Argon blowing protection system

A protection system and protection device technology, applied in the field of molten steel refining outside the furnace, can solve the problems of slow denitrification speed, difficult denitrification, slow nitrogen diffusion speed, etc., to achieve increased nitrogen content, smooth process flow, and high steel tapping rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

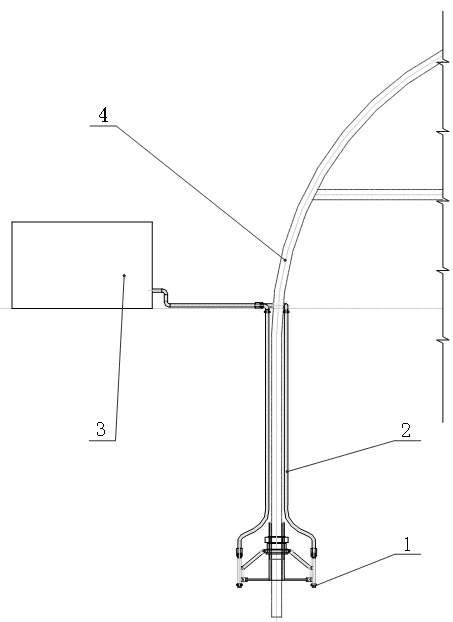

[0024] Example 1, such as figure 1 As shown, the argon blowing protection valve station 3 is connected to the argon blowing protection device 1 through the connecting hose 2, the protective gas argon 20 is decompressed through the argon blowing protection valve station 3 and then enters the argon blowing protection device 1 through the connecting hose 2, and the blowing The argon protection device 1 is located above the liquid steel surface, and the wire 4 output by the wire feeder enters the argon gas 20 atmosphere in the argon blowing protection device 1 from the center of the upper end of the argon blowing protection device 1, and is finally inserted into the molten steel to insulate the steel. The liquid and the splashed molten steel are in contact with the nitrogen fertilizer in the air, which can prevent the nitrogen from melting into the molten steel to increase the content of nitrogen.

Embodiment 2

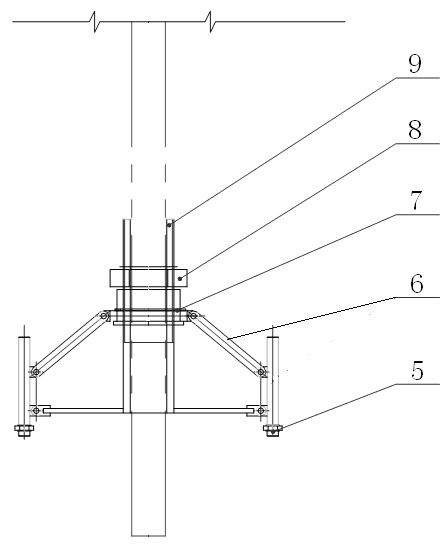

[0025] Example 2, such as figure 2 As shown, the argon blowing protection device 1 is composed of a nozzle 5, an adjustment arm 6, an adjustment nut 7, a lock nut 8, and a support frame 9. The nozzle 5 is fixedly connected to one end of the adjustment arm 6, and the other end of the adjustment arm 6 is adjusted The nut 7 and the locking nut 8 are connected with the support frame 9. The level of the nozzle 5 is not higher than the level of the bottom end of the support frame 9. The nozzle 5 adjusts the size of the spray surface by rotating the adjustment nut 7, and the rotation adjustment nut 7 moves along the support frame. The outer wall of the frame 9 moves up and down, and the adjustment nut 7 drives the adjustment arm 6 to move up and down. The adjustment of the height of the adjustment arm 6 makes the size of the circular surface formed by the argon gas 20 ejected from the nozzle 5 on the liquid steel surface adjusted. According to the requirements of the wire feeding pro...

Embodiment 3

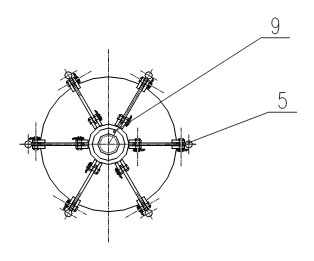

[0026] Example 3, such as image 3 As shown, for the single-wire wire feeding machine, the support frame 9 is circular, and the center of the circular center of the support frame 9 forms a circular through hole sufficient for the passage of the wire 4, and the outer wall of the support frame 9 is distributed through six adjustment arms 6. There are 6 nozzles 5, and the 6 nozzles 5 are evenly distributed on the outer circumference of the support frame 9 by six equal divisions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com