Electrode for welding high-strength and high-toughness steel and preparation and application thereof

A high-toughness steel, high-strength technology, applied in the field of high-strength high-toughness steel welding electrodes, can solve problems such as difficult to achieve, low-temperature impact toughness, etc., to achieve increased strength, improved low-temperature impact toughness, good strength and low-temperature impact The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The weight percent of each component in the low-alloy steel used in welding core in the present embodiment is:

[0027] C: 0.03%, Si: 0.08%, Mn: 0.60%, Ni: 4.0%, S: 0.008%, P: 0.010%, Ti: 0.05%, and the rest is iron.

[0028] The percentage by weight of each component in the drug skin is:

[0029] 40% marble, 20% fluorite, 5% silicon powder, 3% rutile, 5% ferrosilicon, 6% ferromanganese, 3% ferromolybdenum, 0.5% ferrosilicon zirconium, 1% rare earth ferrosilicon, 1% soda ash, magnesium Powder 4%, titanium iron 4%, iron powder 7.5%.

[0030] Prepare welding rods as follows:

[0031] 1) Weigh and mix the components of the drug skin according to the above ratio;

[0032] 2) the mixed component of step 1) gained is bonded with potassium sodium water glass;

[0033] 3) Coating the adhesive obtained in step 2) on a Φ4.0mm welding core to make a Φ6.3mm welding rod.

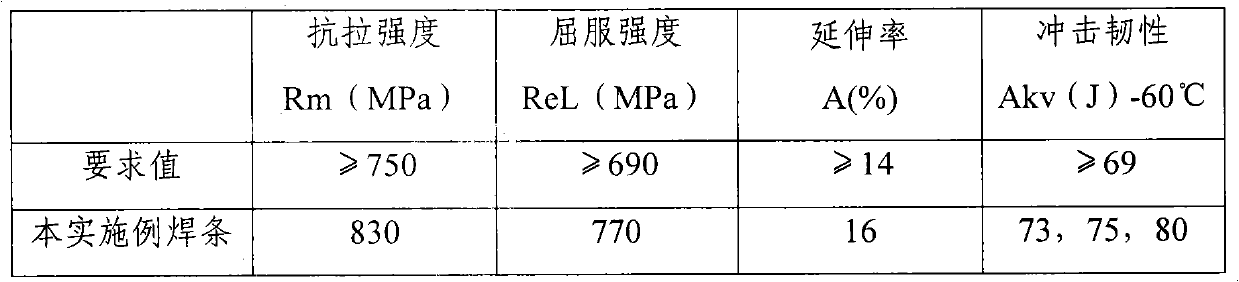

[0034] The welding rod of this embodiment was used to weld the F690 steel plate under the conditions of ro...

Embodiment 2

[0041] The weight percent of each component in the low-alloy steel used in welding core in the present embodiment is:

[0042] C: 0.03%, Si: 0.08%, Mn: 0.60%, Ni: 4.0%, S: 0.008%, P: 0.010%, Ti: 0.05%, and the rest is iron.

[0043] The percentage by weight of each component in the drug skin is:

[0044]Marble 42%, Fluorite 20%, Silica Powder 7%, Rutile 2%, Ferrosilicon 8%, Ferromanganese 5%, Ferromolybdenum 4%, Ferrosilicon 0.6%, Rare Earth Ferrosilicon 1.5%, Soda Ash 2%, Magnesium Powder 2%, titanium iron 2%, iron powder 3.9%.

[0045] Prepare welding rods as follows:

[0046] 1) Weigh and mix the components of the drug skin according to the above ratio;

[0047] 2) the mixed component of step 1) gained is bonded with potassium sodium water glass;

[0048] 3) Coating the adhesive obtained in step 2) on a Φ4.0mm welding core to make a Φ6.3mm welding rod.

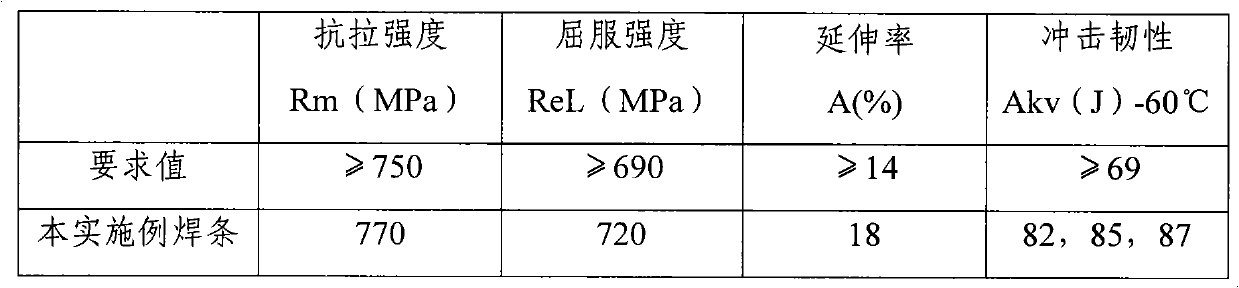

[0049] The welding rod of this embodiment is used to weld the F690 steel plate under the conditions of room temperat...

Embodiment 3

[0056] The weight percent of each component in the low-alloy steel used in welding core in the present embodiment is:

[0057] C: 0.03%, Si: 0.08%, Mn: 0.60%, Ni: 4.0%, S: 0.008%, P: 0.010%, Ti: 0.05%, and the rest is iron.

[0058] The percentage by weight of each component in the drug skin is:

[0059] Marble 45%, Fluorite 20%, Silica Powder 6%, Rutile 3%, Ferrosilicon 6%, Ferromanganese 5%, Ferromolybdenum 3%, Ferrosilicon Zirconium 0.8%, Rare Earth Ferrosilicon 1.4%, Soda Ash 1%, Magnesium Powder 3%, titanium iron 3%, iron powder 2.8%.

[0060] Prepare welding rods as follows:

[0061] 1) Weigh and mix the components of the drug skin according to the above ratio;

[0062] 2) the mixed component of step 1) gained is bonded with potassium sodium water glass;

[0063] 3) Coating the adhesive obtained in step 2) on a Φ4.0mm welding core to make a Φ6.3mm welding rod.

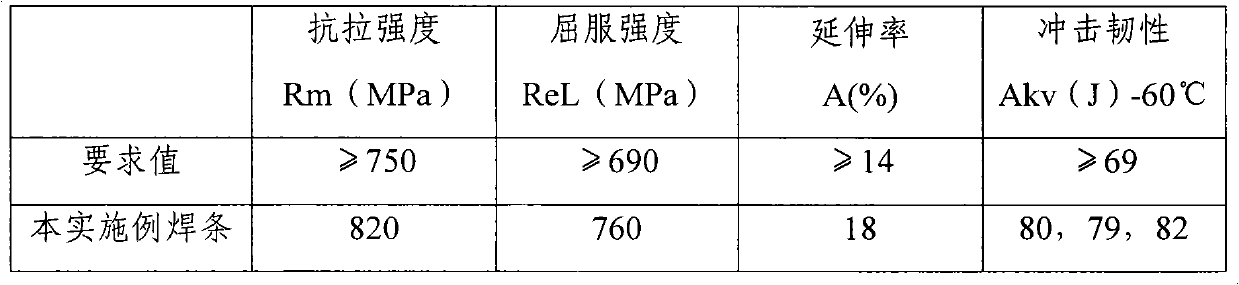

[0064] The welding rod of this embodiment is used to weld the F690 steel plate under the conditions of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com