Submerged-arc welding process method for welding H-shaped steel with web plate more than 16mm thick

A process method, H-beam technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as environmental pollution, channel carbonization, component scrapping, etc., to reduce environmental pollution, small contact area, and labor saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

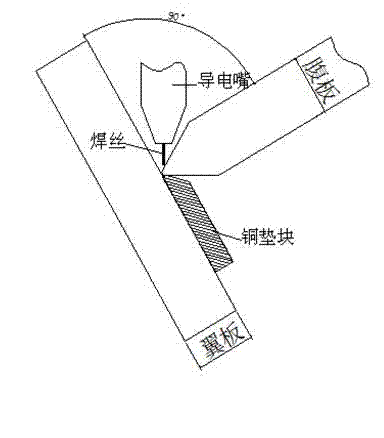

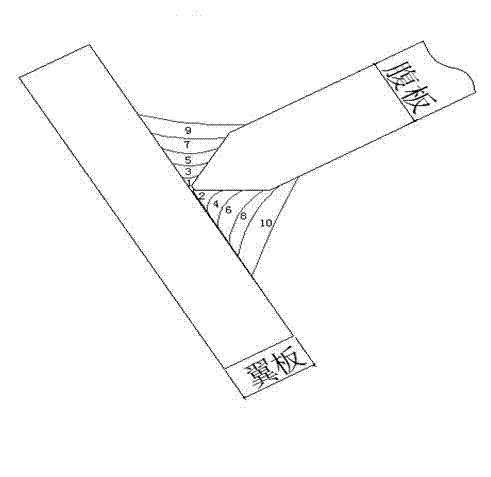

[0021] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments. In this embodiment, the thickness of the H-shaped steel web is 28mm, the specification is H1000*250*28*28mm, the material of the base material is Q345B, and full penetration welding is required. The process method includes the following steps:

[0022] 1) Selection of welding materials: According to the nature of the base metal, the diameter of the welding wire is 4mm, the flux is Xilin HJ101, and the particle size is 10-40 mesh;

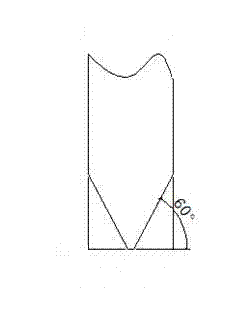

[0023] 2) Processing of web groove: process web groove, the groove form is K-type symmetrical groove, the K-type symmetrical groove angle is 60±2°, and the blunt edge is 1-2mm;

[0024] 3) Assembly of H-shaped steel: assemble the web and the flange together, and form a zero-pair gap after the assembly is completed; the zero-pair gap means that the web and the flange are first corrected before assembly, Ensure that the local flatness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com