3D printed wall body with hollow or spanning structure and machining method for 3D printed wall body

A 3D printing and wall technology, which is applied in the direction of additive processing, building components, manufacturing tools, etc., can solve the problems of easy cavity collapse, wall collapse, and reduce the structural strength of the wall, so as to achieve both overall firmness and reduced Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

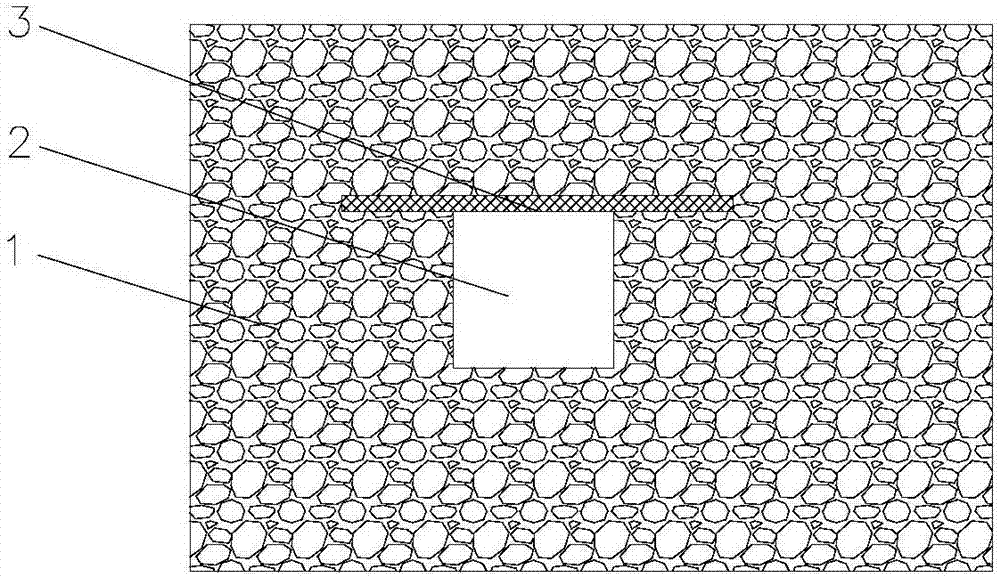

[0019] This embodiment provides a 3D printed wall with a spanning structure, the structure is as figure 1 As shown, including the wall 1, the wall has a spanning groove 2 reserved during the printing process of the wall using the 3D printing equipment, and a spanning screen 3 is laid on the spanning slot 2, and the two ends of the spanning screen are overlapped On the cement mortar on both sides of the spanning groove, the overlapping length is not less than 1 / 4 of the width of the spanning groove, the diameter of the mesh across the mesh plate is greater than the maximum particle size of 2mm in the cement mortar, and the thickness of the spanning mesh plate 5mm, use 3D printing equipment to print the cement mortar wall on the cross-stencil.

[0020] The processing method of the 3D printing wall with a spanning structure of the present embodiment comprises the following steps:

[0021] ⑴ According to the technical requirements of the 3D printer, make suitable cement mortar ra...

Embodiment 2

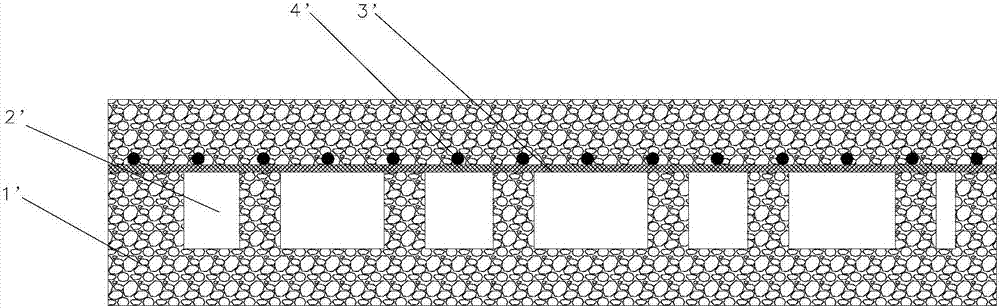

[0027] This embodiment provides a 3D printed wall with a hollow structure, the structure is as follows figure 2 As shown, including the wall 1' printed horizontally, the wall 1' reserves a cavity 2' in the wall during the printing process of the 3D printing equipment, and a reinforcing rib structure is arranged in the reserved cavity. Lay a spanning stencil 3' on the cavity, the diameter of the mesh across the stencil is larger than the maximum particle size of 2mm in the cement mortar, the thickness of the spanning stencil is 2mm, and the two ends of the spanning stencil are lapped in the reserved space On the cement mortar around the cavity 2', a reinforced steel skeleton 4' is laid on the cross-stencil at the same time, and finally cement mortar is printed layer by layer on the cross-stencil and the reinforced skeleton.

[0028] A method for processing a 3D printed wall with a hollow structure, comprising the following steps:

[0029] ⑴ According to the technical requirem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com