Nonaqueous ink

A non-aqueous, solvent-based technology, applied in the direction of ink, printing, copying/marking methods, etc., can solve problems such as high viscosity and increased power consumption, and achieve the effect of suppressing power consumption and suppressing deformation of attached or transparent folders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

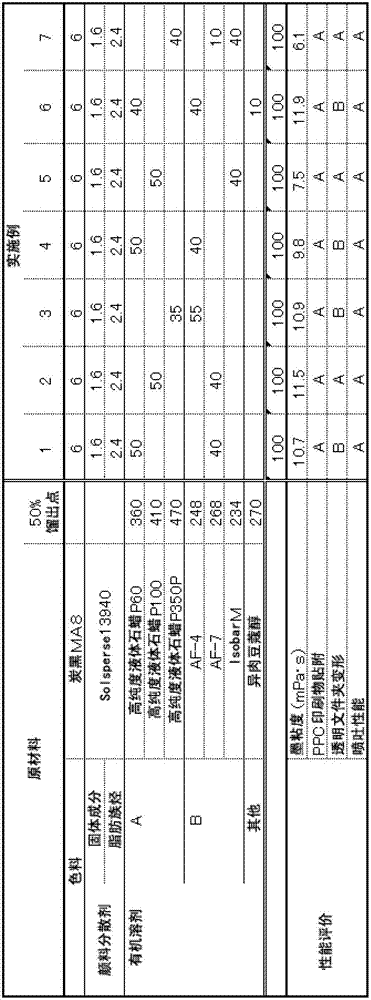

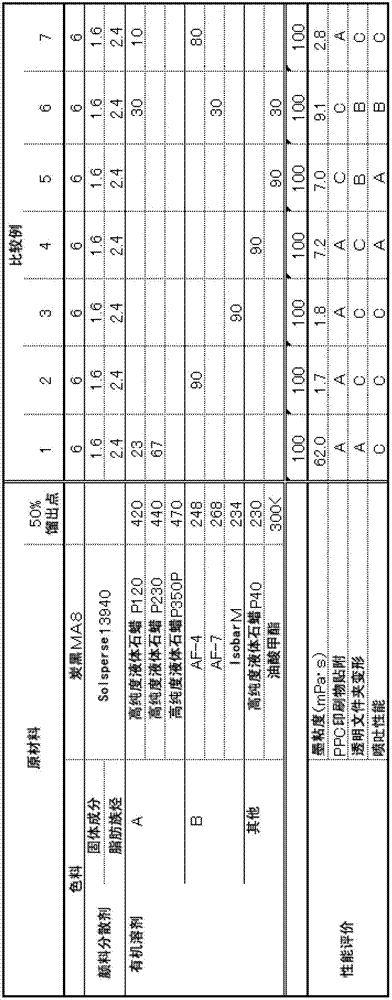

[0058] After the raw materials were premixed in the formulations shown in Table 1 and Table 2, they were stirred at a frequency of 60 Hz for 120 minutes with a rocking mill base (manufactured by Seiwa Technology). After stirring, the nonaqueous inks of Examples 1 to 7 and Comparative Examples 1 to 7 were obtained by filtration using a filter membrane with a pore size of 3 μm.

[0059] The acquisition units of raw materials are as follows.

[0060] Carbon black MA8 (color material): manufactured by Mitsubishi Chemical Corporation

[0061] Solsperse 13940 (pigment dispersant): manufactured by Lubrizol

[0062] High-purity liquid paraffin P60 (n-alkane solvent): manufactured by Matsumura Oil Co., Ltd.

[0063] High-purity liquid paraffin P100 (normal paraffin solvent): Matsumura Oil Co., Ltd.

[0064] High-purity liquid paraffin P120 (n-alkane solvent): manufactured by Matsumura Oil Co., Ltd.

[0065] High-purity liquid paraffin P230 (n-alkane solvent): manufactured by Matsum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com