High chemical resistance and high wear resistance coating based on polyurea elastomer and preparation method and application

A polyurea elastomer and chemical technology, which is applied in the fields of high chemical resistance and high wear resistance based on polyurea elastomer and the fields of preparation and use, can solve the problems of no combination of high chemical resistance and high wear resistance, and achieves The effect of good chemical resistance and high wear resistance, good resistance to organic solvents, good elasticity and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

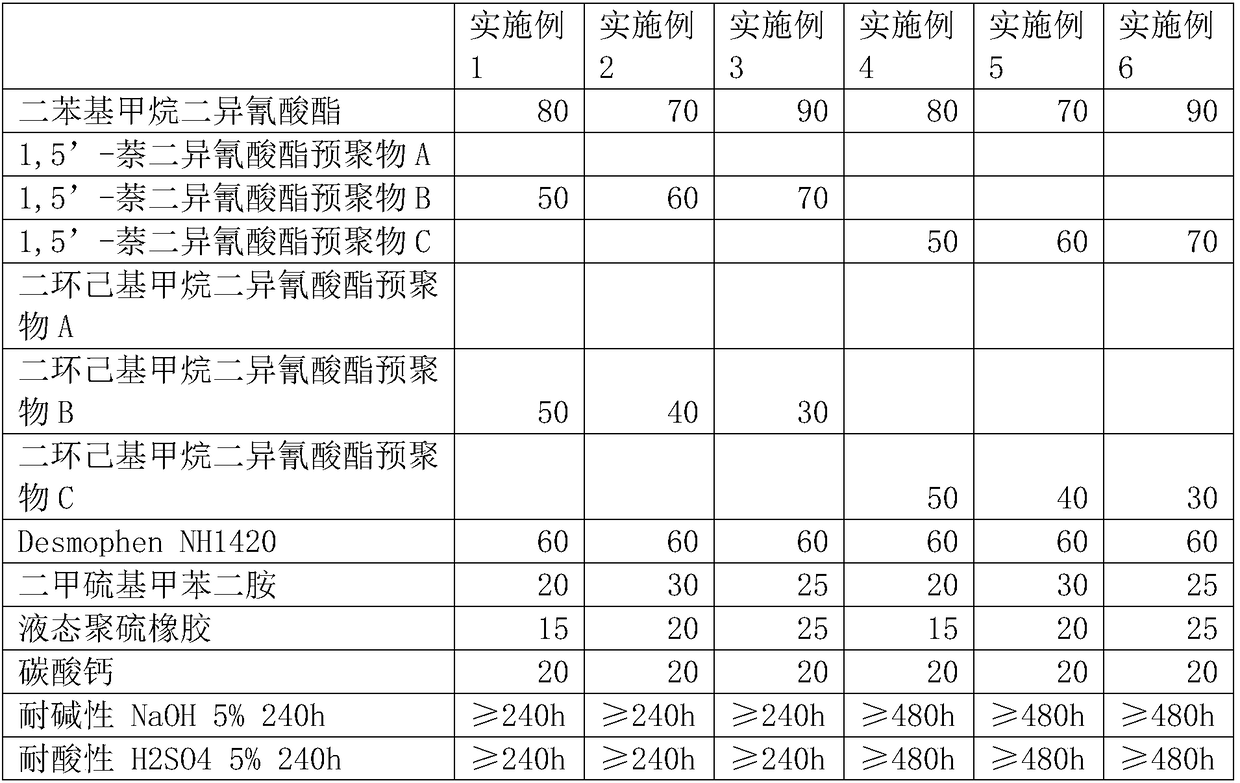

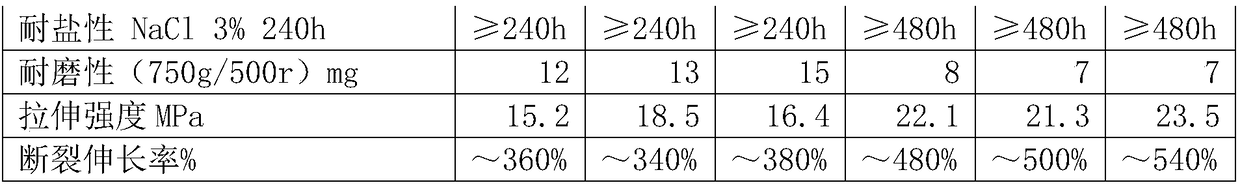

Embodiment 1

[0037] The preparation method of the high chemical resistance and high wear resistance coating of the polyurea elastomer of the present embodiment is as follows:

[0038] The preparation method of the A component: add 1,5'-naphthalene diisocyanate prepolymer and dicyclohexylmethane diisocyanate prepolymer into a reaction kettle protected by nitrogen, and heat to 90-120°C under stirring, Vacuum at constant temperature to -0.09~-0.1MPa, dehydrate for 3 hours, lower the temperature to 50~60℃ under atmospheric pressure, add diphenylmethane diisocyanate, heat to 70~90℃ under nitrogen protection, react for 1~3 hours, cool down and stir Uniform discharge is A component;

[0039] The preparation method of the B component: first add the amino resin containing sterically hindered aliphatic secondary diamine into the reaction kettle, then add dimethylthiotoluenediamine and 15-30 parts of liquid polysulfide rubber under stirring After stirring at high speed for 0.5 to 1 hour, add 0 to 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com