A moving bed roasting process for low-grade molybdenum concentrate

A moving bed, low-grade technology, applied in the field of molybdenum metallurgy, can solve the problems of inability to process low-grade molybdenum concentrates, achieve the effects of inhibiting the formation of insoluble molybdate, increasing the concentration of SO2, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

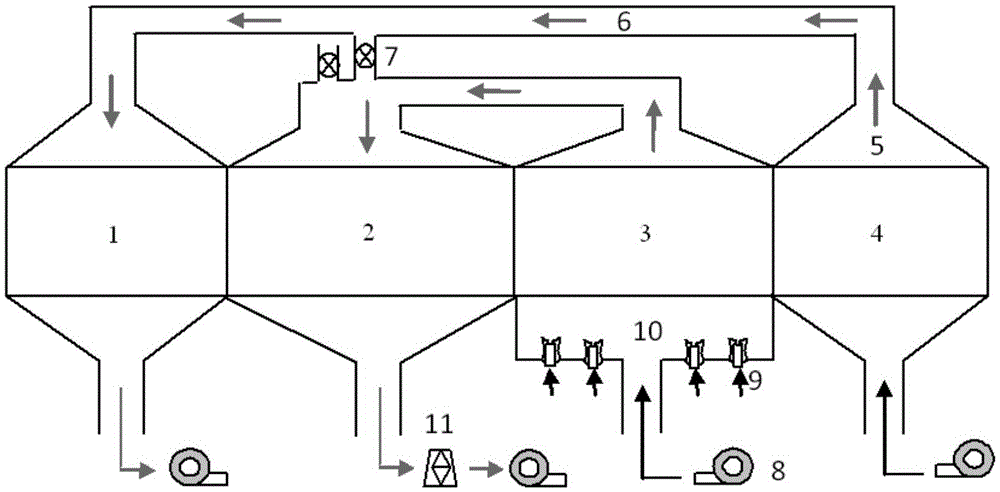

Embodiment 1

[0033] For the molybdenum concentrate with a molybdenum grade of 39.27wt% and a sulfur content of 29.73wt% (see Table 1 for the chemical composition of the raw materials), a chain grate treatment process is used to obtain molybdenum calcined sand after drying, oxidation roasting, and cooling; the chain grate drying section The lengths of , roasting section I, roasting section II, and cooling section account for 5%, 45%, 25%, and 25% of the effective total length (working area) of the grate respectively; 70% of the hot exhaust gas in the cooling section is introduced into the drying section, and the roasting The hot exhaust gas produced in the second section and 30% of the hot exhaust gas in the cooling section are introduced into the roasting section I, the gas is burned to heat the air to provide the hot gas required for the roasting section II, and the air is blown into the cooling section for cooling, and the gas in the hood of the drying section is controlled The temperatur...

Embodiment 2

[0035]For the molybdenum concentrate with a molybdenum grade of 44.13wt% and a sulfur content of 33.70wt% (see Table 1 for the chemical composition of the raw material), a chain grate treatment process is used to obtain molybdenum calcined sand after drying, oxidation roasting, and cooling; the chain grate drying section , The lengths of roasting section I, roasting section II, and cooling section account for 10%, 50%, 30%, and 10% of the effective total length (working area) of the grate respectively; the hot exhaust gas from the cooling section is introduced into the drying section, and the roasting section II The hot exhaust gas produced is introduced into the roasting section I, and part of the air is mixed in the smoke hood of the roasting section I, and the gas is burned to heat the air to provide the hot gas required for the roasting section II, and the air is blown into the cooling section for cooling. Control the gas temperature in the hood of the drying section to 270...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com