Novel organic compound and materials for organic electroluminescent devices comprising the same and organic electroluminescent devices comprising the same

A technology of organic compounds and carbon atoms, applied in luminescent materials, organic chemistry, electric solid-state devices, etc., can solve the problems of insufficient development of organic materials, achieve the effect of reducing driving voltage and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

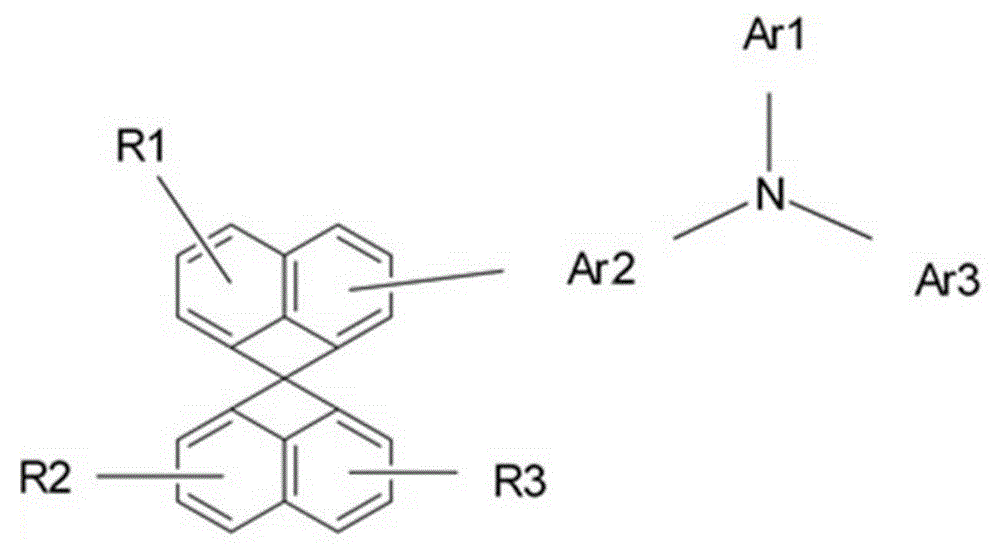

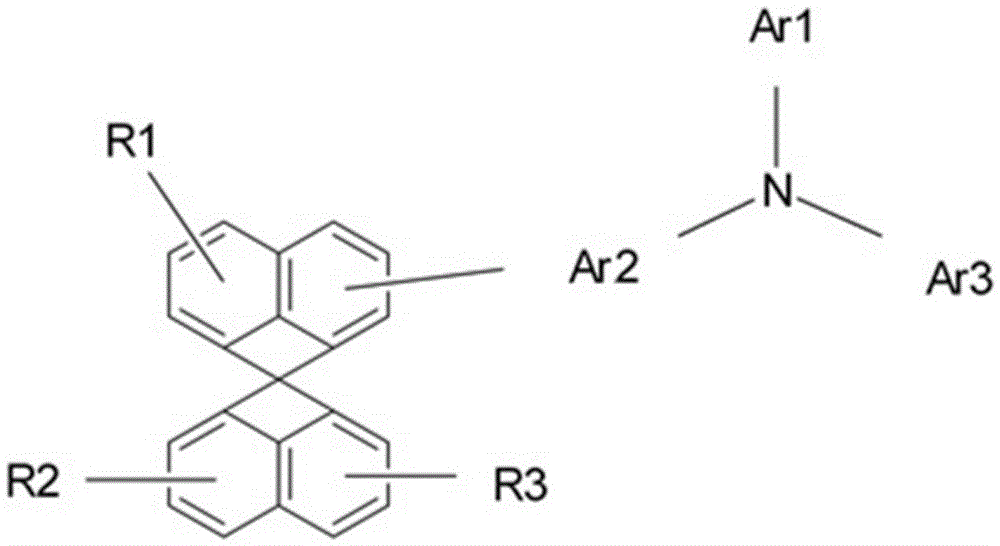

Method used

Image

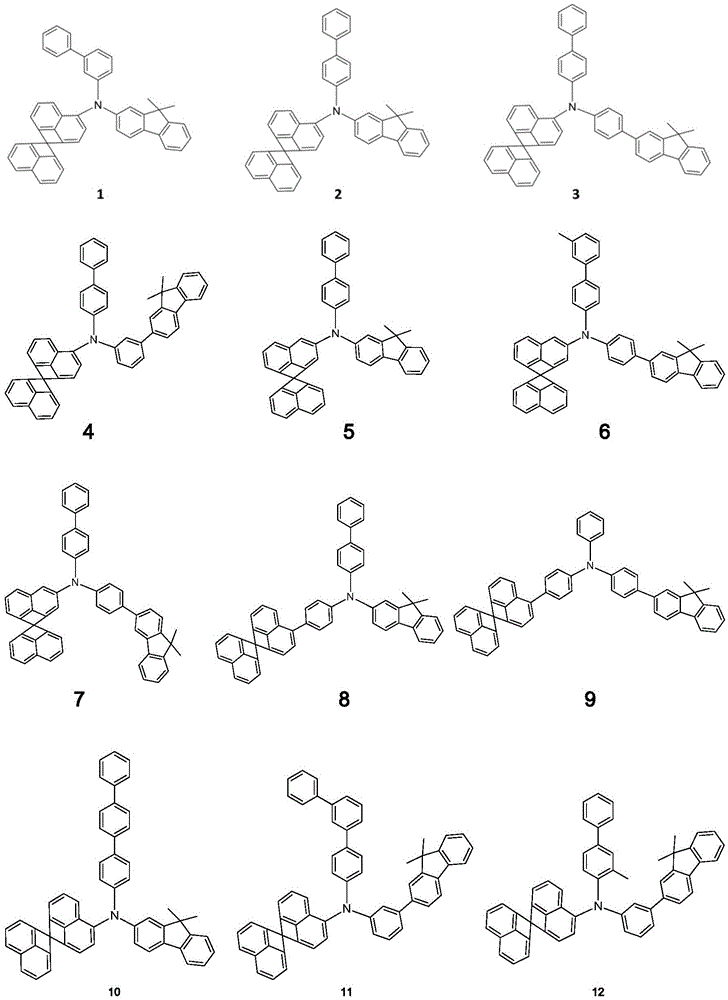

Examples

Embodiment 1~16

[0266] Embodiment 1~16: the manufacture of organic electroluminescence device

[0267] 5Ω / cm 2 The glass substrate of the ITO anode is cut into a size of 45mmx45mmx0.7mm, ultrasonicated in isopropanol and pure water for 5 minutes, cleaned with ozone for 30 minutes under ultraviolet light irradiation, and then the glass substrate is set on the vacuum coating equipment.

[0268] Deposit 2-TNATA on the above ITO layer to form Thick hole injection layer; on the surface of the hole injection layer, selected from compounds 2, 5, 6, 7, 15, 17, 21, 24, 27, 28, 30, 34, 37, 41, 45 of the present invention The corresponding components are vacuum deposited to form thick hole transport layer.

[0269] Next, vacuum-deposit AND and DPAVBi on the surface of the hole transport layer in a weight ratio of 97:3 to form Thick luminescent layer.

[0270] Then, put Alq 3 Deposited on the surface of the above-mentioned light-emitting layer, forming Thick electron transport layer; LiF is ...

experiment example 1

[0274] Experimental example 1: Evaluation of characteristics of organic electroluminescent devices

[0275] The characteristics of the organic electroluminescent devices 1 to 16 manufactured in the above examples and comparative examples and the organic electroluminescent device manufactured in comparative example 1 range from a current density of 10 mA / cm 2 measured, and the results are presented in Table 1.

[0276] 【Table 1】

[0277]

[0278] As can be seen from the experimental results shown in Table 1, compared with the existing organic electroluminescent device described in Comparative Example 1, the organic electroluminescent devices of Examples 1 to 16 of the present invention have significantly higher luminous efficiency. Obvious improvement.

[0279] In addition, from the above experimental results, it can be known that the luminous efficiency of the organic electroluminescent device is improved by using the organic compound of the present invention as the embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com