Anti-climbing hanging roller machine

A suspension roller and anti-climbing technology, which is applied to ceramic forming machines, molds, manufacturing tools, etc., can solve problems such as low safety, small diameter of cement pipes and distortion, unstable operation of molds, etc., and achieve high safety performance and convenient production , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

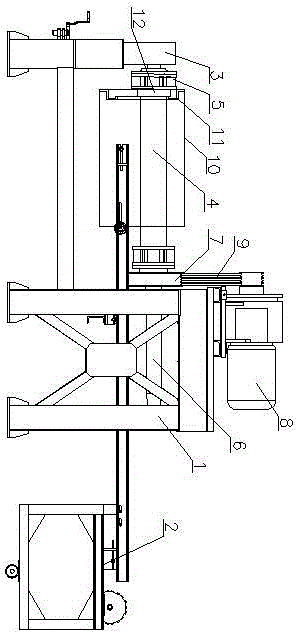

[0011] A kind of anti-climbing suspension roller machine, comprises main frame 1, and the front end of described main frame 1 is provided with feeder 2, and the rear end of described main frame 1 is provided with door frame 3, and described door frame 3 and main frame 1 is provided with a suspension roller shaft 4, the rear end of the suspension roller shaft 4 is connected to the rotating shaft on the door frame 3 through the flange 5, the main frame 1 is provided with a main shaft 6, and the rear end of the main shaft 6 is installed There is a pulley 7, the front end of the suspension roller shaft 4 is connected with the pulley 7 through the flange 5, the main frame 1 is provided with a motor 8, and the output end of the motor 8 is connected with the pulley 7 through a belt 9, The suspension roller shaft 4 is covered with a suspension roller mold 10, and an anti-climbing barrier sleeve 12 is provided between the socket body 11 of the suspension roller mold 10 and the flange 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com