Crystal pulling method and crystal pulling device

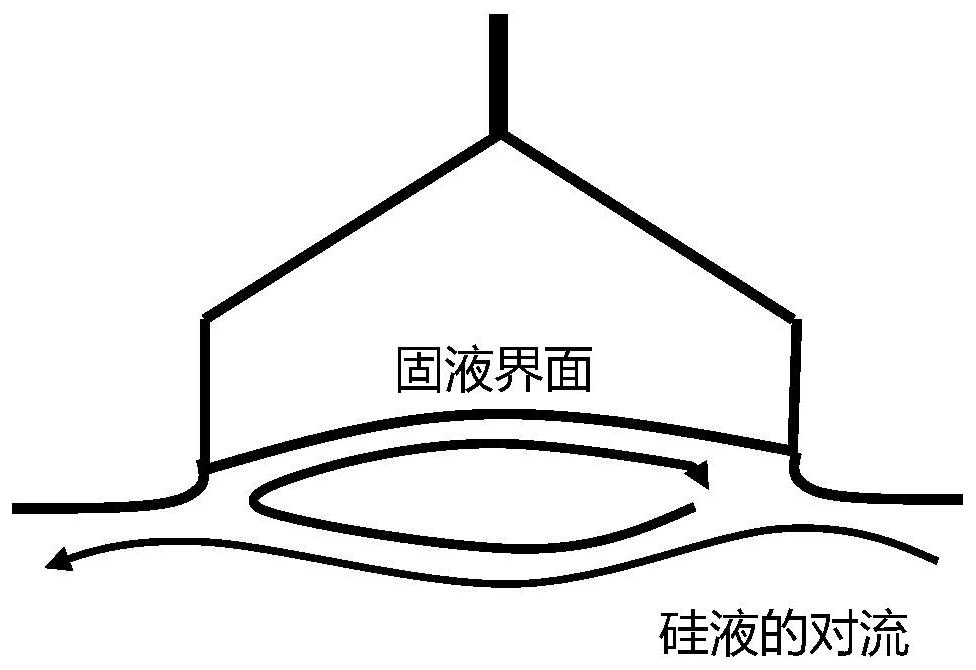

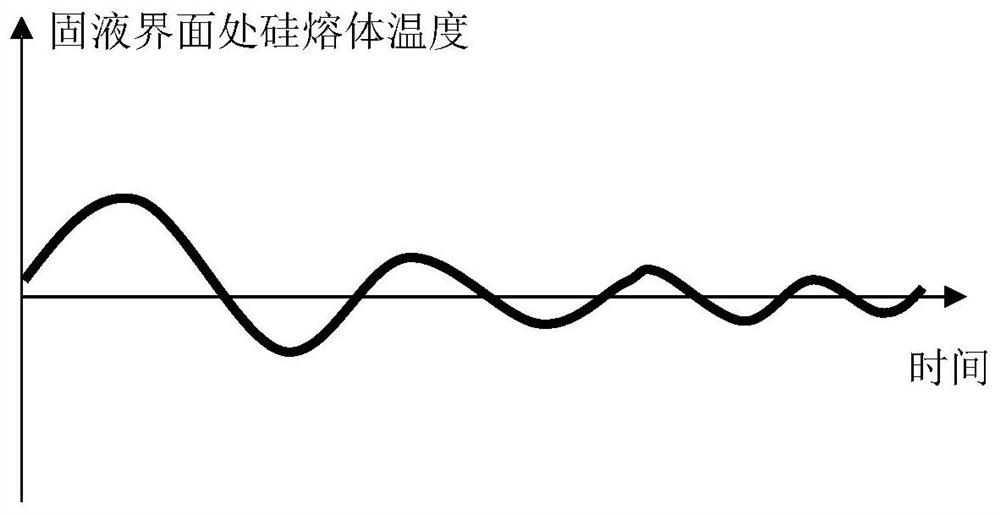

A control device and crystal ingot technology, applied in chemical instruments and methods, self-melt pulling method, single crystal growth, etc., can solve the problems of periodic changes in diameter, difficulty in controlling crystal ingot diameter, and convective behavior of silicon solution Complicated problems, to achieve the effect of stable crystal rod diameter and reduce the fluctuation of solid-liquid interface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In order to solve the problems in the prior art, the invention provides a crystal pulling method, comprising:

[0042] During the crystal pulling process, the crucible for containing the silicon melt is kept rotating while applying a horizontal magnetic field to the silicon melt in the crucible, wherein,

[0043] When and / or after changing the magnetic field strength of the magnetic field, the rotation speed of the crucible is changed.

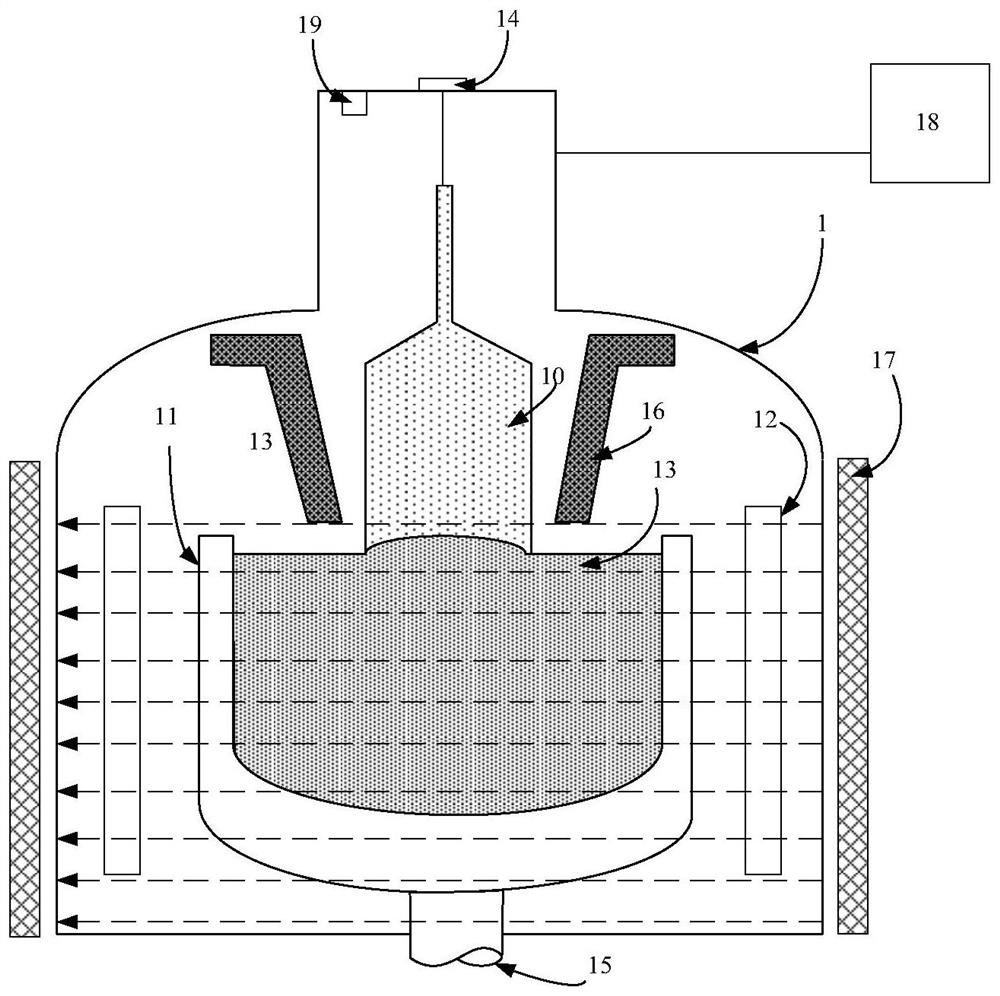

[0044] see figure 1 , shows a schematic structural view of a crystal pulling device according to the present invention, the crystal pulling device includes a furnace body 1, a crucible 11 is arranged in the furnace body 1, a heater 12 for heating it is arranged outside the crucible 11, and the crucible 11 A silicon melt 13 is contained therein.

[0045] Exemplarily, the crucible 11 is composed of a graphite crucible and a quartz crucible sleeved in the graphite crucible. The graphite crucible is heated by a heater to melt the polysili...

Embodiment 2

[0078] The present invention also provides a crystal pulling device, which includes:

[0079] a crucible to contain the silicon melt;

[0080] a pulling device for pulling the silicon melt to form crystal rods;

[0081] a magnetic field applying device, used to apply a horizontal magnetic field to the silicon melt in the crucible and adjust the magnetic field strength of the magnetic field;

[0082] a driving device for driving the crucible to rotate, wherein,

[0083] In the crystal pulling device according to the present invention, a control device is further included, and the control device controls the adjustment of the rotation speed of the crucible by the driving device according to the magnetic field strength of the magnetic field applied by the magnetic field applying device. Specifically, the method for the control device to control the adjustment of the rotation speed of the crucible by the driving device according to the magnetic field strength of the magnetic fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com