Vibration isolating unit for vehicle

A vibration isolation and vehicle technology, applied in non-rotational vibration suppression, mechanical equipment, machine/engine, etc., can solve problems such as increased fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

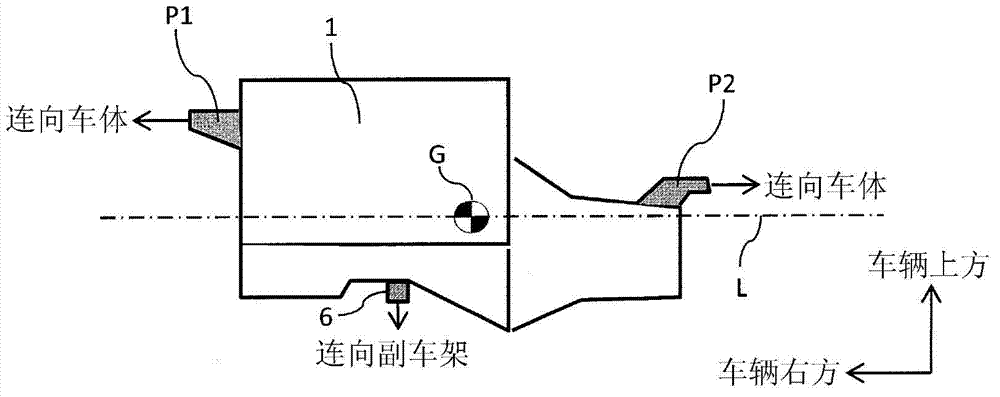

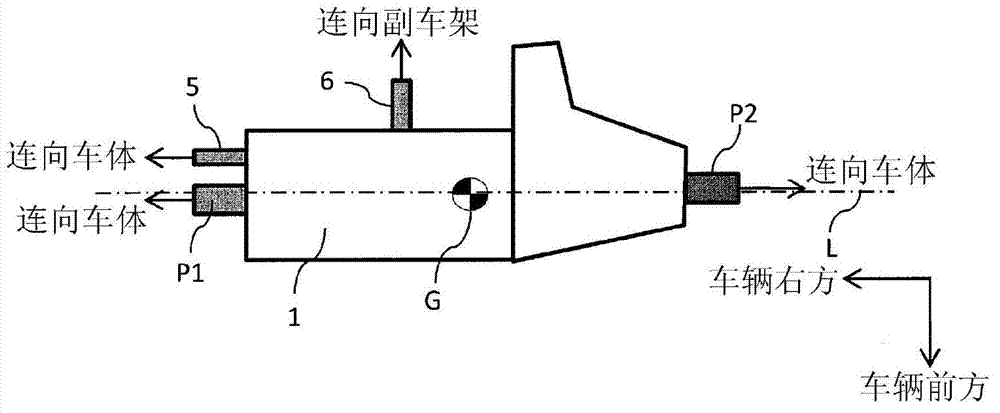

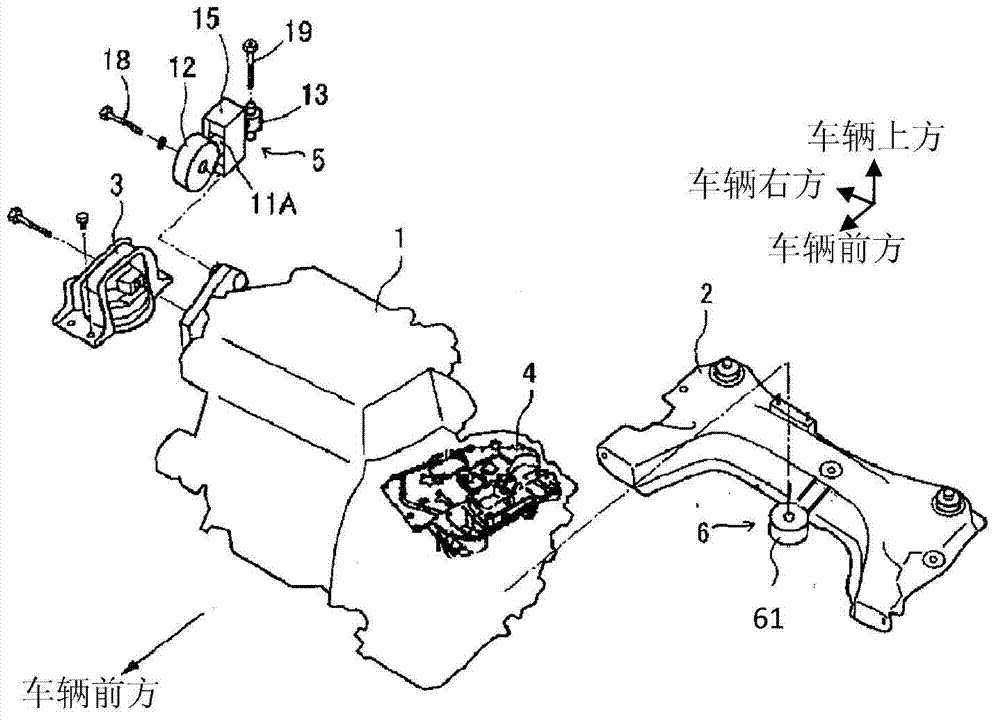

[0027] First, a so-called pendulum engine to which a vibration isolating device for a vehicle according to an embodiment of the present invention is applied will be described. Such as Figure 1A and Figure 1B As shown, the support structure of the engine 1 adopting a pendulum type is a so-called lateral direction that arranges the main axis of inertia L of the engine 1 parallel to the width direction of the vehicle (the direction perpendicular to the direction of travel, also referred to as the vehicle left-right direction). As far as the engine 1 is concerned, the two support points P1 and P2 supporting the engine 1 are at Figure 1B is located near the main axis of inertia L of the engine 1 in a plan view, and is on the opposite side of the axis across the center of gravity G. Figure 1A In the side view of , the two support points P1, P2 are located above the vehicle of the main axis of inertia L. In addition, the two supporting points P1 and P2 are as figure 2 It is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com