Production method of ultra-thick steel plate

A production method and technology of extra-thick steel plates, applied in the direction of manufacturing converters, rolling mill control devices, metal rolling, etc., can solve the problems of small thickness specifications, layered defects, low production efficiency, etc., and achieve the benefits of mass production, Good mechanical properties and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Chemical composition of the present invention and production technology, its steel billet composition are as table 1, and actual process parameter of the present invention is as table 2, and the physical property inspection result of the present invention is as table 3.

[0020] Table 1 Billet Chemical Composition, Wt%

[0021] Numbering

C

Si

mn

P

S

Nb

Ti

V

ALs

1#

0.10

0.32

1.53

0.010

0.005

0.04

0.008

0.04

0.040

2#

0.16

0.35

1.54

0.015

0.004

0.04

0.012

0.04

0.042

3#

0.14

0.29

1.50

0.015

0.004

0.03

0.008

0.04

0.045

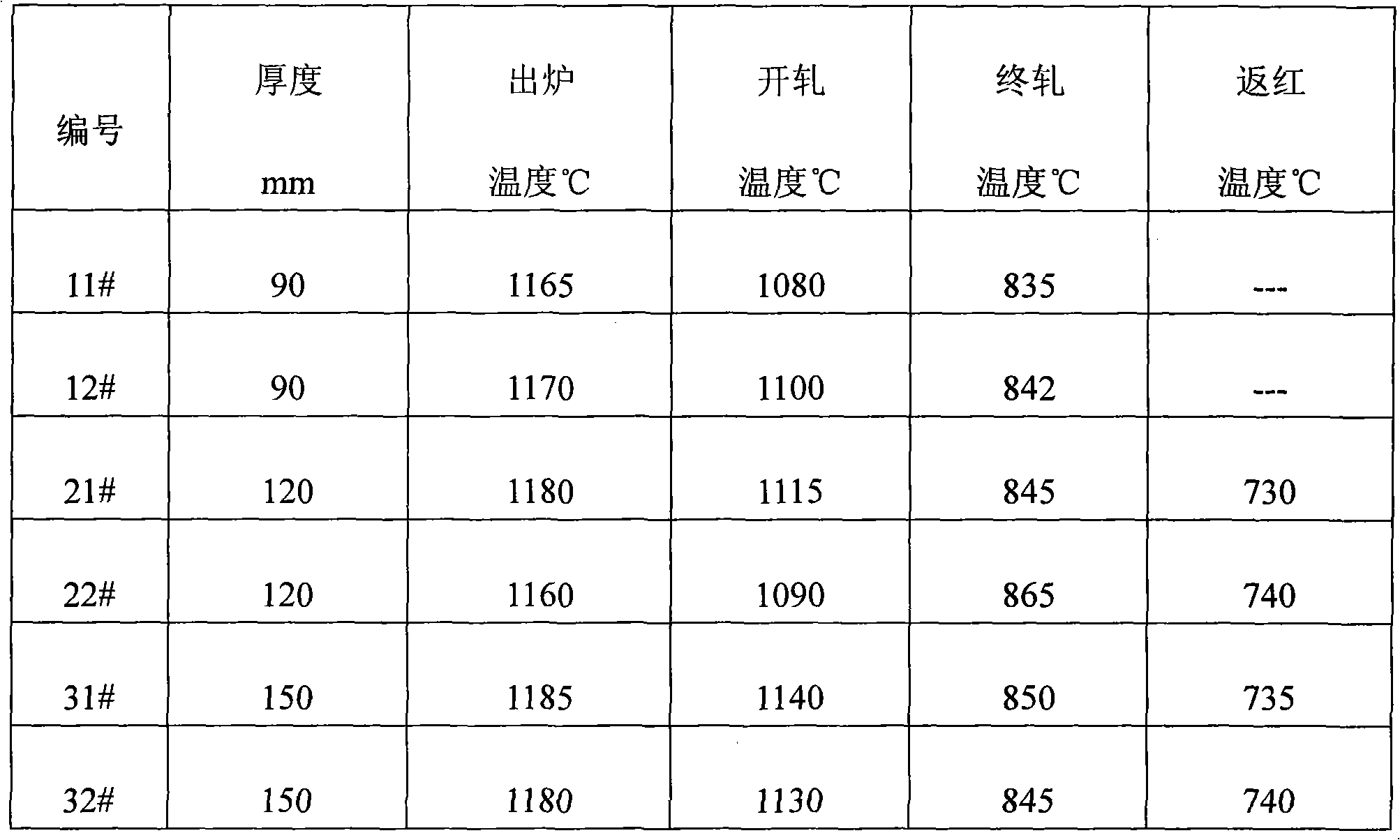

[0022] Table 2 Actual process parameters of the present invention

[0023]

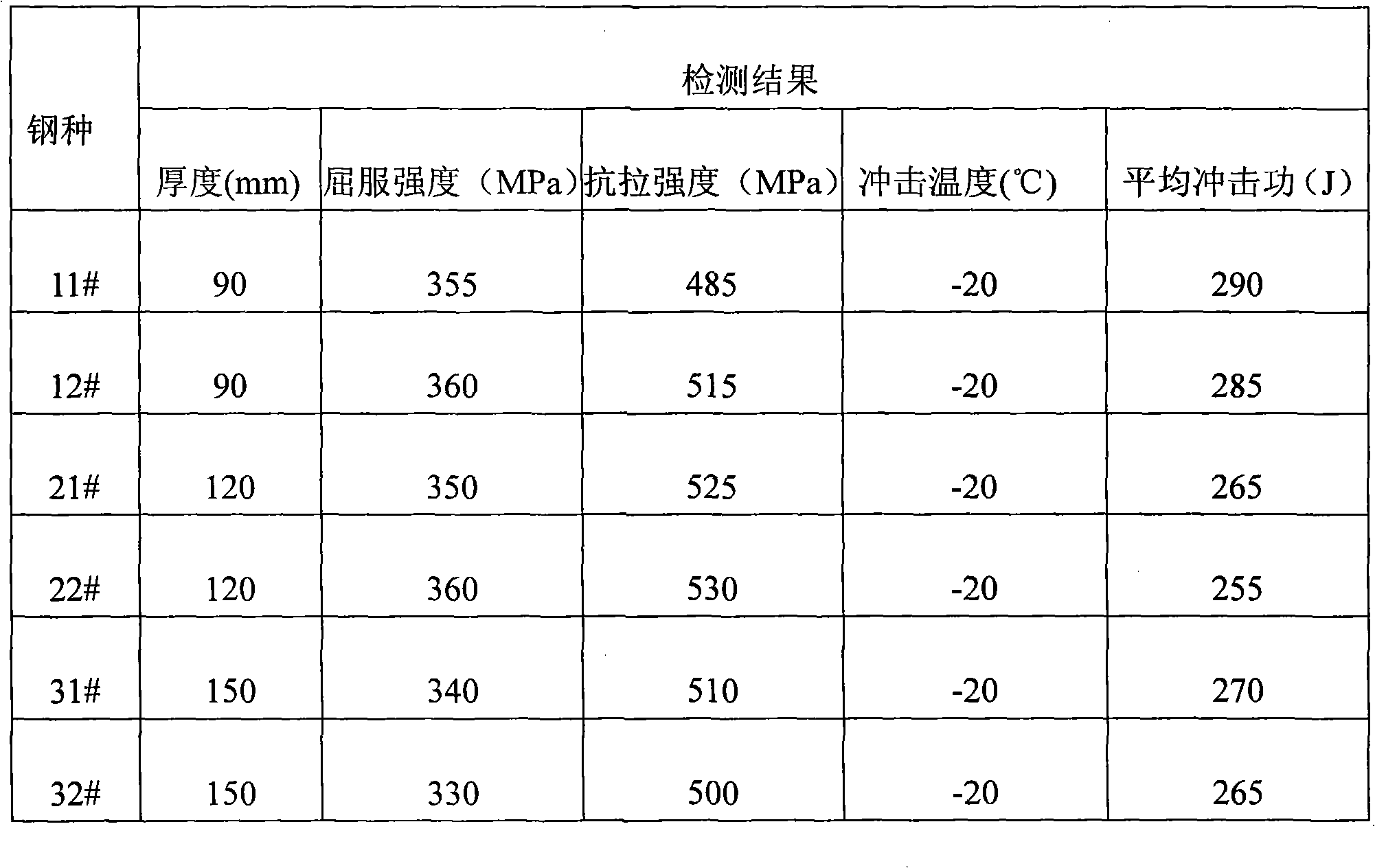

[0024] Table 3 physical inspection result of the present invention

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com