Girth welding technology for vacuum container

A technology of circumferential seam welding and vacuum container, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of concave, welding deformation, etc., to control welding deformation, avoid local high temperature, and ensure absolute welding penetration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

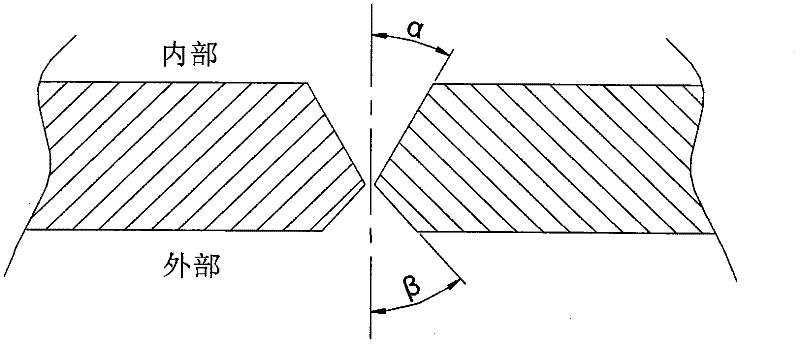

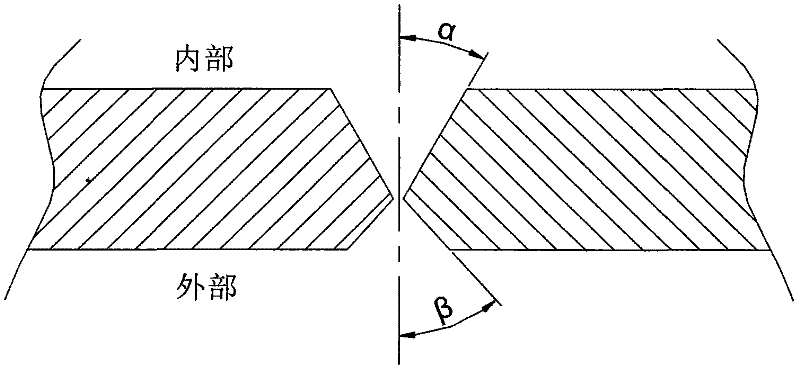

[0016] Such as figure 1 In the shown embodiment, the welding process of the vacuum vessel girth according to the present invention includes three steps of groove processing, assembly and welding.

[0017] In the groove processing process, the Simplified base material is made of 0Cr18Ni9 austenitic stainless steel material with a thickness of 14mm, and an X-shaped groove is used, the inner groove is processed by 10mm, the unilateral angle α is 32.5°, and the outer groove is processed by 4mm. The edge angle β is 35°, and no blunt edge is left.

[0018] During the assembly process, a gap of 2.0-2.5mm is reserved for assembly, and positioning is performed by argon tungsten arc welding. The length of the positioning welding is 10-15mm, and the interval is 200mm. Character support", avoiding the phenomenon of uneven speed and up and down jumping when the cylinder is rotated on the roller frame during welding due to the large diameter of the cylinder and the low roundness of the sim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com