Energy-saving sludge drying process and device

A sludge drying and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of non-compliance with energy conservation and emission reduction policies, large heat energy consumption, poor technical and economical conditions, etc., to ensure long-term stability , Reduce system cost and reduce burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

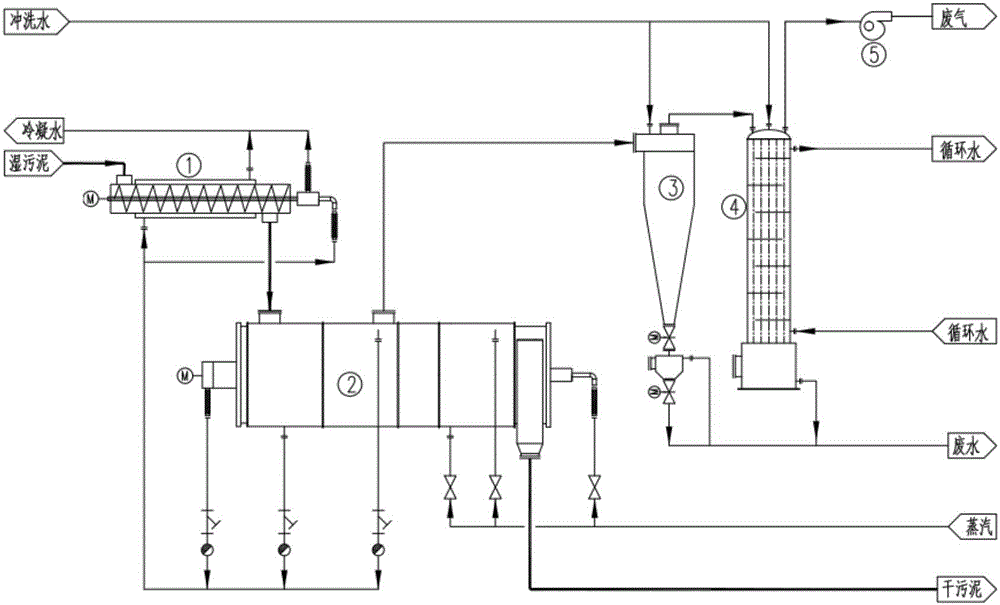

[0015] figure 1 It is a process flow chart of the energy-saving sludge drying process of the present invention. Such as figure 1 As shown, sludge preheater (1), indirect heating sludge dryer (2), cyclone dust collector (3), waste gas condenser (4) and waste gas induced draft fan (5).

[0016] The steam is sent to the indirect heating sludge dryer (2) through the pipe, and the condensed water of the steam after heat release still contains a certain amount of heat, and the condensed water is sent to the sludge preheater (1) through the pipe to release the remaining heat again , this part of the remaining heat can preheat the sludge to be dried, reducing the heat consumption of the sludge in the indirectly heated sludge dryer (2);

[0017] The wet sludge is transported to the sludge preheater (1) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com