Housing components and electronics

A shell assembly and shell technology, applied in the electronic field, can solve problems such as high temperature, affecting the shooting performance of the camera, affecting the performance of the surrounding shell of the camera, etc., and achieve the effect of avoiding local high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

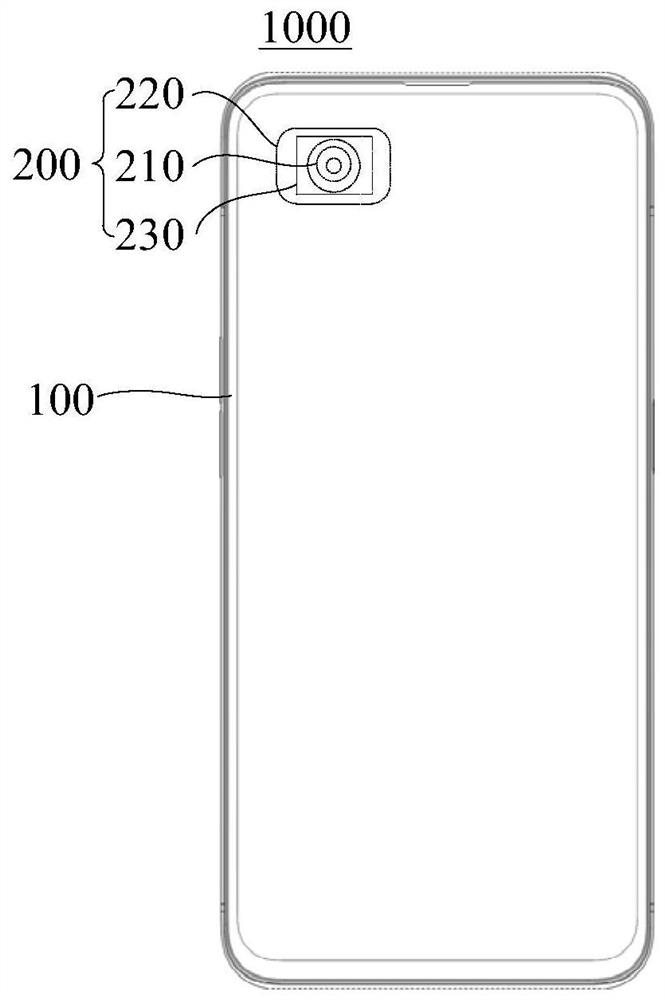

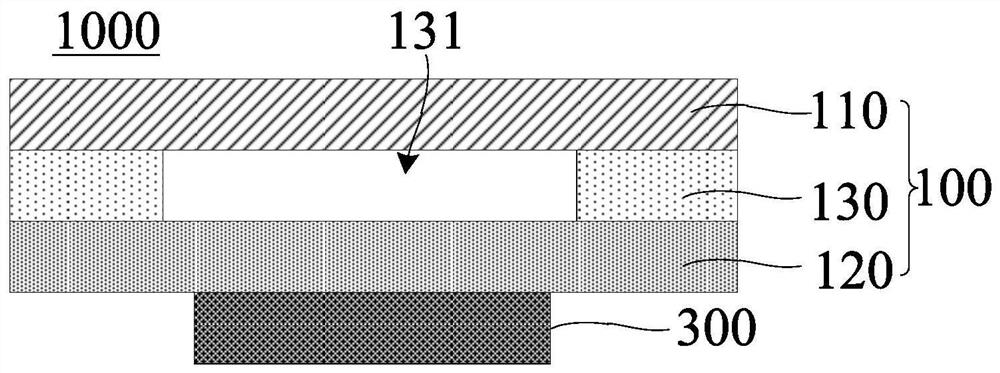

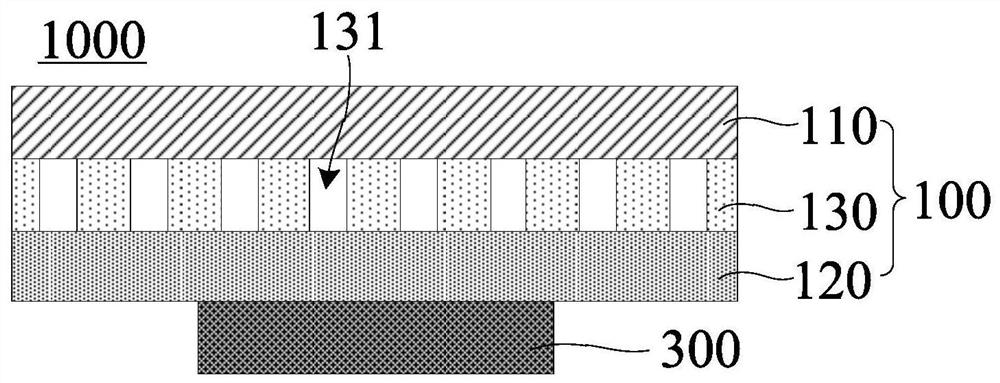

loaded, and will not be repeated here. The electronic device 1000 according to the embodiment of the present application is provided between the rear case 112 and the first graphite sheet 121

The foam 134, on the one hand, utilizes the heat insulating holes 131 on the foam 134 to insulate heat from being transmitted to the casing 110 in the vertical direction

This can prevent the outer surface temperature of the casing 110 from being too high; on the other hand, the foam 134 is disposed between the camera module and the rear casing 112

In the meantime, the foam 134 can provide buffer protection for the camera module to prevent the camera module from being damaged under the action of external force.

At the same time, the insulating holes 131 are formed on the foam 134 , compared with the solution of opening the insulating holes 131 on the platen support 133 , there is no problem.

The structural strength of the platen bracket 133 is reduced.

[0065] In the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com