Polysulfide sealant and preparation method thereof

A technology of polysulfide sealant and sulfur, which is applied in the field of polysulfide sealant, can solve problems such as poor adhesion, unreasonable formula ratio, and inability to meet the needs of use, and achieve the effect of good adhesion and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The polysulfide sealant of the present invention is made up of following components by weight:

[0035]

[0036] The preparation method comprises the following steps

[0037] First add polyether triol, thiol-containing alcohol, isocyanate, liquid polysulfide rubber, graphene oxide, propylene oxide butyl ether, acrylate emulsion, phenolic resin, and dibutyl ester into the kneader according to the above ratio. Roughly mix, then move into the reversing device, stir at 30°C for 20 minutes, then add fillers, tackifiers, plasticizers, vacuumize and heat slowly to 50°C, keep the vacuum, keep stirring for 1 hour, use a cooling device After cooling, filter through a filter device, and then use an automatic filling device to fill and store.

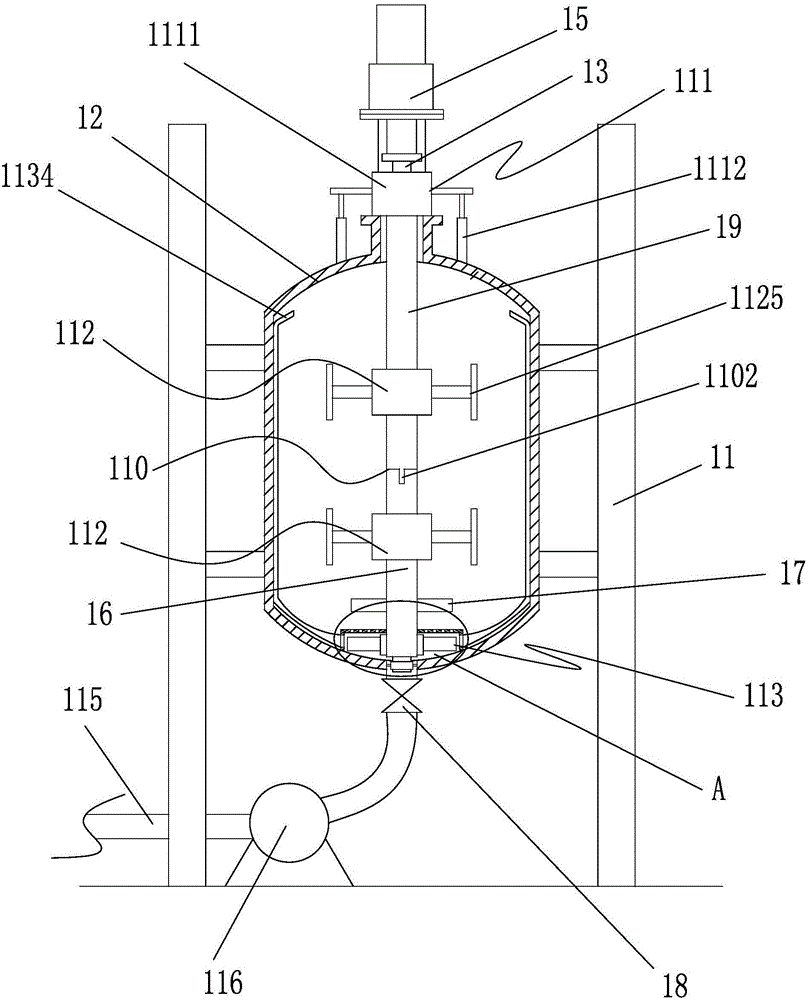

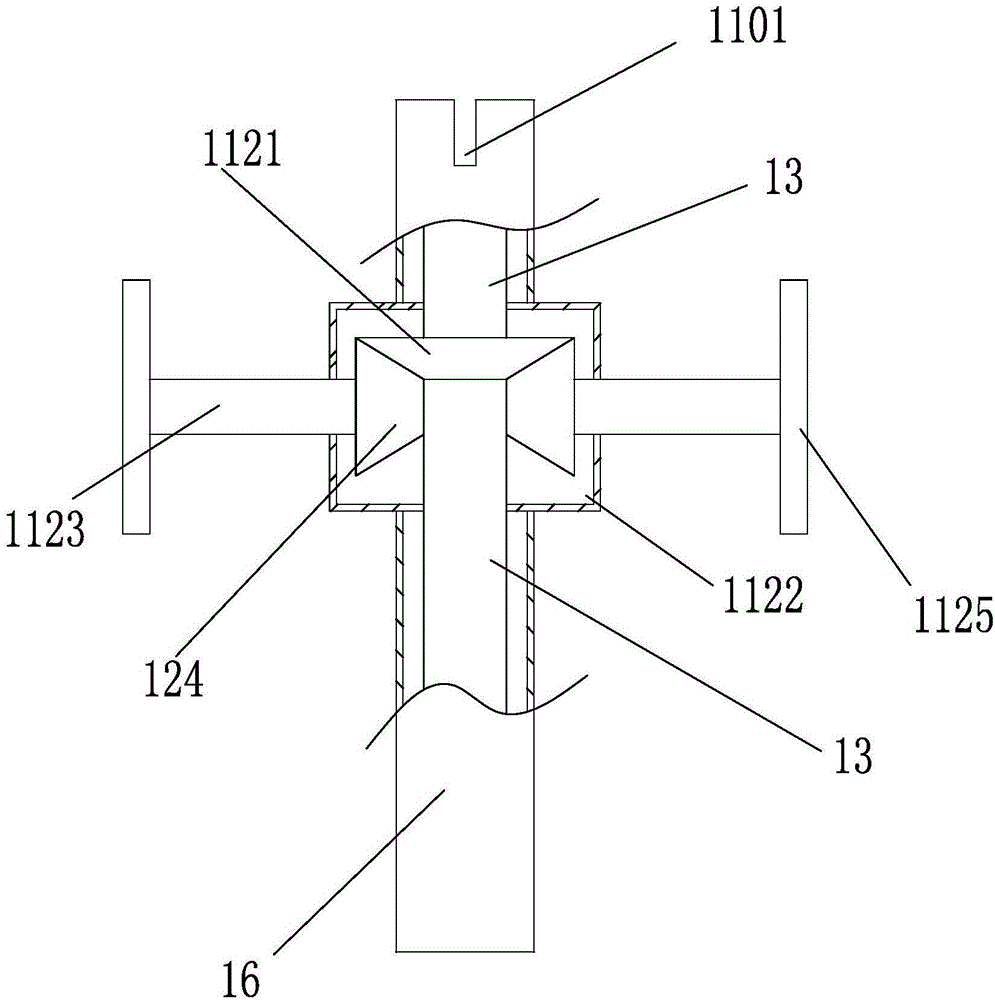

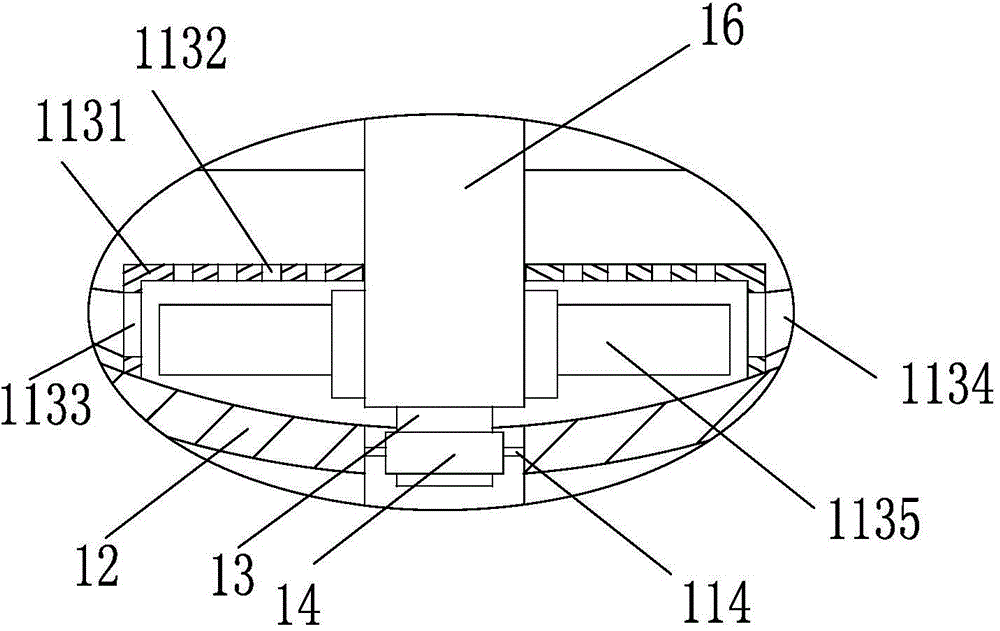

[0038] The reaction device 1 described in the present invention includes a support 11, a reaction kettle 12 is fixedly connected to the support 11, a stirring shaft 13 is arranged in the reaction kettle 12, and one end of the stirring sh...

Embodiment 2

[0054] The polysulfide sealant of the present invention is made up of following components by weight:

[0055]

[0056] The preparation method comprises the following steps

[0057] First add polyether triol, thiol-containing alcohol, isocyanate, liquid polysulfide rubber, graphene oxide, propylene oxide butyl ether, acrylate emulsion, phenolic resin, and dibutyl ester into the kneader according to the above ratio. Roughly mix, then move into the reversing device, stir at 50°C for 30 minutes, then add fillers, tackifiers, plasticizers, vacuumize and heat slowly to 60°C, keep the vacuum, keep stirring for 2 hours, use a cooling device After cooling, filter through a filter device, and then use an automatic filling device to fill and store.

[0058] The reaction device, cooling device, filtering device and automatic filling device described in this example are as described in Example 1.

Embodiment 3

[0060] The polysulfide sealant of the present invention is made up of following components by weight:

[0061]

[0062] The filler is a mixture of light calcium carbonate, white carbon black, aluminum silicate, titanium dioxide, sulfur, lead dioxide, granite powder, illite powder and attapulgite. The plasticizer is a mixture of dibutyl phthalate, dioctyl phthalate and tributyl citrate.

[0063] The preparation method comprises the following steps

[0064] First add polyether triol, thiol-containing alcohol, isocyanate, liquid polysulfide rubber, graphene oxide, propylene oxide butyl ether, acrylate emulsion, phenolic resin, and dibutyl ester into the kneader according to the above ratio. Roughly mix, then move into the reversing device, stir at 40°C for 25 minutes, then add fillers, tackifiers, plasticizers, vacuumize and heat slowly to 55°C, keep the vacuum, keep stirring for 1.5 hours, use a cooling device After cooling, filter through a filter device, and then use an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com