Strength enhanced type low angle dependency structure color material and preparation method thereof

A structural color and enhanced technology, which is applied in the field of preparation of color-producing materials, can solve problems such as difficult to meet and physical strength limitations, and achieve the effects of low cost, improved physical strength, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

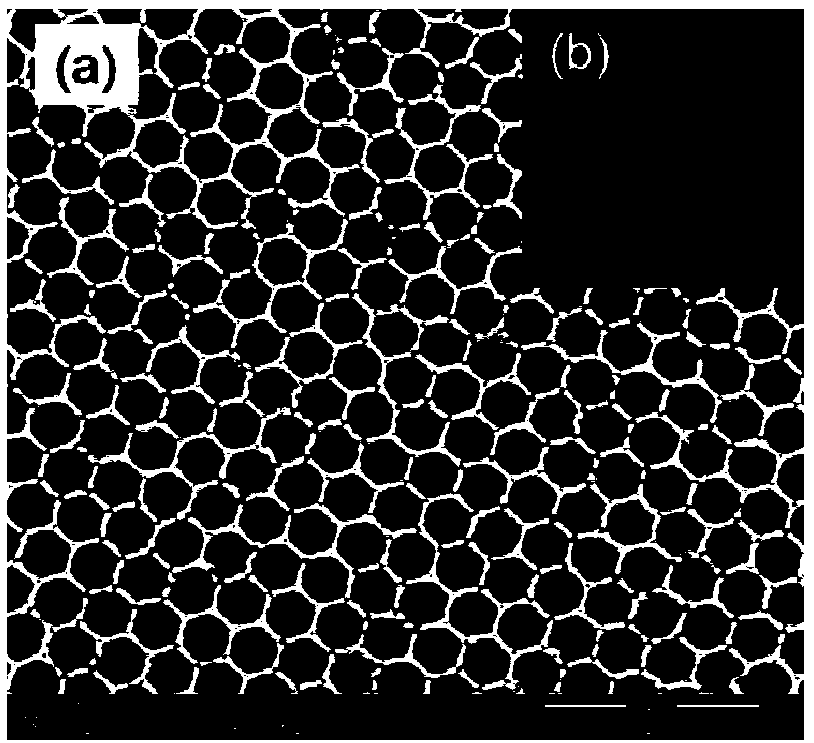

[0027] ① Prepare a tin dioxide inverse protein structure color film with a pore size of 217nm by the template method, as follows: add the tin dioxide precursor dropwise on the polystyrene template and let it infiltrate naturally; place it in a muffle furnace after the solvent evaporates Calcination is carried out to obtain the anti-protein structure color film.

[0028] The polystyrene template is prepared by emulsion polymerization. The specific preparation method is: weigh 0.035g of sodium lauryl sulfate and dissolve it in 135ml of deionized water, stir at 300r / min in a 250ml three-necked flask; heat in a water bath to 85 After the temperature stabilized, 15 g of styrene monomer was added; after 15 minutes, 0.15 g of potassium persulfate was added, and stirred at 85 °C for 5 hours. The obtained emulsion is heated and convectively self-assembled on the substrate on a heating plate at 70°C to obtain an opal-structured polystyrene template.

[0029] ②Put the PDMS monomer and c...

Embodiment 2-7

[0034] Replace tin dioxide inverse protein photonic crystals with titanium dioxide inverse protein photonic crystals, zinc oxide inverse protein photonic crystals, zirconia inverse protein photonic crystals, cerium oxide inverse protein photonic crystals, tantalum pentoxide inverse protein photonic crystals, niobium oxide inverse protein photonic crystals For photonic crystals, other conditions are consistent with those in Example 1.

Embodiment 8

[0036]The polydimethylsiloxane in Example 1 was replaced with polyurethane, and other conditions were consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com