Patents

Literature

33results about How to "Effective power saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

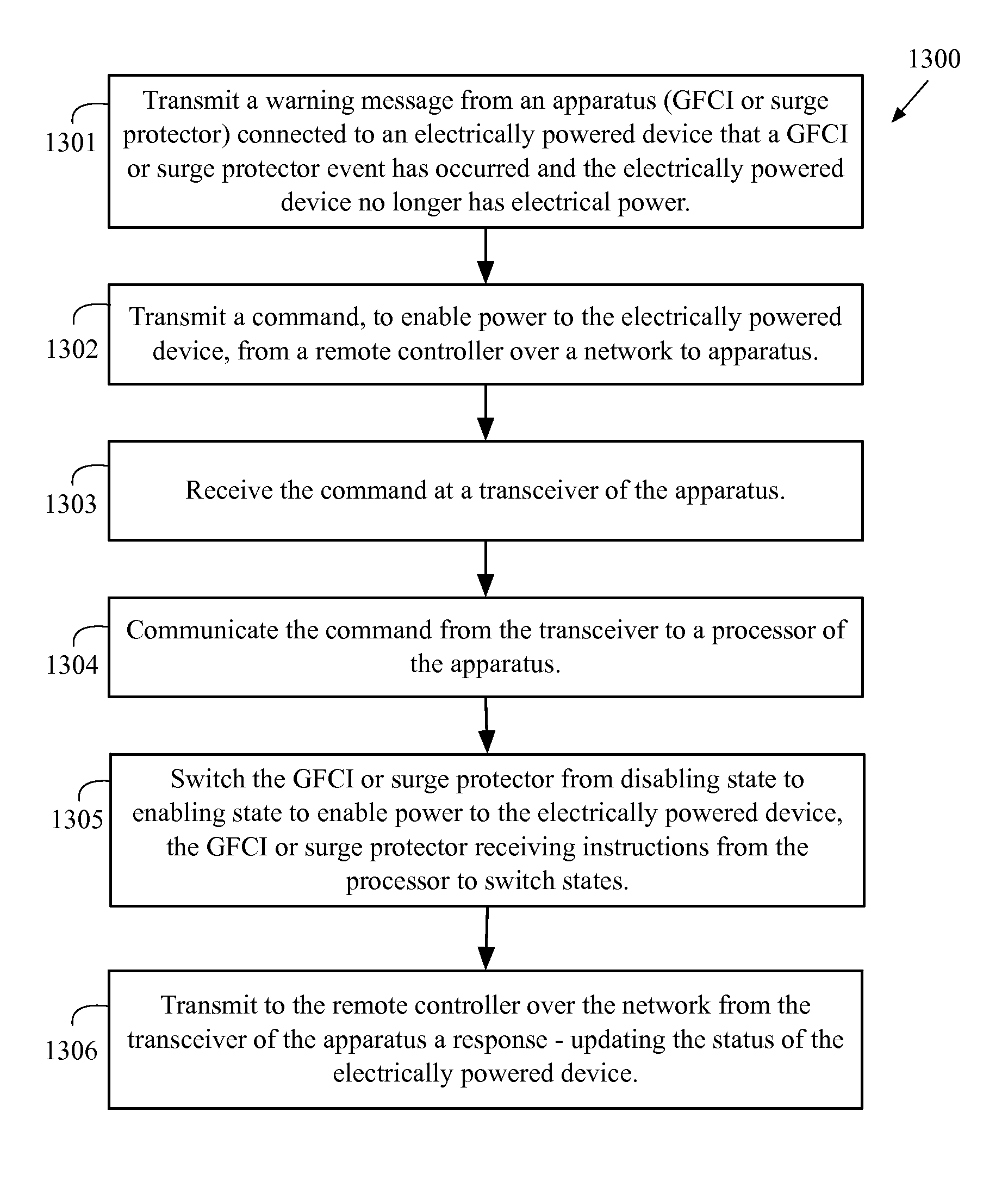

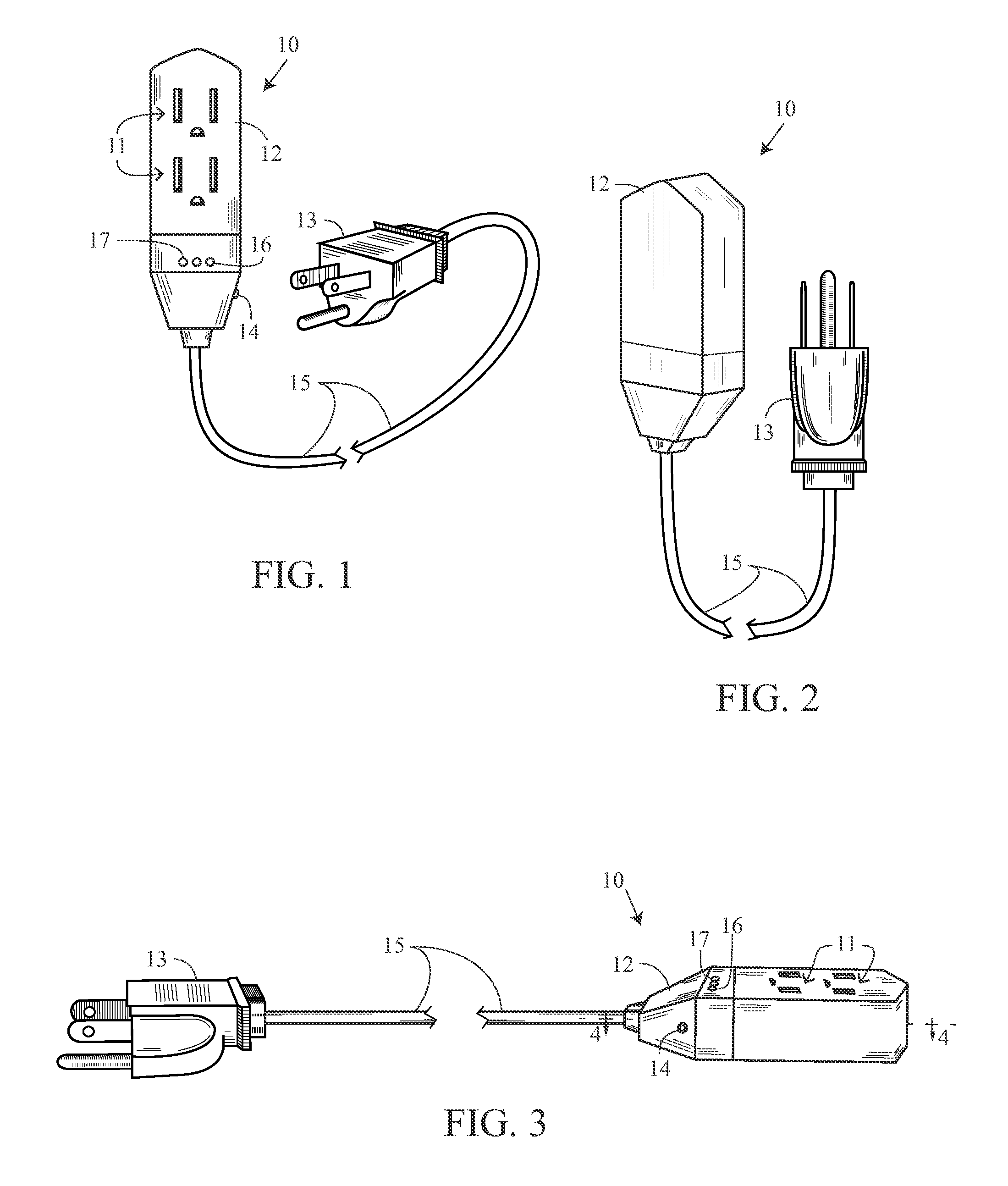

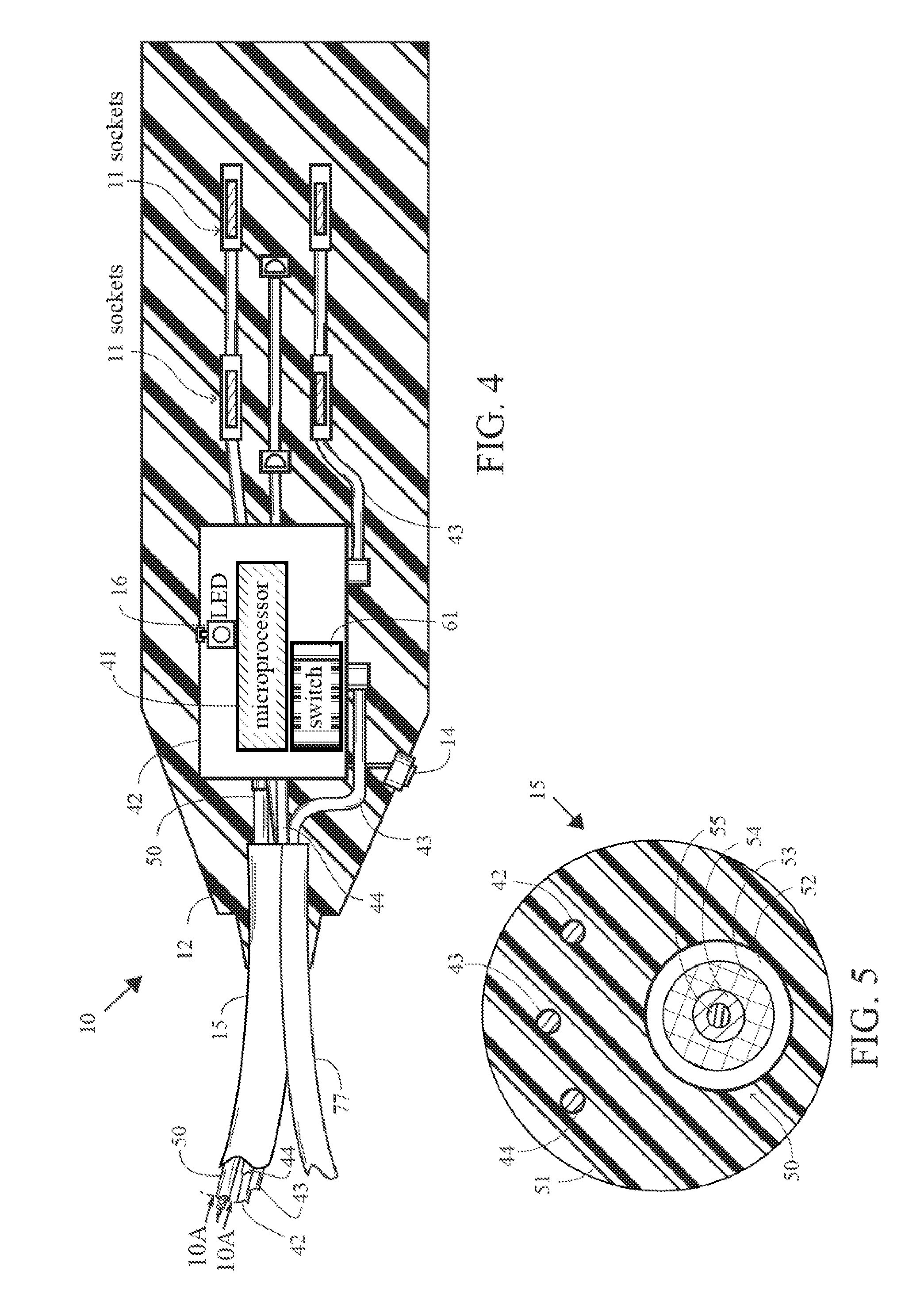

Method and apparatus for controlling power to a device

ActiveUS9007186B1Effective power savingEffective controlElectric signal transmission systemsData processing applicationsEmbedded systemSurge protector

A system and method for remotely controlling power to an electrically powered device having a GFCI or surge protector is disclosed herein. The system preferably comprises an apparatus, an electrically-powered device and a controller. The apparatus preferably comprises a cord, an alternating current outlet socket, an alternating current input plug, a latching relay, a GFCI or surge protector, a processor and a transceiver. The system preferably uses a WiFi communication signal to transmit commands from the remote controller to the apparatus.

Owner:BEST ENERGY REDUCTION TECH

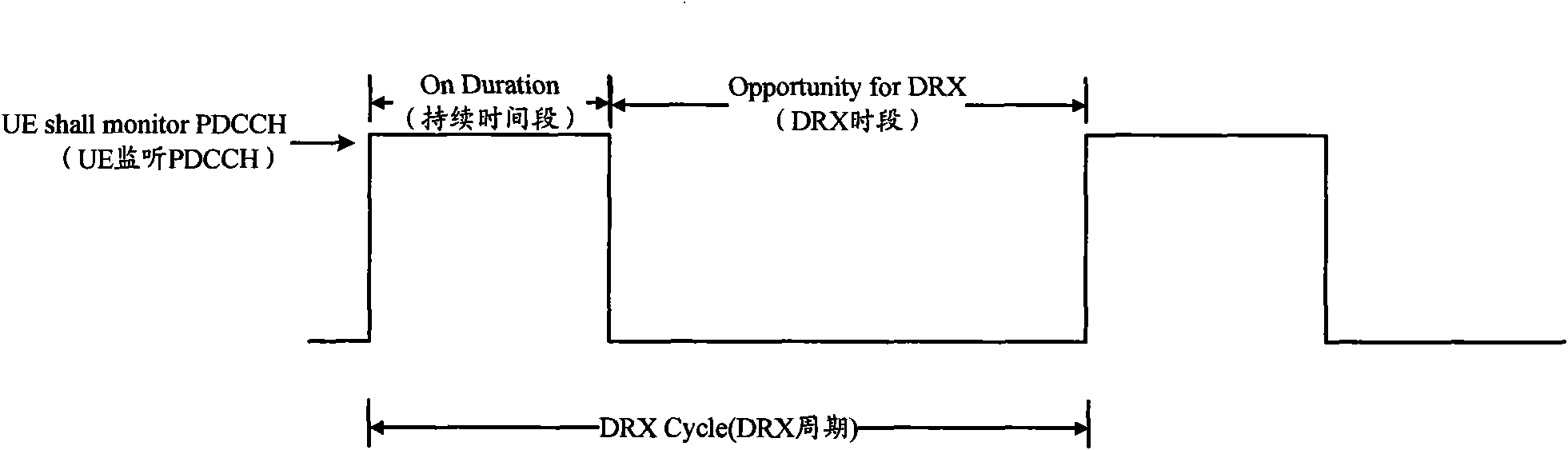

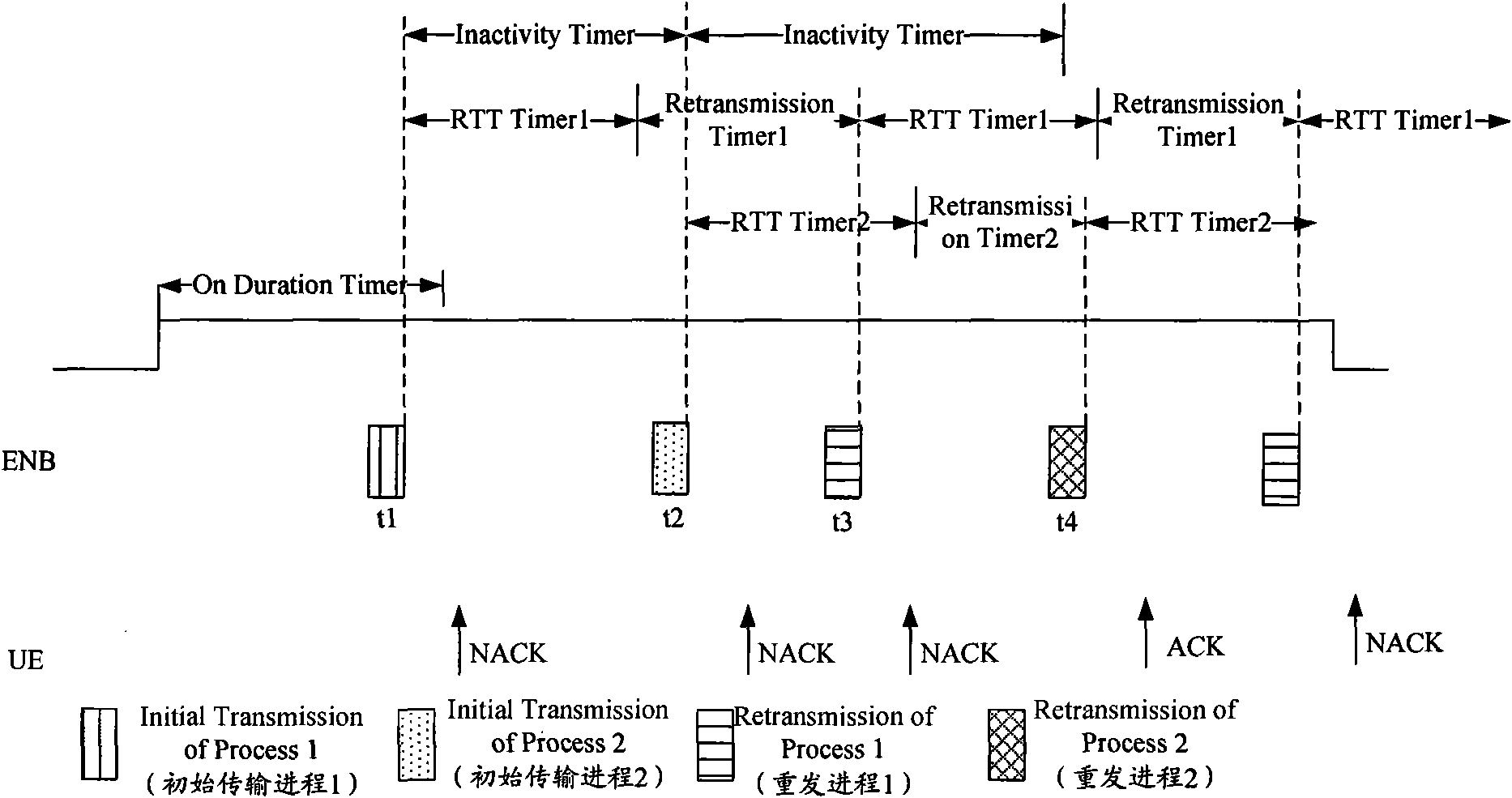

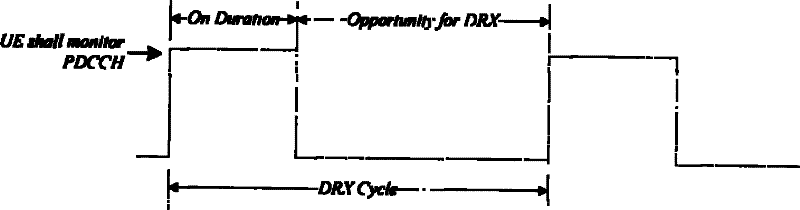

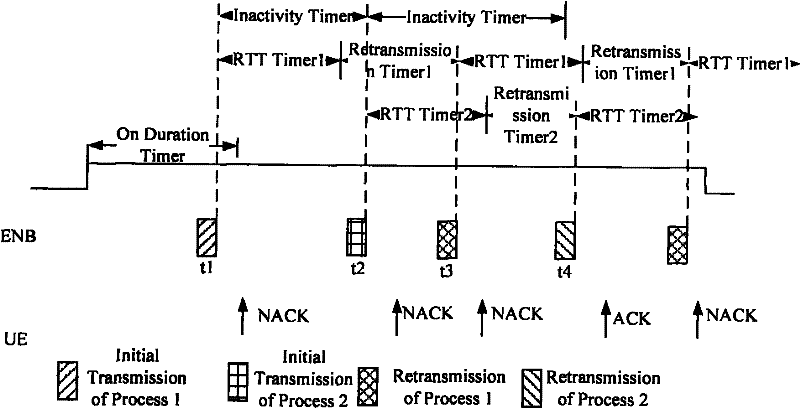

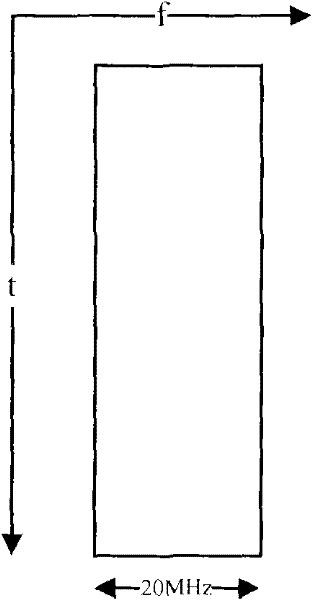

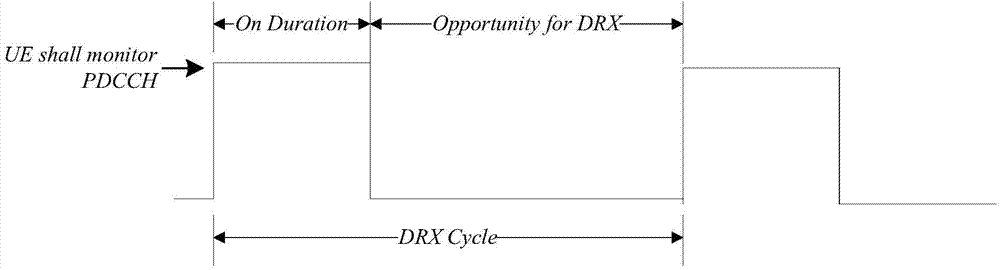

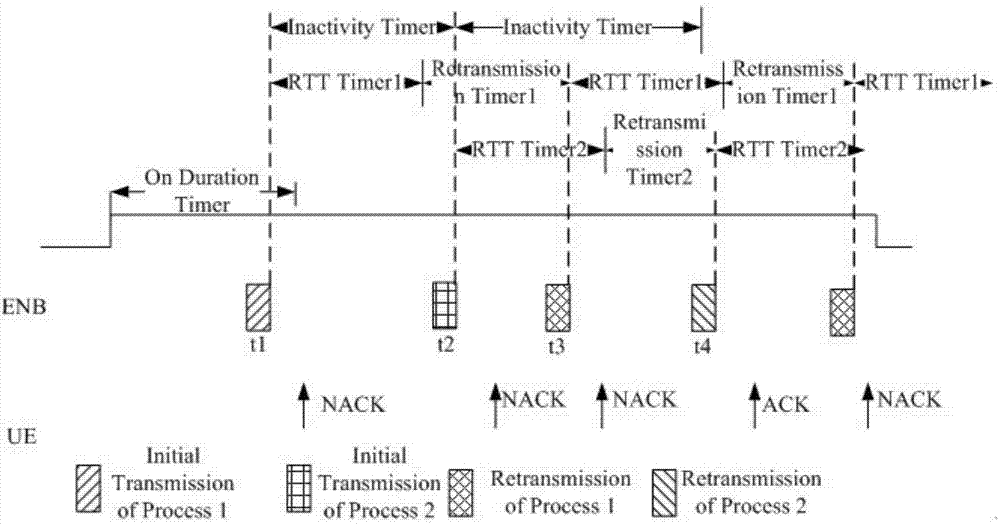

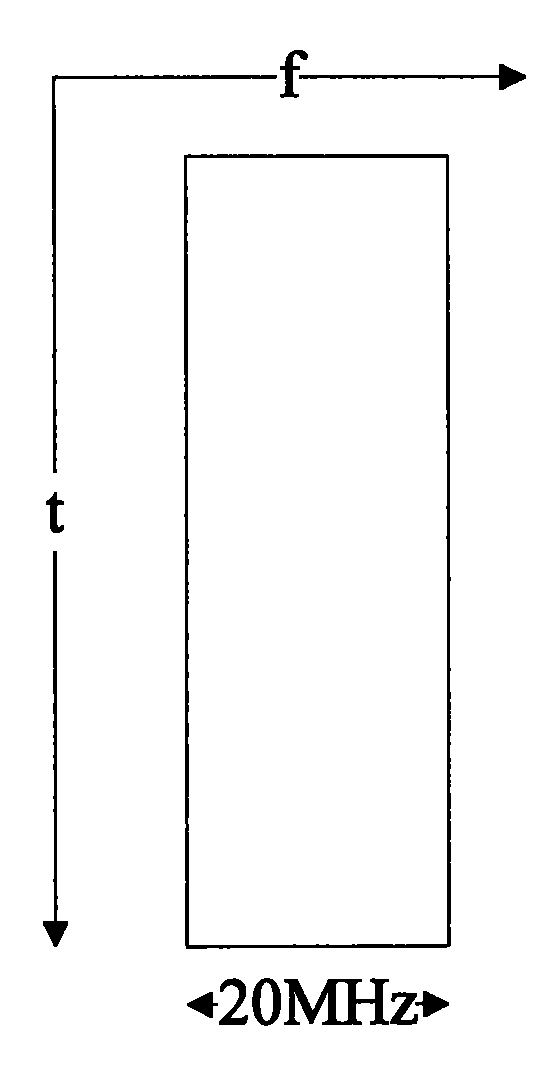

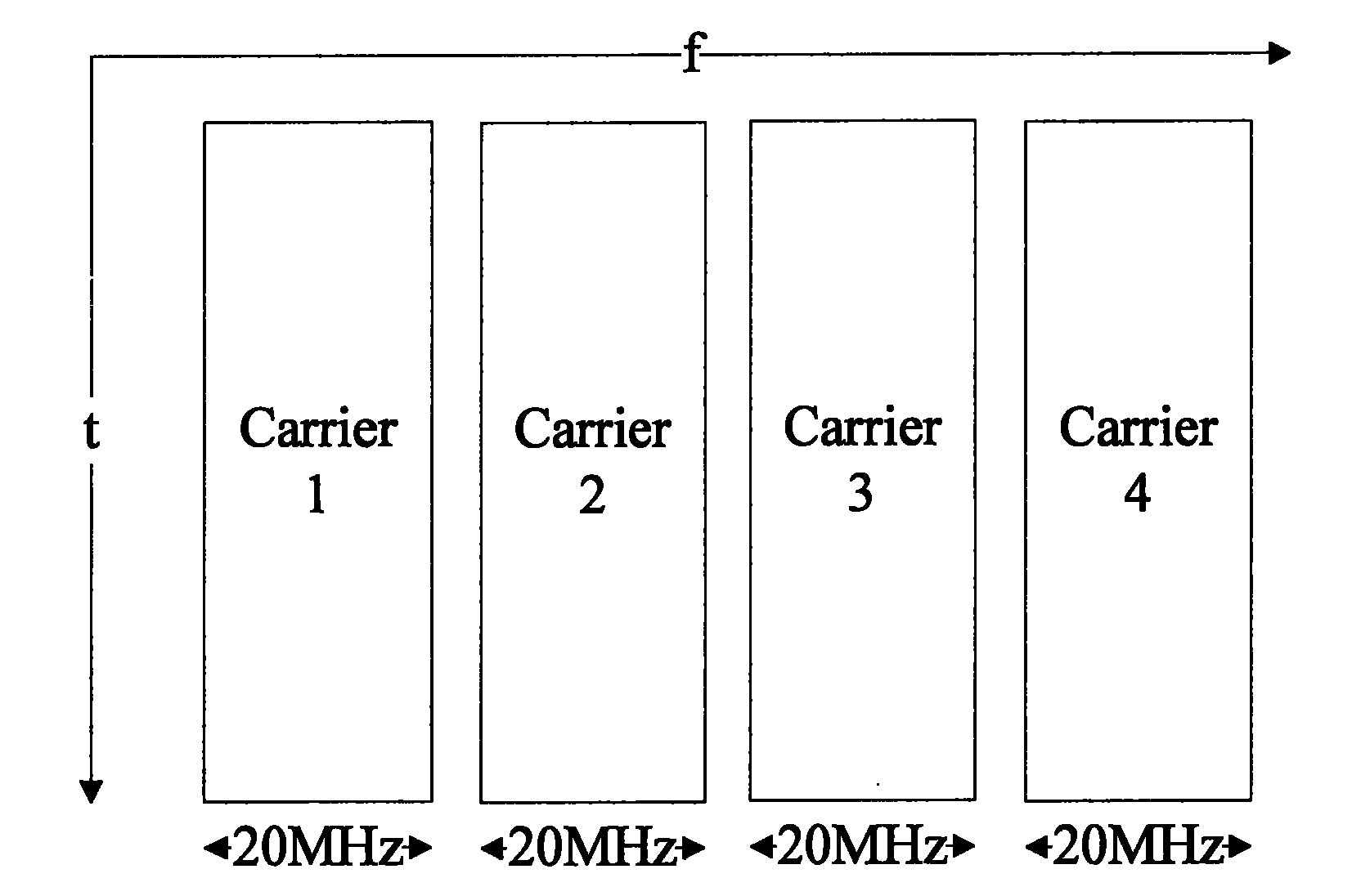

Discontinuous reception processing method and equipment

ActiveCN101965037AFlexible schedulingEffective power savingPower managementCurrent supply arrangementsTelecommunicationsFlexible scheduling

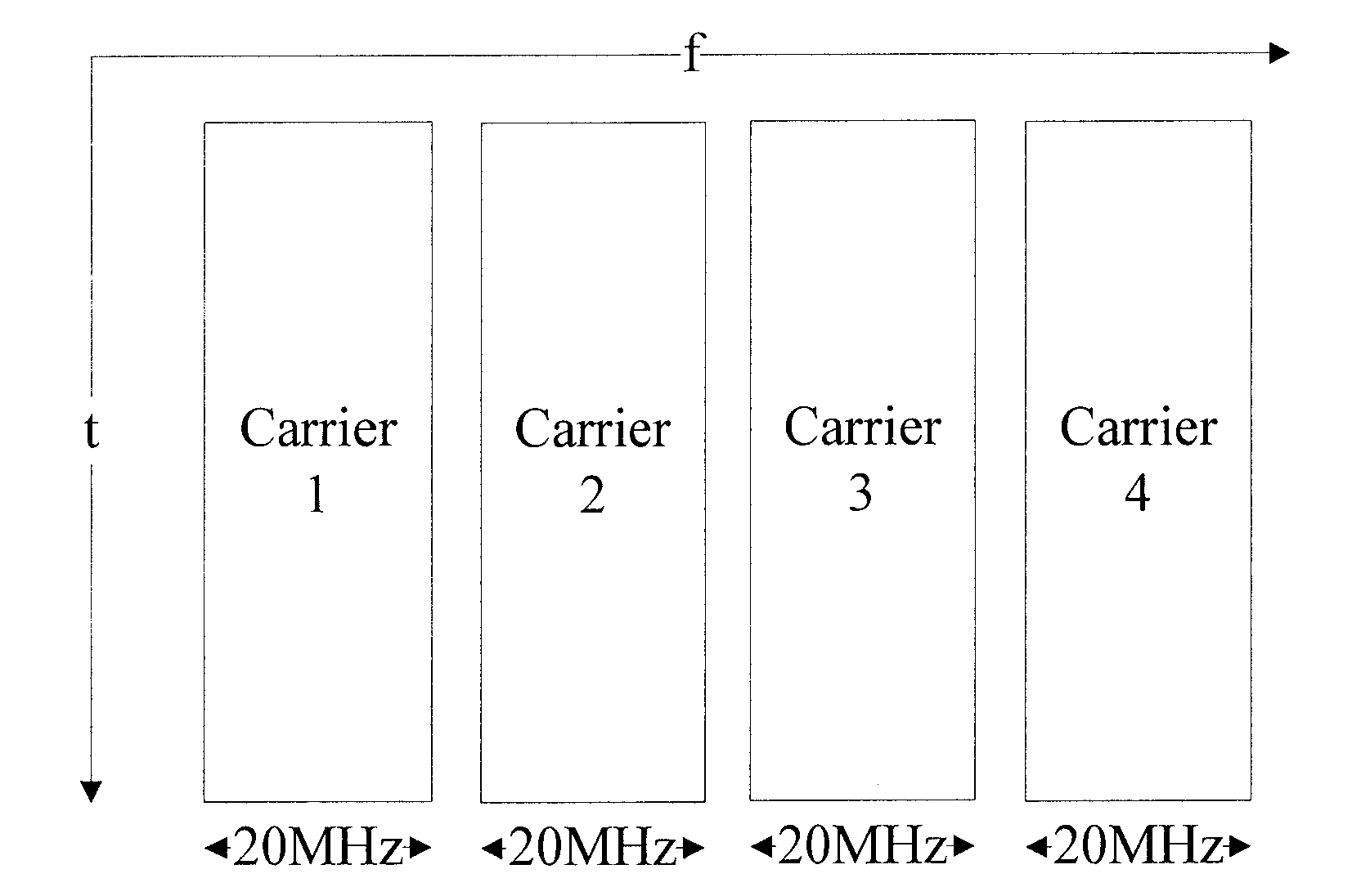

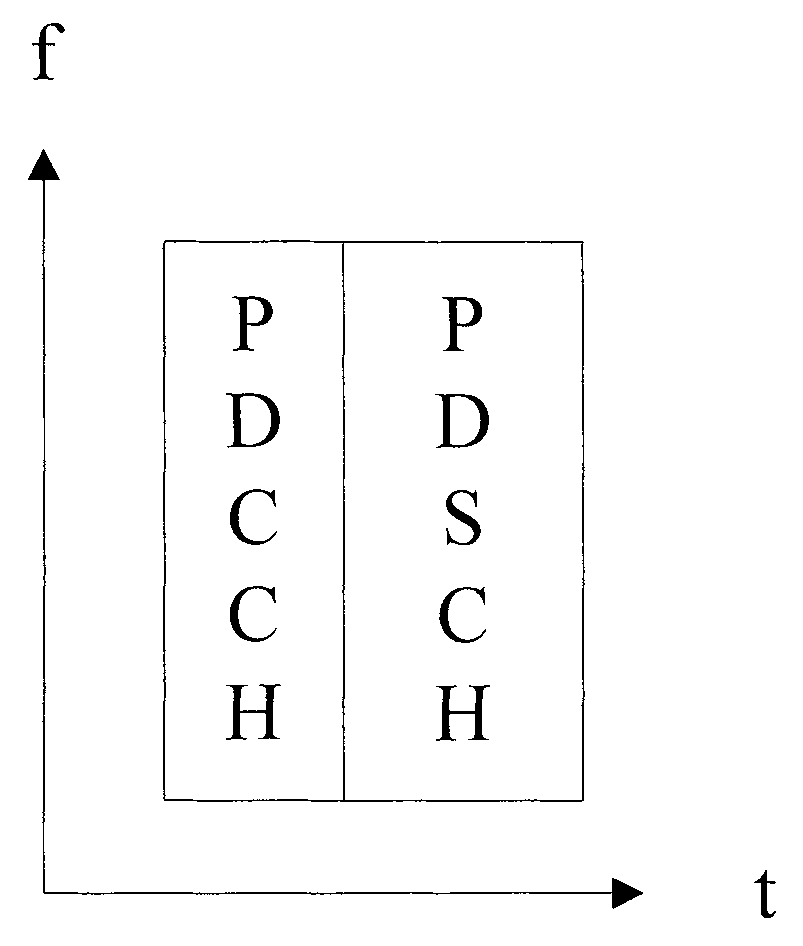

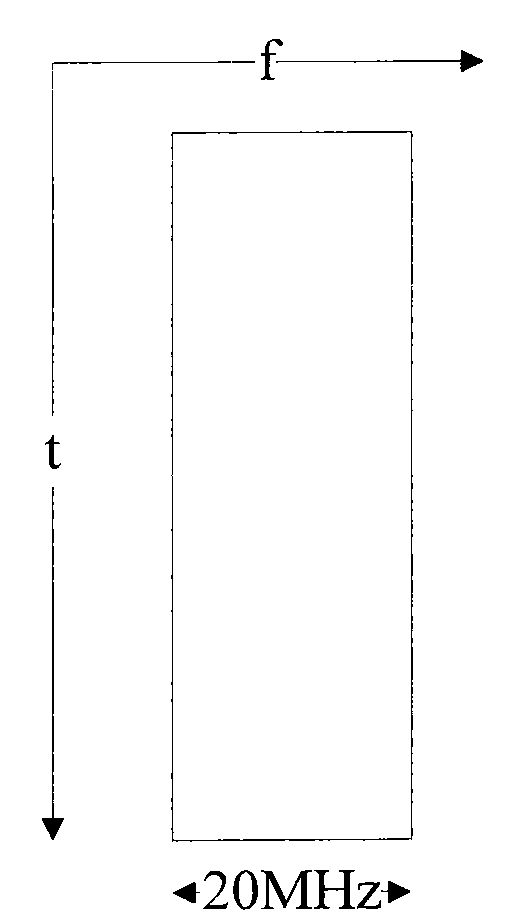

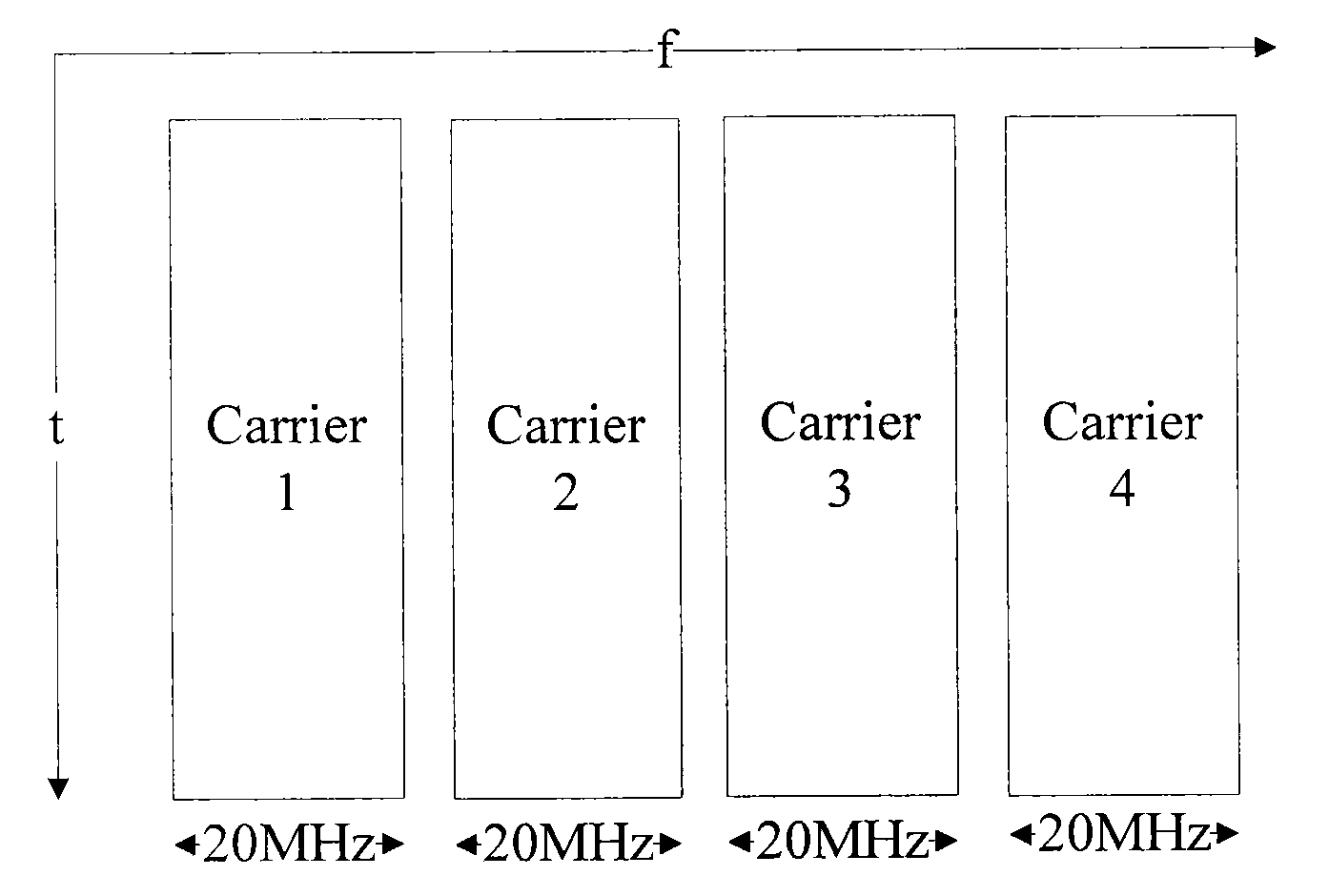

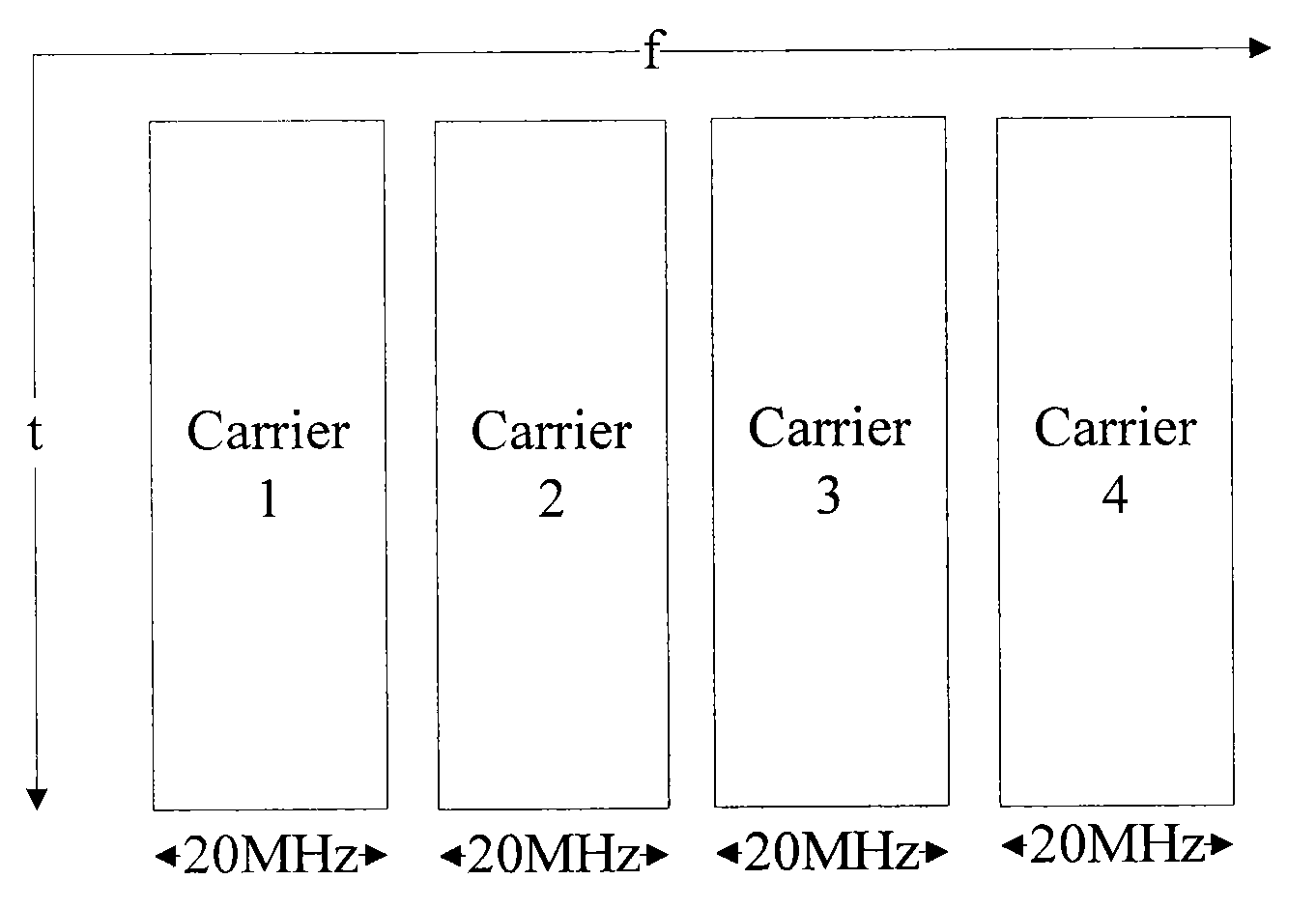

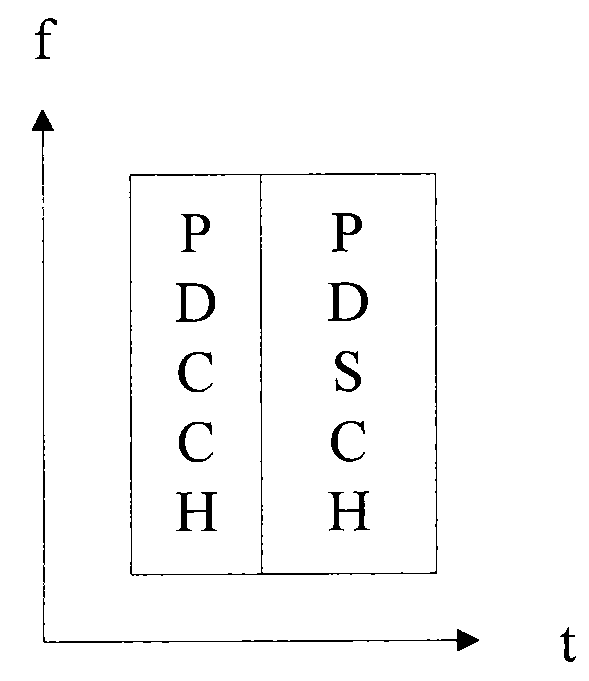

The invention discloses a discontinuous reception processing method and discontinuous reception processing equipment. The discontinuous reception processing method comprises that: in a multicarrier aggregation system, an evolved NodeB (eNB) determines to send a Physical Downlink Control Channel (PDCCH) CC set used aiming at a scheduling signaling of certain User Equipment (UE) and determines a Physical Downlink Shared Channel (PDSCH) CC set required for use and the number of PDSCH CC activated in the PDSCH CC at any time according to a data rate required by the UE; the eNB sends the scheduling signaling to the UE according to a Discontinuous Reception (DRX) parameter through the PDCCH CC set, wherein the scheduling signaling indicates at which time-frequency resources of the PDSCH CC set the UE receives data; and the UE periodically monitors the PDCCH CC set according to the DRX parameter, and receives the data on the PDSCH CC set according to the scheduling signaling acquired by the monitoring. Through the mode, the scheme provided by the method provides a discontinuous reception mechanism under a multicarrier aiming at Rel-10UE, and the mechanism is suitable for PDCCH 1a and PDCCH 1b, and can ensure flexible scheduling and effectively save the power at the same time.

Owner:DATANG MOBILE COMM EQUIP CO LTD

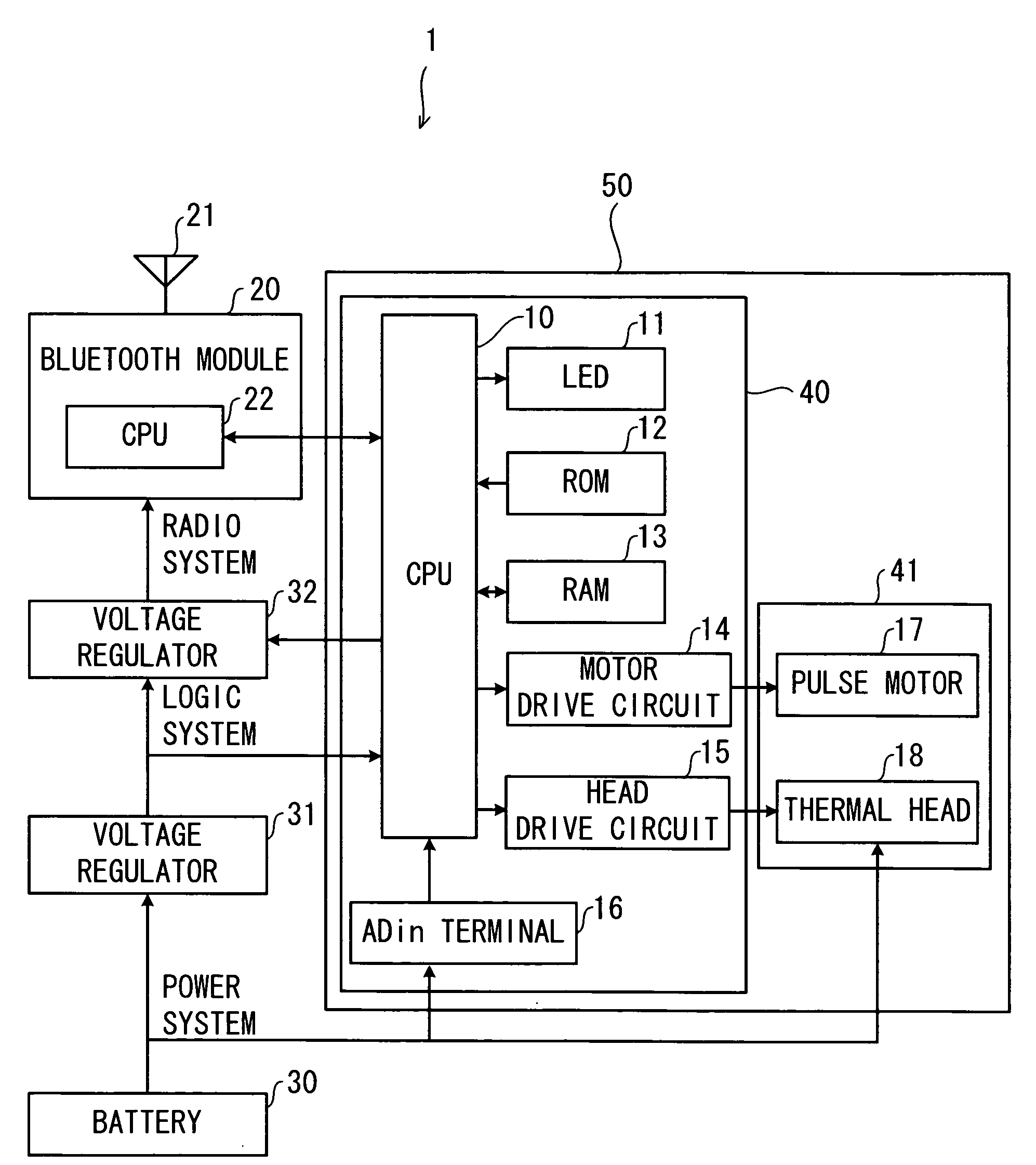

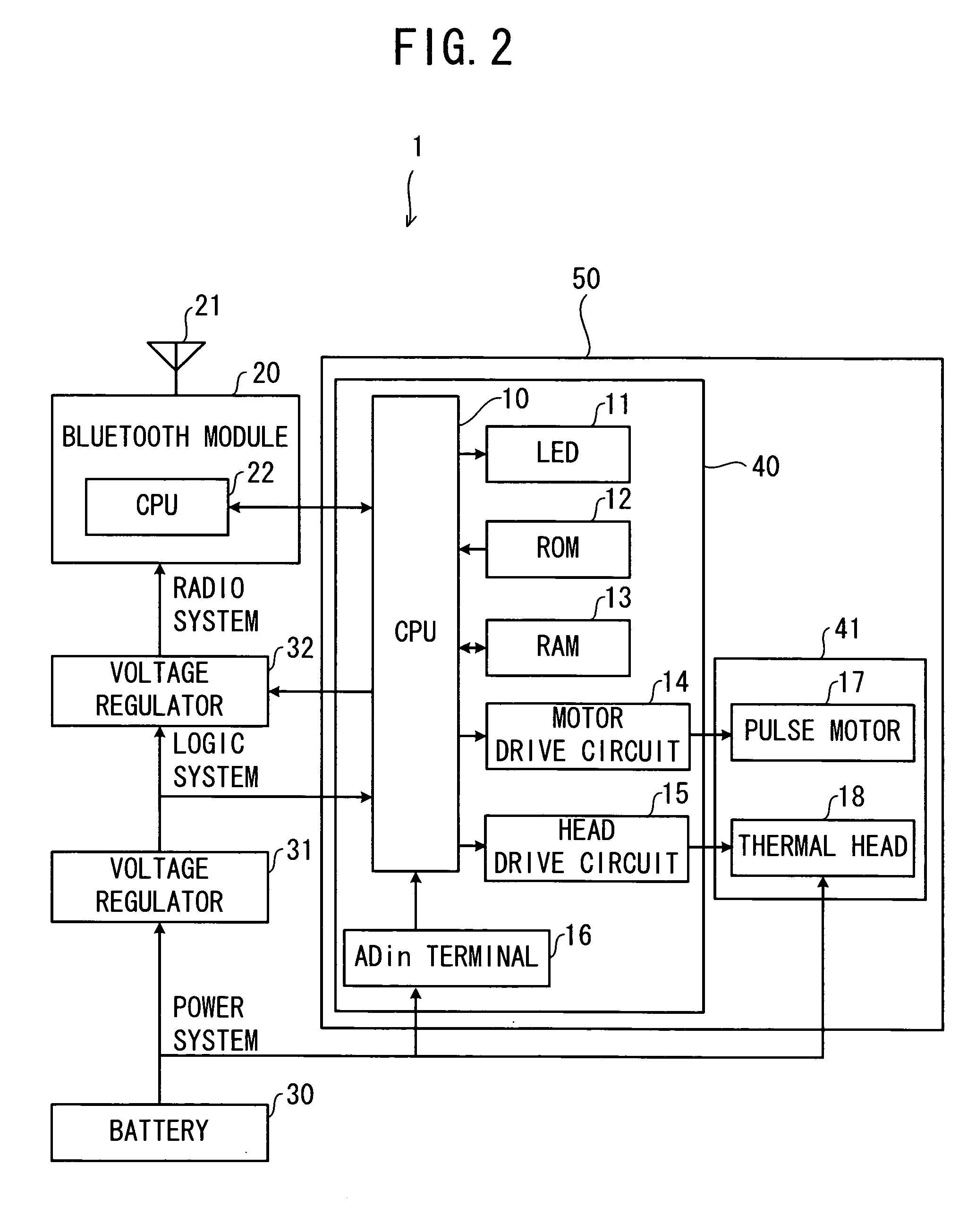

Electronic apparatus that conserves power

InactiveUS20050066208A1Effective power savingSave powerEnergy efficient ICTVolume/mass flow measurementPower savingElectrical battery

An electronic apparatus suppresses consumption of power by saving power for the electronic apparatus main body and a communicating module. In a printing apparatus, power saving mode setting processing is carried out if the printing apparatus is not used in a specified time interval. More specifically, a printing portion is changed into a sleep mode and the communicating module is changed to power saving mode depending on an amount of power remaining in a battery and power ON passage time. Further, auto power OFF setting time is changed depending on the amount of power remaining in the battery. For example, the mode of the communicating module is changed among a plural modes classified depending on consumption of power supplied from the battery and used by the communicating module.

Owner:BROTHER KOGYO KK

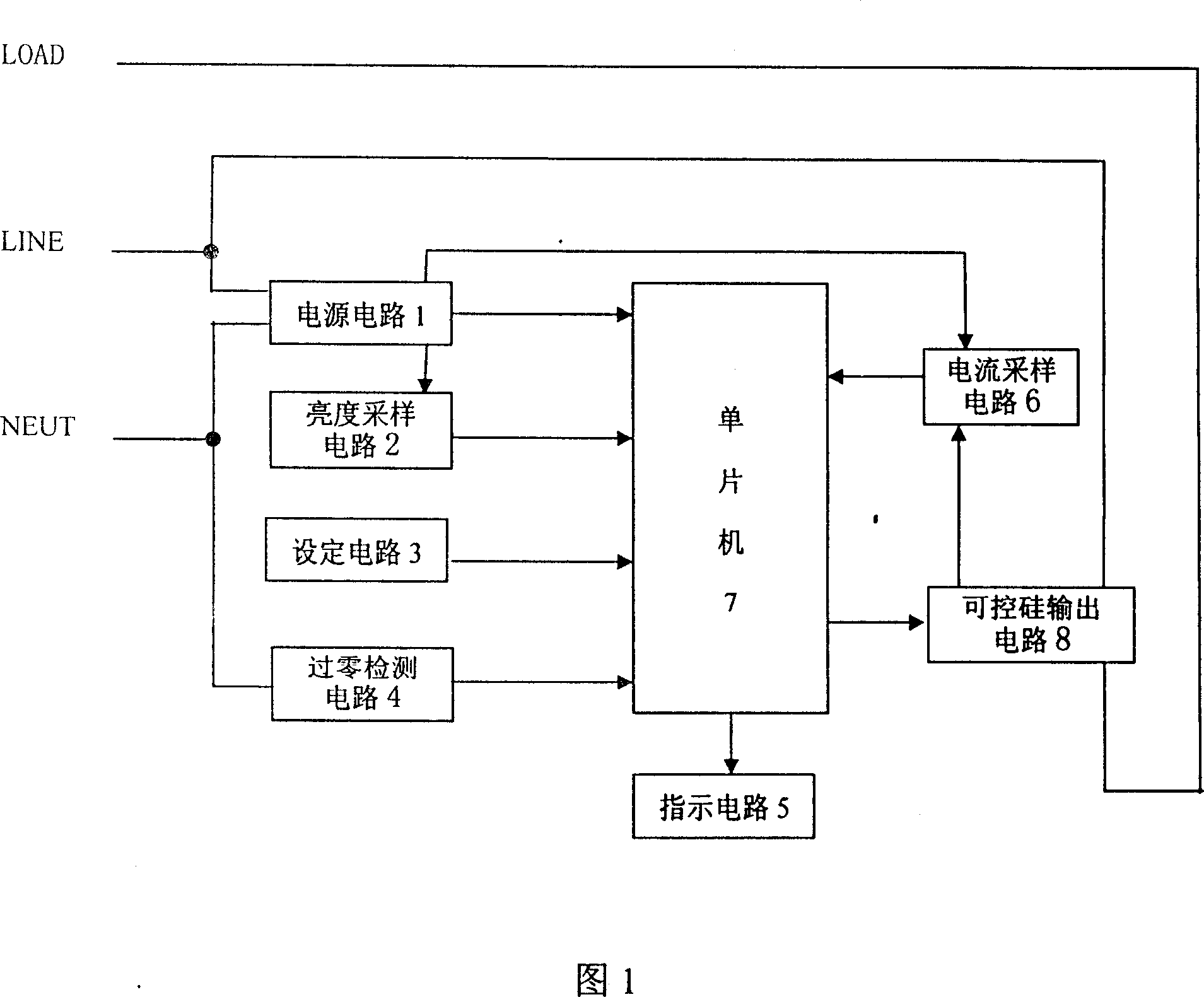

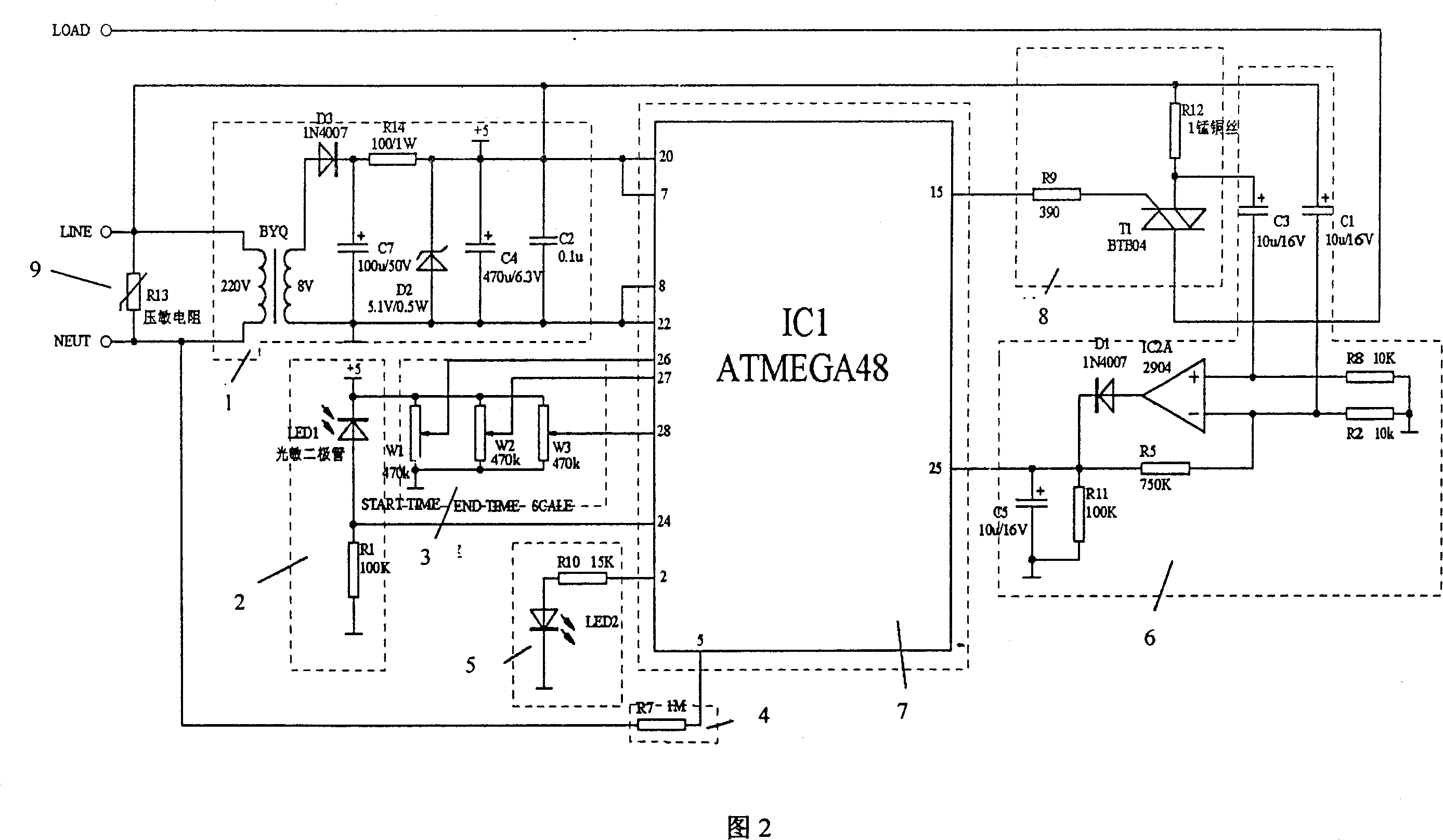

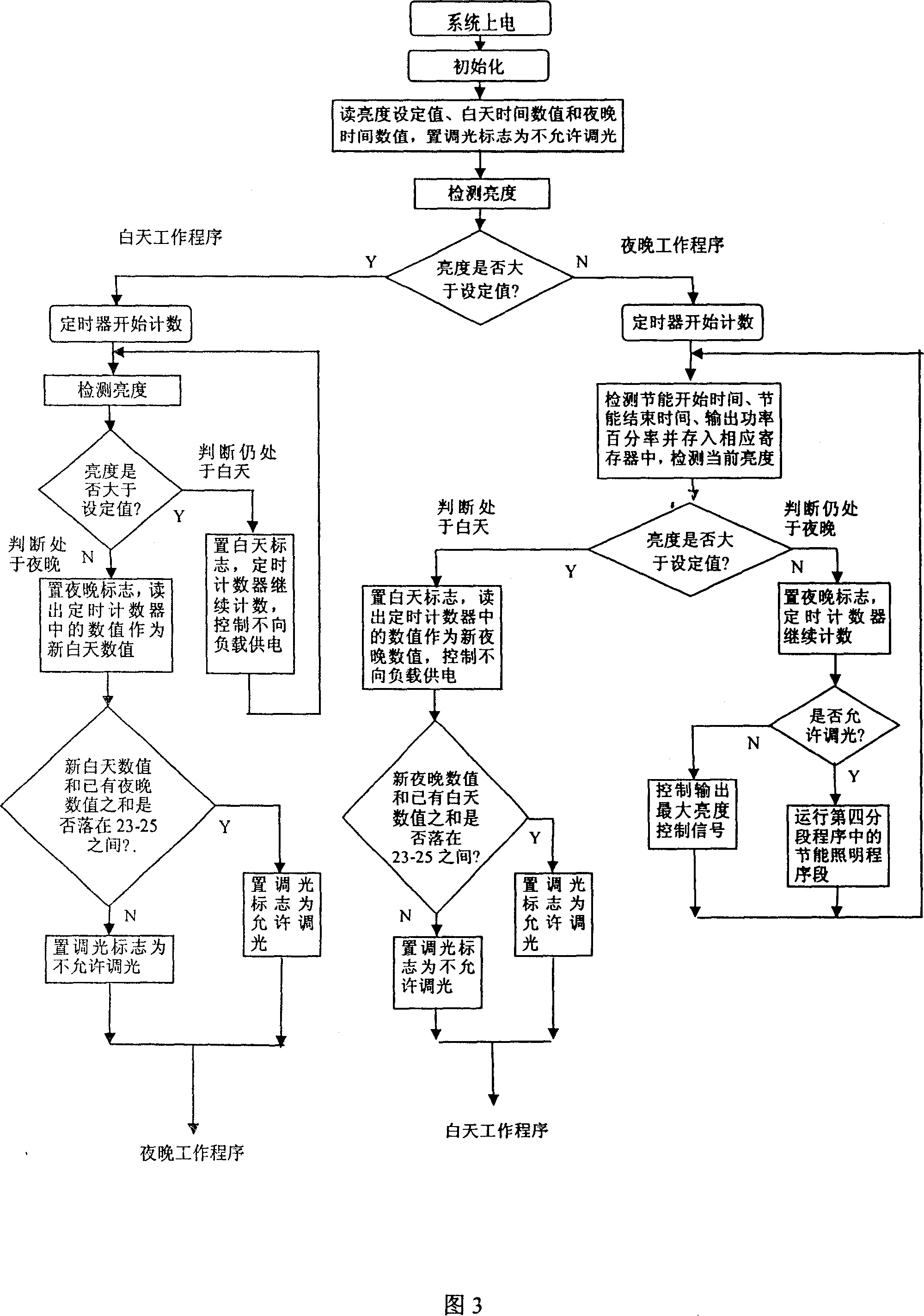

Intelligent light time controller and control method for outdoor spotlight

InactiveCN101102630AExtended service lifeNo cumulative errorElectric light circuit arrangementEnergy saving control techniquesPower circuitsBrightness perception

The controlling device thereof comprise a live wire connector, a earth wire connector, a load current outputting end, a power circuit, a brightness sampling circuit, a setting circuit, a zero-cross sampling circuit, a single-board and a controllable silicon output circuit. The method thereof comprises: the single board processes the brightness signal and compares the brightness value with a pre-set value; if the brightness value is higher than the pre-set value, then it is confirmed to be at daytime; not providing power for the load; if the brightness is less than the pre-set value, it is confirmed to be at night time; starting up the night main control program to control controllable silicon output circuit to provide 100% power supply for the load; when reaching a energy-saving time, the controllable silicon output circuit is controlled to provide a certain percentage power supply for the load.

Owner:陈汉湘

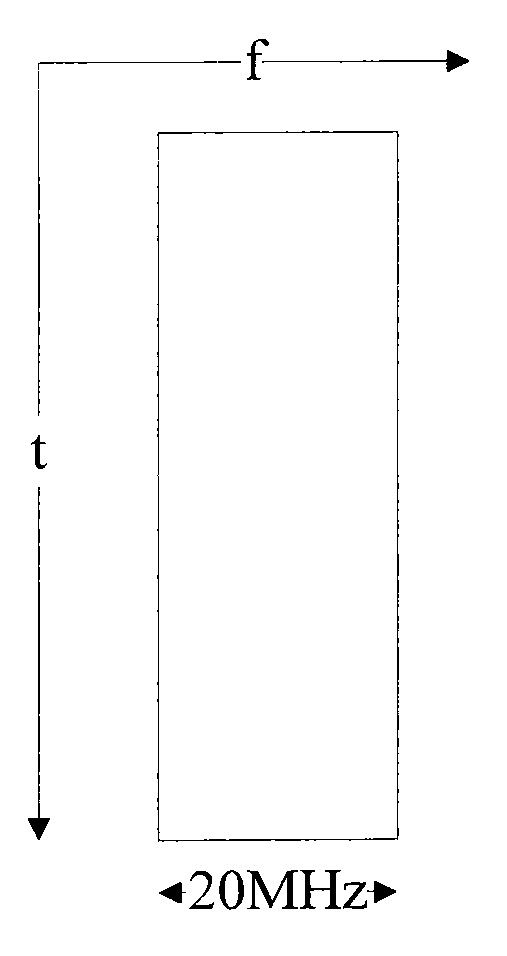

Implicit carrier deactivation method and equipment

ActiveCN102215551AEffective power savingMake up for unreliabilityPower managementHigh level techniquesInformation transmissionSecondary component

The invention provides an implicit carrier deactivation method and equipment. The method comprises that: when learning that a downlink secondary component carrier (DL SCC) does not have data and control information transmission needs, a user terminal deactivates the DL SCC. The invention also provides an implicit carrier deactivation mechanism in a long term evolution-advanced (LTE-A) system.

Owner:DATANG MOBILE COMM EQUIP CO LTD

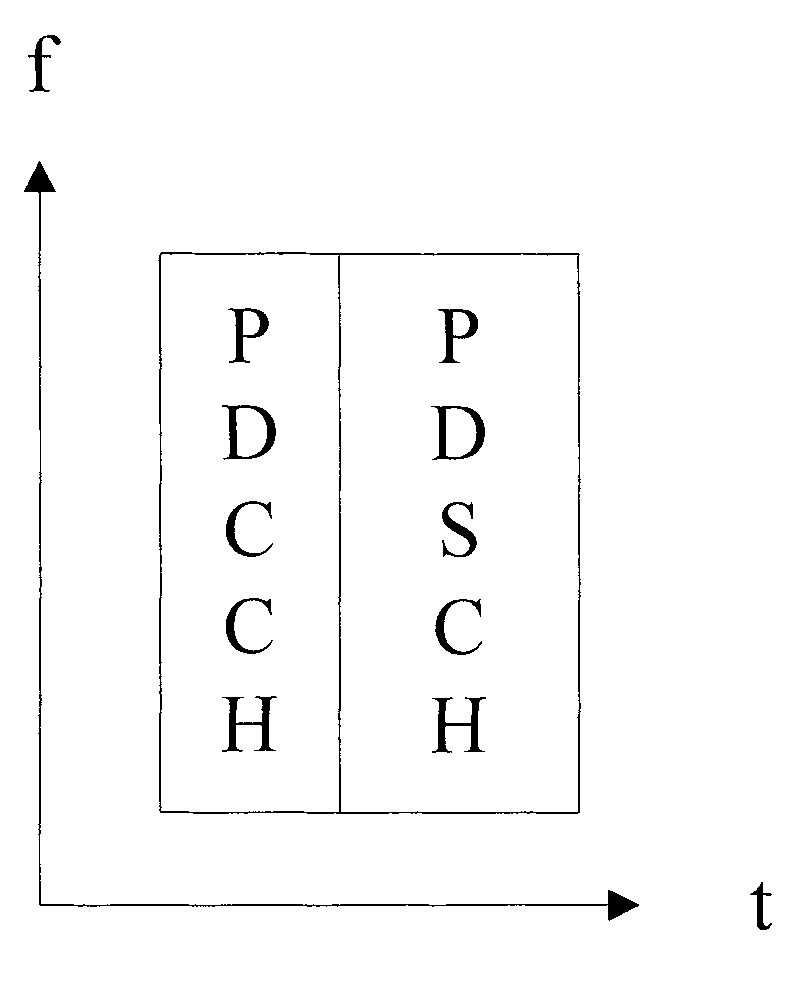

Method and equipment for determining search space of PDCCH CC

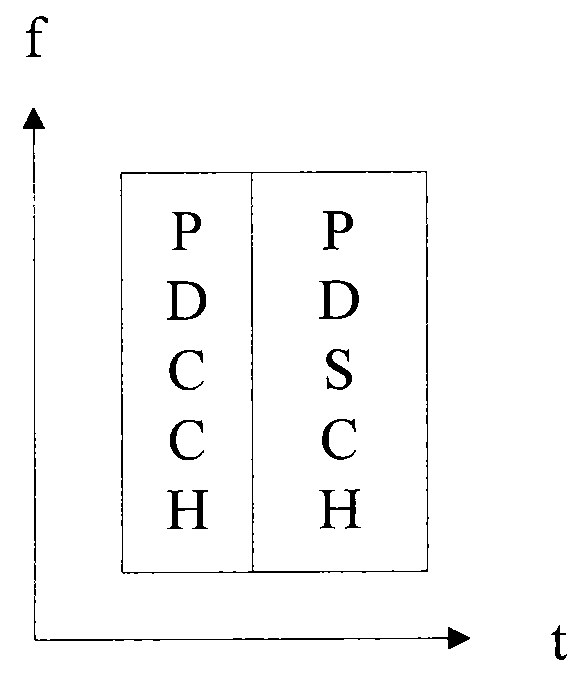

ActiveCN102104866AReduce the number of blind inspectionsAdjust in timeAssess restrictionSignal allocationControl channelBiological activation

The embodiment of the invention discloses a method for determining a search space of a physical downlink control channel component carrier (PDCCH CC), which comprises that: user equipment acquires the activation state of a physical downlink shared channel component carrier (PDSCH CC), and determines the search space of the PDCCH CC according to the activation state of the PDSCH CC. In the embodiment of the invention, the method for determining the search space of the PDCCH CC according to the activation state of the PDSCH CC can regulate the search space in time so as to save power more effectively at the same time of reducing unnecessary PDCCH blind detection.

Owner:XIAOMI INC

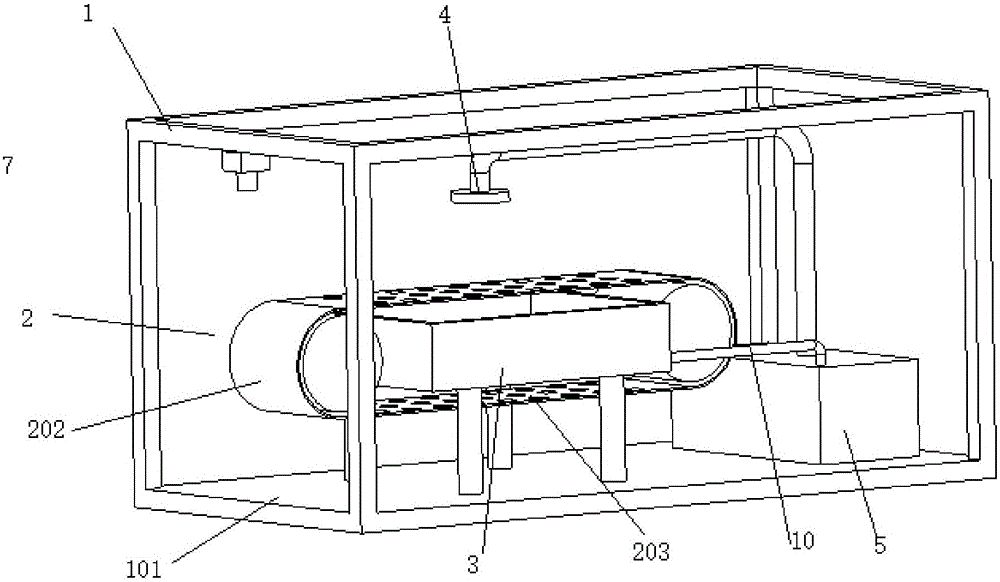

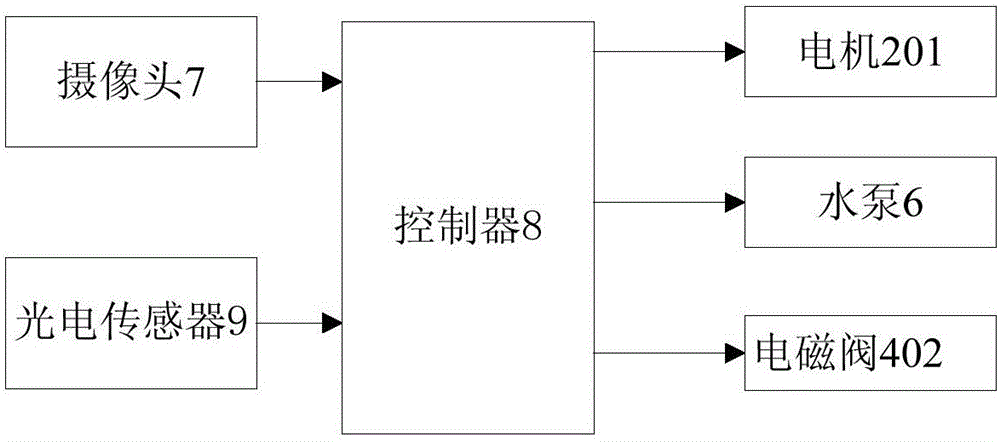

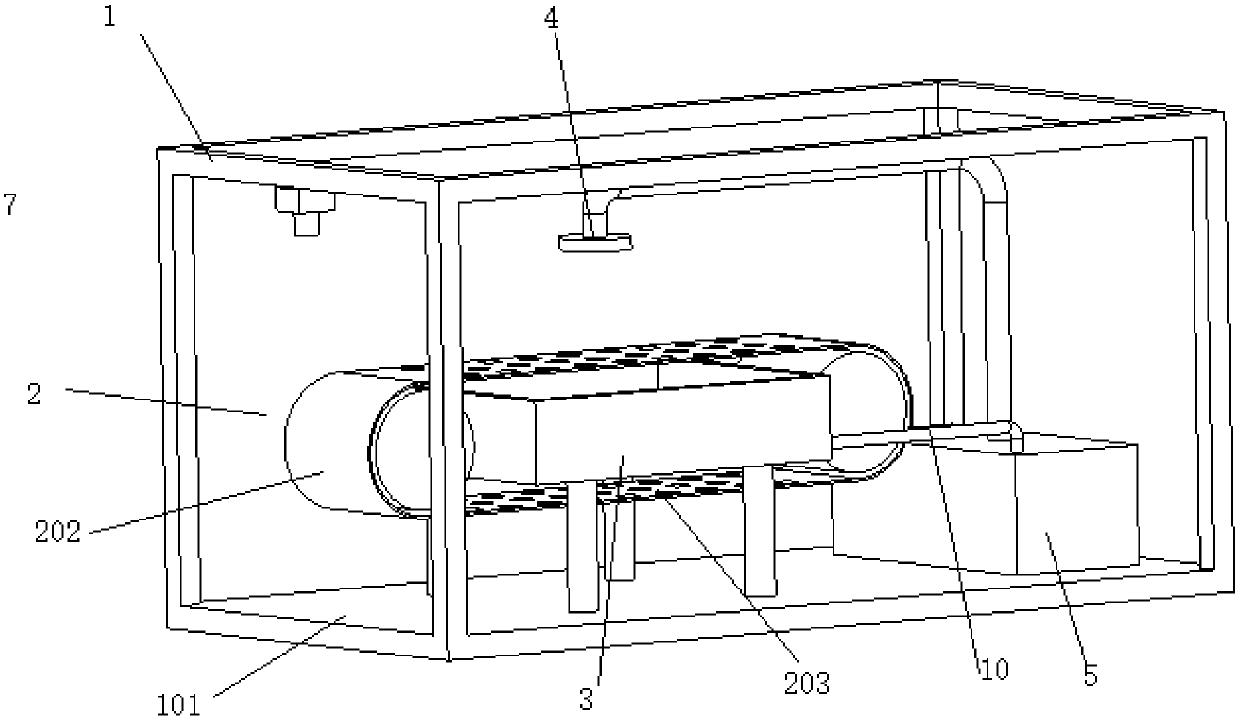

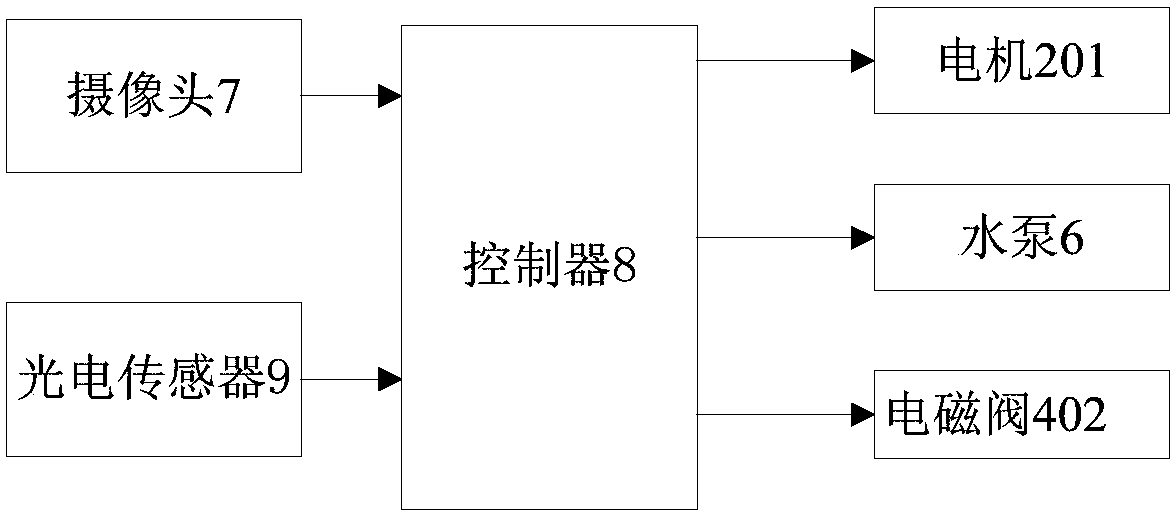

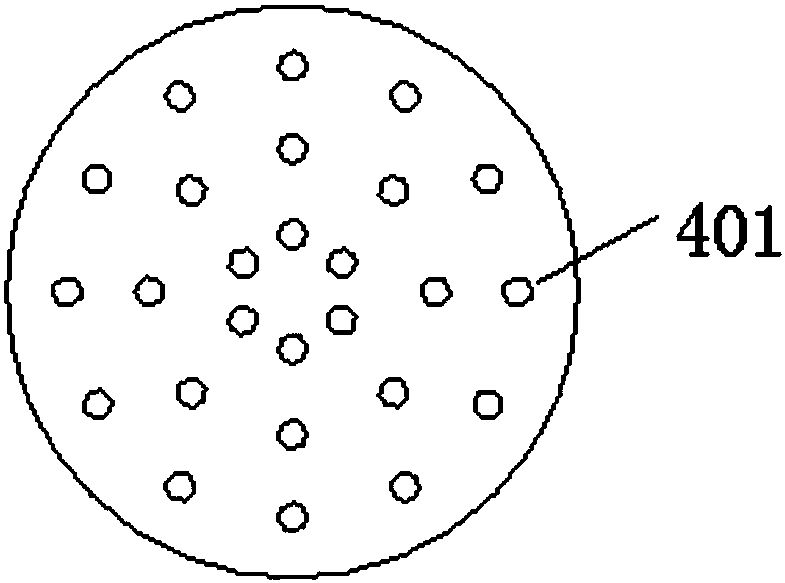

Automatic cleaning device for automobile parts

ActiveCN105728383ASimple structureImprove cleaning efficiencyCleaning using liquidsWater dischargeMotor vehicle part

The invention discloses an automatic cleaning device for automobile parts. The automatic cleaning device comprises a support frame, a material conveying machine, a water discharging device, a spraying device, a cleaning liquid container, a water pump, a camera and a controller, wherein the bottom of the support frame is provided with a bottom plate; the material conveying machine is arranged on the support frame and comprises two material conveying rollers and a material conveying belt; the material conveying rollers are driven by a motor; the material conveying belt is provided with holes; the water discharge device is positioned between the upper surface and the lower surface of the material conveying machine; the top of the water discharge device is provided with an opening; the bottom of the water discharge device is provided with a liquid outlet; the spraying device is positioned above the material conveying machine, and comprises a plurality of sealed spraying head groups in concentric arrangement; an inlet of each spraying head group is connected with the water pump through an electromagnetic valve; the water pump is positioned in the cleaning liquid container; the camera is positioned above the input end of the material conveying machine; the data transmission end of the camera is connected with the controller; the controller is connected with each electromagnetic valve, the motor and the control end of the water pump respectively. The automatic cleaning device has the advantages that different cleaning modes can be automatically selected by aiming at parts in different dimensions; the cleaning liquid can be effectively saved; the cleaning cost is reduced.

Owner:JIANGSU BOYINGTE ELECTRONICS TECH CO LTD

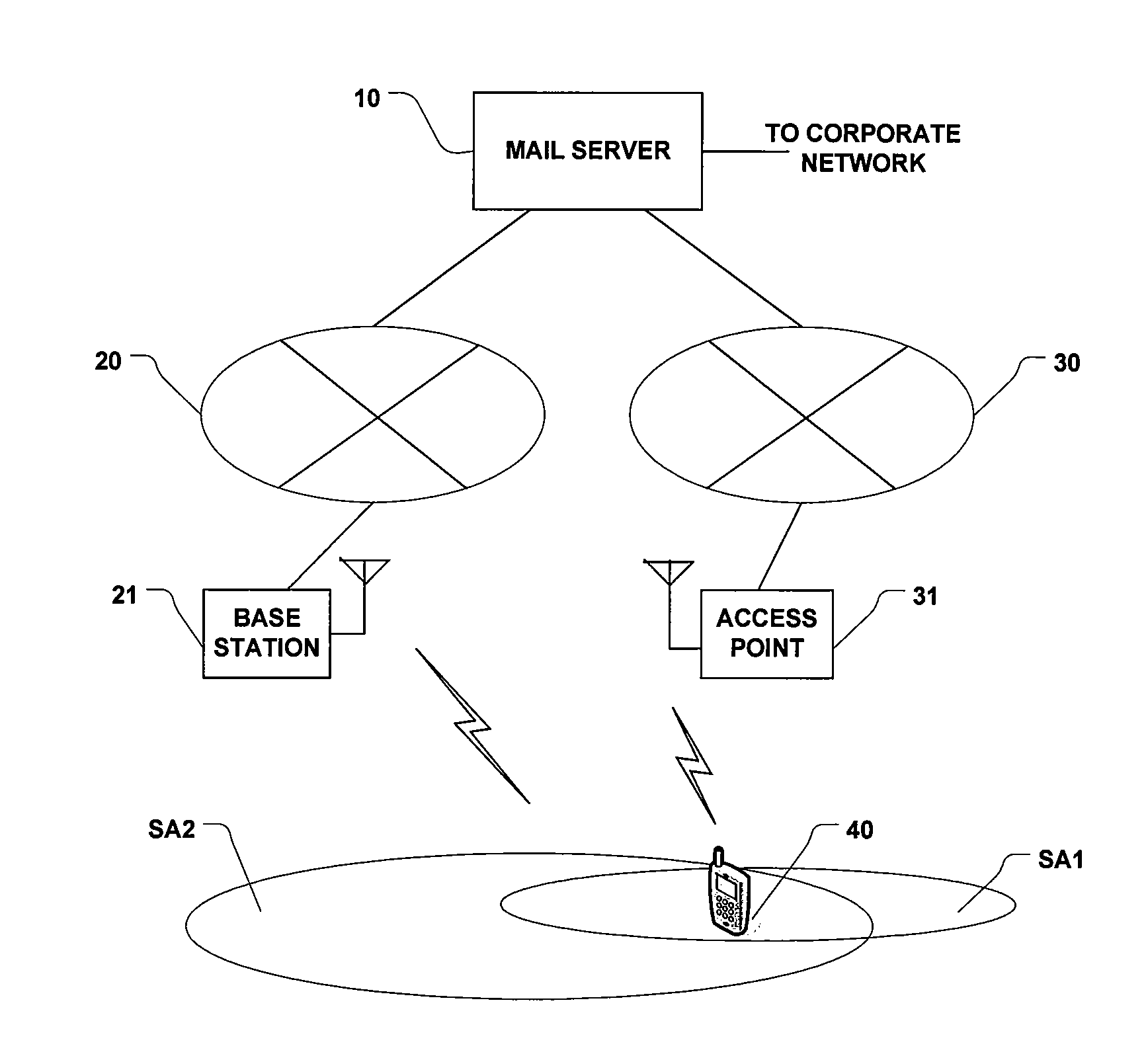

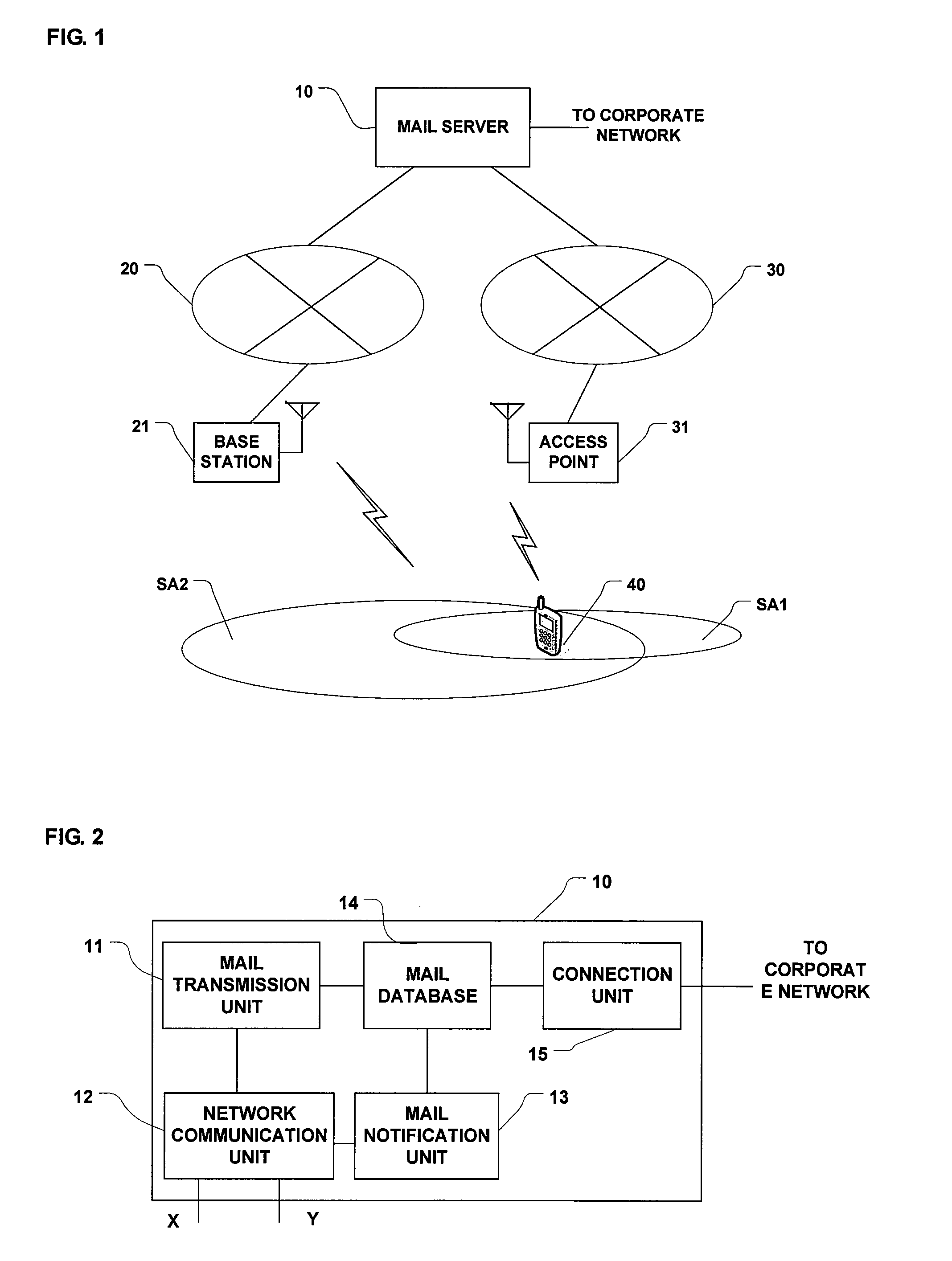

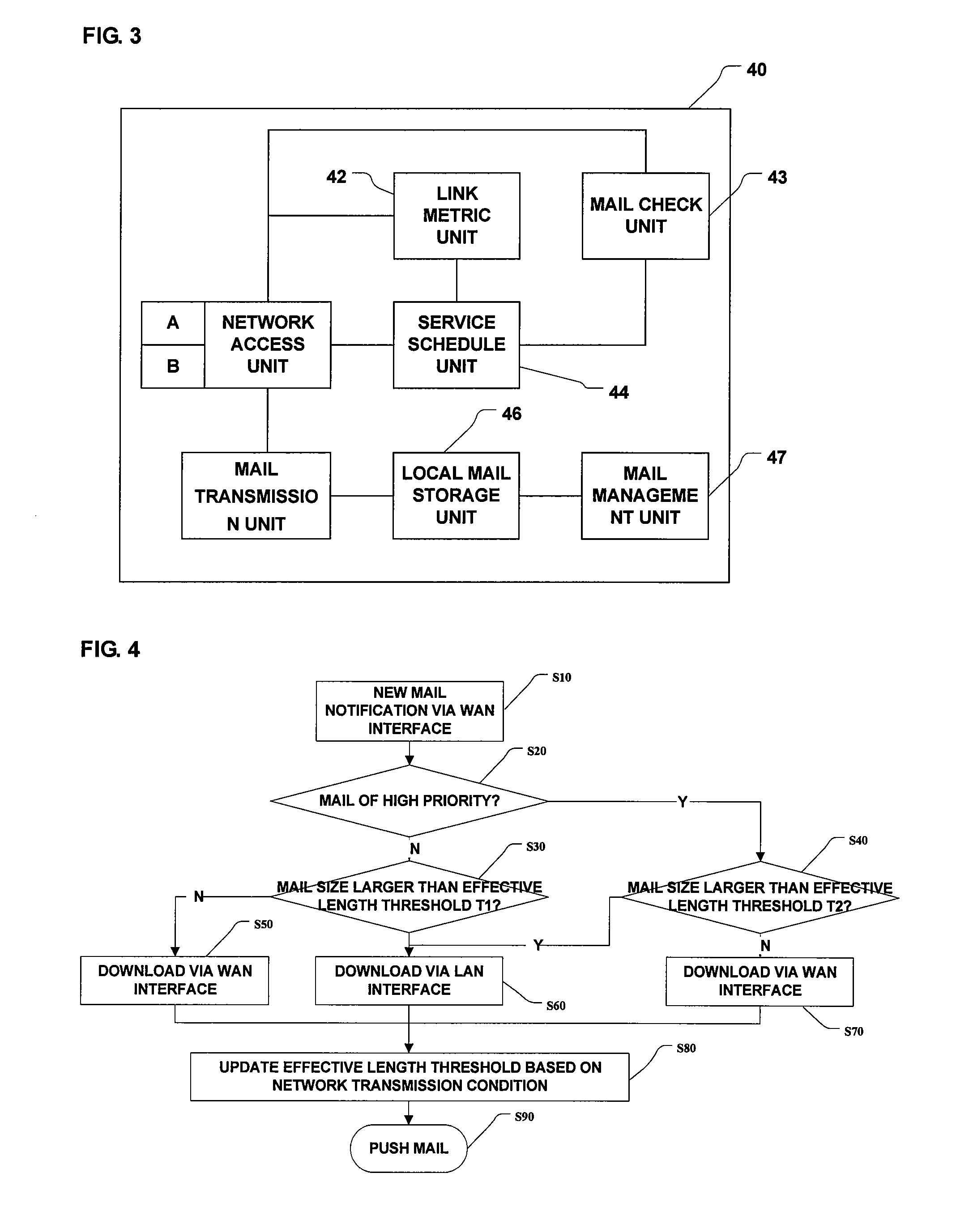

Method for pushing email in heterogeneous networks, mobile terminal and server

ActiveUS20080065734A1Effective power savingIncrease speedEnergy efficient ICTError preventionEffective powerNetwork conditions

A method for pushing email in heterogeneous networks as well as a mobile terminal and a server are disclosed. The method comprise steps of: sending a mail notification including at least mail priority and mail size of the email from a mail-pushing server to a mobile terminal; determining, by the mobile terminal, a download strategy for the email based on at least one predefined threshold, said mail priority and said mail size; and downloading said email from the mail-pushing server based on the determined download strategy. With the above solutions, it is possible to seamlessly integrate the long standby duration in the WAN mode with free-of-charge and high speed in the LAN mode and thus give a full play to these advantages. Moreover, the mobile terminal can select automatically the most suitable mail access strategy based on network condition and mail size for the simultaneous realization of effective power saving and efficient transmission.

Owner:LENOVO (BEIJING) LTD

Method and device for determining active state of PDSCH (Physical Downlink Shared Channel) CC (Communication Centre)

ActiveCN102098765AActivate in timeEffective power savingPower managementHigh level techniquesUser deviceControl channel

The invention discloses a method for determining an active state of a PDSCH (Physical Downlink Shared Channel) CC (Communication Centre), comprising the following steps: a network side device determines the active state of the PDSCH CC according to the active state of a PDCCH (Packet Dedicated Control Channel) CC, and indicates a user device to activate the CC according to the active state of the PDSCH CC when the active state of the PDSCH CC is in an activated state. In the embodiment of the invention, the active state of the PDSCH CC is determined according to the active state of the PDCCH CC, so that the PDSCH CC can be activated in time, and power can be saved more effectively.

Owner:DATANG MOBILE COMM EQUIP CO LTD

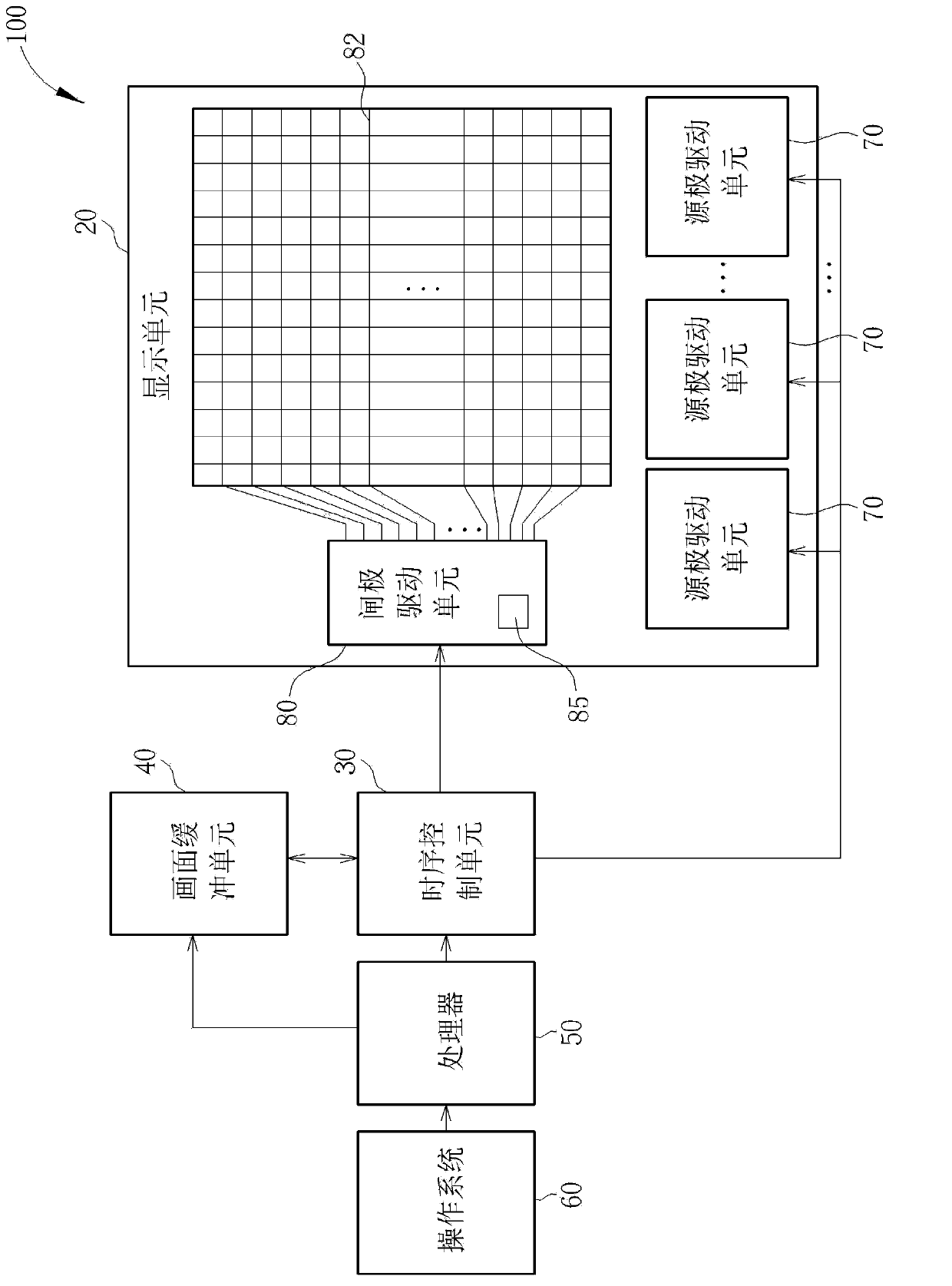

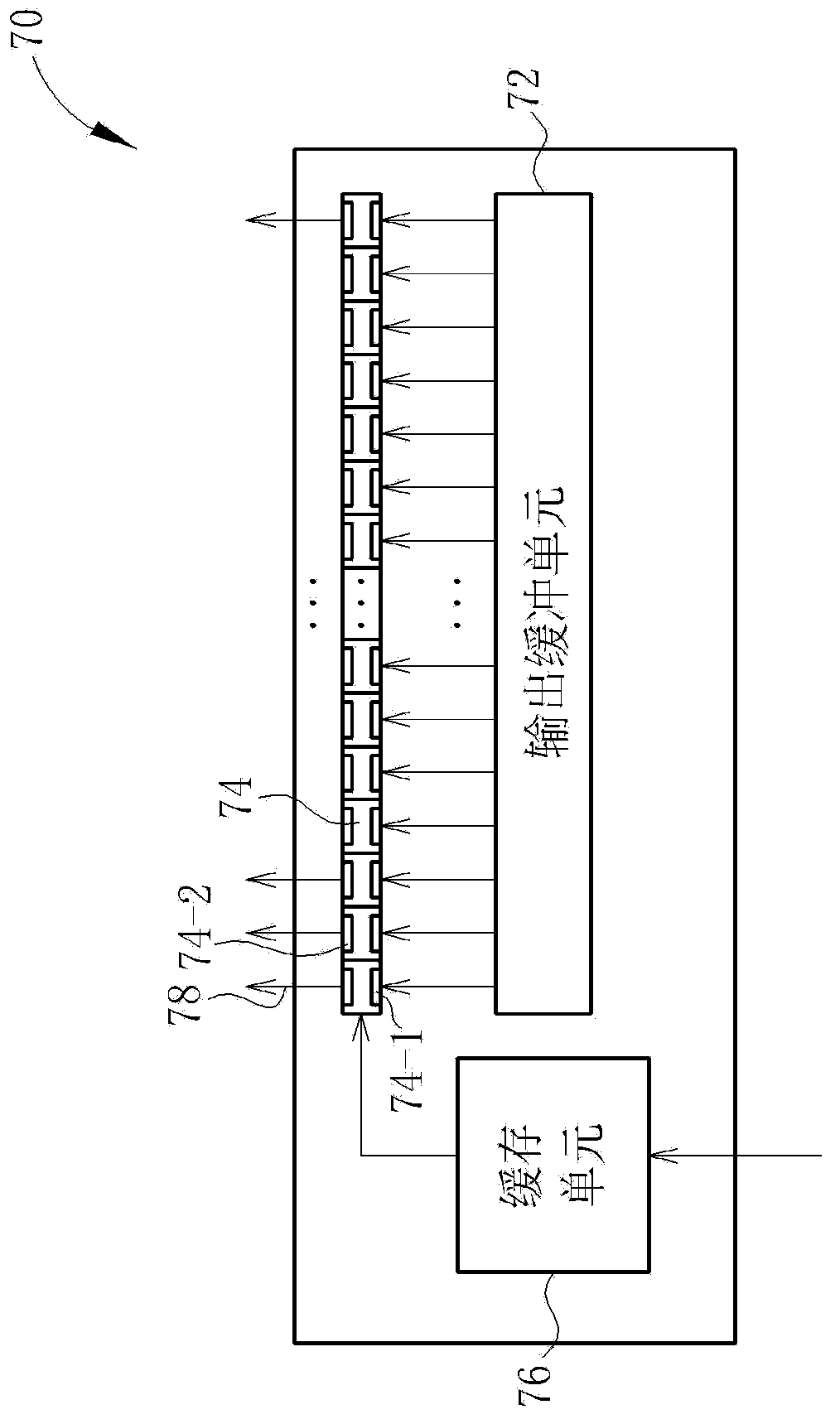

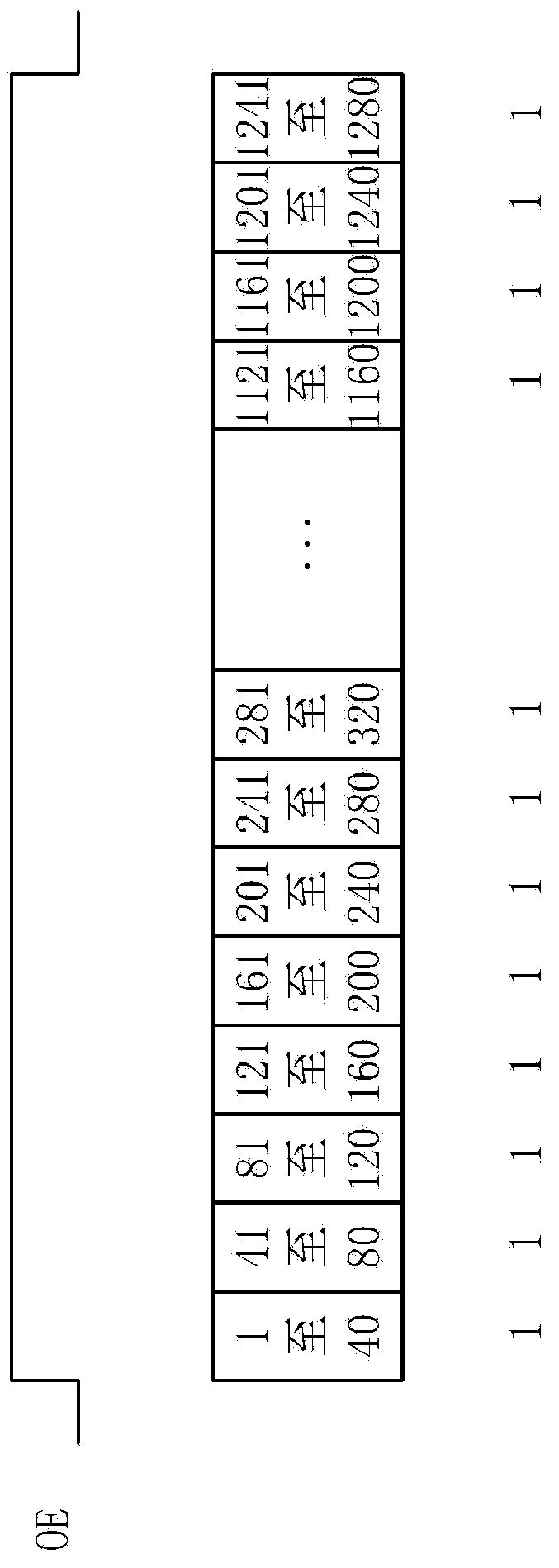

Display control system and electronic device

InactiveCN103377609AEffective power savingCathode-ray tube indicatorsDigital output to display deviceControl systemDisplay device

The invention discloses a display control system and an electronic device. The display control system includes a display unit and a timing control unit. The display unit includes at least one source driving unit and a gate driving unit. The source driving unit includes an output buffer unit, a plurality of switches and a register unit. The output buffer unit is used to output image signals or high impedance signals. The switches are used to receive the image signals or high impedance signals. The gate driving unit is used to output gate driving signals. The timing control unit is used for controlling the timing of the source driving unit and the gate driving unit. Through the display control system provided in the embodiments, a display save power when static images or partial static images are displayed.

Owner:绿触(香港)国际电子有限公司

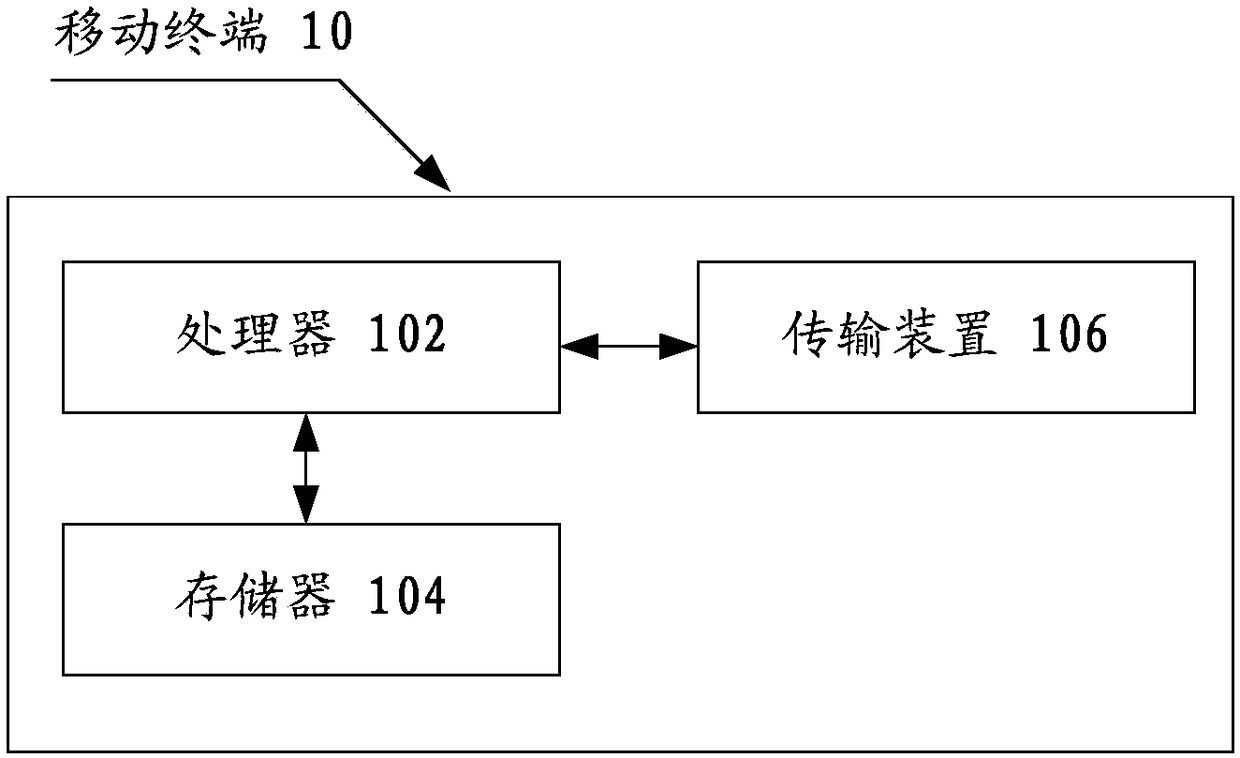

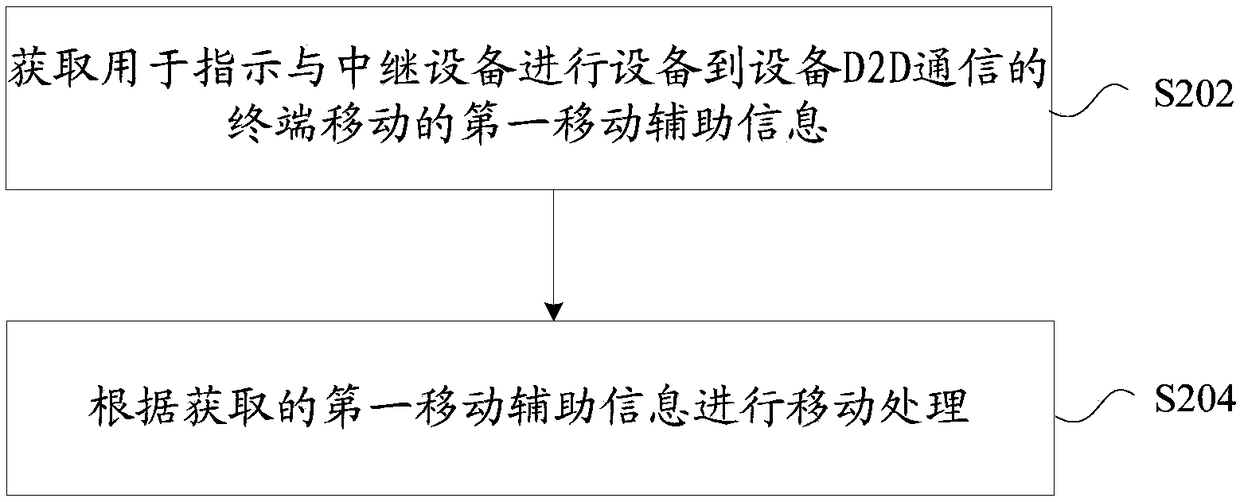

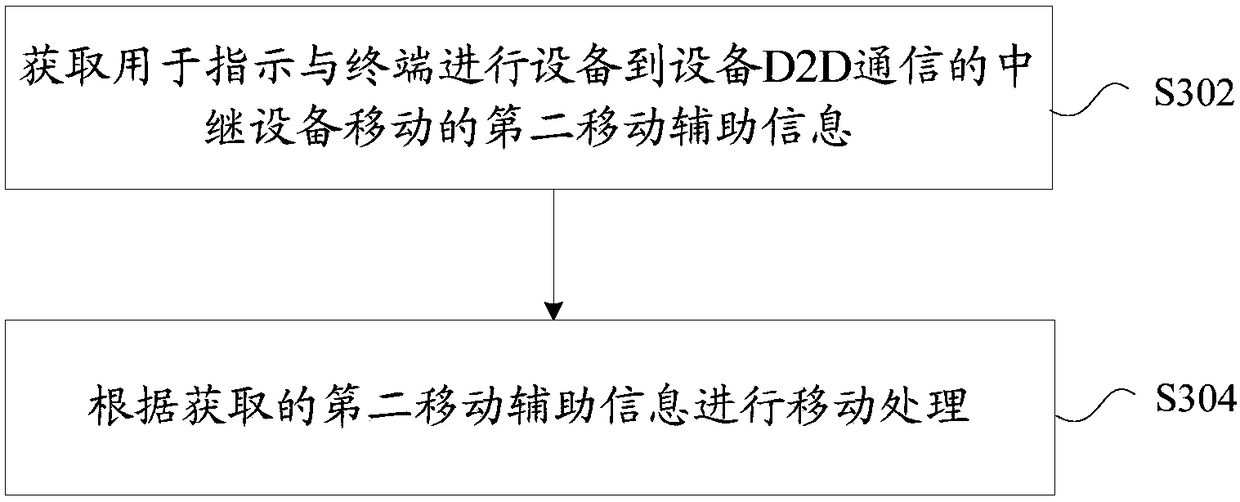

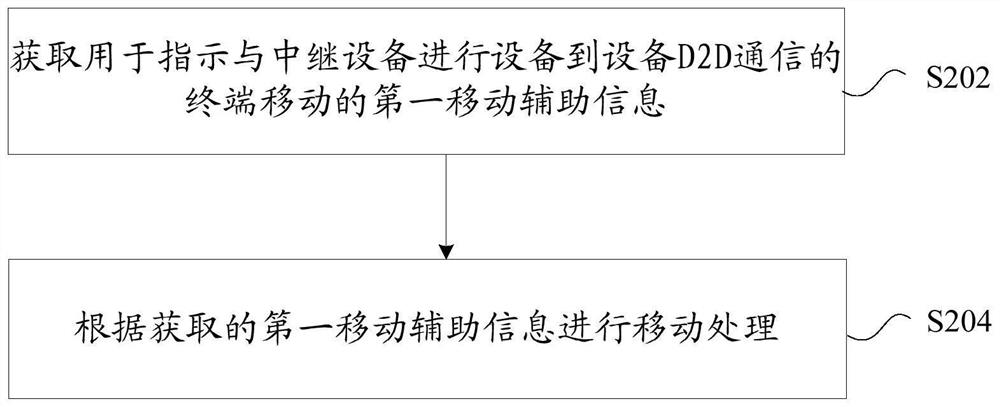

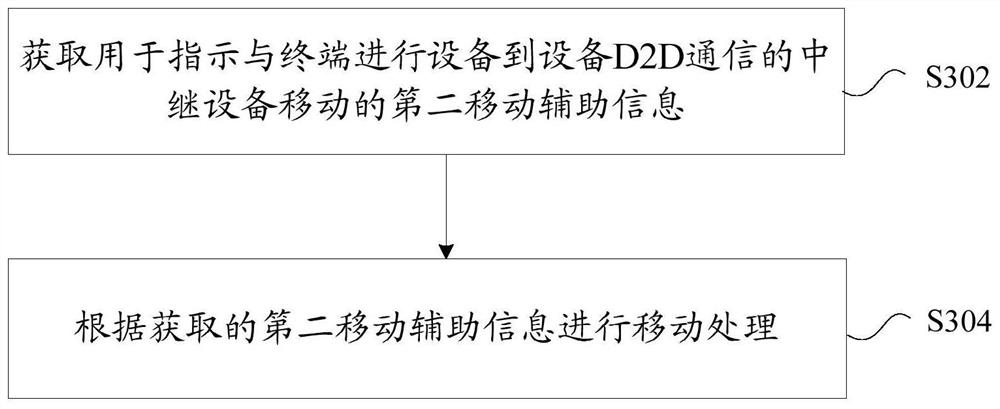

Device moving method, device moving apparatus, device moving system, terminal, and relay device

ActiveCN108307482AEffective power savingPower managementAssess restrictionPower savingDevice to device

The invention provides a device moving method, a device moving apparatus, a device moving system, a terminal, and a relay device. The device moving method comprises steps that first moving auxiliary information used for indicating moving of a terminal used for device-to-device D2D communication with the relay device is acquired; moving processing is carried out according to the acquired first moving auxiliary information, and the problem of the prior art of the insufficient consideration of the power saving of the relay equipment and / or the terminal during the moving processing of the device in the D2D scene is solved, and therefore the effective power saving effect of the relay device and / or the terminal in the D2D scene is realized.

Owner:ZTE CORP

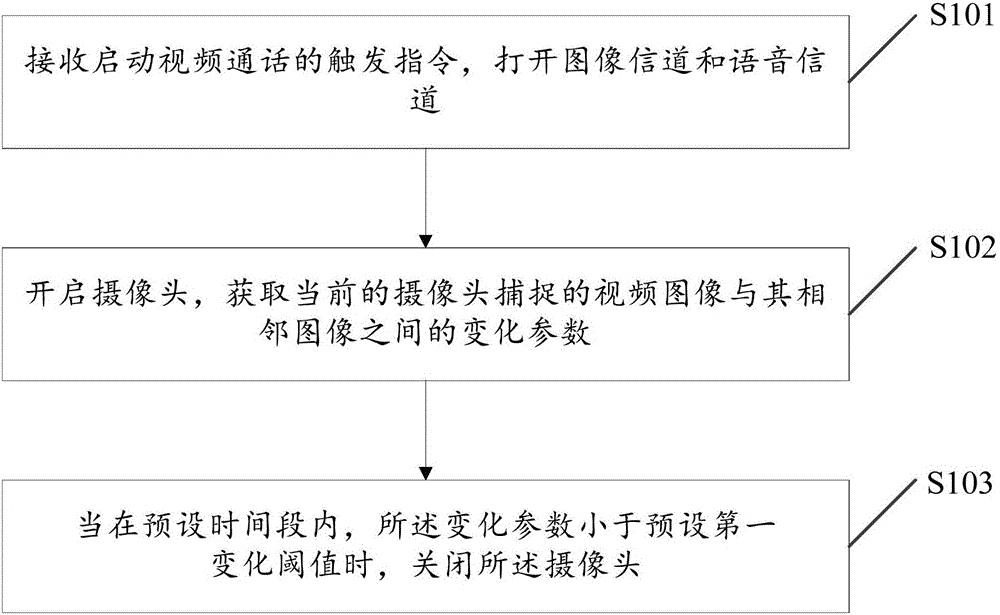

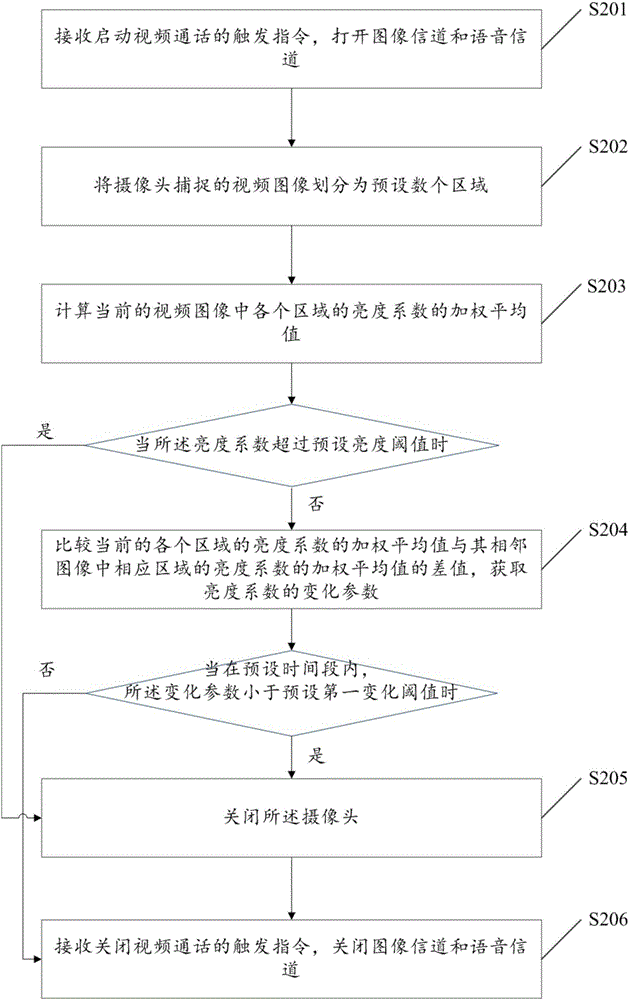

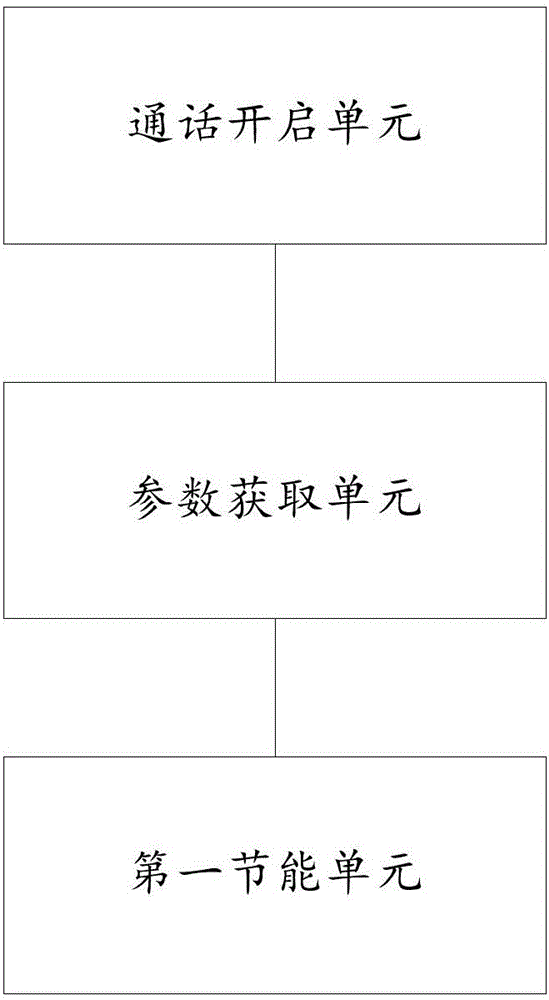

Energy-saving control method and device for video call of smartwatch

InactiveCN106412482AEffective power savingTelevision system detailsColor television detailsTime segmentEngineering

The invention discloses an energy-saving control method and device for a video call of a smartwatch. The method comprises the following steps of: receiving a triggering instruction for starting the video call, and opening an image channel and a voice channel; starting a camera, and obtaining a change parameter between a video image captured by the current camera and an adjacent image; and, turning off the camera when the change parameter is less than a pre-set first change threshold value within a pre-set time slot. By means of the energy-saving control method and device disclosed by the invention, electrical energy can be saved; and thus, the cruising capability of the smartwatch is improved.

Owner:BEIJING QIHOO TECH CO LTD +1

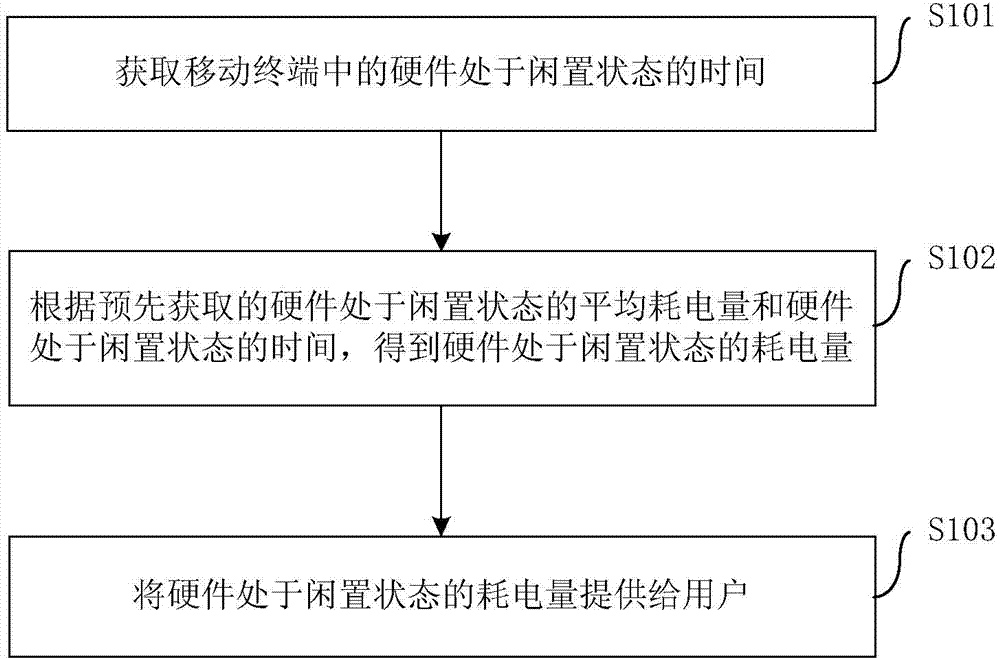

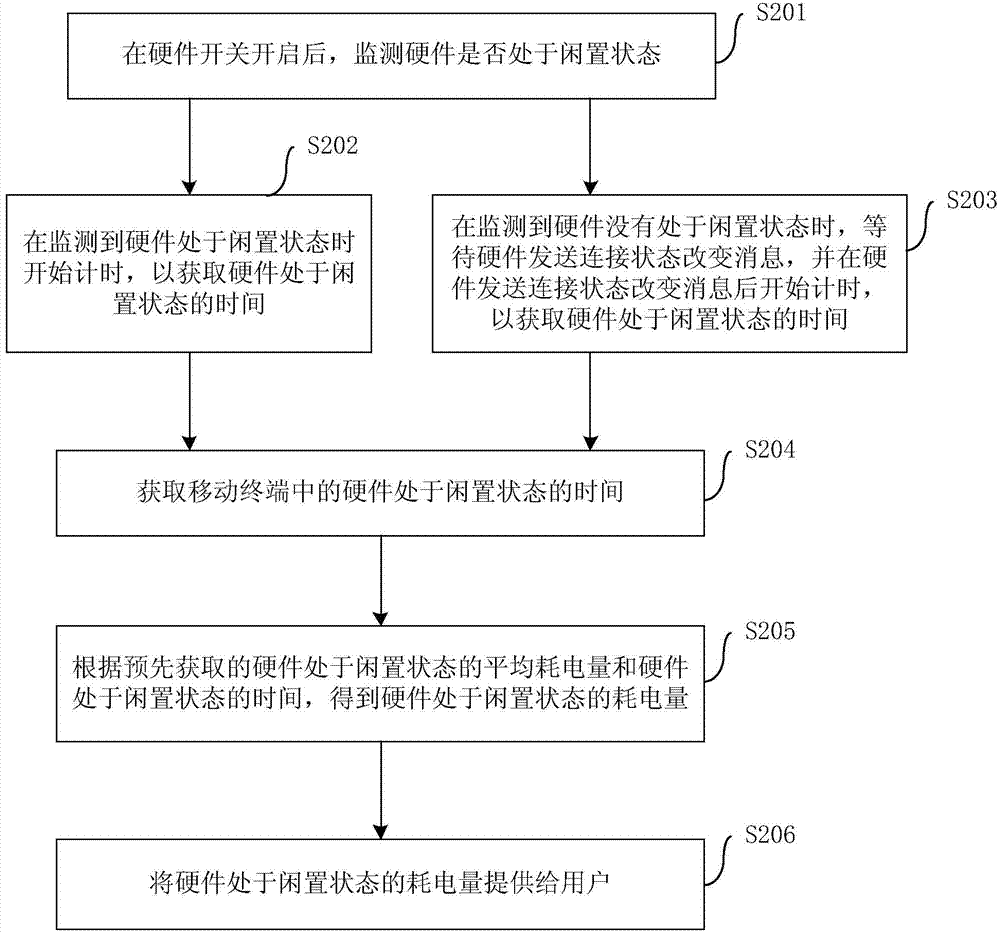

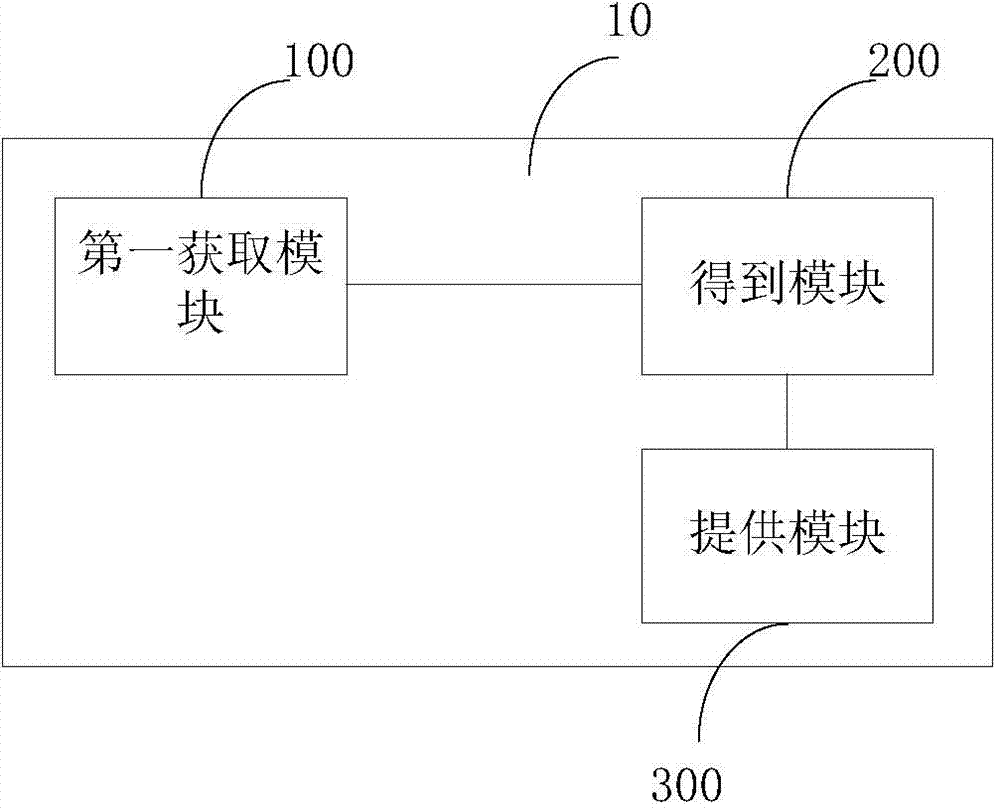

Power consumption providing method and device of mobile terminal

InactiveCN103927249AEffective power savingAvoid power consumptionHardware monitoringEnergy efficient computingElectricityEngineering

The invention provides a power consumption providing method and device of a mobile terminal. The power consumption providing method includes: acquiring the time of hardware in the idle state in the mobile terminal; acquiring power consumption of the hardware in the idle state according to the previously acquired average power consumption and the time of the hardware in the idle state; providing the power consumption of the hardware in the idle state to users. By the power consumption providing method, the power consumption of the hardware in the idle state can be provided to the user, the user can adjust a hardware switch according to their own environment so as to more effectively save electricity.

Owner:KENIU NETWORK TECH BEIJING

Magnetized high combination power high grinding uniform ceramic grinding section and manufacturing method thereof

InactiveCN109534800AImprove bindingGain permeabilityOther chemical processesPlastic materialsNano al2o3

The invention discloses a magnetized high combination power high grinding uniform ceramic grinding section and a manufacturing method thereof. The ceramic grinding section is prepared from three functional ingredients, wherein the first functional ingredient A is a ceramic substrate prepared from low-temperature sintering of raw materials of nanometer aluminum oxide powder, silicon carbide powder,molybdenum disulfide powder, yttrium oxide powder, zirconium dioxide powder, titanium dioxide powder and silicon dioxide powder; the second functional ingredient B is a magnetized lubrication surfacelayer obtained through high-temperature melting curing by using raw materials of ferroferric oxide, molybdenum disulfide, silver, copper and titanium; the third functional ingredient C is a PVA plastic material; the three ingredients have the composition relationship that the grid-shaped ingredient C is firmly and completely mixed with the ingredient A to be combined into an inner core; the ingredient B is a modified film layer sprayed and cured onto the surface of the inner core through high velocity oxy-fuel under the argon gas protection. The ceramic grinding section provided by the invention has the advantages that the surface layer is lubricated; the grinding efficiency is high; the combination power is high; the abrasion is small; the energy consumption is low; the grinding is moreuniform.

Owner:SHANDONG TIANHUI GRINDING WEAR TECH DEV CO LTD

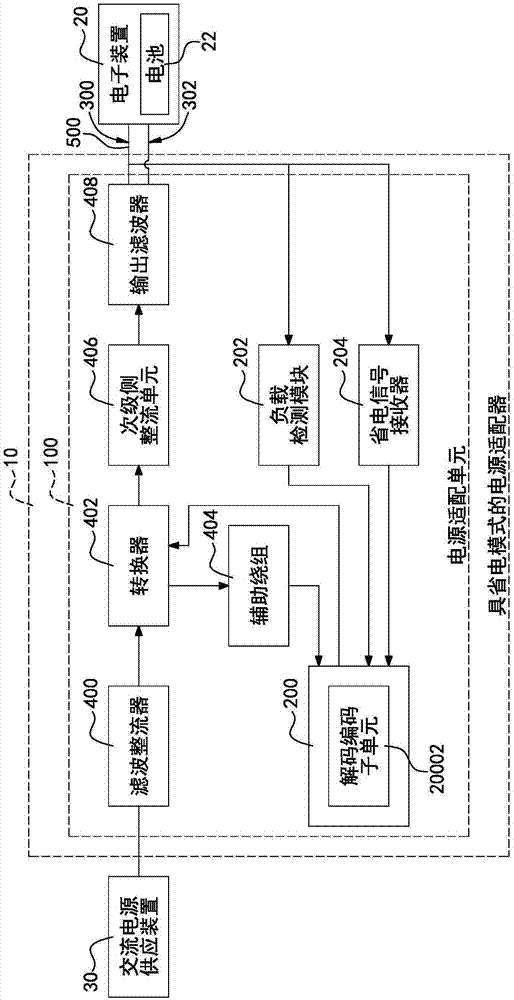

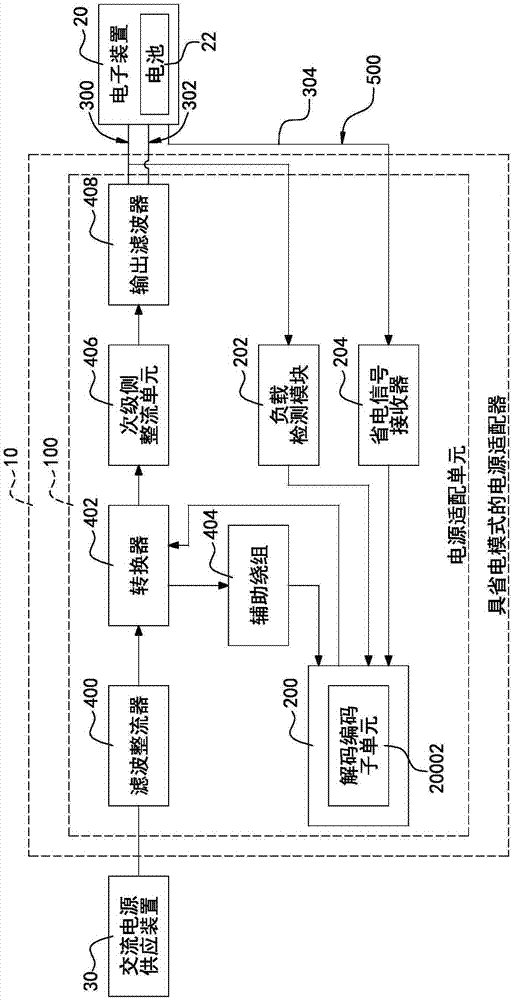

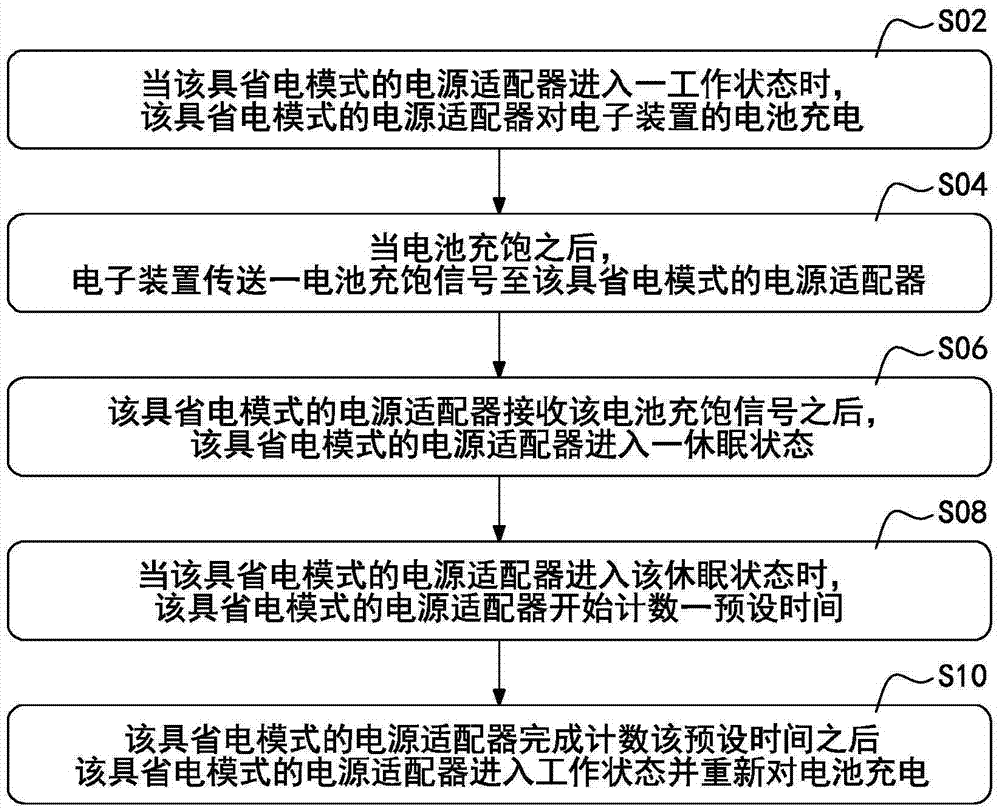

Power adaptor having power saving mode and power saving method of power adaptor

InactiveCN106921181AEffective power savingBatteries circuit arrangementsAc-dc conversion without reversalPower savingEngineering

The invention provides a power adaptor having a power saving mode and a power saving method of the power adaptor. The power adaptor having the power saving mode comprises a power adaption unit, wherein the power adaption unit comprises a pulse width modulation control unit and a power saving signal receiver, and the power saving signal receiver is electrically connected with the pulse width modulation control unit. The power adaptor having the power saving mode charges a battery when the power adaptor having the power saving mode enters a working state, and the power adaptor having the power saving mode enters a dormant state after a fully-charged signal of the battery is received by the power saving electrical signal receiver.

Owner:CHICONY POWER TECH CO LTD

Method and apparatus for implicit carrier deactivation

ActiveCN102215551BEffective power savingMake up for unreliabilityPower managementHigh level techniquesInformation transmissionSecondary component

The invention provides an implicit carrier deactivation method and equipment. The method comprises that: when learning that a downlink secondary component carrier (DL SCC) does not have data and control information transmission needs, a user terminal deactivates the DL SCC. The invention also provides an implicit carrier deactivation mechanism in a long term evolution-advanced (LTE-A) system.

Owner:DATANG MOBILE COMM EQUIP CO LTD

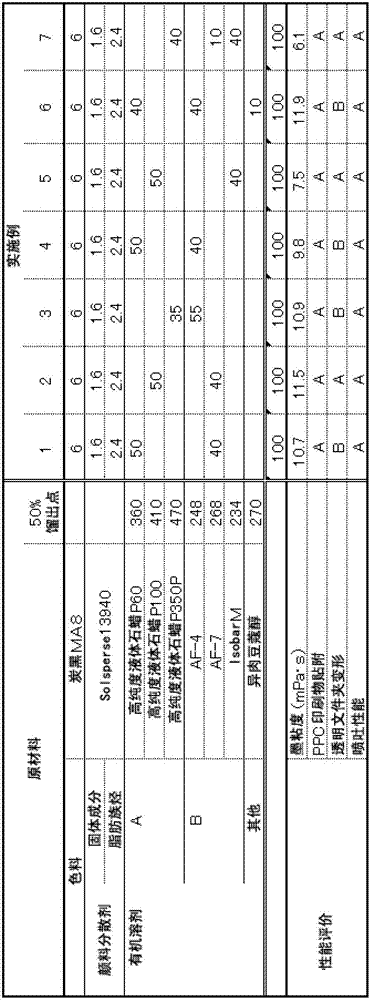

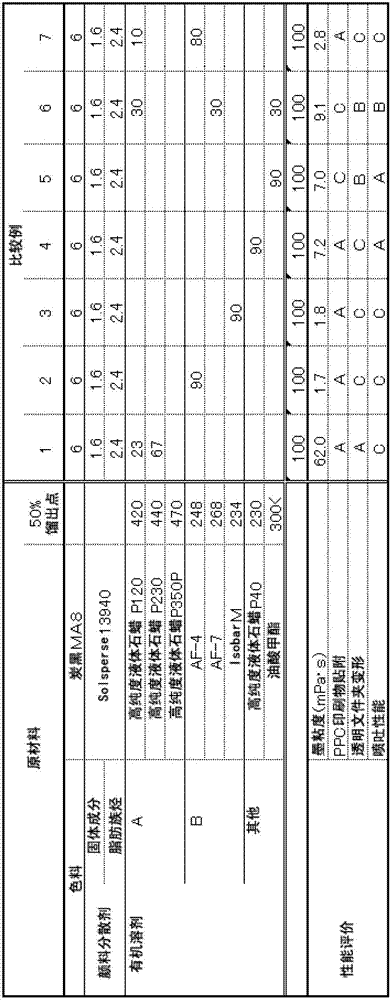

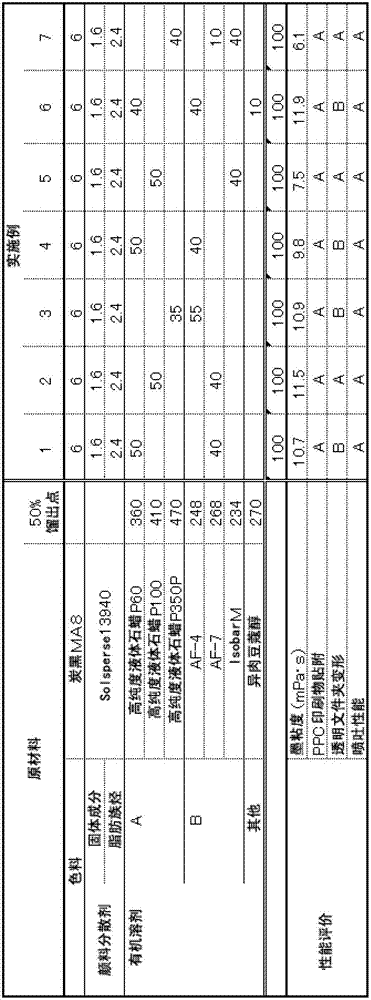

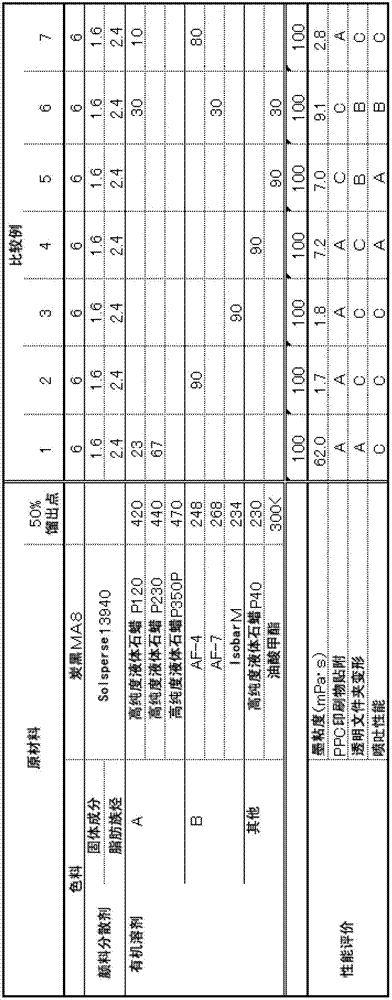

Nonaqueous ink

ActiveCN102964905AAvoid deformationReduce power consumptionDuplicating/marking methodsInksOrganic solventDistillation

The invention provides a nonaqueous ink for ink jet and the nonaqueous ink can restrict attaching with a toner resin of a PPC print and deformation of a transparent folder. The nonaqueous ink comprises color material and organic solvent. The organic solvent comprises 50% of solvent (a) containing (in %mass) normal paraffin-type solvent (30 or more) having distillation-temperature of 320-480[deg] C, and 50% of solvent (b) containing naphthene-type solvent and / or isoparaffin-type solvent (30 or more) having distillation temperature of 200-320[deg] C with respect to total content of organic solvent. The content of solvent (a) and solvent (b) is 80 %mass or more with respect to the total content of organic solvent. Ink viscosity preferably 5-30 mPas.

Owner:RISO KAGAKU CORP

An automatic cleaning device for auto parts

ActiveCN105728383BSimple structureImprove cleaning efficiencyCleaning using liquidsWater dischargeMotor vehicle part

The invention discloses an automatic cleaning device for automobile parts. The automatic cleaning device comprises a support frame, a material conveying machine, a water discharging device, a spraying device, a cleaning liquid container, a water pump, a camera and a controller, wherein the bottom of the support frame is provided with a bottom plate; the material conveying machine is arranged on the support frame and comprises two material conveying rollers and a material conveying belt; the material conveying rollers are driven by a motor; the material conveying belt is provided with holes; the water discharge device is positioned between the upper surface and the lower surface of the material conveying machine; the top of the water discharge device is provided with an opening; the bottom of the water discharge device is provided with a liquid outlet; the spraying device is positioned above the material conveying machine, and comprises a plurality of sealed spraying head groups in concentric arrangement; an inlet of each spraying head group is connected with the water pump through an electromagnetic valve; the water pump is positioned in the cleaning liquid container; the camera is positioned above the input end of the material conveying machine; the data transmission end of the camera is connected with the controller; the controller is connected with each electromagnetic valve, the motor and the control end of the water pump respectively. The automatic cleaning device has the advantages that different cleaning modes can be automatically selected by aiming at parts in different dimensions; the cleaning liquid can be effectively saved; the cleaning cost is reduced.

Owner:JIANGSU BOYINGTE ELECTRONICS TECH CO LTD

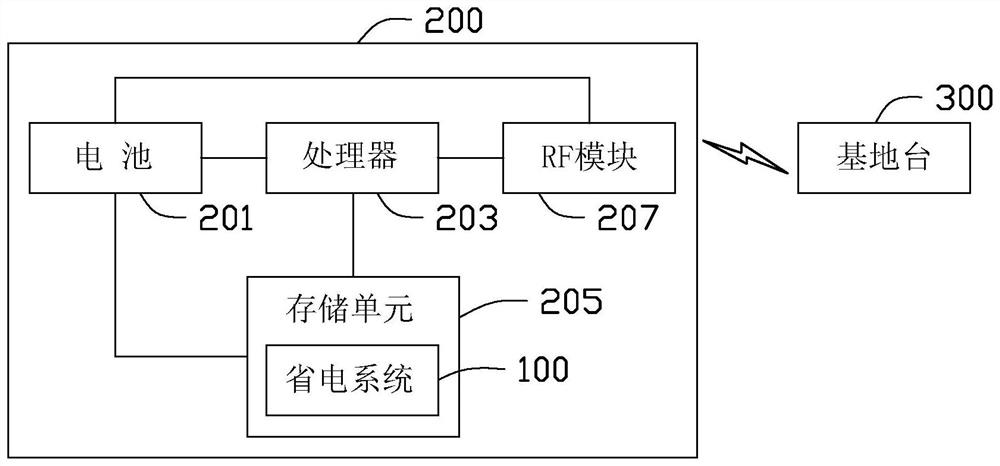

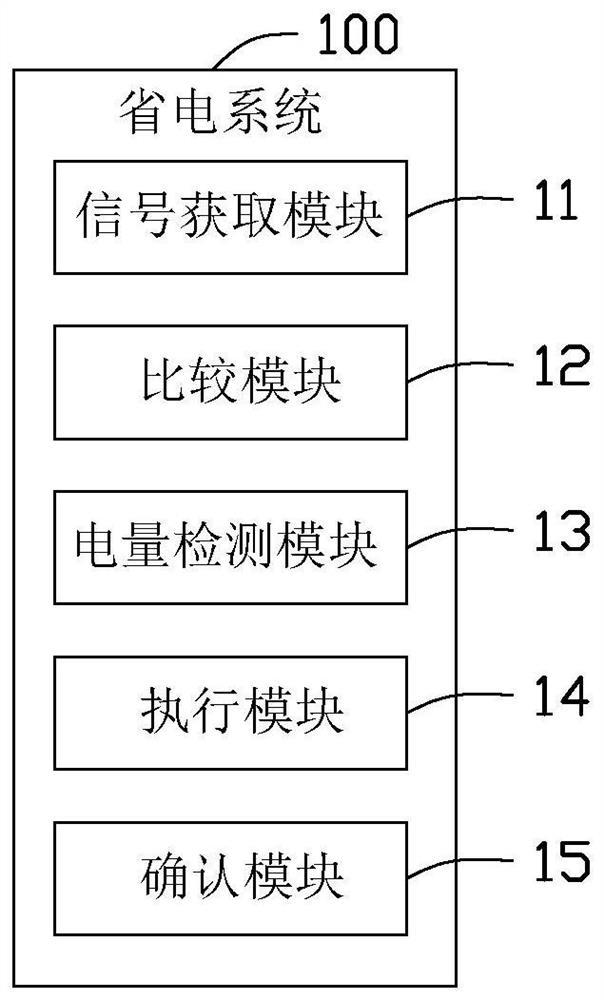

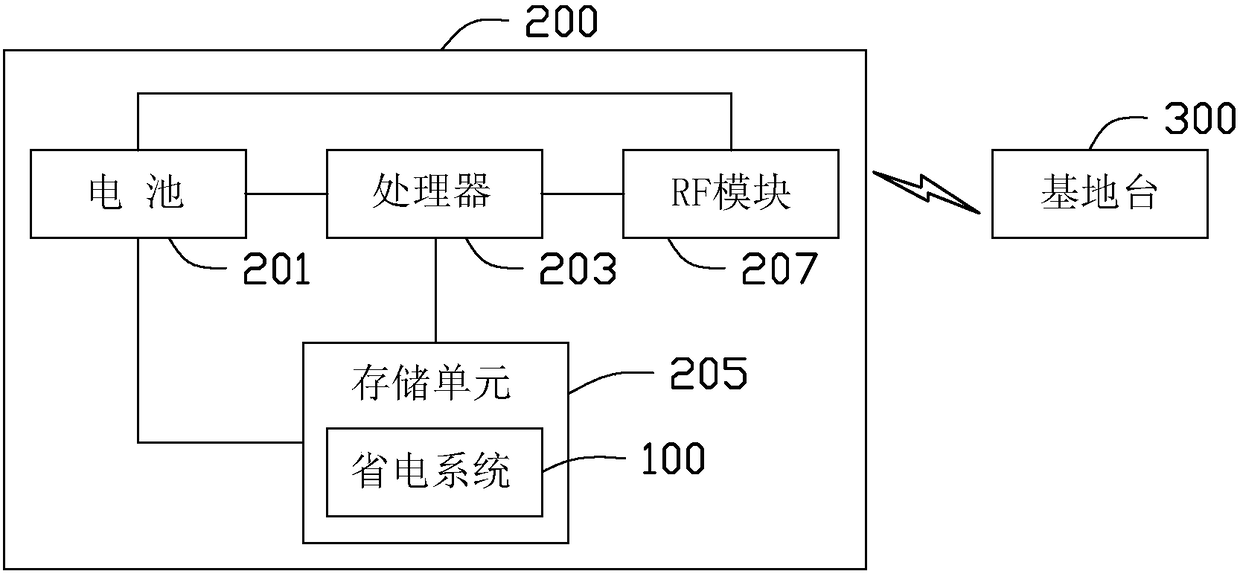

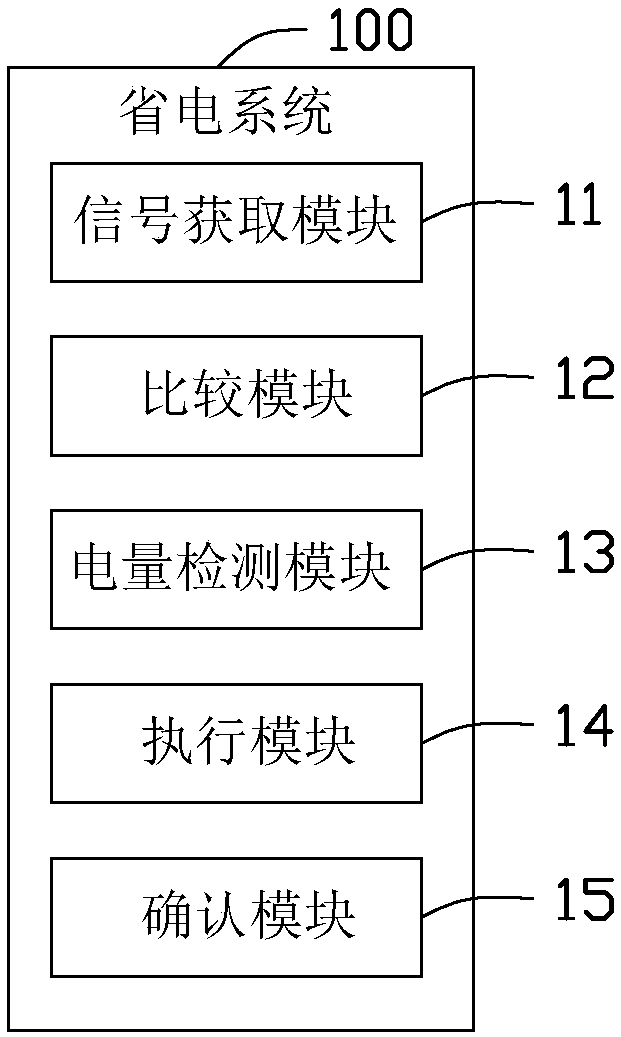

Power saving system, electronic device having the power saving system, and power saving method thereof

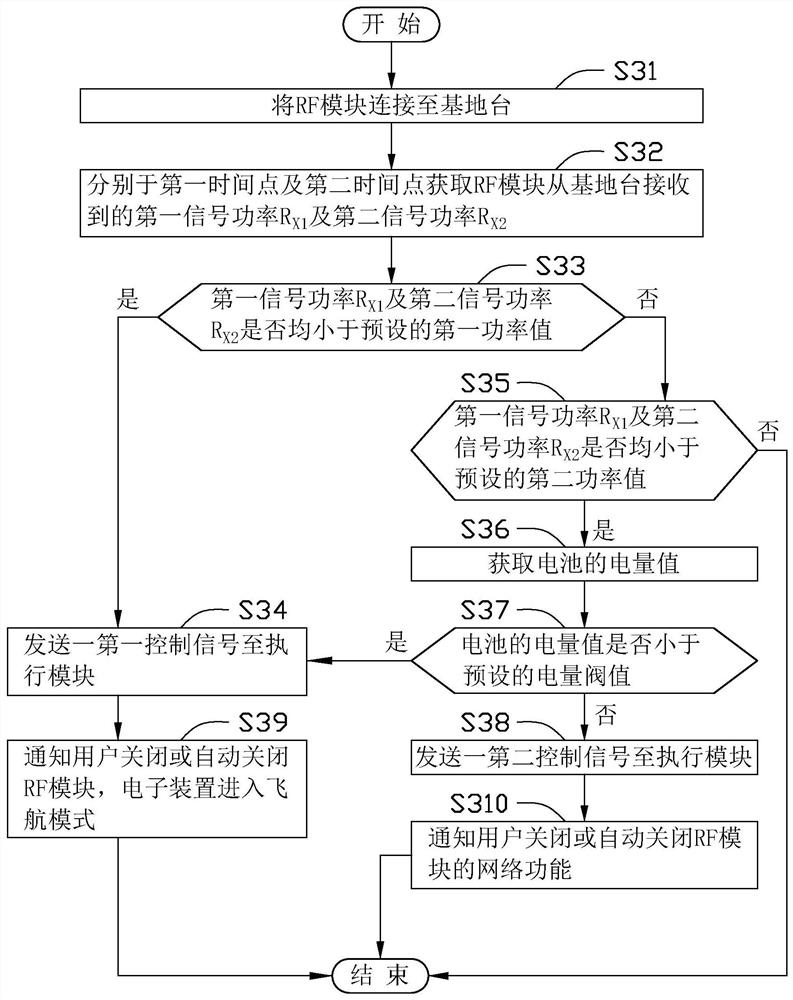

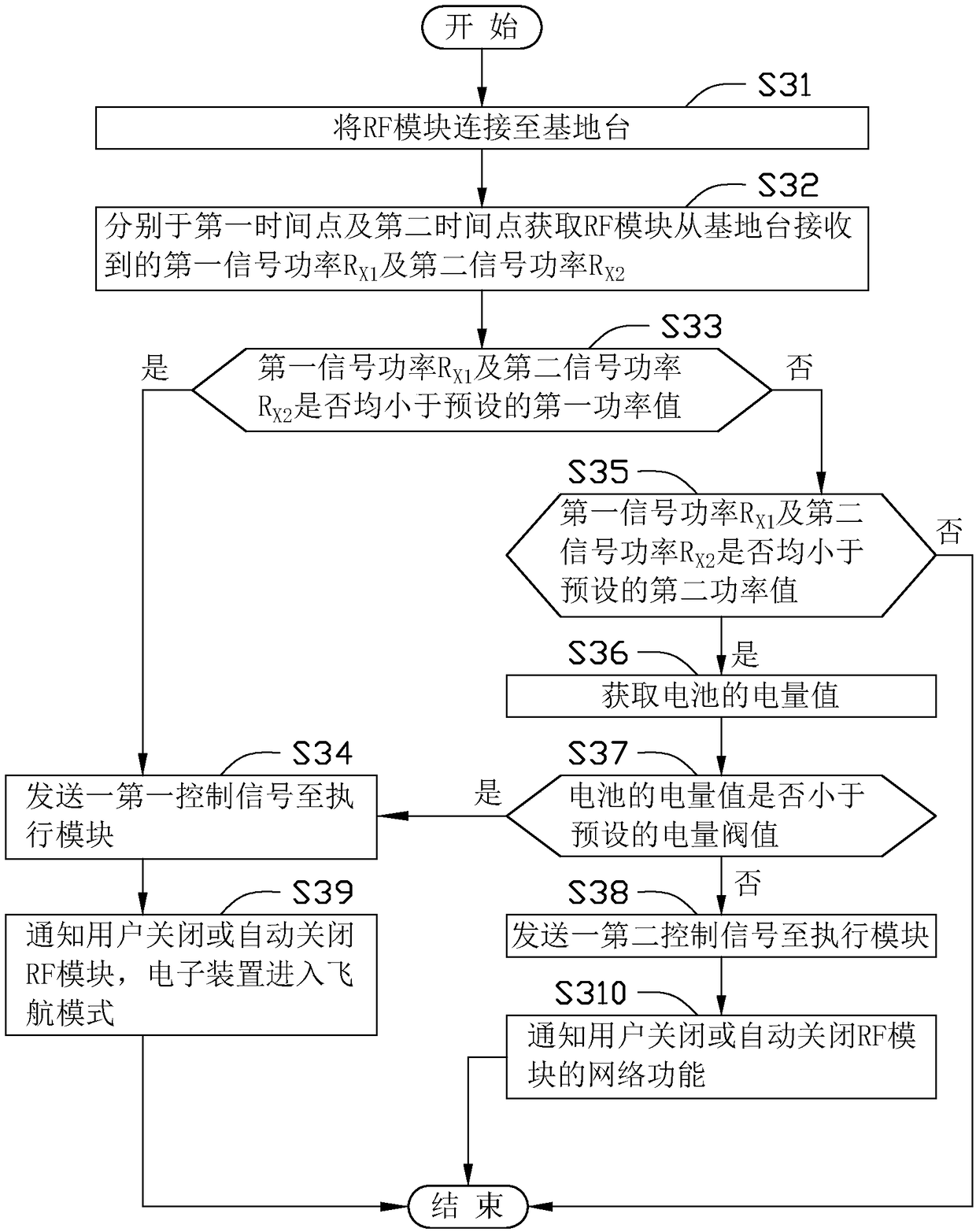

ActiveCN108574980BEffective power savingPower managementHigh level techniquesAirplane modeReliability engineering

The present invention provides a power saving system, including a signal acquisition module, used to acquire the signal power received by the electronic device from the base station at the first time point and the second time point respectively; The signal acquisition module compares the first signal power acquired at the first time point and the second signal power acquired at the second time point with the preset first power value to determine whether the first signal power and the second signal power are both smaller than the first power value; and an execution module, configured to execute a first preset function when the comparison module judges that both the first signal power and the second signal power are smaller than the first power value. The above-mentioned power saving system can turn off the network function of the electronic device or directly activate the flight mode when the electronic device is in an area with poor signal or the power is insufficient, so as to achieve the purpose of effectively saving power. The invention also provides an electronic device with the power saving system and a power saving method thereof.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

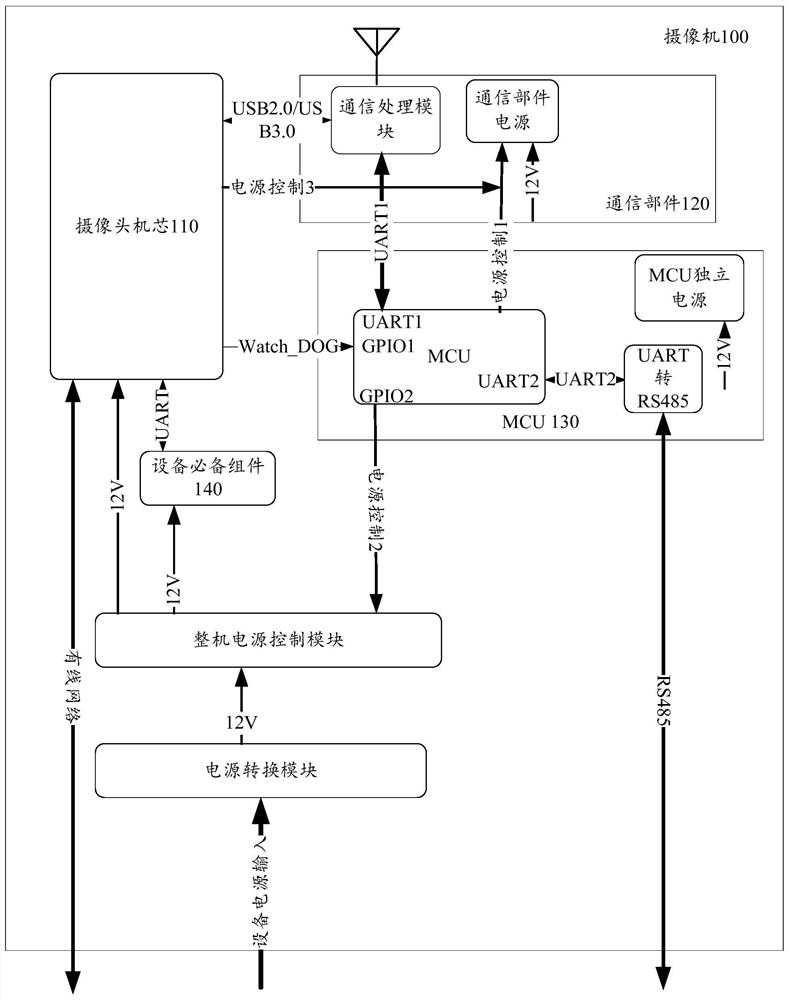

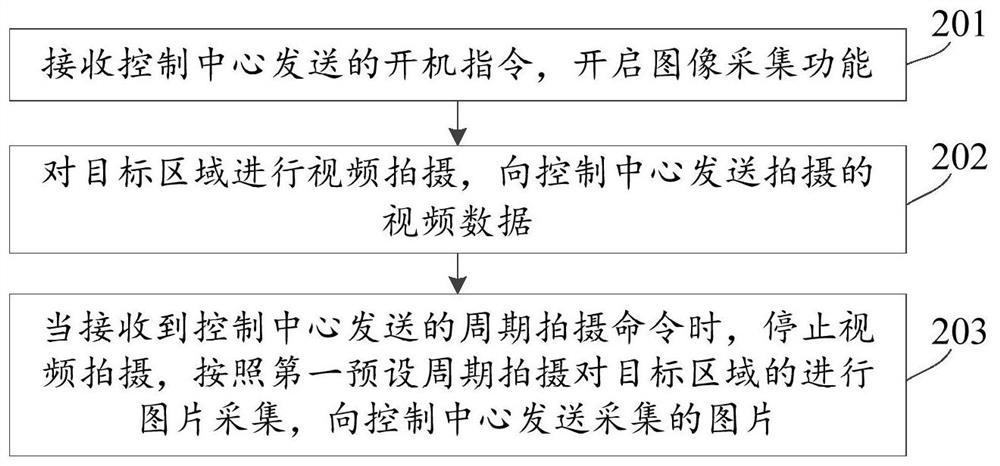

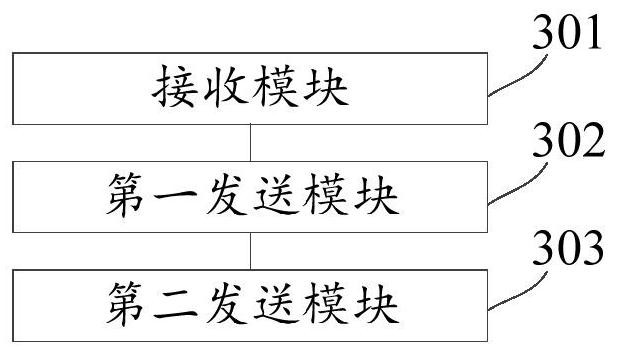

Camera control method and device

ActiveCN108632522BReduce power consumptionFix issues that drain a lot of batteryTelevision system detailsColor television detailsComputer hardwareCamera control

The embodiment of the invention discloses a camera control method and device, belonging to the field of video surveillance. The method includes: receiving a start-up command sent by the control center, and starting the image acquisition function; performing video shooting on the target area, and sending the captured video data to the control center; when receiving the periodic shooting command sent by the control center, Stop video shooting, collect pictures of the target area according to a first preset period, and send the collected pictures to the control center. The technical solution provided by the embodiments of the present invention solves the problem that the camera consumes a large amount of power when collecting images in real time in the prior art, and achieves the effect of reducing the power consumption of the camera and thus effectively saving power.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Nonaqueous ink

ActiveCN102964905BAvoid deformationReduce power consumptionDuplicating/marking methodsInksOrganic solventDistillation

Owner:RISO KAGAKU CORP

Power saving system, electronic device having same, and power saving method

ActiveCN108574980AEffective power savingPower managementHigh level techniquesEngineeringAirplane mode

The invention provides a power saving system comprising a signal acquisition module used for separately acquiring signal power received by an electronic device from a base station at a first time point and a second time point; a comparison module used for separately comparing the first signal power acquired by the signal acquisition module at the first time point and the second signal power acquired by the signal acquisition module at the second time point with a preset first power value, to judge whether both the first signal power and the second signal power are less than the first power value; and an execution module used for executing a first preset function when the comparison module judges that both the first signal power and the second signal power are less than the first power value. When the electronic device is in an area with poor signal or insufficient electric quantity, the power saving system can close a network function of the electronic device or directly start an airplane mode to achieve the purpose of effectively saving power. The invention also provides the electronic device having the power saving system, and a power saving method.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

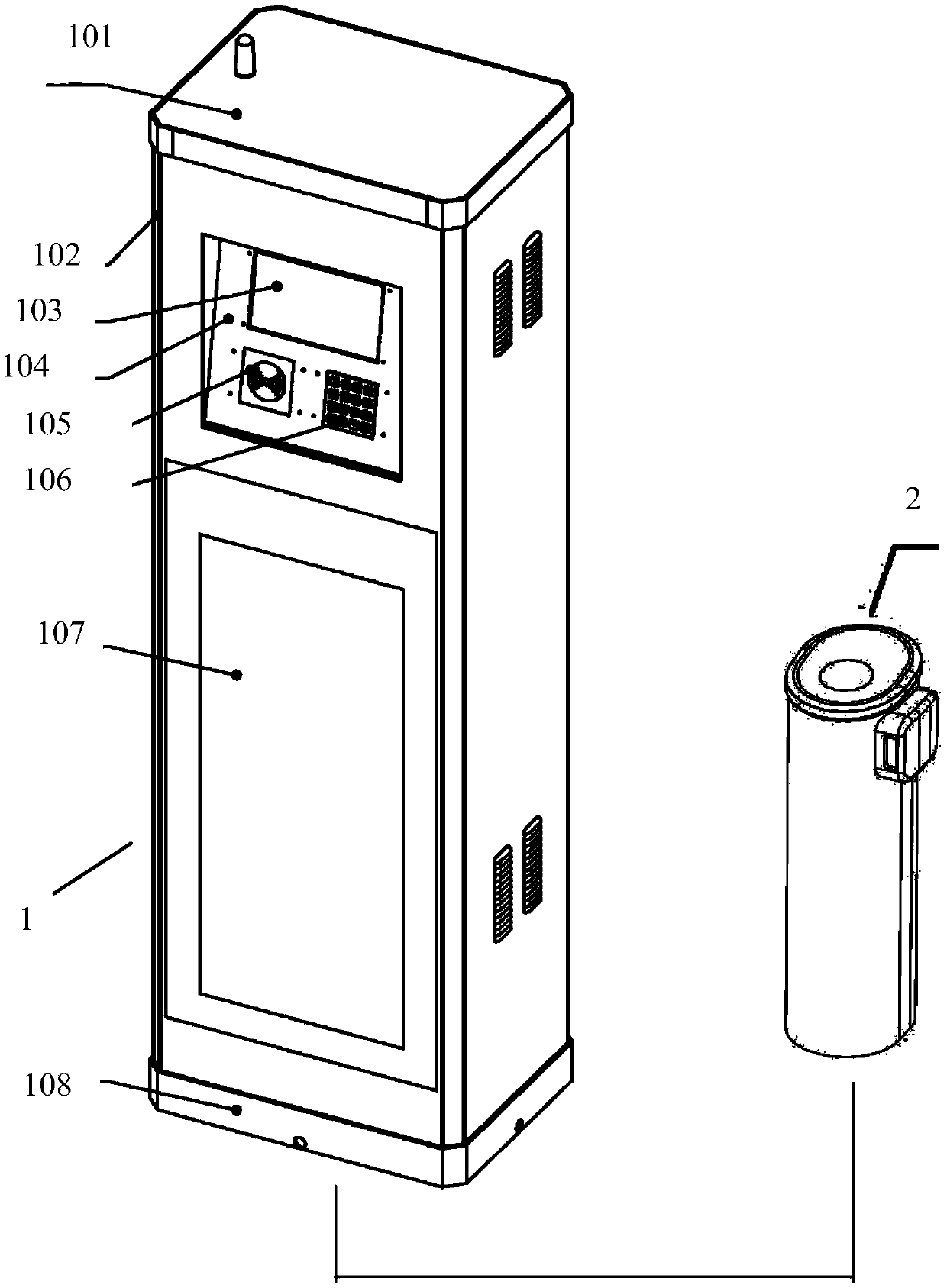

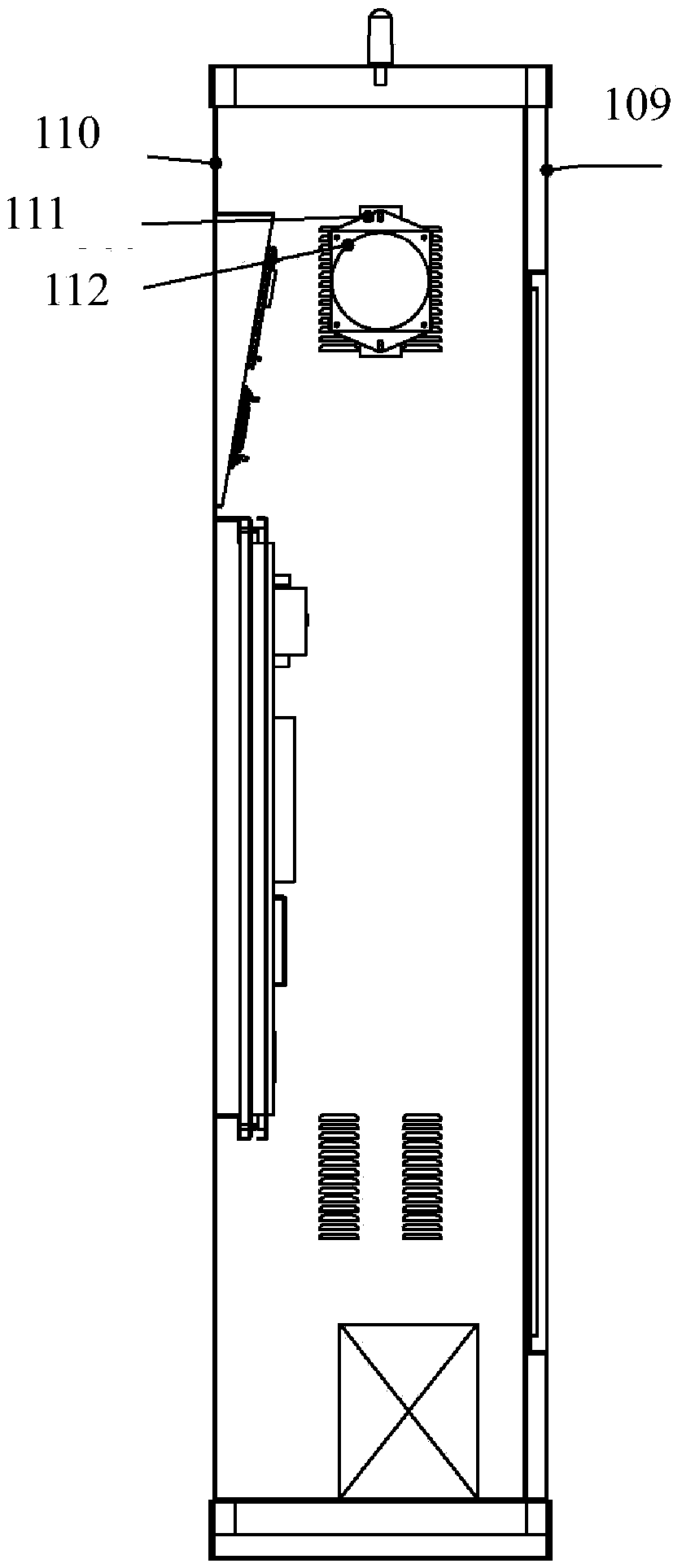

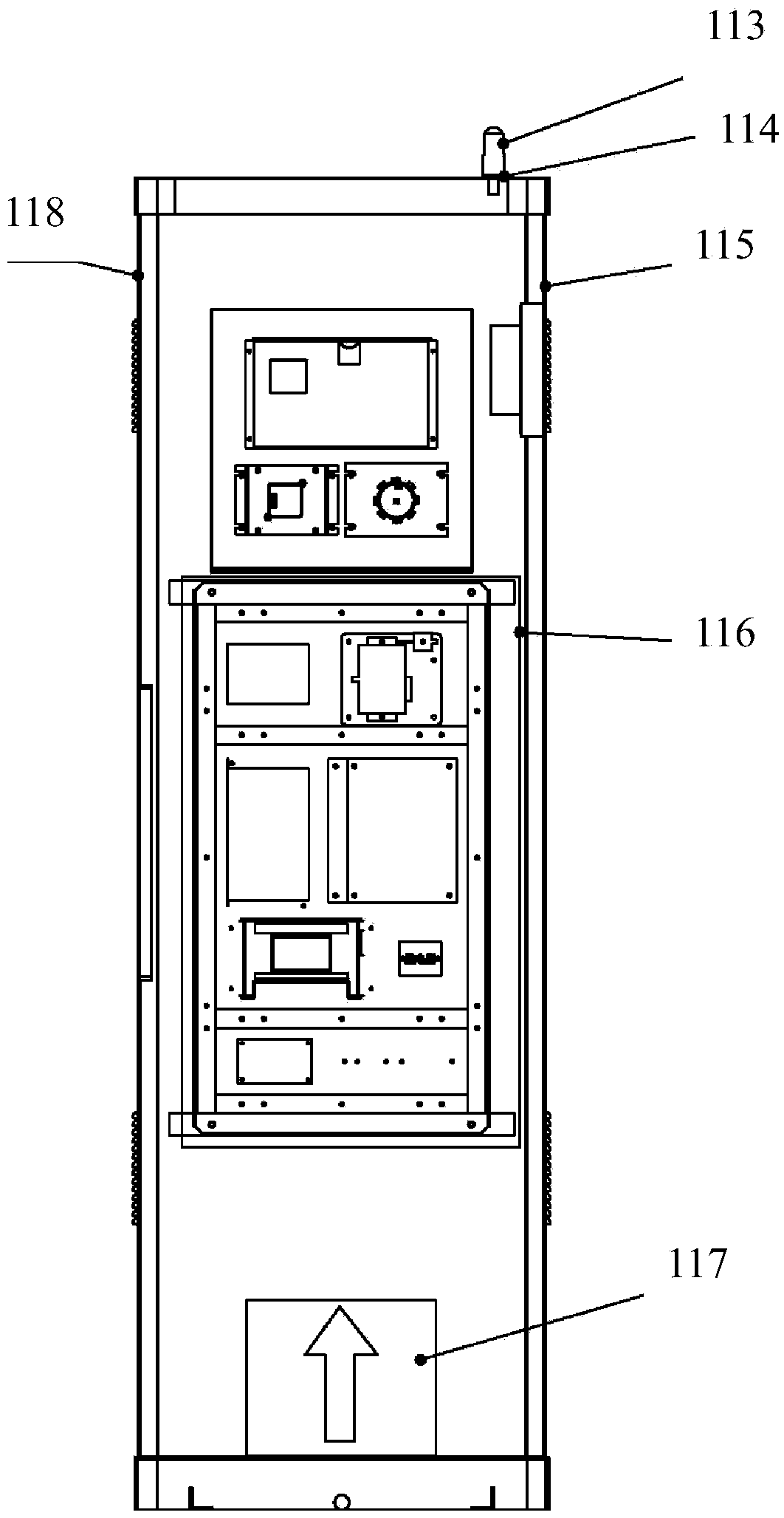

A Power-Saving Public Vehicle Rental System

ActiveCN103473860BEffective power savingLightning protectionCycle standsApparatus for meter-controlled dispensingEngineeringCommunication link

The invention aims to provide a power-saving utility car leasing system. The power-saving utility car leasing system provided by the invention comprises a station controller and a car lock which are in mutual communication link, wherein the station controller comprises a controller mainboard; the controller mainboard is set to generate and output a level signal; the car lock is set to receive the level signal; according to changes of the high level and the low level of the level signal, the car lock is switched between a normal state and a low-power consumption state.

Owner:YOUON TECH CO LTD

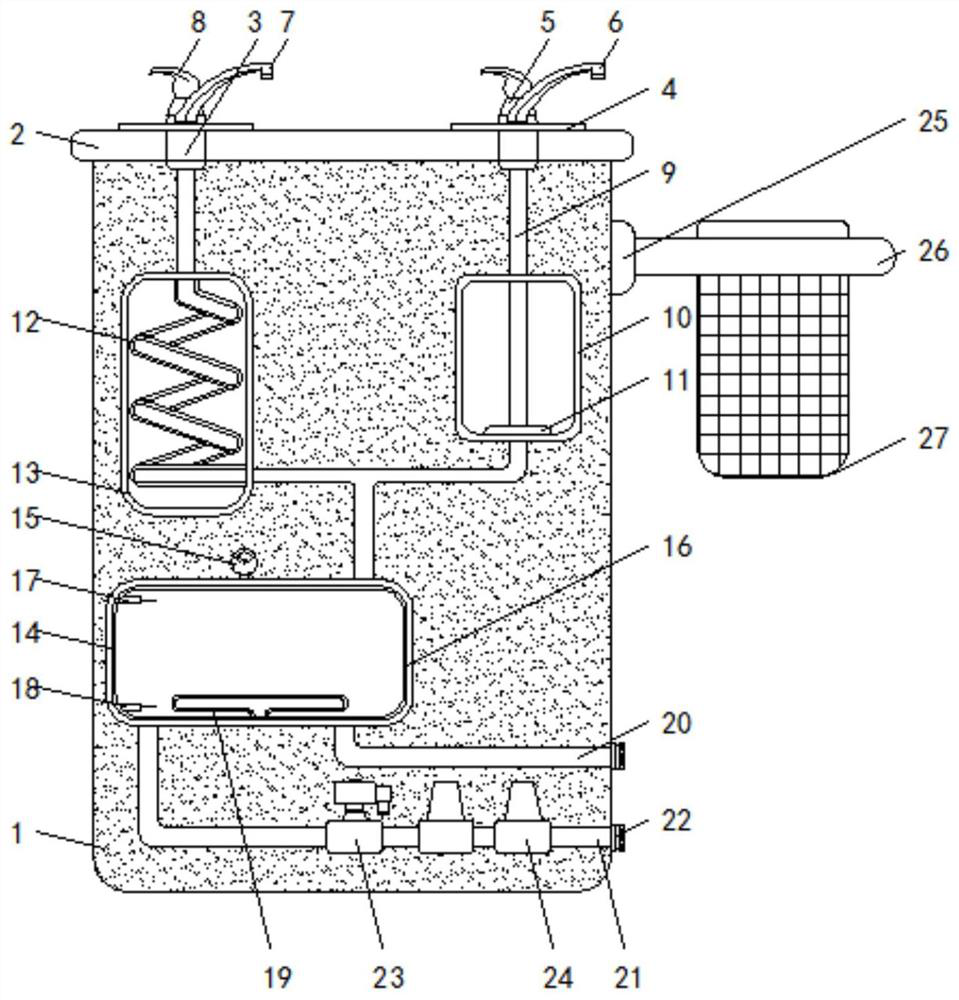

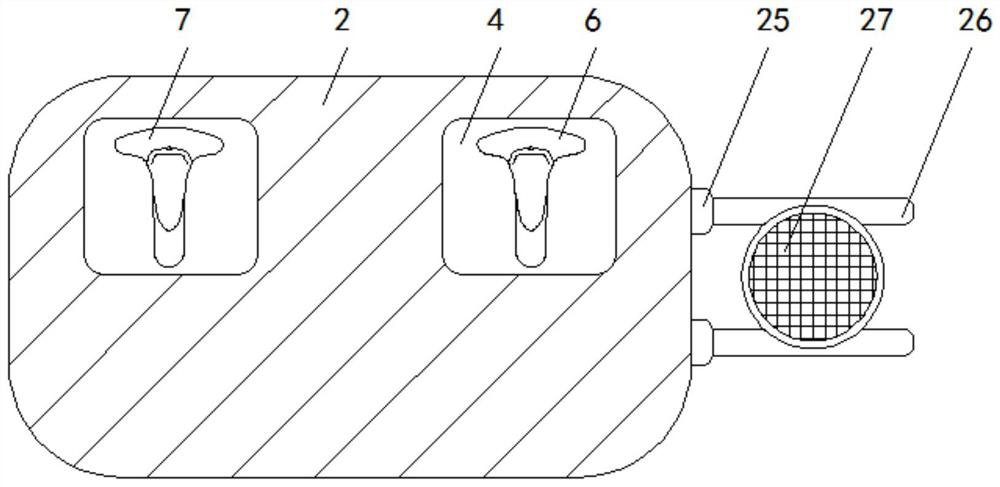

Intelligent container-free instant-heating normal-pressure type commercial drinking water equipment with good energy-saving effect

InactiveCN112471901AGood energy saving effectAvoid breakingBeverage vesselsHazardous substanceTap water

The invention relates to the technical field of water drinking equipment and discloses intelligent container-free instant-heating normal-pressure commercial water drinking equipment with a good energy-saving effect. The equipment comprises a water dispenser body, wherein a panel is fixedly connected to the top of the water dispenser body, and a guide pipe sleeve is fixedly connected to the interior of the panel; faucet bases are fixedly connected to the tops of the two guide pipe sleeves correspondingly, water and electricity linkage valves are fixedly connected to the tops of the two faucet bases correspondingly, and a cold water outlet faucet and a hot water outlet faucet are fixedly connected to the front faces of the two water and electricity linkage valves correspondingly. According to the intelligent container-free instant-heating normal-pressure type commercial drinking water equipment with the good energy-saving effect, tap water is preheated through the electric water boiler,hazardous substances in the water are eliminated, the preheated water is reheated through the heat exchanger to provide hot drinking water for a user, and the preheated water provides cold drinking water for the user through the cold water tank; the semiconductor chilling plate in the cold water tank cools water to reduce generation of unboiled water and boiled water.

Owner:林发猷

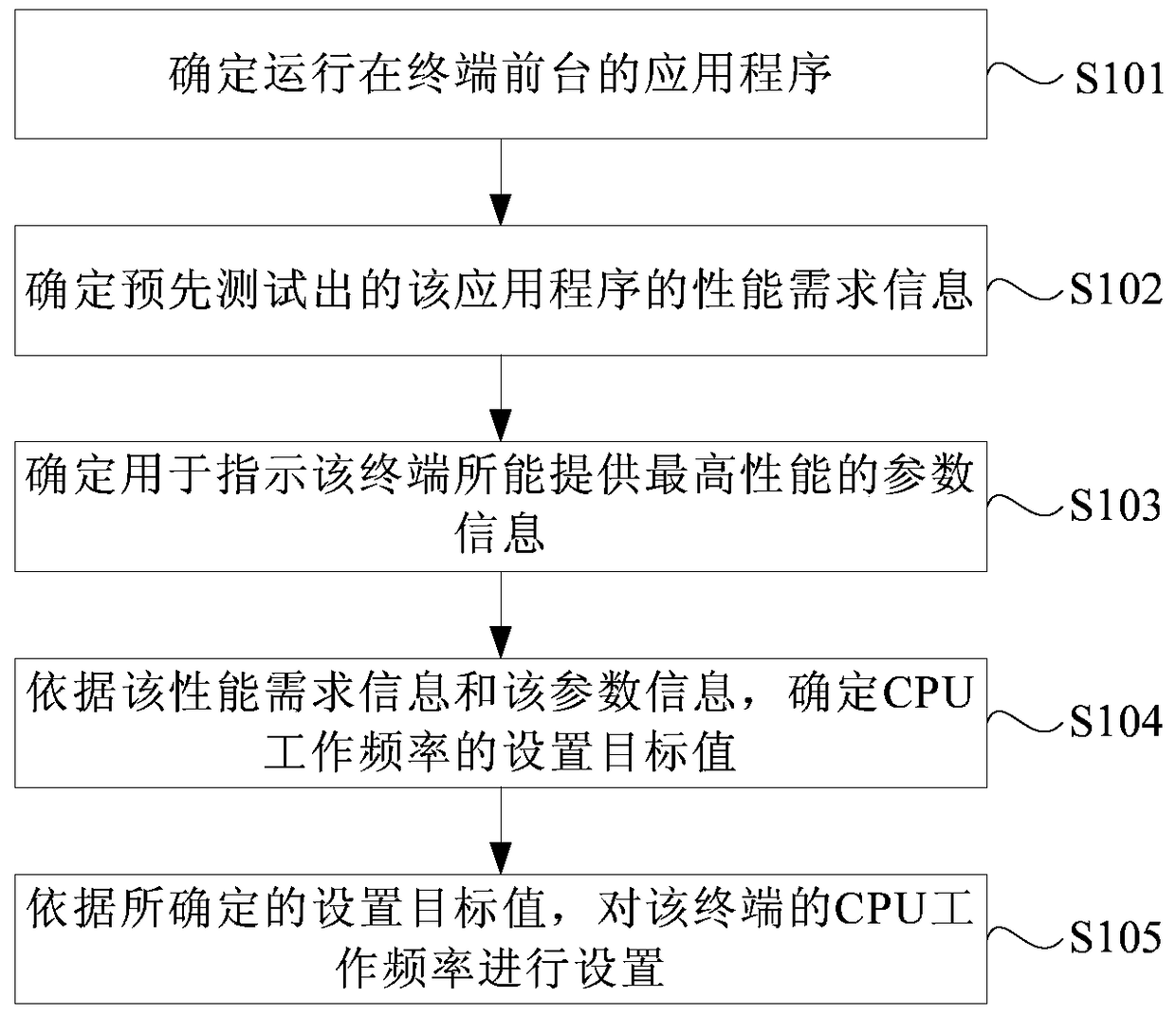

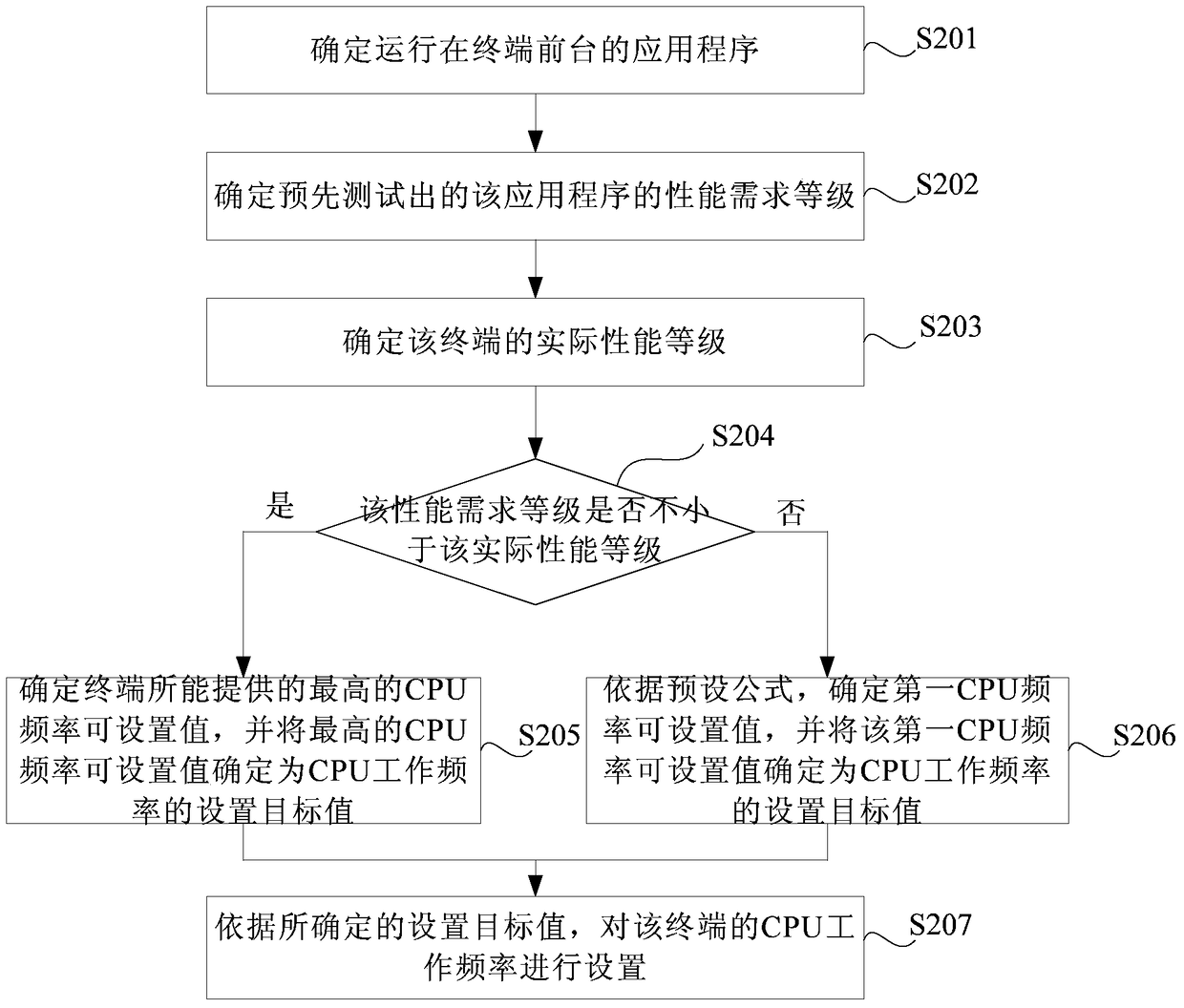

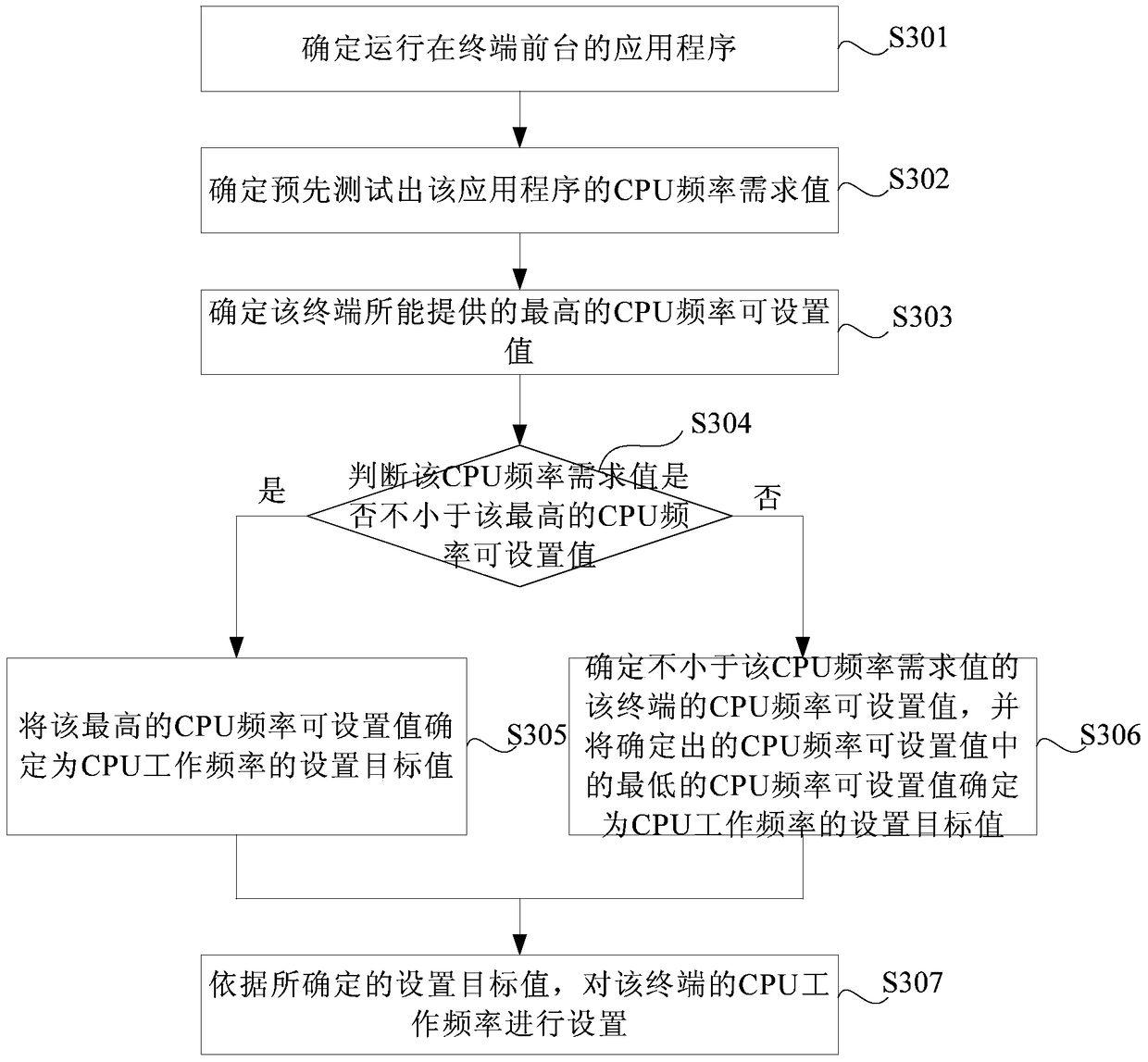

Terminal power consumption control method and device

ActiveCN105334939BImprove user experienceGuaranteed uptimeDigital data processing detailsTest performanceElectricity

The embodiment of the invention discloses a terminal power consumption control method and a terminal power consumption control device. The method comprises the following steps of determining an application program operating in a foreground of a terminal; determining pre-tested performance demand information of the application program, wherein the performance demand information is used for representing the performance demand when the application program normally operates; determining parameter information used for indicating the best performance capable of being provided by the terminal; according to the performance demand information and the parameter information, determining the set objective value of the CPU (Central Processing Unit) work frequency; setting the CPU work frequency according to the determined set objective value, wherein a user is sensitive on the use feeling of the foreground application program, so that the CUP work frequency is set according to the performance demand of the foreground application program so as to possibly ensure the normal operation of the foreground application program, and the user has better use experience; and when the performance demand is low, the CPU work frequency can be set to be low, so that the goal of effectively saving the electricity is achieved.

Owner:BEIJING ANTUTU TECH

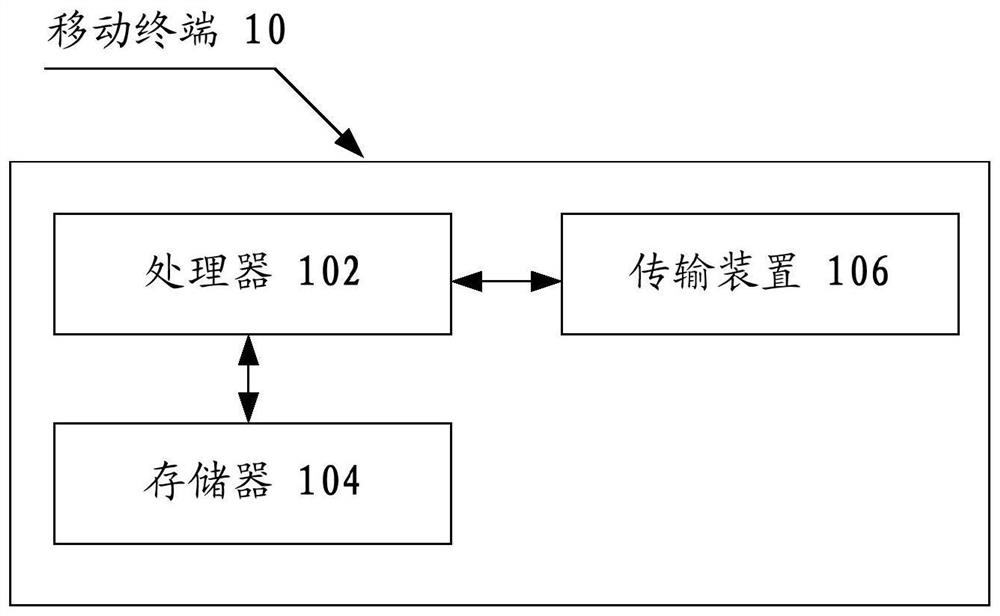

Equipment moving method, device and system, terminal and relay equipment

ActiveCN108307482BEffective power savingPower managementAssess restrictionComputer hardwareEffective power

Owner:ZTE CORP

Method and equipment for determining search space of PDCCH CC

ActiveCN102104866BReduce the number of blind inspectionsAdjust in timeAssess restrictionSignal allocationControl channelComputer science

A method and device for determining search spaces on a Physical Downlink Control Channel Component Carrier (PDCCH CC) are disclosed in the embodiments of the present invention. The method comprises the following steps: a user equipment obtains the activity state of a Physical Downlink Shared Channel Component Carrier (PDSCH CC), and according to the activity state of the PDSCH CC, determines the search spaces on the PDCCH CC. In the embodiments of the present invention, determining the search spaces on a PDCCH CC according to the activity state of a PDSCH CC, the search spaces can be adjusted in time, thus reducing unnecessary PDCCH blind decoding and saving power more effectively.

Owner:XIAOMI INC

Method and device for determining active state of PDSCH (Physical Downlink Shared Channel) CC (Communication Centre)

ActiveCN102098765BActivate in timeEffective power savingPower managementHigh level techniquesUser deviceControl channel

The invention discloses a method for determining an active state of a PDSCH (Physical Downlink Shared Channel) CC (Communication Centre), comprising the following steps: a network side device determines the active state of the PDSCH CC according to the active state of a PDCCH (Packet Dedicated Control Channel) CC, and indicates a user device to activate the CC according to the active state of the PDSCH CC when the active state of the PDSCH CC is in an activated state. In the embodiment of the invention, the active state of the PDSCH CC is determined according to the active state of the PDCCH CC, so that the PDSCH CC can be activated in time, and power can be saved more effectively.

Owner:DATANG MOBILE COMM EQUIP CO LTD

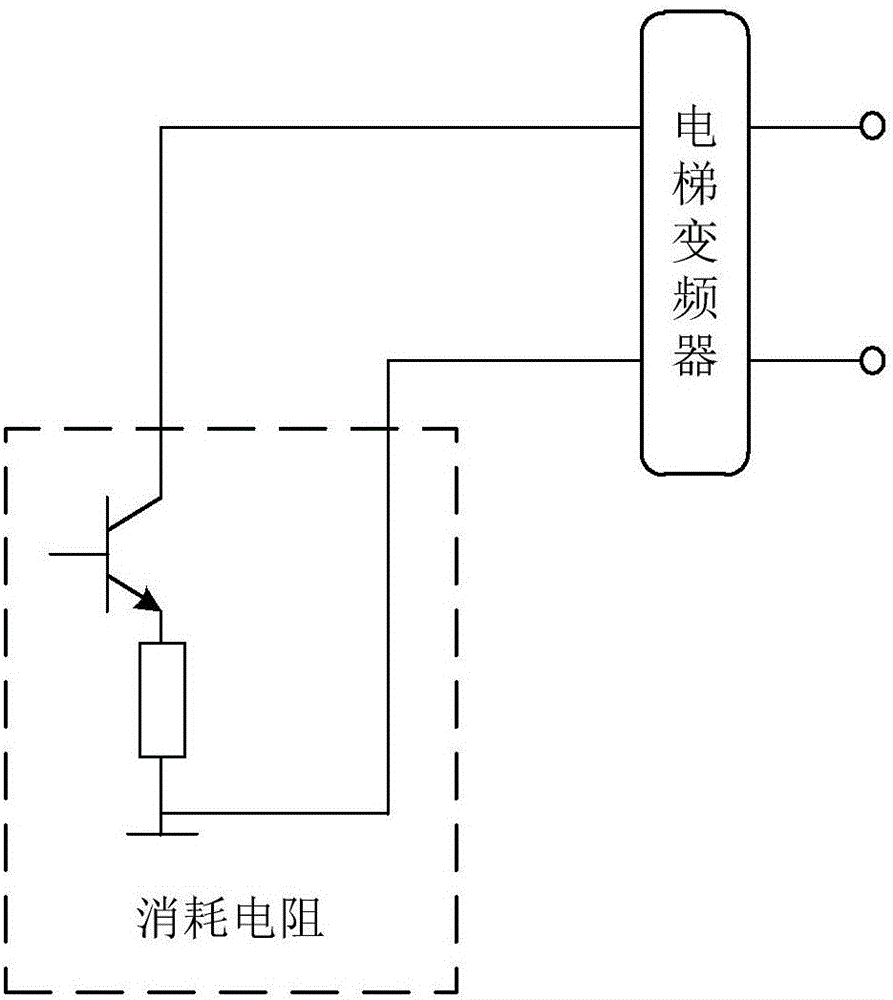

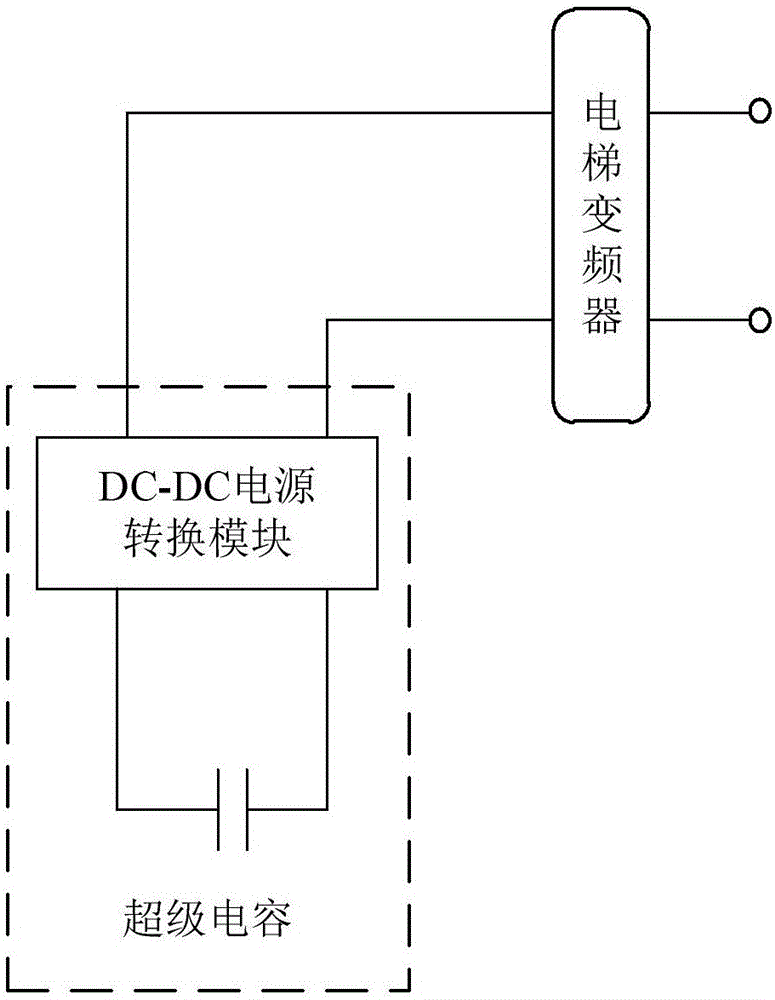

Energy-saving device for elevator

PendingCN106505710AEffective power savingBatteries circuit arrangementsElectric powerCapacitanceFrequency changer

The invention discloses an energy-saving device for an elevator. The energy-saving device comprises an elevator frequency converter connected to a power supply, a control unit, and a super capacitor connected in parallel to the elevator frequency converter. The control unit connected to the super capacitor is used for realizing conduction with a connection branch circuit of the super capacitor when a car of an elevator moves downwardly relative to a counter weight, thereby charging the super capacitor. When the car of the elevator moves upwardly relative to the counter weight, the control unit controls the super capacitor carries out discharging to realize upward operation of the car; when the super capacitor completes the discharging, the control unit is connected to the elevator frequency converter to provide power for the car operation. The super capacitor includes a DC-DC power conversion module connected in parallel to the elevator frequency converter and a capacitor connected to the DC-DC power conversion module. Using the energy-saving device, the 30 to 40% of power can be saved on the condition of maintaining normal operation of the elevator.

Owner:天津市升阳电子科技有限公司

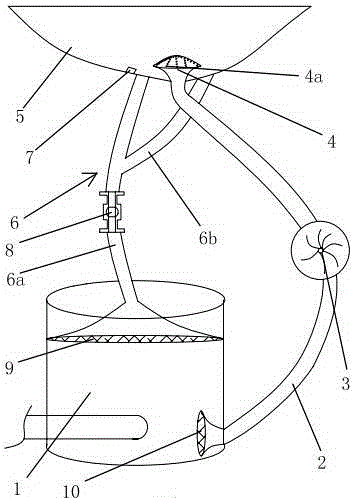

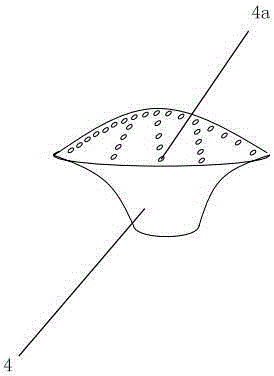

Fountain type chilled water storage system for large place

InactiveCN105157132AEffective power savingSpectacular viewing anglesMechanical apparatusSpace heating and ventilation safety systemsInsulation layerThermocline

The invention provides a fountain type chilled water storage system for a large place and belongs to the field of energy storage. The chilled water storage system comprises a cylindrical cold energy storage tank. A heat insulation layer wraps the outer wall of the cold energy storage tank. The cold energy storage tank is internally provided with a refrigerating pipe. The interior of the cold energy storage tank is divided into a hot water layer, a thermocline layer and a cold water layer from top to bottom according to water temperatures. The cold water layer is communicated with a water outlet pipe. The water outlet pipe is provided with a water pump. The inner end of the water outlet pipe is communicated with the cold energy storage tank. The outer end of the water outlet pipe is connected with a conical spray head. The spray head is provided with a plurality of spray holes. The chilled water storage system further comprises a spray pond. The bottom of the spray pond is in a circular arc shape. The cold energy storage tank is located underground. The spray pond is located on the ground. The spray head extends out of the bottom of the spray pond. The hot water layer is communicated with a water inlet pipe. The inner end of the water inlet pipe is communicated with the cold energy storage tank. The outer end of the water inlet pipe is communicated with the bottom of the spray pond. The bottom wall of the spray pond is provided with a pressure sensor. The water inlet pipe is provided with a solenoid valve. The pressure sensor controls the solenoid valve. The chilled water storage system is attractive in appearance and high in refrigerating efficiency in the using process.

Owner:许文辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com