Beam-column semi-rigid connection structure based on bamboo frame

A connection structure, semi-rigid technology, applied in the direction of building structure, construction, etc., can solve the problems of weakening of the original bamboo strength, affecting the service life and bearing capacity of beam-column joints, loose bolts, etc., to increase the stressed area and improve The effect of improving bearing capacity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

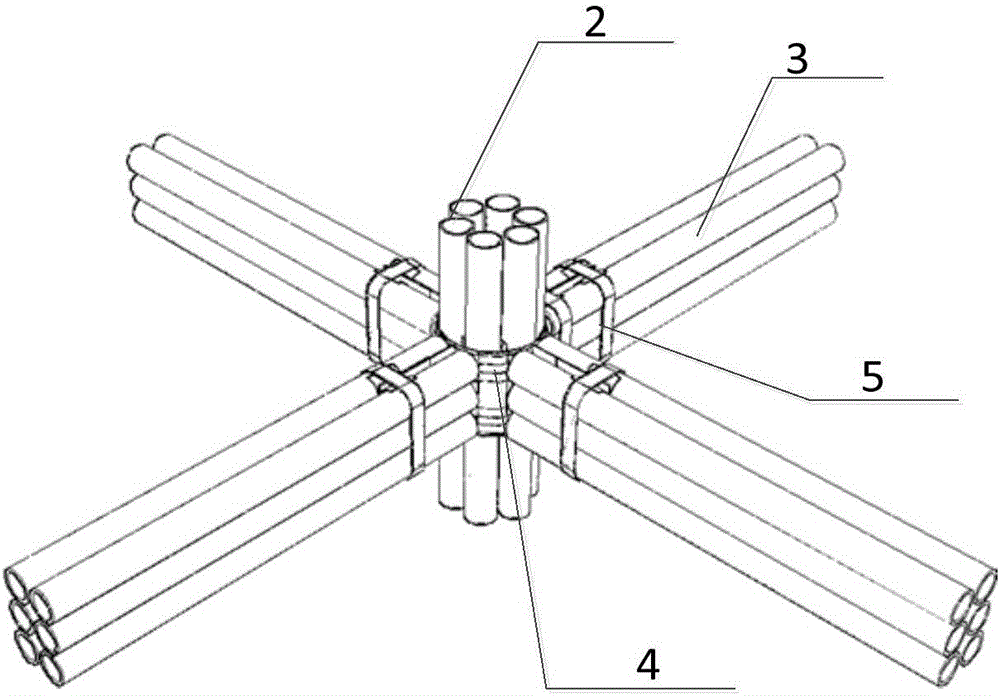

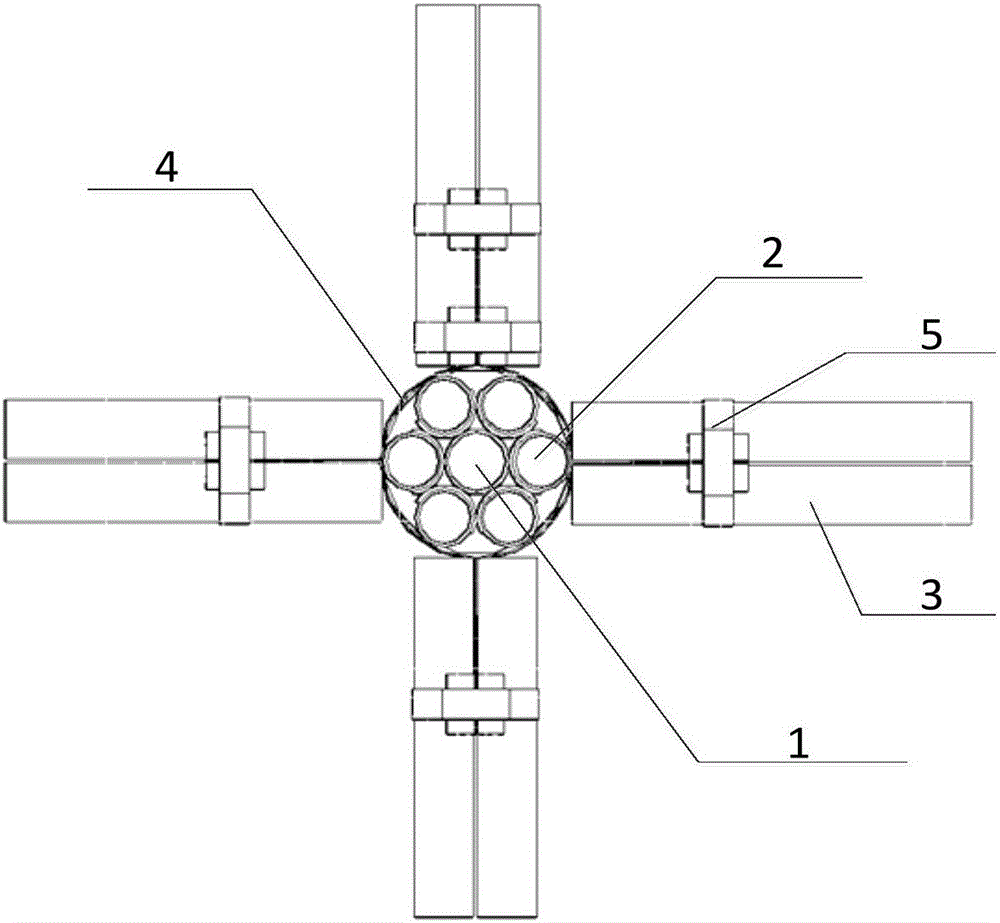

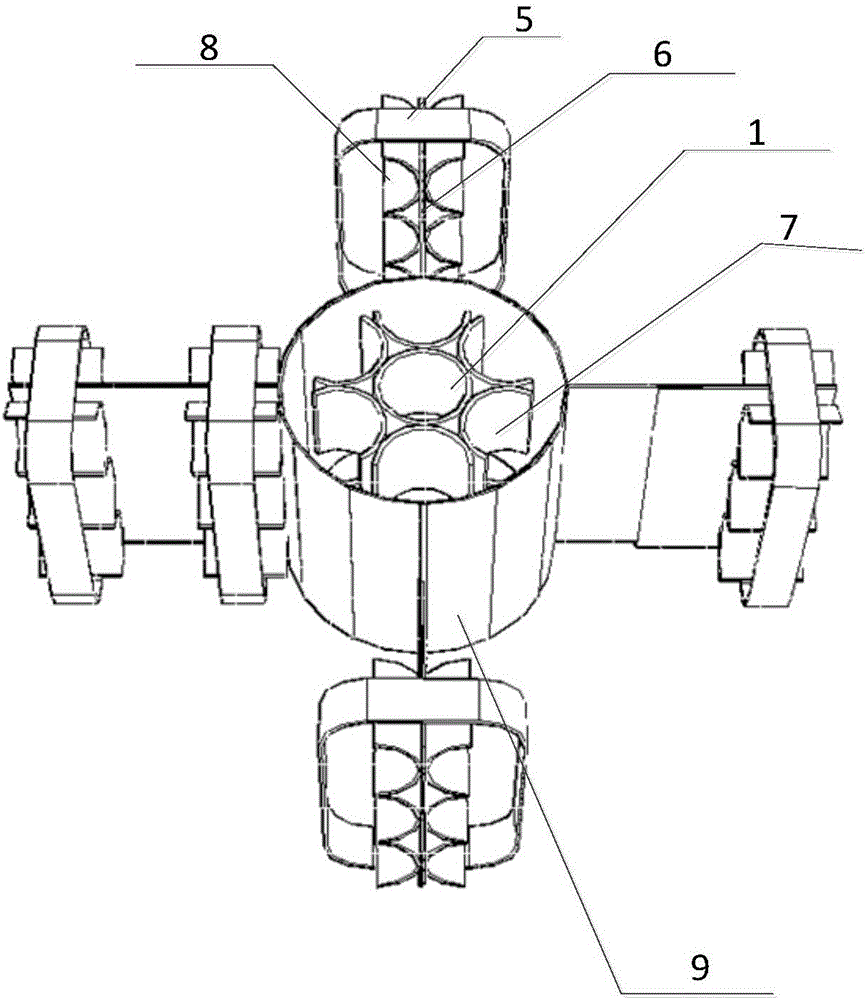

[0021] refer to figure 1 The beam-column semi-rigid connection structure based on the original bamboo skeleton of the present invention includes a column and a beam, and the column includes a central connector, a first connecting plate 9, a second connecting plate 6, some first original bamboos 2 and some first Ferrule 4, wherein the central connector includes a central steel pipe 1 and a plurality of first fixed plates 7, wherein a first fixed plate 7 corresponds to a first original bamboo 2, and the back of the first fixed plate 7 is fixed on the center steel pipe 1 Side, the front of the first fixed plate 7 is a curved surface matched with the side of the corresponding first original bamboo 2, the first original bamboo 2 is embedded on the front of the first fixed plate 7, the central connector and each first original bamboo The bamboo 2 is all socketed in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com