Single-component high-elasticity epoxy adhesive

An epoxy adhesive, high-elasticity technology, applied in the direction of adhesive type, adhesive, epoxy resin, etc., can solve the problem of not meeting the requirements of use, and achieve the effect of good adhesion and good thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

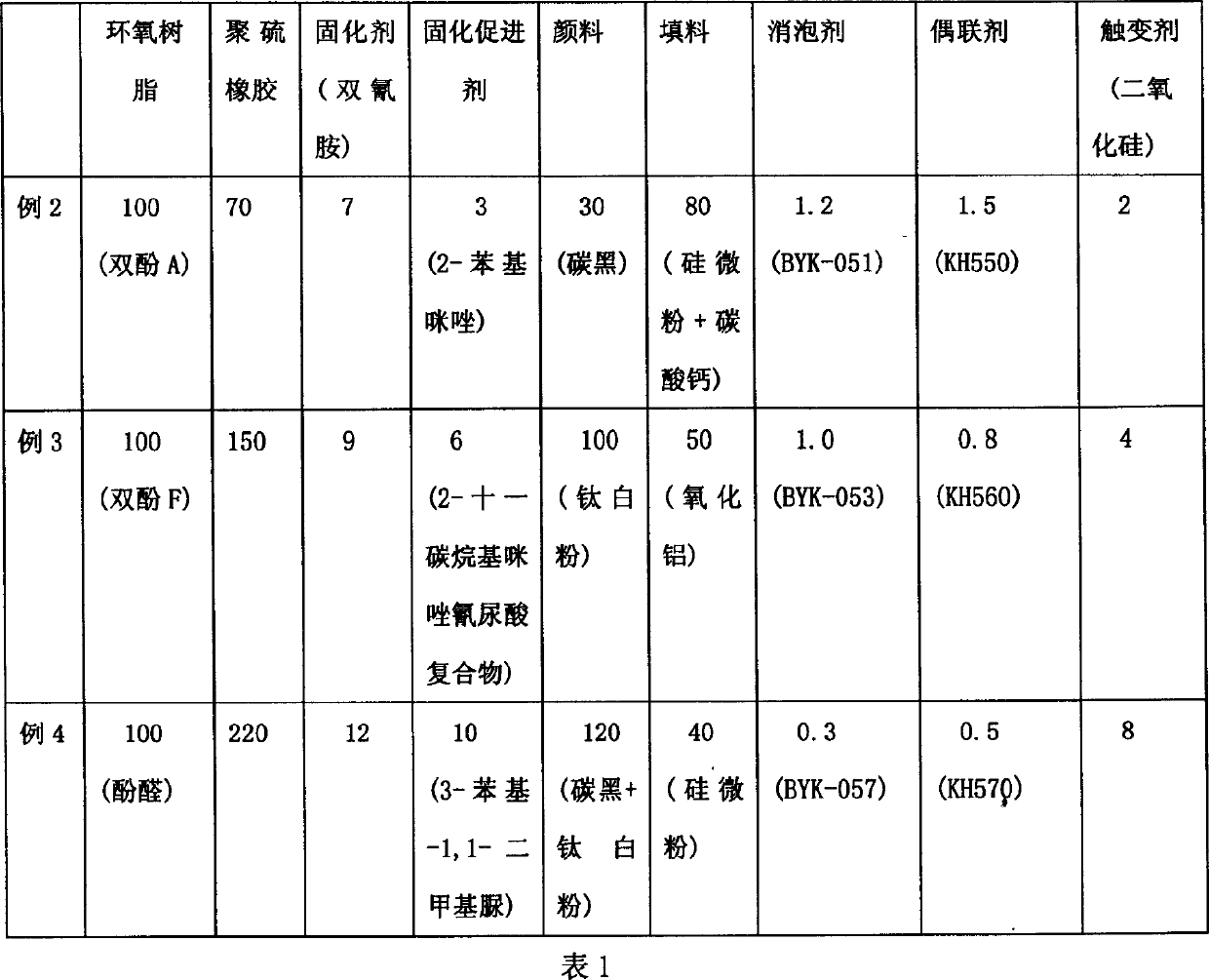

Examples

example 1

[0042] 10 grams of 2-heptadecyl imidazole, 12 grams of dicyandiamide and 190 grams of epoxy-terminated polysulfide rubber were placed in an oil bath at 100° C. for 1 hour to obtain a pre-reaction product. After cooling, add 100 grams of epoxy resin, 60 grams of calcium carbonate, 100 grams of titanium dioxide, 1 gram of carbon black, 0.5 gram of defoamer BYK-555, 0.5 gram of KH550, and 2 grams of fumed silica. Rolled twice on the roller machine. Then put it in a pressure vessel, vacuumize and defoam under stirring, and then it becomes an adhesive. The viscosity of the adhesive is 300 Pa.s. The adhesive can be fully cured at 130°C for 1 hour. Thixotropy is less than 5mm. The shear strength (normal temperature) is 7.5 MPa, and it is 6.0 MPa after 120 hours in warm water at 40°C. T-peel strength (room temperature) 500N / 20mm, 350N / 20mm after 120 hours in warm water at 40°C. Adhesive strength with glass plate (room temperature) 80N without peeling, 60N without peeling after 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com