Submerged arc welding flux material for X80 pipeline steel and preparing method thereof

A pipeline steel and flux technology, applied in arc welding equipment, welding/cutting medium/material, welding equipment, etc., can solve the problem of low strength, and achieve the effect of good low temperature toughness, easy access and high weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

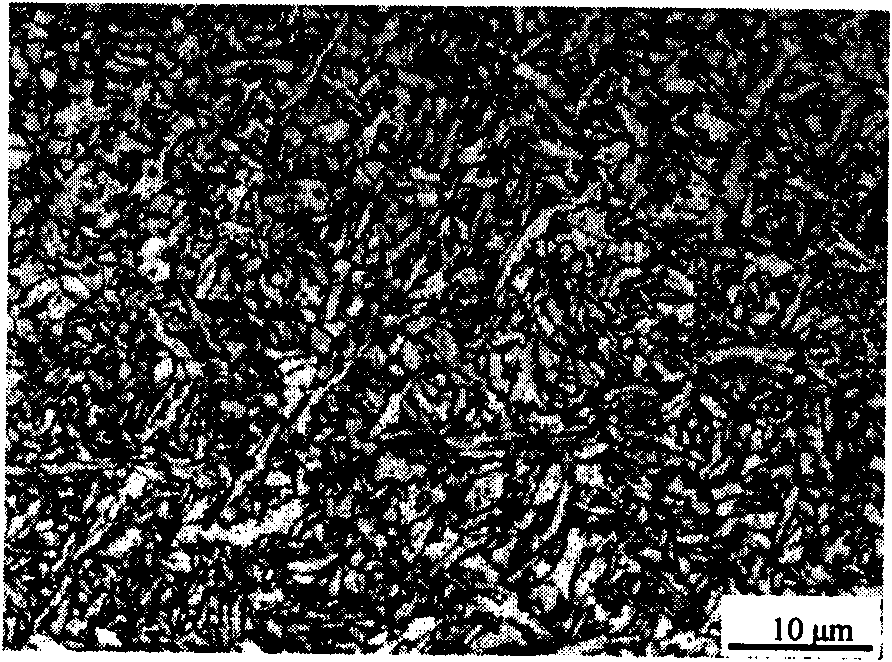

Image

Examples

Embodiment 1

[0041] Take 20.0% CaF by weight 2 , 24.0% MgO, 13.0% Al 2 o 3 , 7.0% CaSiO 3 , 8.0% MnO, 8.0% TiO 2 , 6.0% SiO 2 , 1% Na 2 O, 1.9% B 2 o 3 , 0.2% Re(Mg), 7.3% ZrO 2 , the others are ore powder impurities. It is sintered by conventional electric furnace sintering method, the sintering temperature is 800°C, and the sintering time is 2 hours.

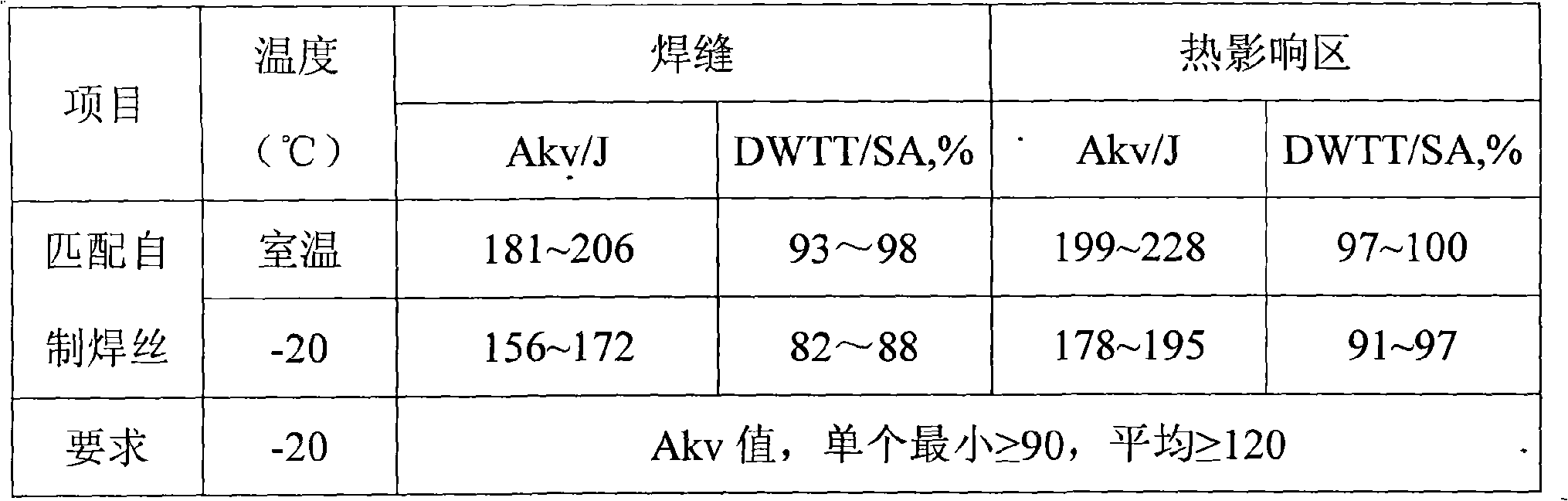

[0042] The flux is matched with self-made H05MnNiMo welding wire ("Submerged Arc Welding Wire Material for High Grade Pipeline Steel", Patent No. ZL 200410073353.0, Publication No. CN1285444C) to weld 15mm thick X80 grade pipeline steel. The chemical composition of the steel mainly contains 0.06% C, 1.57% Mn, 0.24% Si, 0.29% Mo, 0.14% Ni, 0.045% Cu, 0.04% Nb, 0.013% Ti, 0.0006% B, 0.01% V, 0.005% S, 0.033% P. The welding process is an asymmetrical X-shaped groove, one weld on the front and back sides, and root cleaning on the back side. The welding process parameters are welding current 600A on the first side, 700A on the second...

Embodiment 2

[0049] Take 23.0% CaF by weight 2 , 28.0% MgO, 11.0% Al 2 o 3 , 6.0% CaSiO 3 , 5.0% MnO, 6.0% TiO 2 , 7.0% SiO 2 , 2.0% Na 2 O, 1.5% B 2 o 3 , 0.4% Re(Mg), 8.1% ZrO 2 , the others are ore powder impurities. It is sintered by conventional electric furnace sintering method, the sintering temperature is 900°C, and the sintering time is 3 hours.

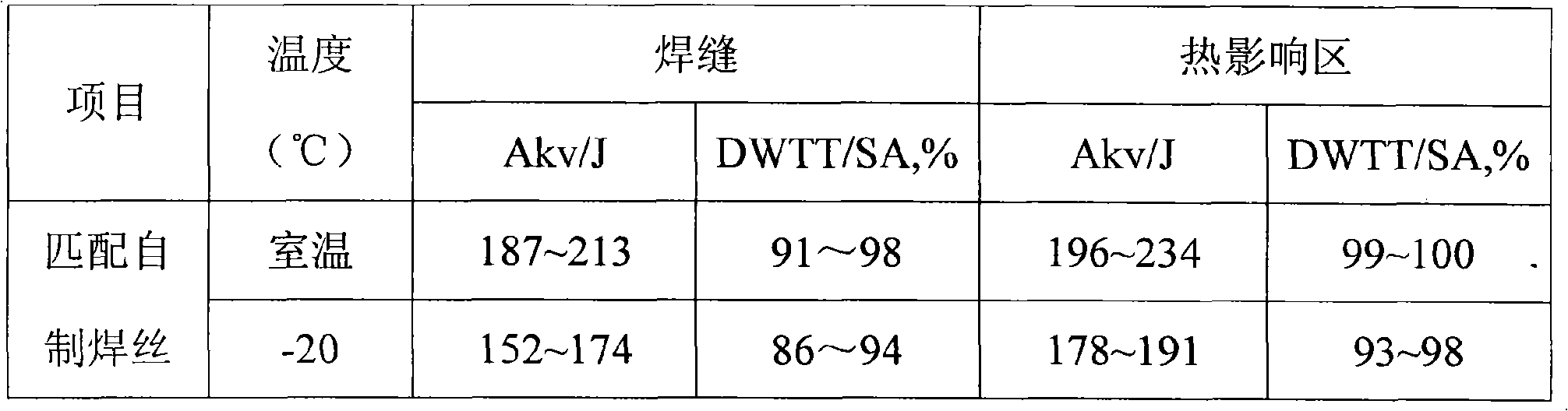

[0050] The flux is matched with H05MnNiMo welding wire ("Submerged Arc Welding Wire Material for High Grade Pipeline Steel", Patent No. ZL 200410073353.0, Publication No. CN1285444C) to weld 15mm thick X80 grade pipeline steel. The chemical composition and welding process of the steel are the same as in Example 1. The welded joints are tested according to API 5L standard, and the cold bending performance is qualified. The tensile and hardness test results are shown in Table 3, and the impact test results are shown in Table 4.

[0051] Table 3 Tensile and hardness tests of welded joints of grade X80 pipeline steel

[0052] ...

Embodiment 3

[0056] Take 25.0% CaF by weight 2 , 15.0% MgO, 14.0% Al 2 o 3 , 6.0% CaSiO 3 , 8.0% MnO, 10.0% TiO 2 , 9.0% SiO 2 , 2.5% Na 2 O, 2.0% B 2 o 3 , 0.3% Re(Mg), 6.0% ZrO 2 , the others are ore powder impurities. It is sintered by conventional electric furnace sintering method, the sintering temperature is 800°C, and the sintering time is 4 hours.

[0057] The flux is matched with H05MnNiMo welding wire ("Submerged Arc Welding Wire Material for High Grade Pipeline Steel", Patent No. ZL 200410073353.0, Publication No. CN1285444C) to weld 15mm thick X80 grade pipeline steel. The chemical composition and welding process of the steel are the same as in Example 1. The welded joints are tested according to API 5L standard, and the cold bending performance is qualified. The tensile and hardness test results are shown in Table 5, and the impact test results are shown in Table 6.

[0058] Table 5 Tensile and hardness tests of welded joints of grade X80 pipeline steel

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com