Method for recleaning of vanadium-titanium magnetite concentrate by using alkaline leaching, grading and magnetic separation

A technology of vanadium-titanium magnetite concentrate and magnetic separation, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc., to achieve the effects of improving the utilization factor of blast furnaces, reducing emissions, and reducing ironmaking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

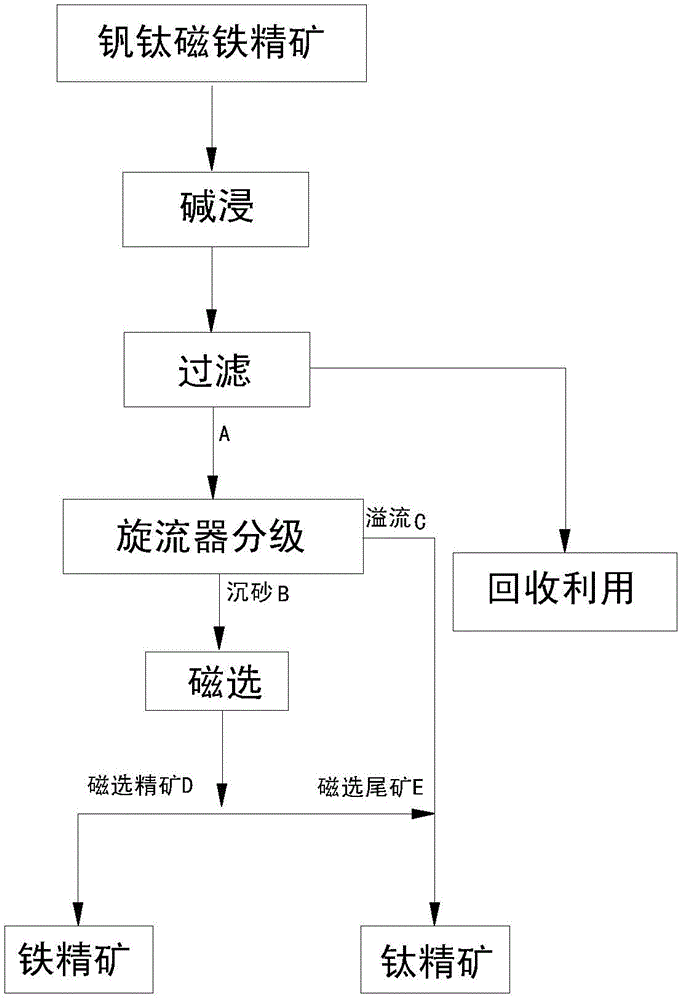

[0036] Such as figure 1 shown.

[0037] 1) Alkaline leaching

[0038] The TFe content is 50.3%, TiO 2 content of 14.9%, SiO 2 The content is 4.95%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.98% and a S content of 0.82% is placed in a NaOH alkali solution with a mass concentration of 25%, and is subjected to alkali leaching reaction at a temperature of 360° C. for 3 hours, and the reactant is filtered to obtain a filtrate and Alkali leaching filter cake A, NaOH consumption 83kg / t is fed to ore, and described filtrate is fed into recovery treatment system, and its chemical reaction formula is:

[0039]

[0040] 2) Grading

[0041] Add water to the alkali leaching filter cake A in step 1) to form an ore slurry with a mass concentration of 20% and feed it into a cyclone for classification, and classify the grit B and overflow C.

[0042] 3) Magnetic separation

[0043] The grit B in the step 2) is added with water to make a mass concentrat...

Embodiment 2

[0045] Such as figure 1 shown.

[0046] 1) Alkaline leaching

[0047] The TFe content is 51.6%, TiO 2 content of 13.7%, SiO 2 The content is 4.88%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.96% and a S content of 0.78% is placed in a NaOH alkali solution with a mass concentration of 15%, and is subjected to alkali leaching reaction at a temperature of 310° C. for 2 hours, and the reactant is filtered to obtain a filtrate and Alkali leaching filter cake A, NaOH consumption 80kg / t is fed to ore, and described filtrate is fed into recovery treatment system, and its chemical reaction formula is the same as embodiment 1.

[0048] 2) Grading

[0049] Add water to the alkali leaching filter cake A in step 1) to form an ore slurry with a mass concentration of 21% and feed it into a cyclone for classification, and classify the grit B and overflow C.

[0050] 3) Magnetic separation

[0051] The grit B in the step 2) is added with water to make a ma...

Embodiment 3

[0053] Such as figure 1 shown.

[0054] 1) Alkaline leaching

[0055] The TFe content is 50.6%, TiO 2 content of 14.3%, SiO 2 The content is 4.55%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.68% and a S content of 0.72% is placed in a NaOH alkali solution with a mass concentration of 45%, and is subjected to alkali leaching reaction at a temperature of 290° C. for 4 hours, and the reactant is filtered to obtain a filtrate and Alkali leaching filter cake A, NaOH consumption 89kg / t feeds ore, and described filtrate feeds recovery treatment system, and its chemical reaction formula is the same as embodiment 1.

[0056] 2) Grading

[0057] Add water to the alkali leaching filter cake A in step 1) to form an ore slurry with a mass concentration of 22% and feed it into a cyclone for classification, and classify the grit B and overflow C.

[0058] 3) Magnetic separation

[0059] The grit B in step 2) is added with water to make a mass concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com