A production process for synthesizing 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)-4-nitrobenzene

A trifluoromethylphenoxy, production process technology, applied in the field of pesticides, can solve the problems of affecting the yield and purity of products, severe heat release, etc., to suppress side reactions, improve reaction efficiency, and improve heat and mass transfer. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

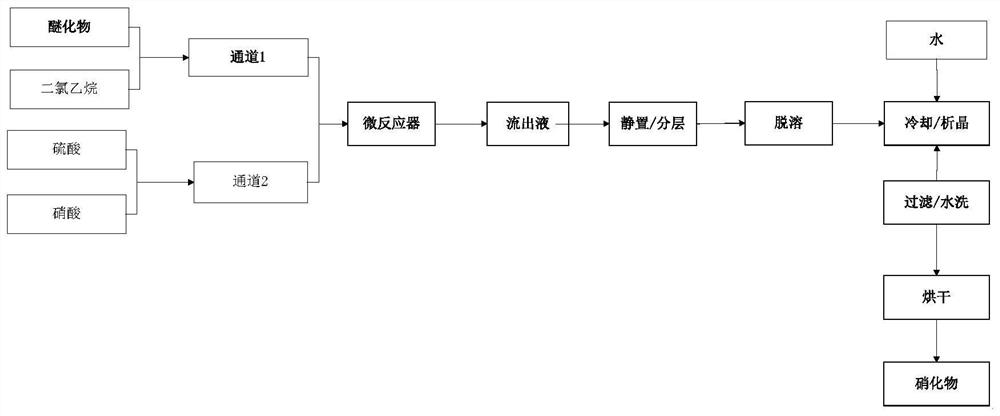

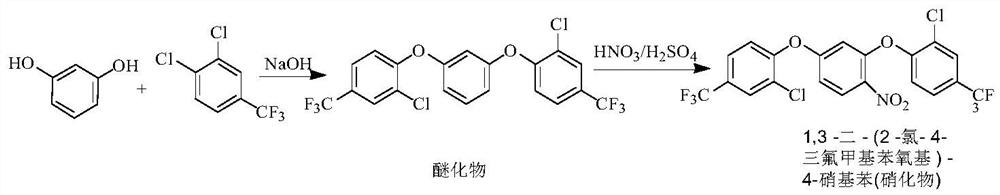

[0030] A production process for synthesizing 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)-4-nitrobenzene, comprising the following steps:

[0031] Step S1, add 1,3-bis-(2-chloro-4-trifluoromethylphenoxy) benzene dichloroethane solution in No. 1 storage tank, add concentrated sulfuric acid and A mixed acid solution composed of fuming nitric acid; among them, the dichloroethane solution of 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)benzene is used as a reactant; the mixture composed of concentrated sulfuric acid and fuming nitric acid Mixed acid solution as a nitrating reagent; 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)dichloroethane solution of 1,3-bis-(2-chloro-4-trifluoro Methylphenoxy) benzene is solute, and ethylene dichloride is solvent; The quality of 1,3-bis-(2-chloro-4-trifluoromethylphenoxy) benzene is 467kg; The mass is 1401kg; the mass of the mixed acid solution composed of concentrated sulfuric acid and fuming nitric acid is 467kg; in the mixed acid solution compos...

Embodiment 2

[0038] A production process for synthesizing 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)-4-nitrobenzene, comprising the following steps:

[0039] Step S1, add 1,3-bis-(2-chloro-4-trifluoromethylphenoxy) benzene dichloroethane solution in No. 1 storage tank, add concentrated sulfuric acid and A mixed acid solution composed of fuming nitric acid; among them, the dichloroethane solution of 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)benzene is used as a reactant; the mixture composed of concentrated sulfuric acid and fuming nitric acid Mixed acid solution as a nitrating reagent; 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)dichloroethane solution of 1,3-bis-(2-chloro-4-trifluoro Methylphenoxy) benzene is solute, and ethylene dichloride is solvent; The quality of 1,3-bis-(2-chloro-4-trifluoromethylphenoxy) benzene is 467kg; The mass is 4670kg; the mass of the mixed acid solution composed of concentrated sulfuric acid and fuming nitric acid is 389.17kg; in the mixed acid solution com...

Embodiment 3

[0046] A production process for synthesizing 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)-4-nitrobenzene, comprising the following steps:

[0047] Step S1, add 1,3-bis-(2-chloro-4-trifluoromethylphenoxy) benzene dichloroethane solution in No. 1 storage tank, add concentrated sulfuric acid and A mixed acid solution composed of fuming nitric acid; among them, the dichloroethane solution of 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)benzene is used as a reactant; the mixture composed of concentrated sulfuric acid and fuming nitric acid Mixed acid solution as a nitrating reagent; 1,3-bis-(2-chloro-4-trifluoromethylphenoxy)dichloroethane solution of 1,3-bis-(2-chloro-4-trifluoro Methylphenoxy) benzene is solute, and ethylene dichloride is solvent; The quality of 1,3-bis-(2-chloro-4-trifluoromethylphenoxy) benzene is 467kg; The mass is 1500kg; the mass of the mixed acid solution composed of concentrated sulfuric acid and fuming nitric acid is 424.55kg; in the mixed acid solution com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com