Pervious concrete and construction method

A technology of permeable concrete and concrete, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problem of no large-area application, and achieve the effect of high speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

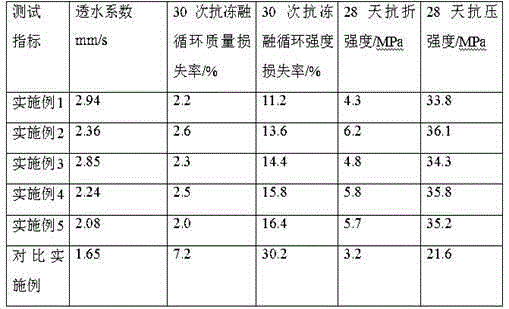

Examples

Embodiment 1

[0025] A kind of permeable concrete, including the following raw materials per square meter: 400Kg of cement, 1632Kg of gravel, 10Kg of reinforcing agent, 9Kg of water reducing agent, and 100Kg of water; the cement is ordinary silicate with a strength grade of not less than 42.5 For cement, the reinforcing agent uses silicone acrylic emulsion.

[0026] In this embodiment, the gravel is basalt with a particle size of 2.36-4.75 mm and limestone with a particle size of 5-10 mm.

[0027] In this embodiment, the water reducing agent is transparent liquid melamine.

[0028] In this embodiment, the curing agent is polyamide.

Embodiment 2

[0030] A kind of permeable concrete, including the following raw materials per square meter: 500Kg of cement, 1600Kg of gravel, 20Kg of reinforcing agent, 10Kg of water reducing agent, and 110Kg of water; the cement is ordinary silicate with a strength grade of not less than 42.5 For cement, the reinforcing agent uses silicone acrylic emulsion.

[0031] In this embodiment, the gravel is basalt with a particle size of 2.36-4.75mm and basalt with a particle size of 5-10mm

[0032] In this embodiment, the water reducing agent is transparent liquid melamine.

[0033] In this embodiment, the curing agent is epoxy resin.

Embodiment 3

[0035] A kind of permeable concrete, the distribution ratio of raw materials includes: 450Kg of cement, 1650Kg of crushed stone, 15Kg of reinforcing agent, 8.9Kg of water reducing agent, and 126Kg of water; the cement is ordinary silicic acid with a strength grade of not less than 42.5 For salt cement, the reinforcing agent is silicone acrylic emulsion.

[0036] In this embodiment, the gravel is basalt with a particle size of 2.36-4.75 mm and limestone with a particle size of 5-10 mm.

[0037] In this embodiment, the water reducing agent is transparent liquid melamine.

[0038] In this embodiment, the curing agent is alicyclic amine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com