Longitudinal seam red copper liner welding process of steel sheet pressure vessel and red copper liner used by same

A pressure vessel and welding process technology, applied in the field of pressure vessel welding process, can solve the problems of high repair rate, increased product manufacturing cost, large consumption of flux materials, etc., and achieve the effects of saving flux materials, improving manufacturing quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Please also see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the steel thin plate pressure vessel longitudinal seam copper liner welding process of the present invention includes the following points:

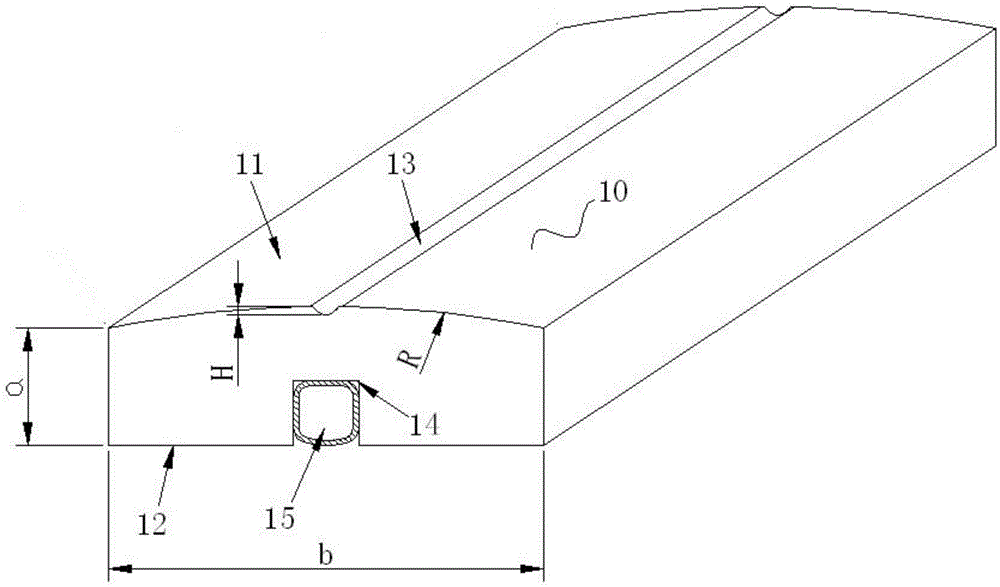

[0033] (1) Select a suitable copper pad 10 .

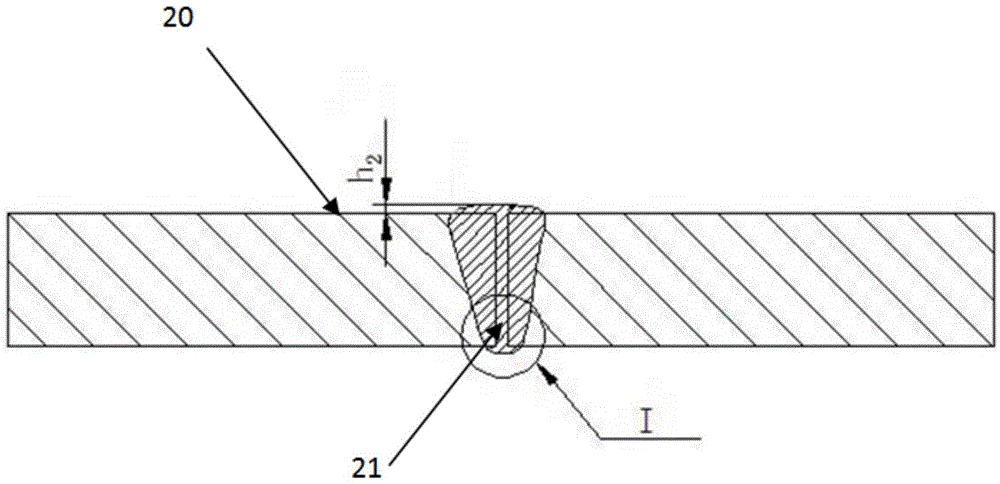

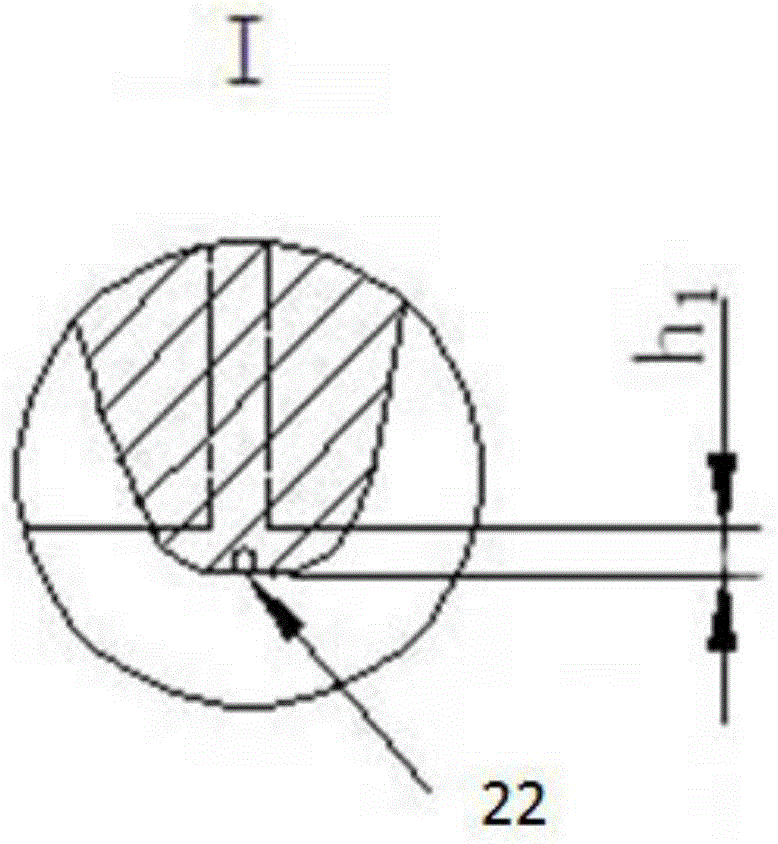

[0034] The copper pad 10 is block-shaped. It should be noted that the surface of the copper liner 10 that contacts and welds with the processing cylinder 20 is the upper end surface 11 of the copper liner 10 , which is a convex curved surface. The opposite surface of the upper end surface 11 of the copper liner 10 is the lower end surface 12 of the copper liner 10 . The cross-section of the red copper gasket 10 is the orthographic plane surrounded by the upper end face 11, the lower end face 12 and the two sides adjacent to the two straight sides of the upper end face 11, and the height a of the cross-section is the upper end face The average distance from the two straight sides of 11 to the lower end s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com