Submerged arc welding method of plank boards and jointing boards

A technology of submerged arc welding and submerged arc welding wire, which is applied in the direction of welding equipment, arc welding equipment, and the edge of the workpiece, and can solve the problems of large residual stress in the weld, incomplete penetration, and high rigidity of the large-thickness plate structure. Satisfied performance and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

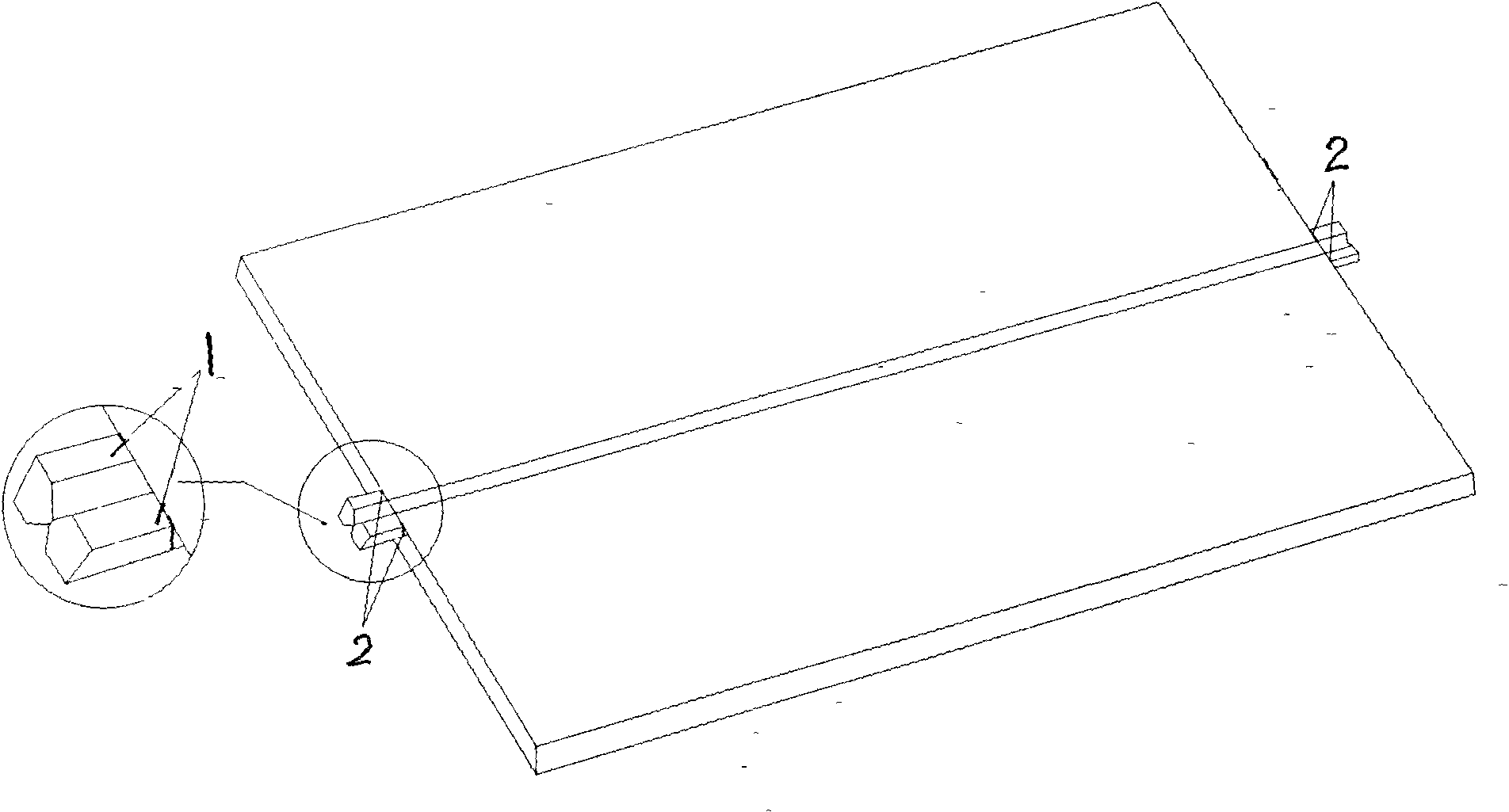

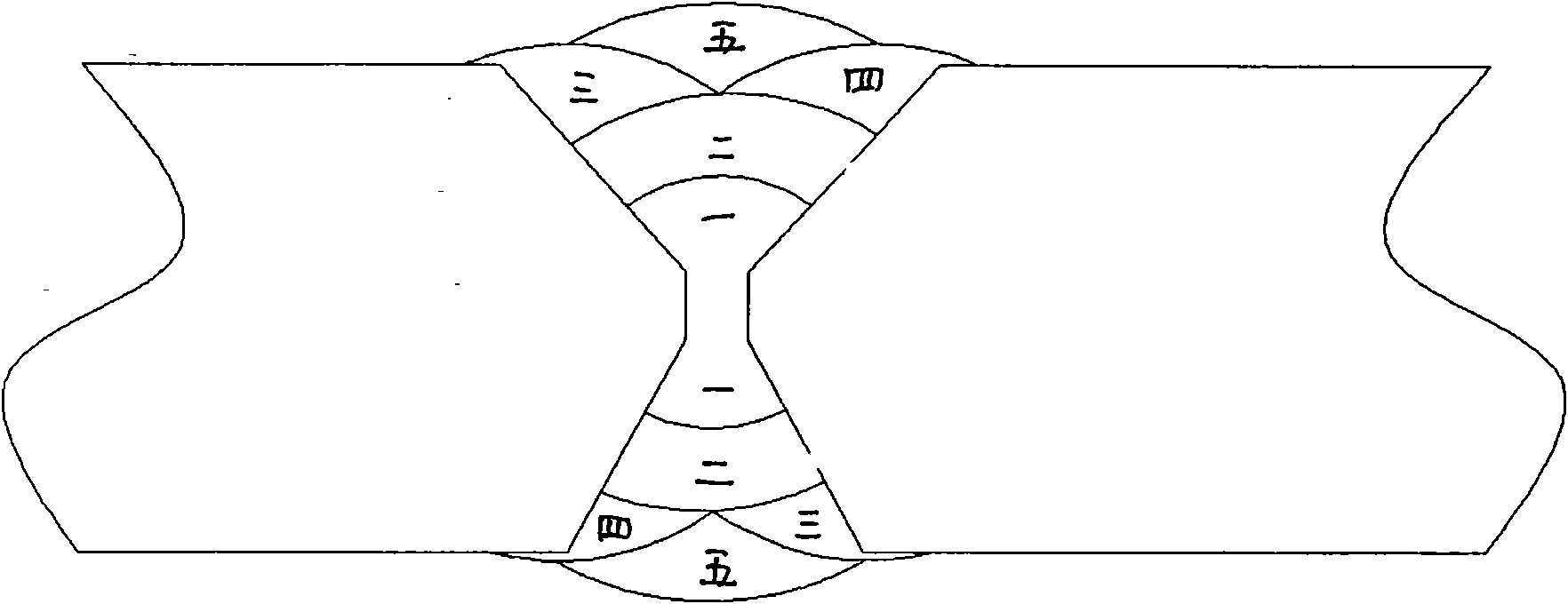

[0035] like figure 1 , 2 As shown in , 3, a kind of submerged arc welding method of thick plates in this embodiment, taking a plate thickness of 35mm as an example, performs submerged arc welding of plates:

[0036] 1. Plate type: CCSE plate thickness: 35mm plate length: 10100mm plate width: 2380mm×2

[0037] The plates are low-alloy high-strength steels. According to the principle of equal strength, the welding materials are selected according to Table 1.

[0038] Table 1: Welding Material Parameters

[0039]

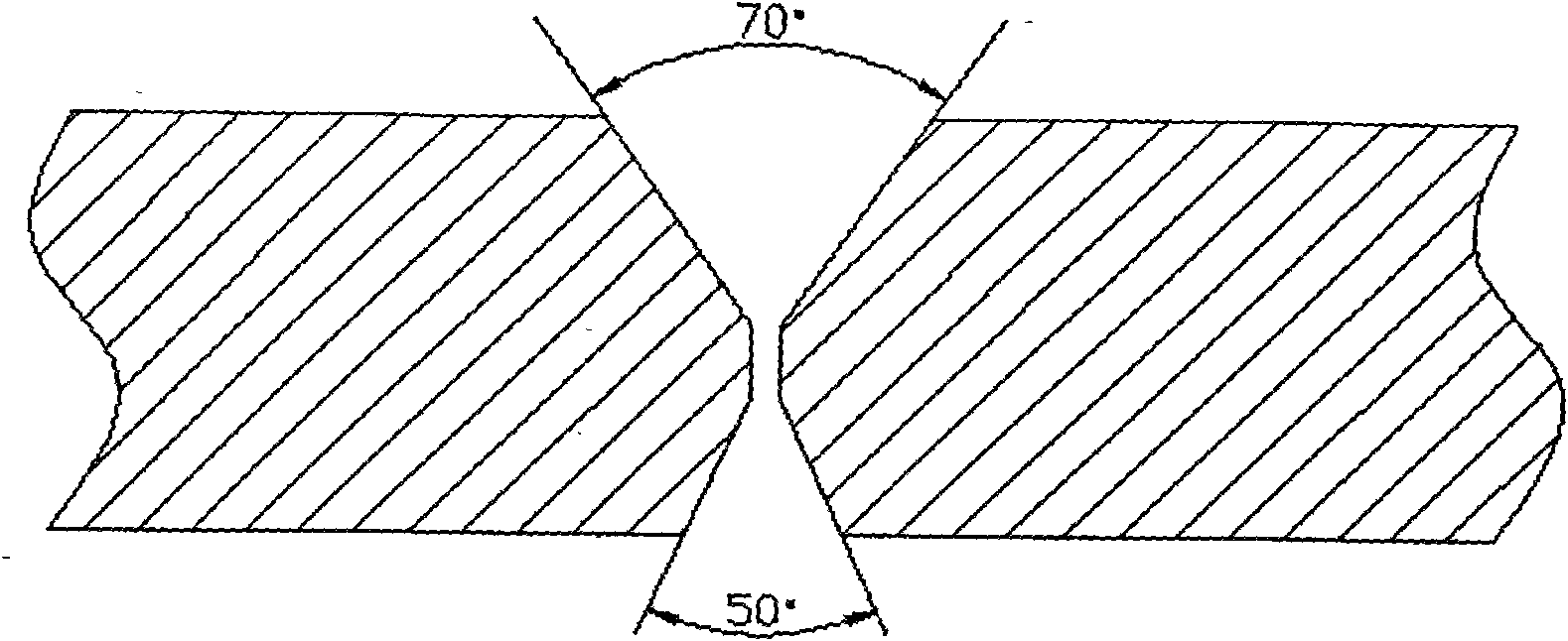

[0040] 2. Groove form: such as figure 1 As shown, by mechanical processing, a 35-degree bevel is made on the upper part of the steel plate material 1 to be butted, and a 25-degree bevel is made on the lower part. After the steel plate materials are butted, the upper bevel is 70 degrees, and the lower bevel is 50 degrees. .

[0041] 3. Preparation before welding:

[0042] ① Remove harmful substances such as oil stains, rust, oxides and moisture within 20mm of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com