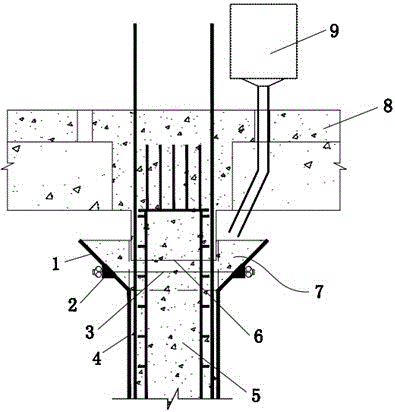

Basement reverse-construction scape post-casting pre-stressed construction method

A construction method and basement technology, which is applied in the direction of columns, pier columns, pillars, etc., can solve problems such as the mouth of the funnel is too large, the concrete is difficult to vibrate sufficiently compact, and the volume of concrete at the funnel is large, so as to improve the compactness of the vibration , improve the construction quality, prolong the effect of vibrating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

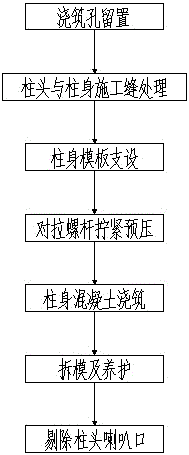

Method used

Image

Examples

Embodiment 1

[0053] Wenzhou Jianshe Business Building Project adopted this construction method in the second pouring and tamping of basement columns. The project is located in Lucheng District, Wenzhou City, with a total construction area of 57208.1㎡, including 35315.3㎡ above ground and 21892.8㎡ underground. The foundation pit is 81m long from north to south, 98m wide from east to west, the circumference of the foundation pit is 358m, the excavation area is 7938m2, the excavation depth is about 12.7-13.6m, and the basement has three floors. The generation of cracks and honeycomb pockmarks has significantly improved the quality of the joints between old and new concrete, which survived once and reduced the trouble of later repairs, laying the foundation for the project to create high-quality projects.

Embodiment 2

[0055] This construction method was adopted in the reconstruction and expansion project of the ophthalmology and optometry medical teaching building of Wenzhou Medical University. The project is located in Lucheng District, Wenzhou City, with a total construction area of 49181.3㎡. The above ground building is a 22-story main building and a 5-story podium. The basement is the second floor and is a whole basement. This project belongs to the frame-shear structure, raft foundation, and there are 94 columns with core lattice columns in the basement and need to be poured twice. After collecting data on the quality problems of post-cast columns, the qualified rate of one-time pouring and ramming has been significantly improved, and quality problems including honeycomb pockmarks, cracks, mold swelling, rotten roots, and holes have been significantly reduced, and the quality of column pouring and ramming has been improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com