Production method of high-transverse/longitudinal-impact-ratio high-thickness Q690E high-strength steel

A technology of Q690E and production method, which is applied in the field of iron and steel, can solve the problems of long and unsuitable slow cooling process, and achieve the effect of short production process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

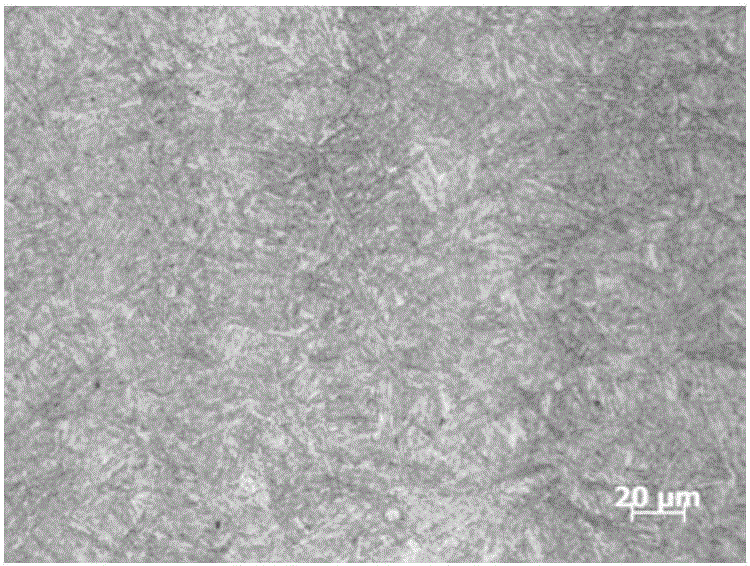

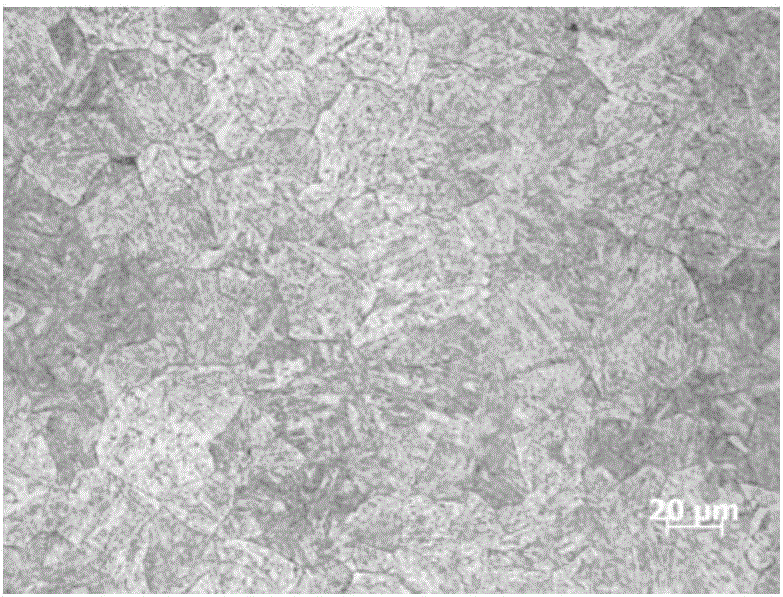

Image

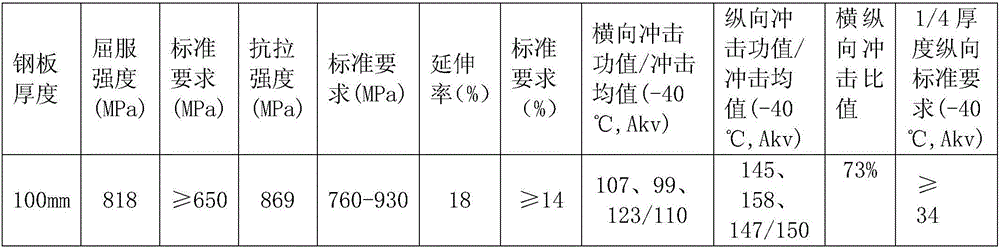

Examples

Embodiment 1

[0027] This example provides a method for producing high-strength Q690E high-strength steel with high transverse and longitudinal impact ratio and large thickness. The production method includes the following process:

[0028] Hot metal desulfurization pretreatment→converter smelting→LF+RH refining→continuous casting→slab stacking and slow cooling→slab inspection→slab judgment→slab acceptance→slab heating→descale→rolling→air cooling→flaw detection→throwing Shot→quenching→tempering→straightening→cutting, sampling→printing mark→inspection→warehousing, of which:

[0029](1) The chemical composition of the high-strength steel includes, by weight percentage, C: 0.17%, Si: 0.25%, Mn: 1.1%, P≤0.015%, S≤0.002%, Cu≤0.1%, Cr: 0.37%, Ni: 0.41%, Mo: 0.42%, Nb: 0.011%, Ti: 0.017%, V: 0.032%, B: 0.0013%, Alt: 0.026%, Ceq: 0.54%, the balance is Fe and unavoidable impurities, The carbon equivalent Ceq (percentage) in the chemical composition of this high-strength steel is calculated accordin...

Embodiment 2

[0039] This example provides a method for producing high-strength Q690E high-strength steel with high transverse and longitudinal impact ratio and large thickness. The production method includes the following process:

[0040] Hot metal desulfurization pretreatment→converter smelting→LF+RH refining→continuous casting→slab stacking and slow cooling→slab inspection→slab judgment→slab acceptance→slab heating→descale→rolling→air cooling→flaw detection→throwing Shot→quenching→tempering→straightening→cutting, sampling→printing mark→inspection→warehousing, of which:

[0041] (1) The chemical composition of the high-strength steel includes, by weight percentage, C: 0.15%, Si: 0.23%, Mn: 1.17%, P≤0.010%, S≤0.0010%, Cr: 0.3%, Cu≤0.1%, Ni: 0.45%, Mo: 0.45%, Nb: 0.014%, Ti: 0.013%, V: 0.034%, B: 0.0015%, Alt: 0.033%, Ceq: 0.53%, the balance is Fe and unavoidable impurities;

[0042] (2) Select a slab with a thickness of 320mm and heat the slab. The temperature in the heating section is 1...

Embodiment 3

[0049] This example provides a method for producing high-strength Q690E high-strength steel with high transverse and longitudinal impact ratio and large thickness. The production method includes the following process:

[0050] Hot metal desulfurization pretreatment→converter smelting→LF+RH refining→continuous casting→slab stacking and slow cooling→slab inspection→slab judgment→slab acceptance→slab heating→descale→rolling→air cooling→flaw detection→throwing Shot→quenching→tempering→straightening→cutting, sampling→printing mark→inspection→warehousing, of which:

[0051] (1) The chemical composition of the high-strength steel includes, by weight percentage, C: 0.18%, Si: 0.28%, Mn: 1.15%, P≤0.015%, S≤0.002%, Cr: 0.48%, Cu≤0.1%, Ni: 0.48%, Mo: 0.49%, Nb: 0.018%, Ti: 0.011%, V: 0.038%, B: 0.0011%, Alt: 0.044%, Ceq: 0.60%, the balance is Fe and unavoidable impurities, The carbon equivalent Ceq (percentage) in the chemical composition of this high-strength steel is calculated accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com