Skin damage repair method for aluminum alloy skin foam sandwich part

A damage repair and aluminum alloy technology, applied in the direction of aircraft parts, adhesive types, adhesive additives, etc., can solve the problems of high cost, difficulty in external factory installation, and affecting the use of aircraft flight, so as to achieve strong operability and ensure The effect of normal flight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

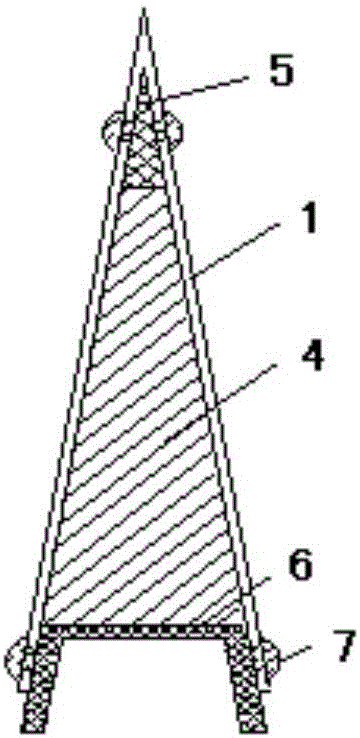

[0026] The specific implementation process of the present invention is described in detail below: (describe technical feature in detail)

[0027] The skin damage repairing method of the aluminum alloy skin foam sandwich part of the present invention, the specific maintenance steps are as follows:

[0028] Step 1: Determine the extent of the damage;

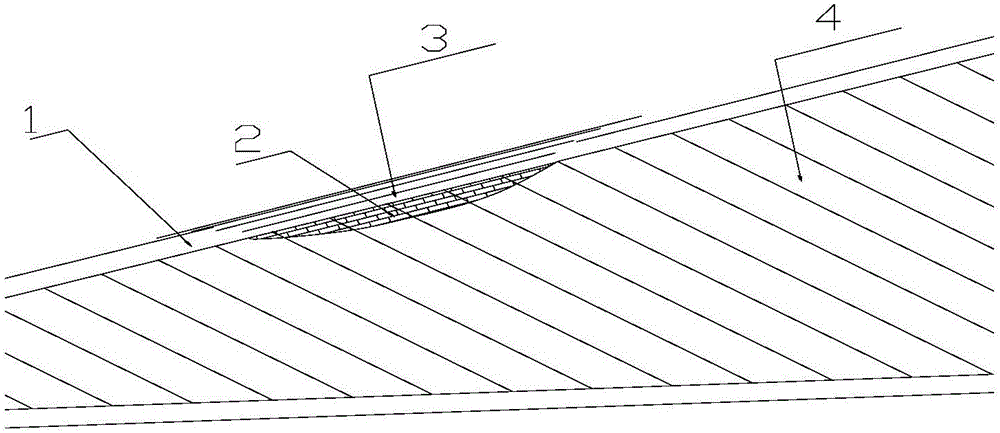

[0029] Step 2: remove the metal skin in the damage range, and then trim the skin edge to ensure that the skin in the damage range is removed;

[0030] The third step: preparing a curing adhesive, the weight ratio of E-51 epoxy resin, quartz powder, m-xylylenediamine and 201 polysulfide rubber in the curing adhesive is; 100:20:22:50; Mix the ingredients and stir well;

[0031] Step 4: Cut a group of high-strength glass cloth patches of the same shape and different sizes according to the shape of the damage area. The distance between the edges of the patches of adjacent sizes in the group is 25mm, and lay the patches on the damage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com