Optical fiber laser dynamic focusing vibration mirror scanning type spot welding system and welding method thereof

A dynamic focusing and galvanometer scanning technology, applied in laser welding equipment, welding equipment, optics, etc., can solve the problems of uncontrolled welding points, the charging and discharging speed of the laser power supply cannot meet the requirements, and the scanning speed of the galvanometer is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

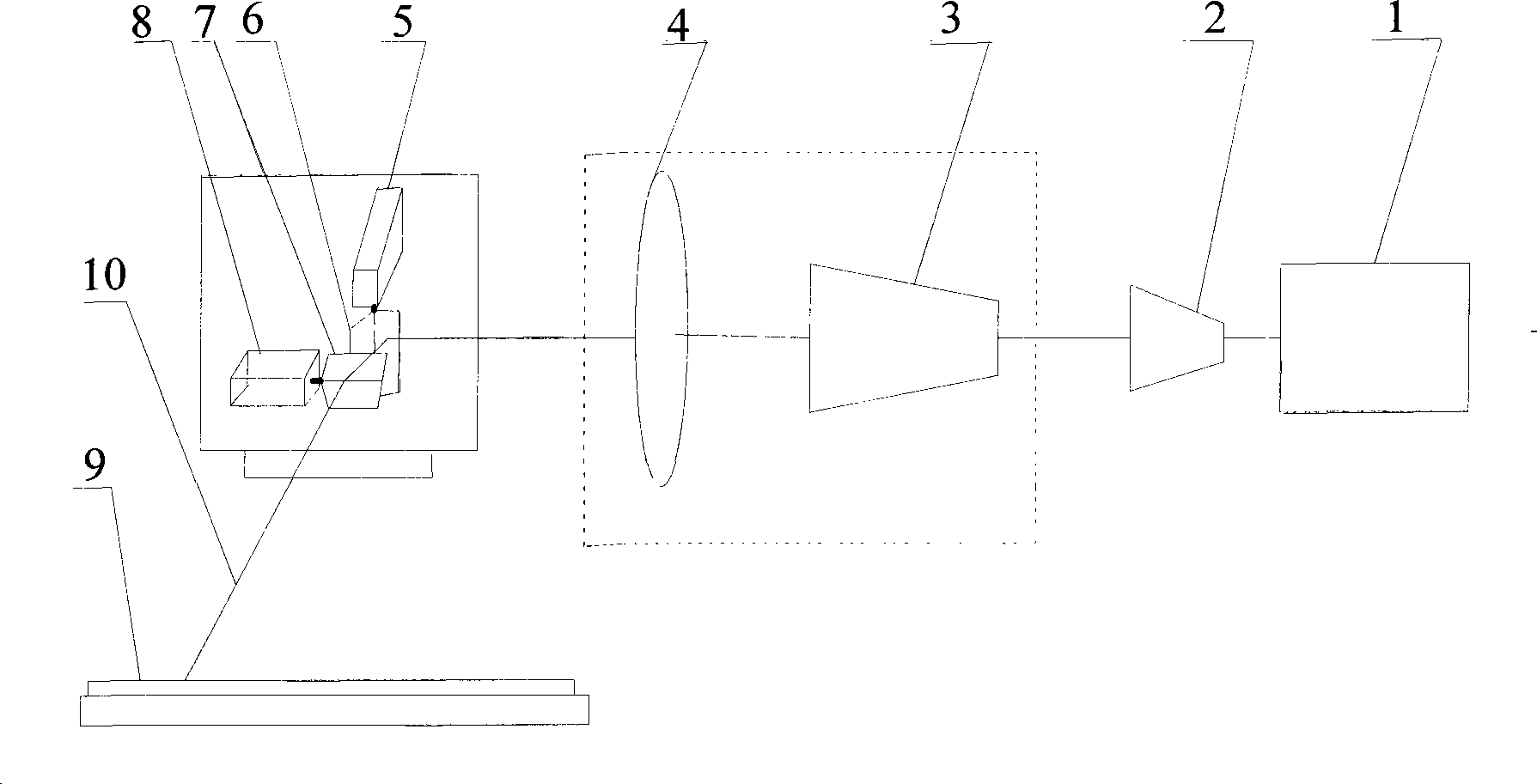

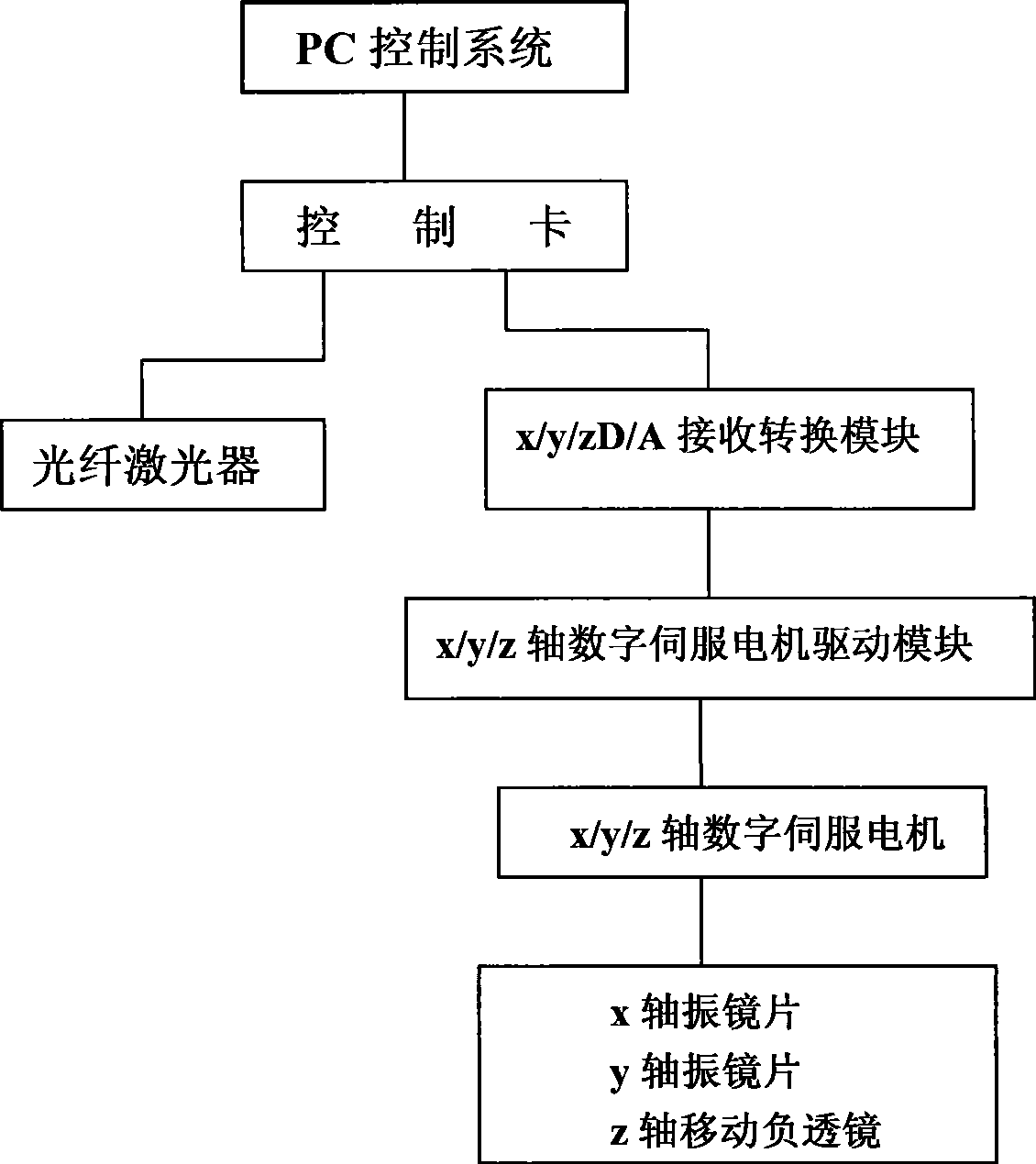

[0022] Such as figure 1 , figure 2 As shown, the fiber laser dynamic focusing vibrating mirror scanning spot welding system of the present invention includes a PC control system and a fiber laser 1, a beam expander 2, a dynamic focusing unit, an X-axis vibrating mirror 5, and a Y-axis vibrating mirror 7. The X-axis vibrating mirror 5 is mounted on the rotating shaft of the X-axis digital servo motor 6, the Y-axis vibrating mirror 7 is mounted on the rotating shaft of the Y-axis digital servo motor 8, and the dynamic focusing unit is composed of a moving negative lens 3 Composed of focusing lens 4, the moving negative lens 3 is installed on the rotating shaft of the Z-axis digital servo motor (not shown in the figure), and the PC control system is connected with the X-axis digital servo motor, Y-axis digital servo motor, Z Axis digital servo motor signal connection.

[0023] The output power of the fiber laser 1 is 100-150 W, and the wavelength is 1060-1090 nm, and the focus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com