Solvent-free anticorrosive coating based on polyurea elastomer and preparation method of solvent-free anticorrosive coating

A technology for polyurea elastomers and anti-corrosion coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced elasticity and easy wear, and achieve reduced usage, reduced environmental pollution, and good organic resistance Effect of Solvent Corrosion Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

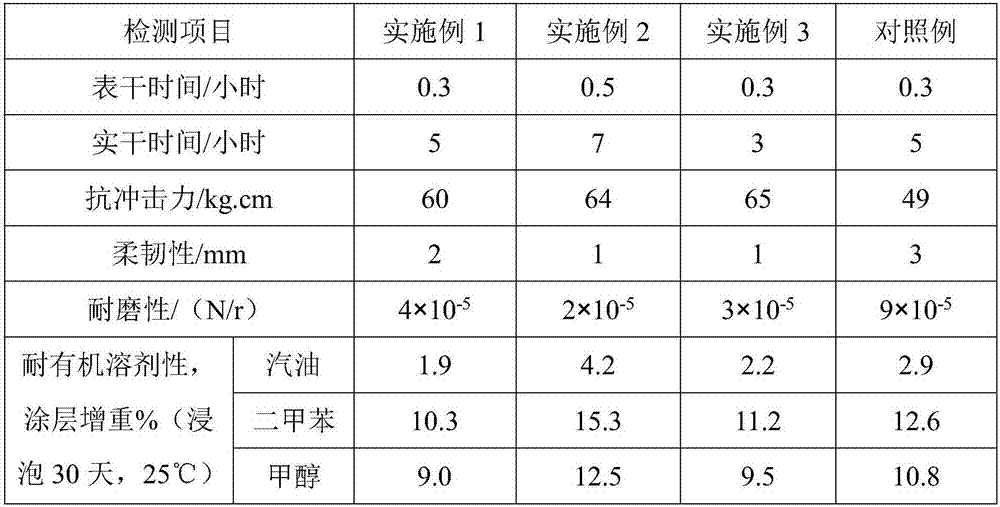

Examples

Embodiment 1

[0025] The polyurea anticorrosion coating of this embodiment is formulated from the raw materials of the following parts by weight (kg): the coating is made up of components A and B, and the component A is made up of the following parts by weight: p-phenylene diisocyanate 70 parts, 10 parts of butyl acetate, and the B component is made up of the following materials by weight: 70 parts of polyamide polyamine epoxy fluoropropane, 25 parts of diethyltoluenediamine, 25 parts of liquid polysulfide rubber, talc 30 parts of powder, 2 parts of γ-glycidyl propyl-trimethoxysilane, 5 parts of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole.

[0026] The preparation scheme of the present embodiment polyurea anticorrosion coating is as follows:

[0027] The preparation method of the A component: Add butyl acetate into a reaction kettle protected by nitrogen, heat to 100°C under stirring, vacuumize at a constant temperature to -0.1MPa, dehydrate for 3 hours, and cool down to 50°C under atmosphe...

Embodiment 2

[0032] The polyurea anticorrosion coating of this embodiment is formulated from the raw materials of the following parts by weight (kg): the coating is made up of components A and B, and the component A is made up of the following parts by weight: tetramethylbenzene 100 parts of dimethyl diisocyanate, 20 parts of ethyl carbonate, and the B component is made up of the following materials by weight: 70 parts of polyamide polyamine epichlorohydrin, 20 parts of isophorone diamine, liquid polysulfide 15 parts of rubber, 40 parts of carbon black, 5 parts of vinyltrichlorosilane, 0.5 part of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole.

[0033] The preparation scheme of the present embodiment polyurea anticorrosion coating is as follows:

[0034] The preparation method of the A component: add ethyl carbonate into a reaction kettle protected by nitrogen, heat to 90°C under stirring, vacuumize at a constant temperature to -0.09MPa, dehydrate for 3 hours, and cool do...

Embodiment 3

[0039]The polyurea anticorrosion coating in this embodiment is prepared from the following raw materials in parts by weight (kg): a solvent-free anticorrosion coating based on polyurea elastomer, the coating is composed of A component and B component, and the A component Parts are made up of the following parts by weight: 70 parts of diphenylmethane diisocyanate, 5 parts of dibutyl phthalate, and the B component is made up of the following parts by weight: polyamide polyamine epibromohydrin 50 parts Parts, 30 parts of 4,4-bis-sec-butylaminodiphenylmethane, 30 parts of liquid polysulfide rubber, 20 parts of titanium dioxide, 5 parts of γ-aminopropyl-trimethoxysilane, 2-(2'-hydroxyl-5 10 parts of '-methylphenyl) benzotriazole.

[0040] The preparation scheme of the present embodiment polyurea anticorrosion coating is as follows:

[0041] The preparation method of the A component: add dibutyl phthalate into a reaction kettle protected by nitrogen, heat to 120°C under stirring, v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com