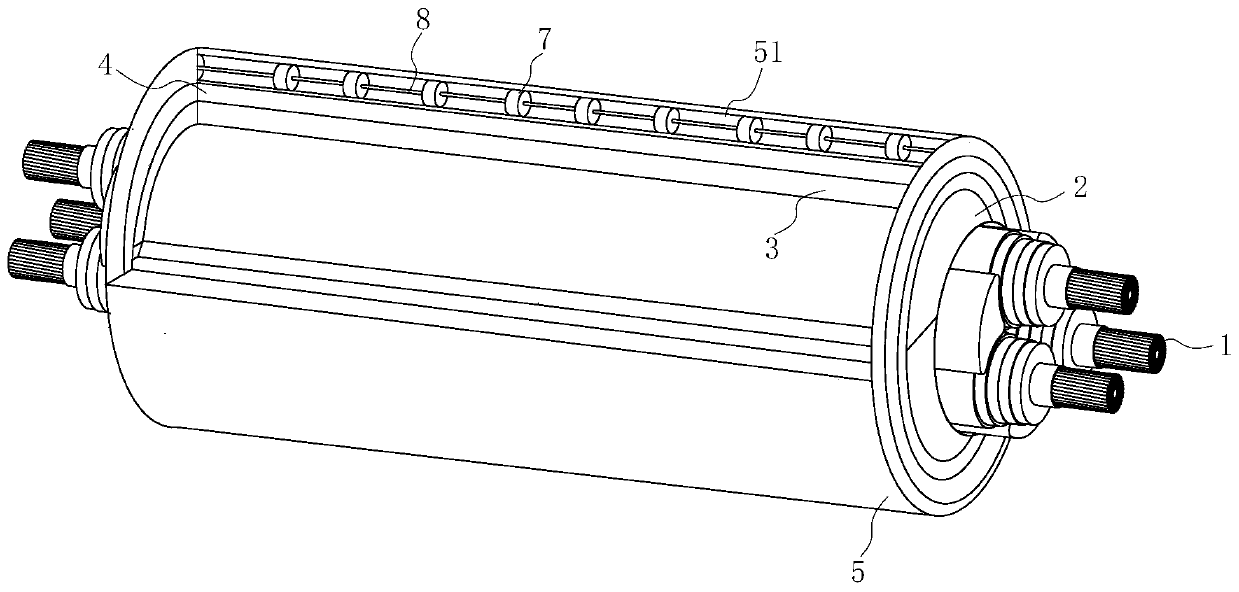

High-strength impact-resistant flame-retardant insulation cable

An insulated cable, impact-resistant technology, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve the problems affecting the strength and stiffness of the wear-resistant layer, achieve the effect of improving strength and impact resistance, and preventing large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

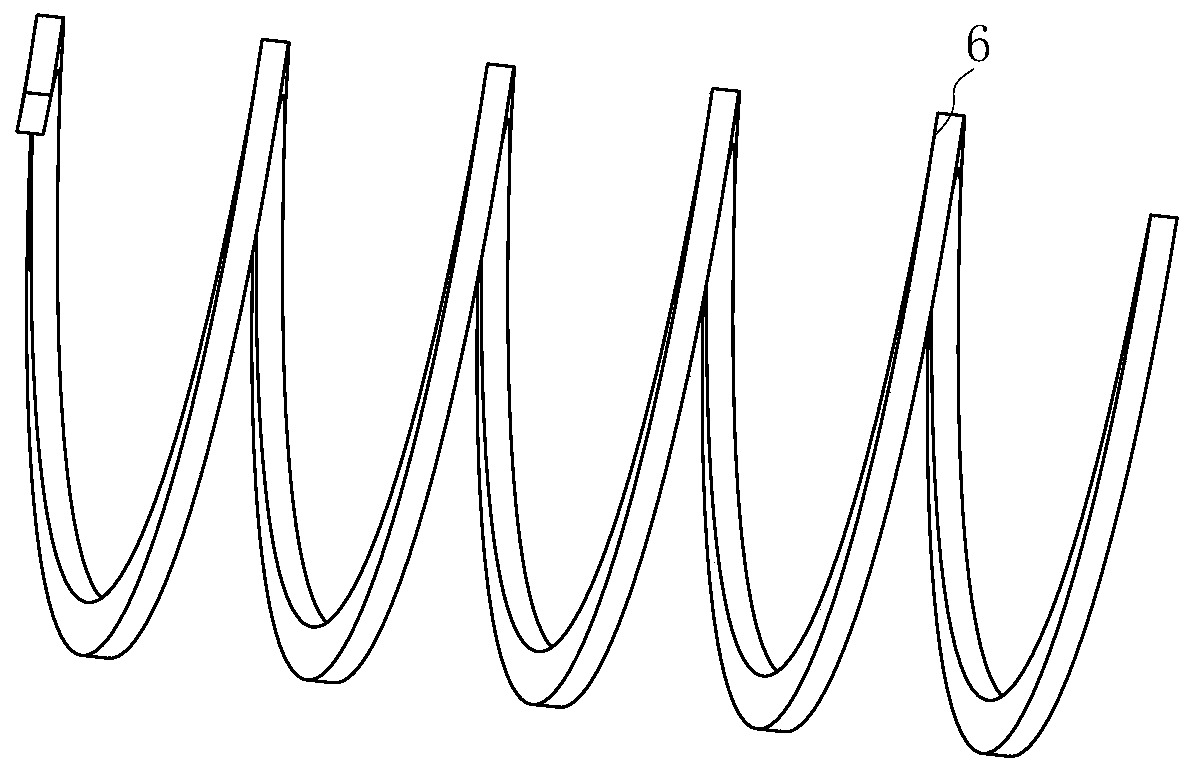

Method used

Image

Examples

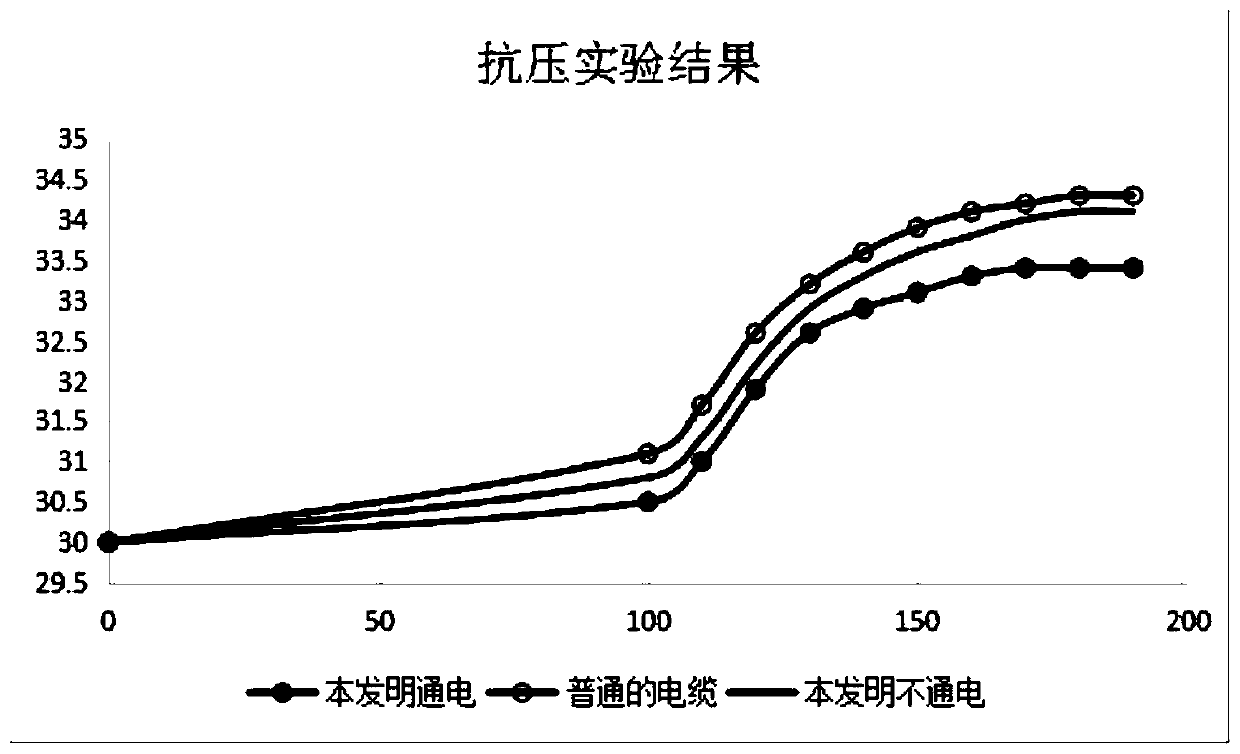

Embodiment 1

[0035] Embodiment 1, fire extinguishing agent mainly comprises following components:

[0036] The solid particles made of the mixture of aluminum sulfate solution, sodium bicarbonate and brominated epoxy resin will squeeze the cavity when the memory alloy strip expands in a fire, thereby causing damage to the waterproof layer of the cavity, and further Sodium bicarbonate reacts with aluminum sulfate solution, and when the volume of carbon dioxide in the cavity increases, the cavity will expand; when the fire source burns and damages the elastic base layer, the carbon dioxide in the cavity will be ejected, and the resulting Fire extinguishing operation at the fire source; red / yellow pigment, when the elastic base layer is damaged, the red / yellow pigment is sprayed out, which is convenient for maintenance personnel to repair the cable; the proportion of brominated epoxy resin and sodium bicarbonate The ratio is 1:1, which is mainly used to improve the ability of the fire extingu...

Embodiment 2

[0037] Embodiment 2, fire extinguishing agent mainly comprises following components:

[0038] The solid particles made of the mixture of aluminum sulfate solution, sodium bicarbonate and brominated epoxy resin will squeeze the cavity when the memory alloy strip expands in a fire, thereby causing damage to the waterproof layer of the cavity, and further Sodium bicarbonate reacts with aluminum sulfate solution, and when the volume of carbon dioxide in the cavity increases, the cavity will expand; when the fire source burns and damages the elastic base layer, the carbon dioxide in the cavity will be ejected, and the resulting Fire extinguishing operation at the fire source; red / yellow pigment, when the elastic base layer is damaged, the red / yellow pigment is sprayed out, which is convenient for maintenance personnel to repair the cable; the proportion of brominated epoxy resin and sodium bicarbonate The ratio is 1:1.3, which is mainly used to improve the ability of the fire extin...

Embodiment 3

[0039] Embodiment 3, fire extinguishing agent mainly comprises following components:

[0040] The solid particles made of the mixture of aluminum sulfate solution, sodium bicarbonate and brominated epoxy resin will squeeze the cavity when the memory alloy strip expands in a fire, thereby causing damage to the waterproof layer of the cavity, and further Sodium bicarbonate reacts with aluminum sulfate solution, and when the volume of carbon dioxide in the cavity increases, the cavity will expand; when the fire source burns and damages the elastic base layer, the carbon dioxide in the cavity will be ejected, and the resulting Fire extinguishing operation at the fire source; red / yellow pigment, when the elastic base layer is damaged, the red / yellow pigment is sprayed out, which is convenient for maintenance personnel to repair the cable; the proportion of brominated epoxy resin and sodium bicarbonate The ratio is 1:1.5, which is mainly used to improve the ability of the fire extin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com