Automatic wire diameter control device of cable extruder

A technology of automatic control device and control device, applied in cable/conductor manufacturing, insulation of conductor/cable, circuit, etc., can solve the problem of increasing production cost in cable manufacturing industry, low cable product quality and pass rate, rotational speed drift, etc. problems, to achieve the effect of improving production assurance and fault handling capabilities, realizing remote online monitoring, and improving heat shrinkage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0017] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

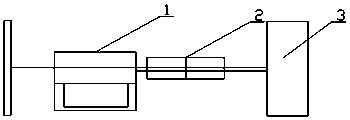

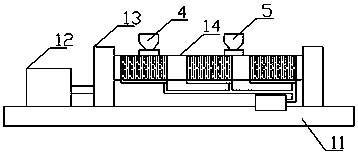

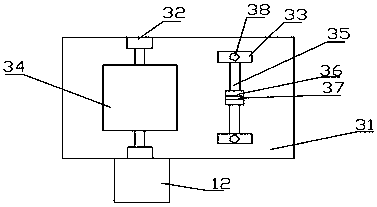

[0018] Such as figure 1 , 2 , 3, and 4, a wire diameter automatic control device for a cable extruder includes an extruder 1, a cooling device 2, a wire coil mechanism 3 and a control device, and the extruder 1 includes a base 11 and a motor 12 , gear device 13 and barrel 14, screw rod is arranged in the barrel 14, motor 12 drives the screw rod to rotate through gear device 13, is provided with electromagnetic heating device on barrel 14, and electromagnetic heating device is connected with control device, and electromagnetic heating device is used In order to heat the barrel 14, a first feed mechanism 4 and a second feed mechanism 5 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com