Processing technique for bent aluminum strip double-silver LOW-E hollow glass

A processing technology and glass technology, applied in glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problem of dew or frost on insulating glass, no secondary sealing, affecting the use of insulating glass life and other issues, to save resources, improve overall performance, and prevent air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Production of tempered glass: place the float glass after cutting, edging and cleaning horizontally on the roller table, and send it into the convection tempering furnace through the roller table for heating treatment: preheat at 480°C for 350s; then heat at 690°C for 350s ; The heated glass is taken out of the furnace and sent to the flat air grid, firstly passed through the upper and lower air grids in the flat air grid, and quenched under the wind pressure of 2.5KPa for 100s, quenched to the glass surface at 250°C, and finally cooled to room temperature, that is Prepare tempered glass;

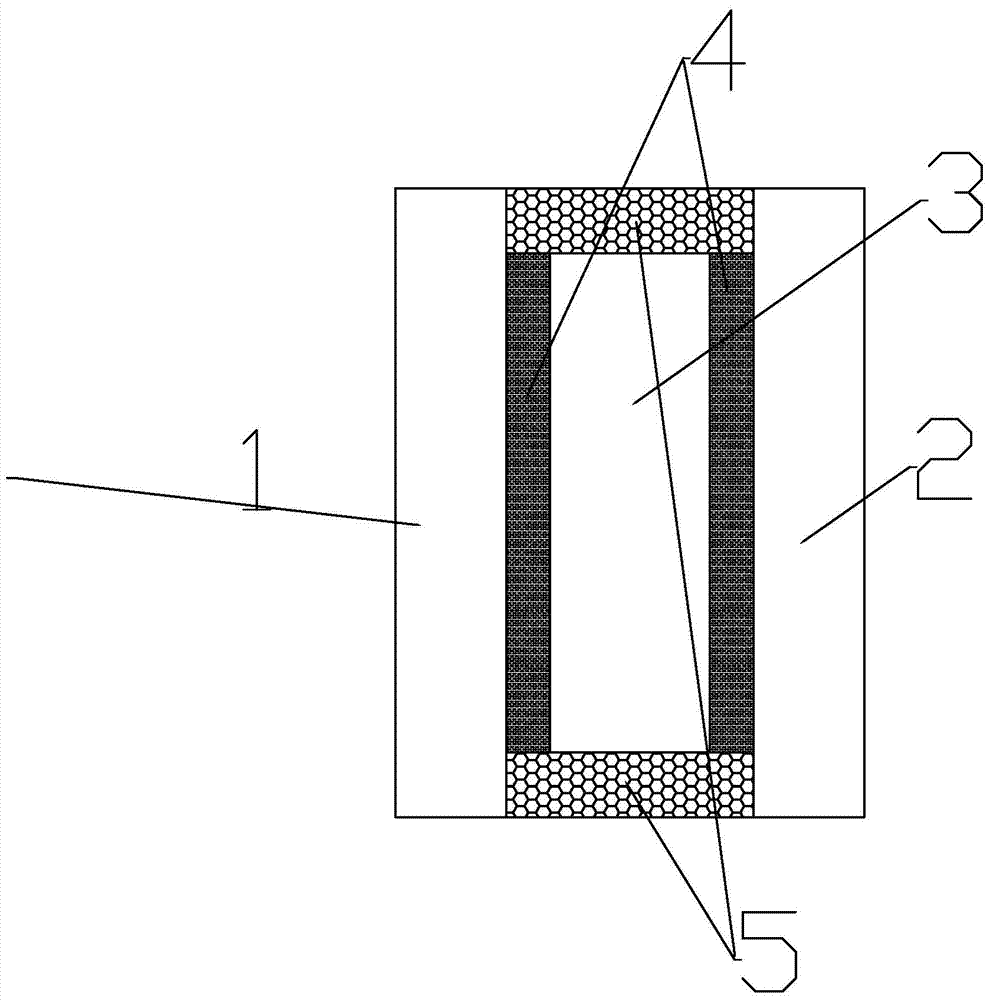

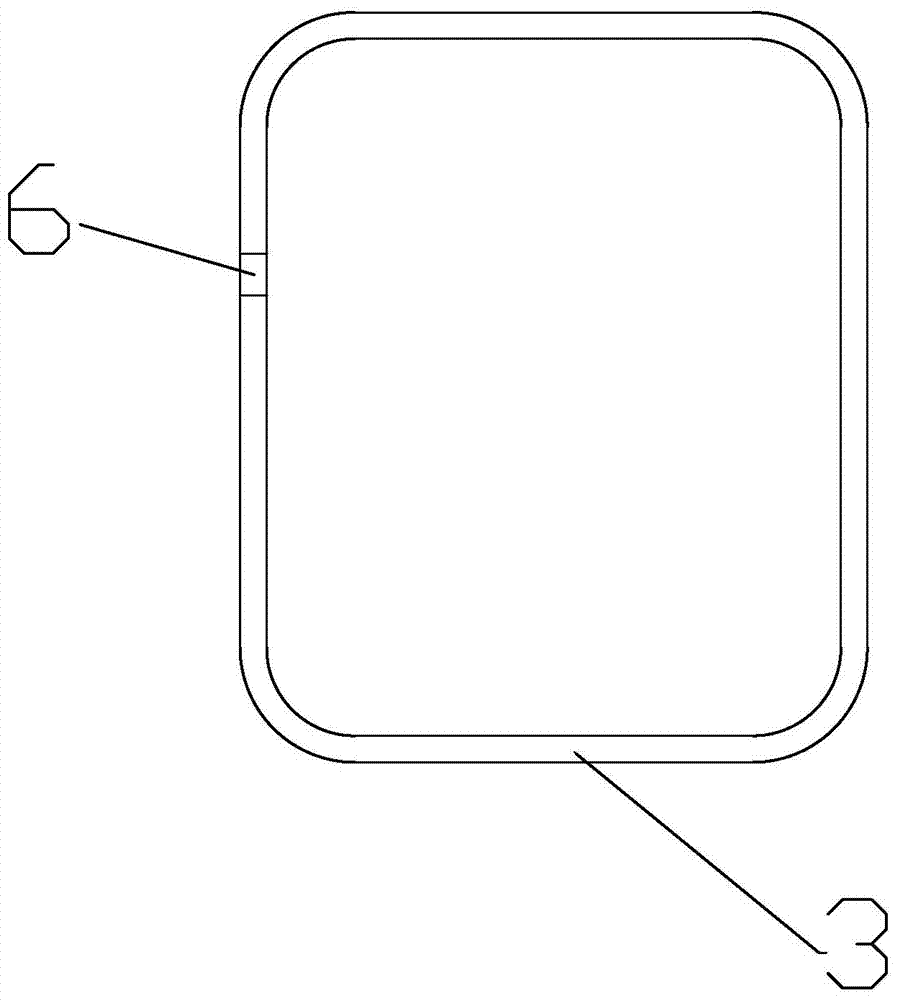

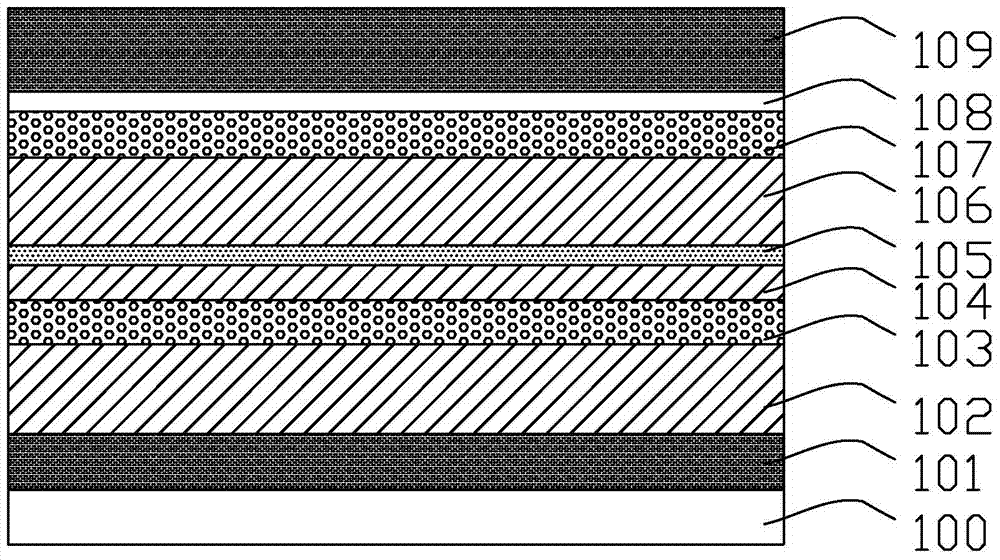

[0033] Prepare double-silver LOW-E glass: select the double-silver LOW-E glass including the glass substrate, and compound the double-silver LOW-E glass with nine film layers adjacently from the inside to the outside on the composite surface of the glass substrate. The first film layer is The innermost layer is Si 3 N 4 layer, the second layer is TiO 2 layer, the third layer is Ag...

Embodiment 2

[0040] Production of tempered glass: place the cut, edged and cleaned float glass horizontally on the roller table, and send it into the convection tempering furnace through the roller table for heat treatment: preheat at 500°C for 340s; then heat at 700°C for 360s ; The heated glass is taken out of the furnace and sent to the flat air grid, firstly through the upper and lower air grids in the flat air grid, and quenched for 120s under a wind pressure of 1.5KPa, quenched to a glass surface of 240°C, and finally cooled to room temperature, that is Prepare tempered glass;

[0041] Prepare double-silver LOW-E glass: select the double-silver LOW-E glass including the glass substrate, and compound the double-silver LOW-E glass with nine film layers adjacently from the inside to the outside on the composite surface of the glass substrate. The first film layer is The innermost layer is Si 3 N 4 layer, the second layer is TiO 2 layer, the third layer is Ag layer, the fourth layer i...

Embodiment 3

[0048]Production of tempered glass: place the float glass after cutting, edging and cleaning horizontally on the roller table, and send it into the convection tempering furnace through the roller table for heating treatment: preheat at 450°C for 360s; then heat at 680°C for 340s ; The heated glass is taken out of the furnace and sent to the flat air grid, firstly through the upper and lower air grids in the flat air grid, and quenched for 120s under the wind pressure of 2.0KPa, quenched to the glass surface at 260°C, and finally cooled to room temperature, that is Prepare tempered glass;

[0049] Prepare double-silver LOW-E glass: select the double-silver LOW-E glass including the glass substrate, and compound the double-silver LOW-E glass with nine film layers adjacently from the inside to the outside on the composite surface of the glass substrate. The first film layer is The innermost layer is Si 3 N 4 layer, the second layer is TiO 2 layer, the third layer is Ag layer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com