Center-seal & gusset mechanism of center-seal & gusset machine of film label

A palm-joining machine and label technology, which is applied in the field of film-label joint-palm machines, to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

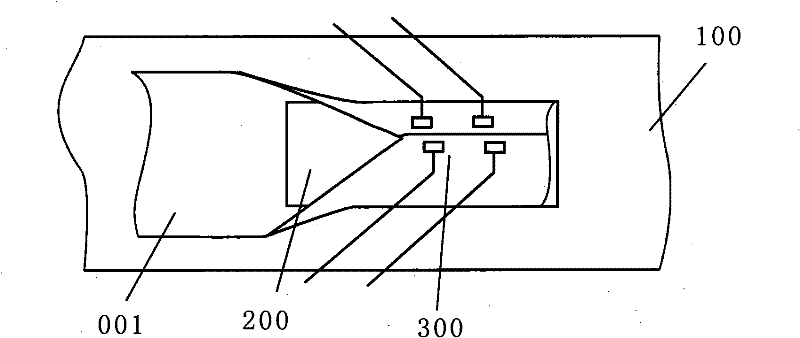

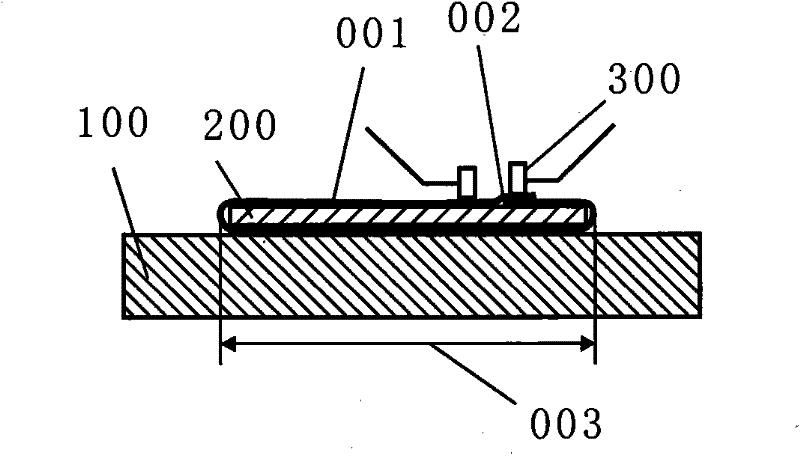

Image

Examples

Embodiment 1

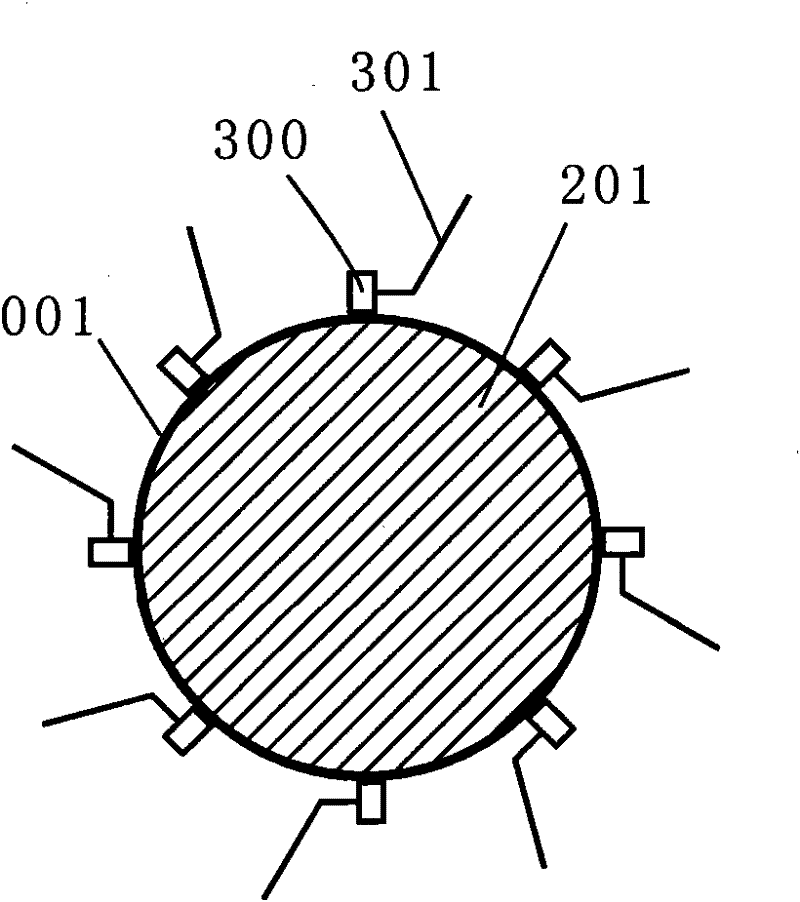

[0020] Such as image 3 As shown, the clasping mechanism of the film label clasping machine of this embodiment includes a mold 201 and a pressing member.

[0021] Wherein the mold 201 is in the shape of a cylinder, and the pressing parts are several pressure rollers 300 fixed around the mold 201 . The pressure roller 300 is connected to the frame of the palm-joining machine by a fixed rod 301

Embodiment 2

[0023] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the pressing member is a spring coil 400 which is set on the cylindrical mold 201 . The spring ring 400 is fixed by a plurality of clips 500 surrounding the mold 201, and the clips 500 are installed on a ring 600, which is fixed on the frame of the palm-joining machine.

[0024] Adopt above-mentioned technical scheme, because mold 201 is cylindrical shape, and pressing member is arranged around mold 201, the label film that is enclosed within on mold 201 like this is in any position of the circumference of mold 201 no matter its bonding position, and film label is received from surrounding pressing member. The pressure is the same, so there will be no problem of large diameter deviation of the film label due to the offset of the bonding position on the mold 201. In addition, the mold adopts a cylindrical shape, and the film label will not be scratched.

[0025] Therefore, the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com