Double-wire submerged arc welding method for high heat input energy welding of high-strength super-thick steel plates

A technology of large heat input welding and extra-thick steel plates, which is applied in the direction of welding/welding/cutting items, welding media, welding equipment, etc., to achieve the effect of simple method, excellent quality and improved welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A double-wire submerged arc welding method for high-strength extra-thick steel plates for high-energy-input welding, comprising the following steps:

[0031] 1) The substrate is made of 60mm thick Q420 with yield strength R eh =475MPa, tensile strength R m =605MPa, the elongation rate is 25%, the average impact energy at -40°C is 253J, and the size of the welding test plate is 600mm×380mm×60mm.

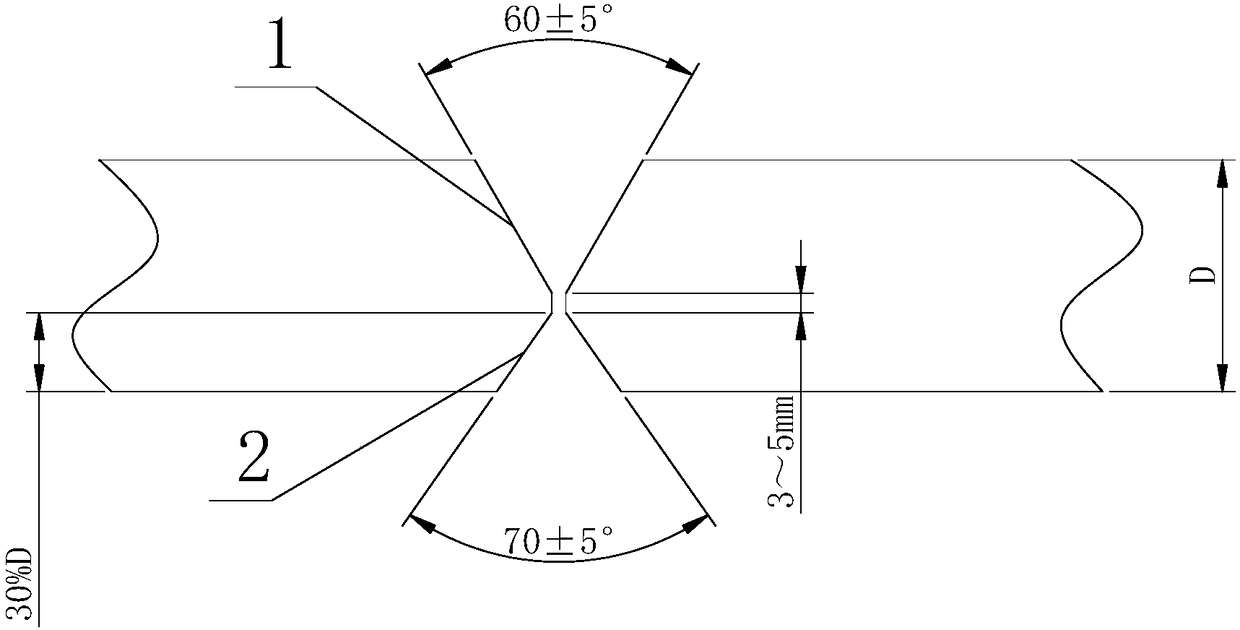

[0032] 2) see figure 1 , the groove type is asymmetrical X type, the groove angle of the first welding surface 2 is 71°, the penetration depth of the first welding surface 2 is 17mm; the groove angle of the rear welding surface 1 is 60°, and the penetration depth of the rear welding surface 1 is 40mm; blunt The side is 3mm, and the assembly clearance is reserved for 3mm.

[0033] 3) Selected Submerged arc welding wire suitable for large heat input welding, the chemical composition of the submerged arc welding wire is by weight percentage: C: 0.063%, Si: 0.07%, Mn: 1.52%, N...

Embodiment 2

[0036] A double-wire submerged arc welding method for high-strength extra-thick steel plates for high-energy-input welding, comprising the following steps:

[0037] 1) The substrate adopts 100mm thick EH40 ship plate with yield strength R eh =427MPa, tensile strength 541MPa, elongation 24%, and average impact energy at -40°C is 313J. The size of the welding test plate is 600mm×380mm×100mm.

[0038] 2) see figure 1 The groove type is asymmetrical X type; the groove angle of the first welding surface 2 is 73°, and the penetration depth of the first welding surface 2 is 28mm; the groove angle of the rear welding surface 1 is 58°, and the penetration depth of the rear welding surface 1 is 68mm; blunt edge 4mm, reserve 4mm for assembly clearance.

[0039] 3) Selected The chemical composition of submerged arc welding wire suitable for large heat input welding (by weight%): C: 0.083%, Si: 0.02%, Mn: 1.47%, Ni: 0.53%, Ti: 0.082%, B: 0.0090% , S: 0.0040%, P: 0.014%, the balance i...

Embodiment 3

[0042] A double-wire submerged arc welding method for high-strength extra-thick steel plates for high-energy-input welding, comprising the following steps:

[0043] 1) The substrate is made of 80mm thick EH36 ship plate, with a yield strength of 384MPa, a tensile strength of 496MPa, an elongation of 23.5%, and an average impact energy of -40°C of 331J. The size of the welding test plate is 600mm×380mm×80mm.

[0044] 2) see figure 1 The groove type is asymmetrical X type; the groove angle of the first welding surface 2 is 68°, and the penetration depth of the first welding surface 2 is 22mm; the groove angle of the rear welding surface 1 is 62°, and the penetration depth of the rear welding surface 1 is 53mm; blunt edge 5mm, reserve 4mm for assembly clearance.

[0045] 3) Selected The chemical composition of submerged arc welding wire suitable for large heat input welding (by weight%): C: 0.092%, Si: 0.05%, Mn: 1.74%, Ni: 0.28%, Ti: 0.058%, B: 0.0077% , S: 0.0048%, P: 0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com