Butt-joint manual welding method for high-strength bridge steel with thickness of 80 mm

A manual welding, high-strength technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of construction environment, manufacturing cost and manufacturing cycle difficulties, unable to meet the technical requirements of construction, etc., to achieve high impact toughness reserve and The effect of safety margin, excellent low temperature performance and crack resistance, excellent low temperature impact toughness and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

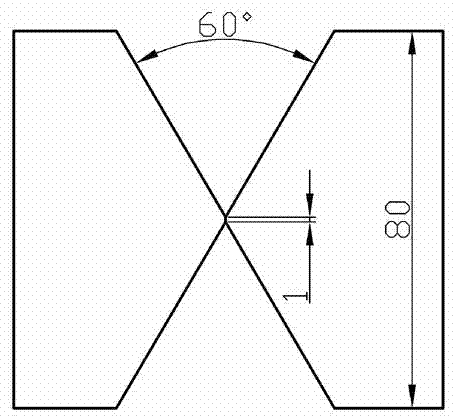

[0025] Base material: the tensile strength is R m 600MPa, yield strength R eL 500MPa, elongation: A is 25%, impact energy -40 o CKV 2 Butt welding of equal-thickness bridge steel of 223J and thickness of 80 mm; the matching welding wire tensile strength is greater than 600 MPa, and the diameter of the welding rod is Ф4.0mm; Type double-sided symmetrical bevel, the bevel angle is 60°, and the blunt edge is 2mm;

[0026] Welding material matching: the chemical composition and weight percentage of the electrodes used are C 0.040~0.060, Si 0.25~0.40, Mn 1.20~1.50, Ni 1.2~1.50, Mo 0.20~0.30 P 0.008~0.012, S 0.003~0.005; Prepared for iron and unavoidable impurities; the mechanical properties of the deposited metal of the electrode are R el : 540MPa, R m : 650 MPa, elongation A: 28%, impact energy -40℃KV 2 : 150J;

[0027] Welding process: Welding current 165A, welding voltage 24V, welding speed 15cm / min, welding line energy 16kJ / cm, manual welding butt joints adopt multi-laye...

Embodiment 2

[0030] Base material: the tensile strength is R m 605MPa, yield strength R eL 505MPa, elongation: A is 23%, impact energy -40 o CKV 2 Butt welding of equal-thickness bridge steel of 233J and thickness of 80 mm; the matching welding wire tensile strength is greater than 600 MPa, and the diameter of the welding rod is Ф4.0mm; Type double-sided symmetrical bevel, the bevel angle is 60°, and the blunt edge is 2mm;

[0031]Welding material matching: the chemical composition and weight percentage of the electrodes used are C 0.040~0.060, Si 0.25~0.40, Mn 1.20~1.50, Ni 1.2~1.50, Mo 0.20~0.30 P 0.008~0.012, S 0.003~0.005; Prepared for iron and unavoidable impurities; the mechanical properties of the deposited metal of the electrode are R el : 540MPa, R m : 650 MPa, elongation A: 28%, impact energy -40℃KV 2 : 150J;

[0032] Welding process: Welding current 170A, welding voltage 25V, welding speed 15cm / min, welding line energy 17kJ / cm, manual welding butt joints adopt multi-layer...

Embodiment 3

[0035] Base material: the tensile strength is R m 595MPa, yield strength R eL is 490MPa, elongation: A is 24%, impact energy -40 o CKV 2 Butt welding of equal-thickness bridge steel of 219J and thickness of 80 mm; the matching welding wire tensile strength is greater than 600 MPa, and the diameter of the welding rod is Ф4.0mm; Type double-sided symmetrical bevel, the bevel angle is 60°, and the blunt edge is 2mm;

[0036] Welding material matching: the chemical composition and weight percentage of the electrodes used are C 0.040~0.060, Si 0.25~0.40, Mn 1.20~1.50, Ni 1.2~1.50, Mo 0.20~0.30 P 0.008~0.012, S 0.003~0.005; Prepared for iron and unavoidable impurities; the mechanical properties of the deposited metal of the electrode are R el : 540MPa, R m : 650 MPa, elongation A: 28%, impact energy -40℃KV 2 : 150J;

[0037] Welding process: Welding current 165A, welding voltage 24V, welding speed 14cm / min, welding line energy 17kJ / cm, manual welding butt joints adopt multi-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com