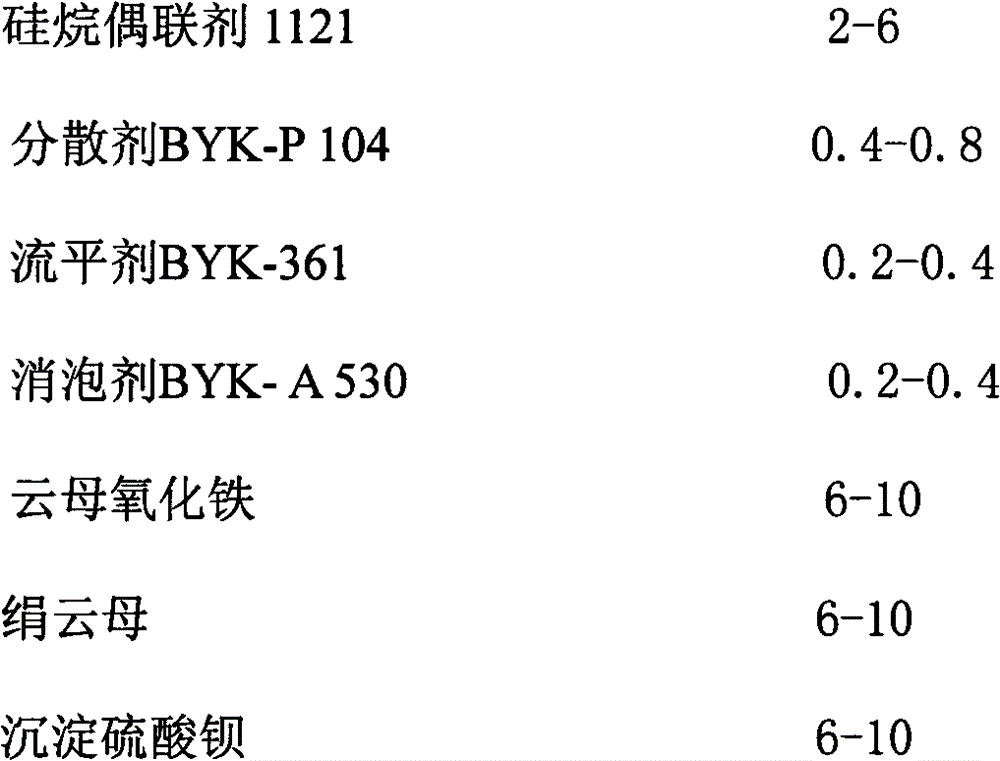

[0029] The present invention is described in further detail below in conjunction with specific examples: a kind of epoxy anticorrosion coating for underwater concrete, take liquid epoxy resin DER 351 as base material; Liquid polysulfide rubber is toughening agent; With pentylene glycol glycidyl ether 6286 as diluent; zinc phosphate and iron oxide red as active anticorrosion pigments, spherical silicon carbide, ceramic microbeads, mica iron oxide, sericite, precipitated barium sulfate as fillers; cashew nut shell oil modified phenalkamine and modified fat Amine is used as curing agent; silane coupling agent 1121 is used as adhesion promoter, and a solvent-free, two-component epoxy anti-corrosion coating for underwater concrete is prepared through a conventional preparation process with the cooperation of functional additives; the ingredients in the coating The composition is as follows:

[0030] A component:

[0031]

[0032] The measurement units of the above components ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com