Patents

Literature

37results about How to "Large difference in specific gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

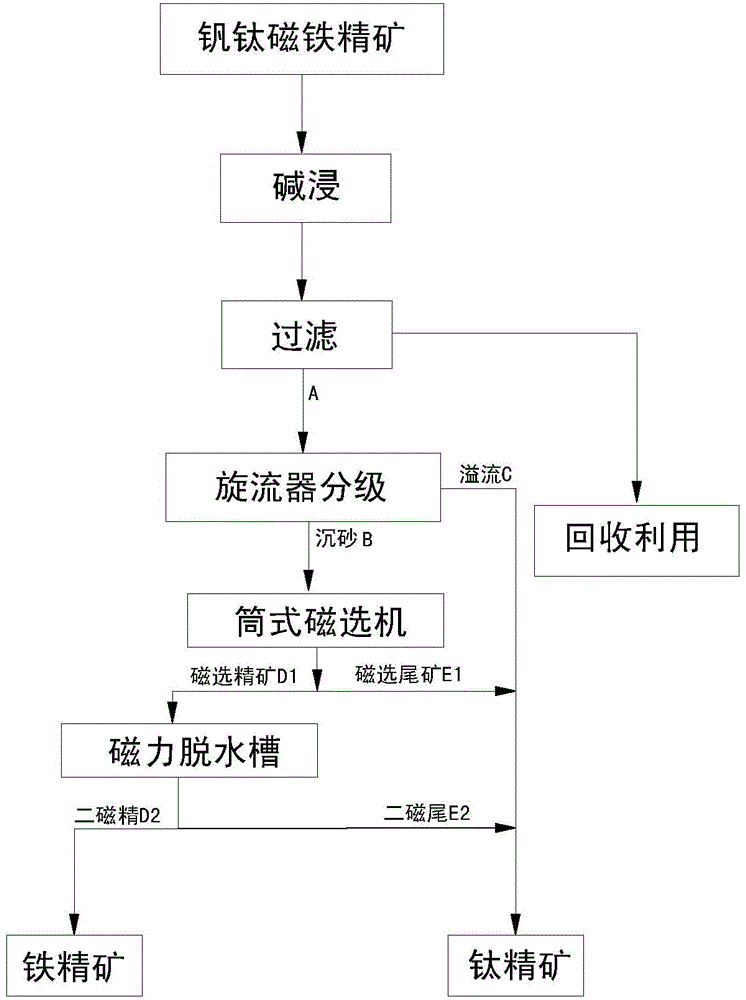

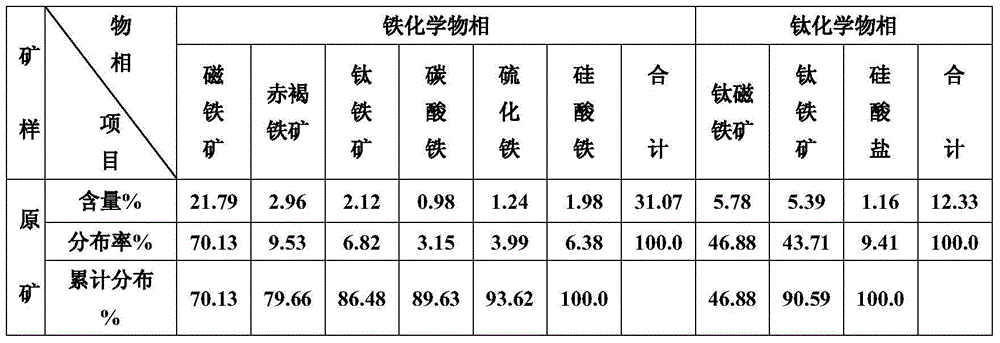

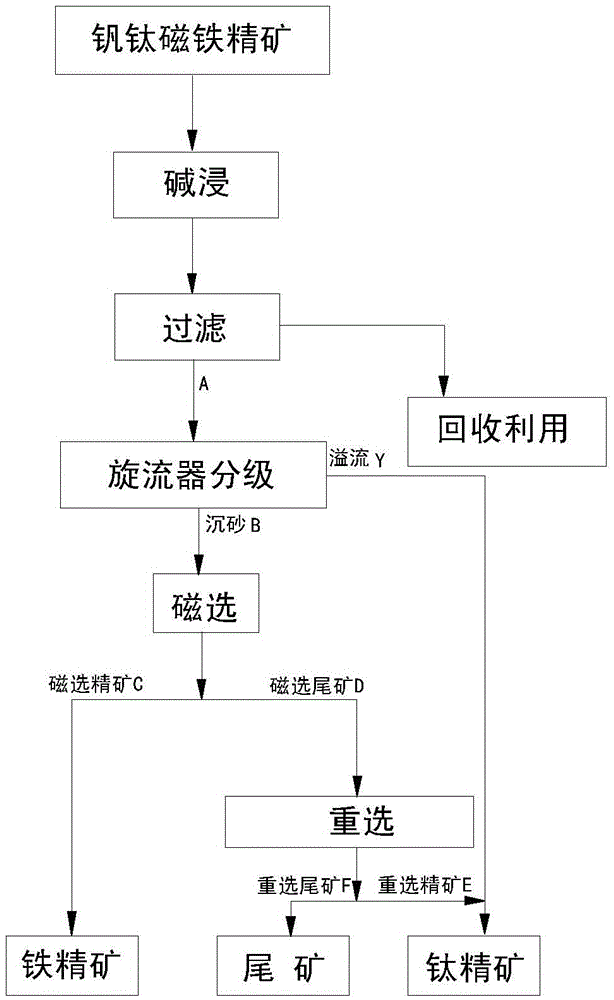

Vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, classification and combined magnetic-gravity separation

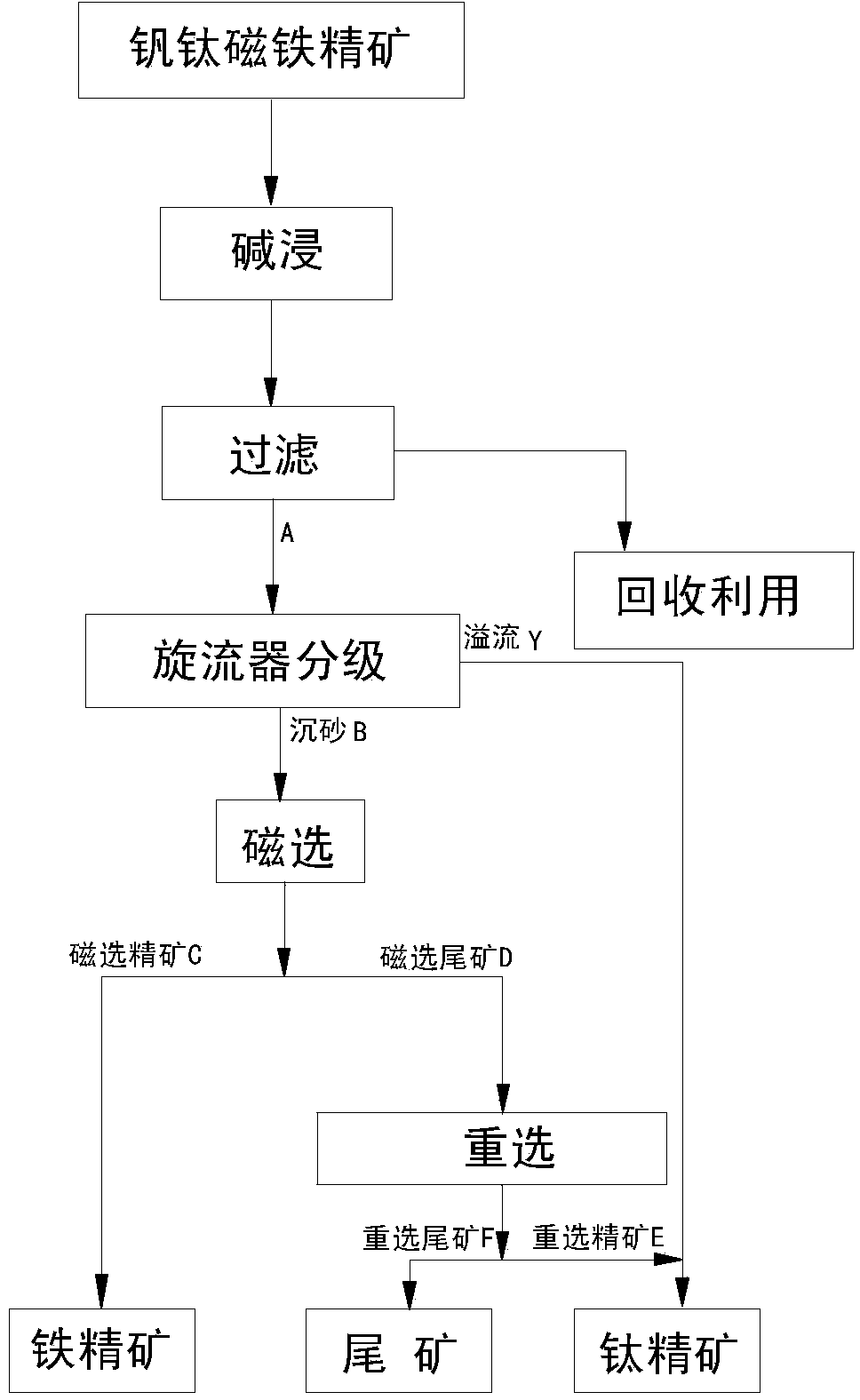

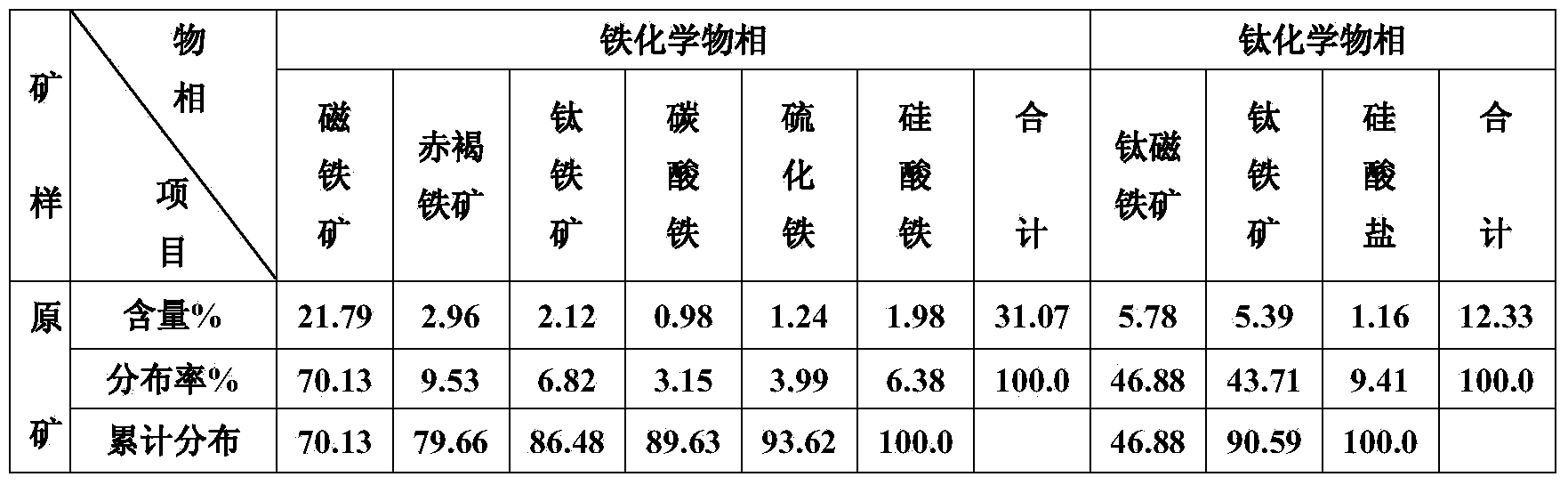

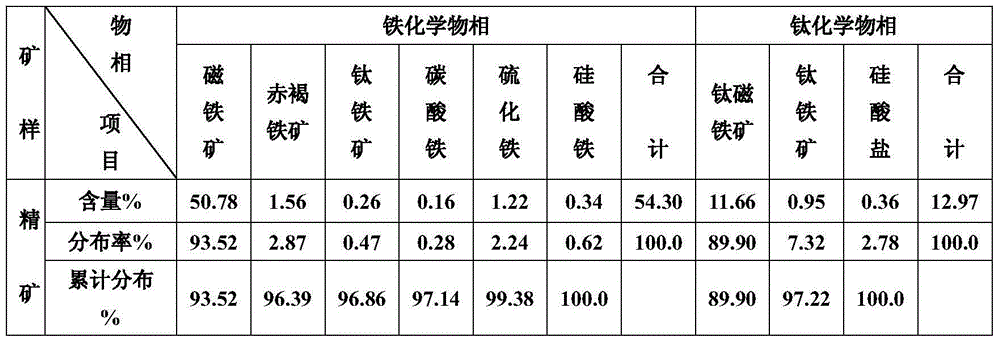

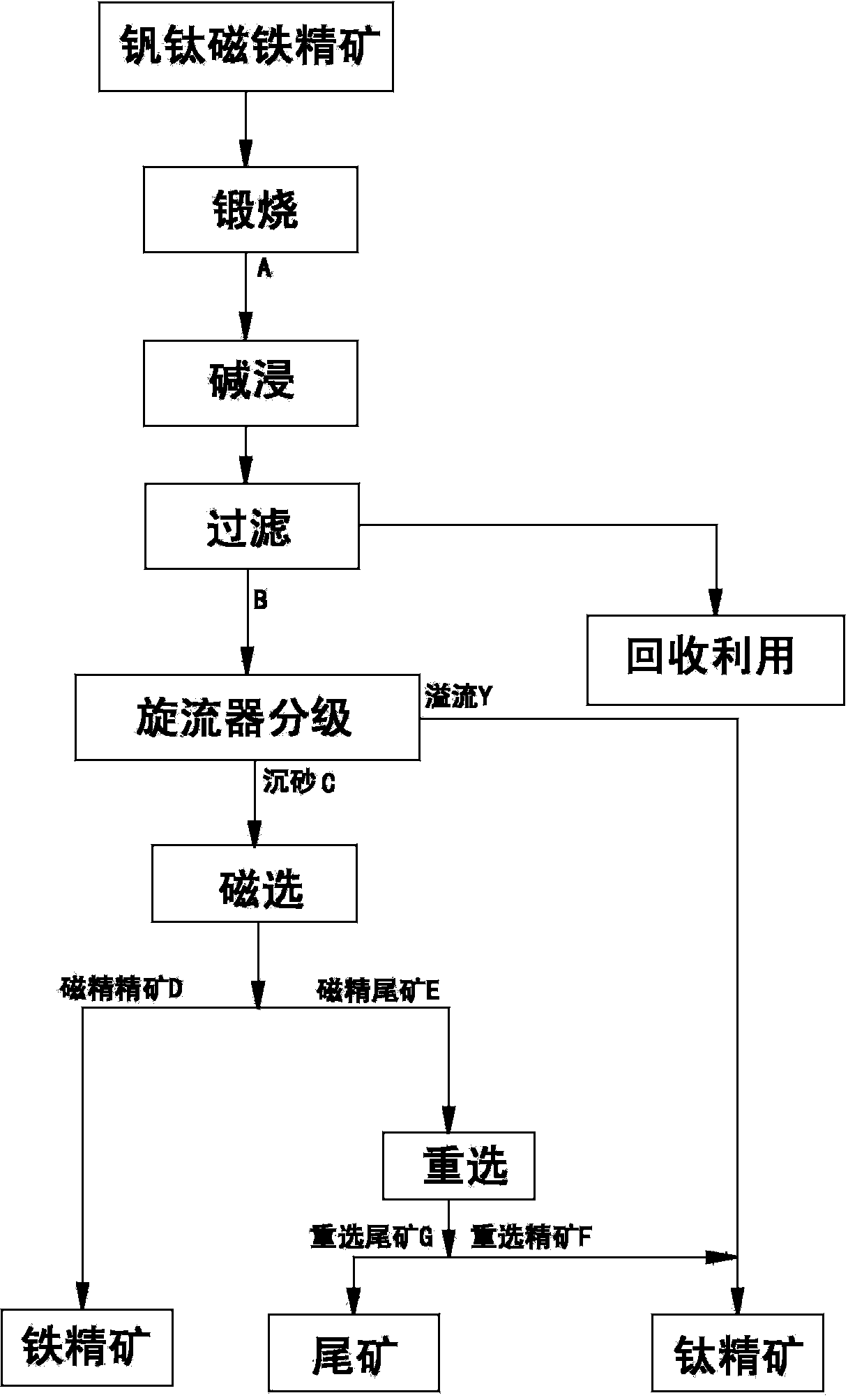

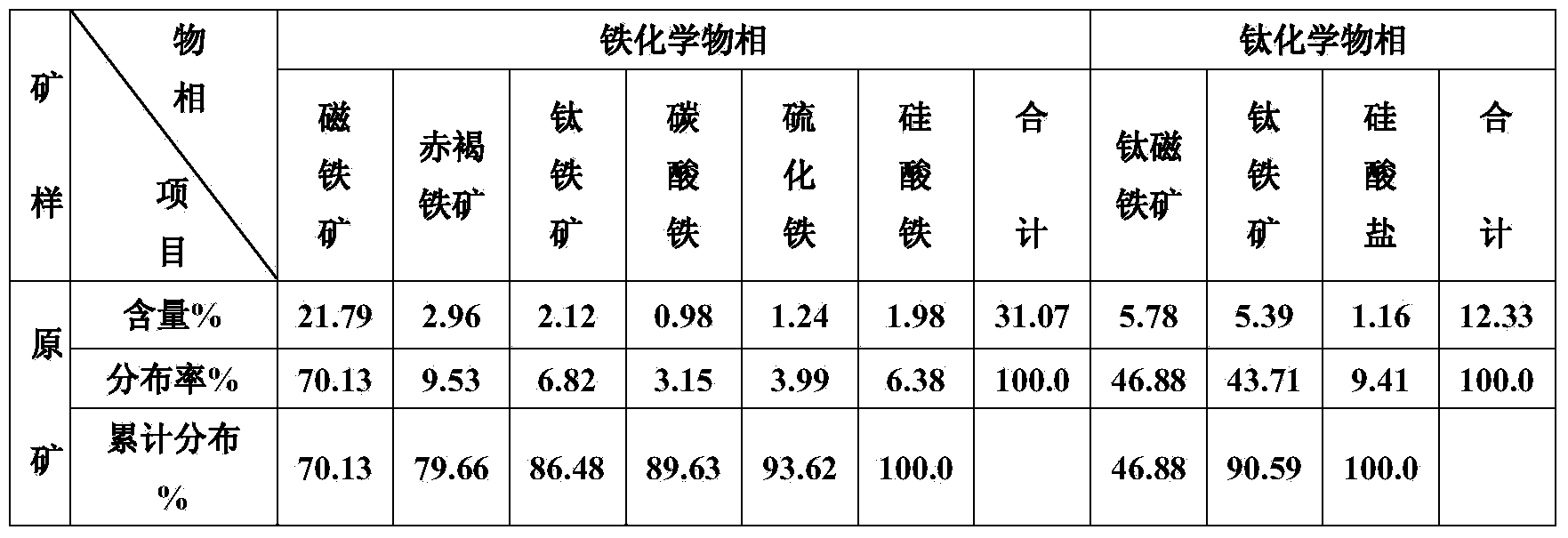

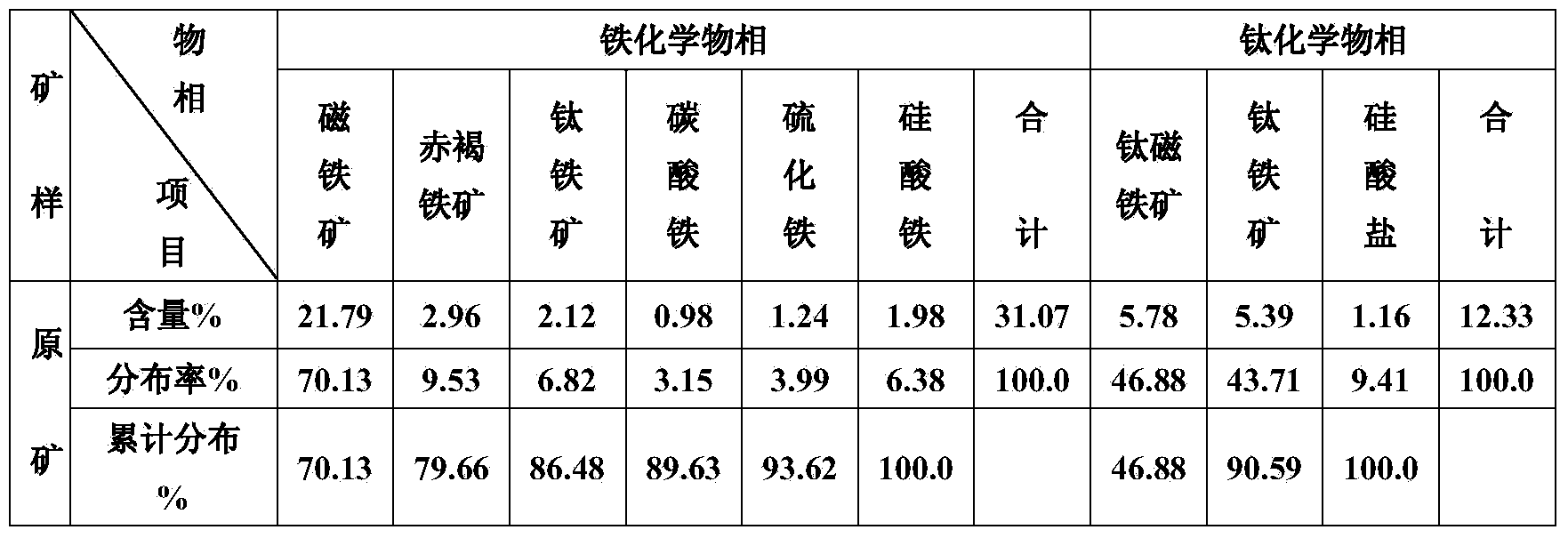

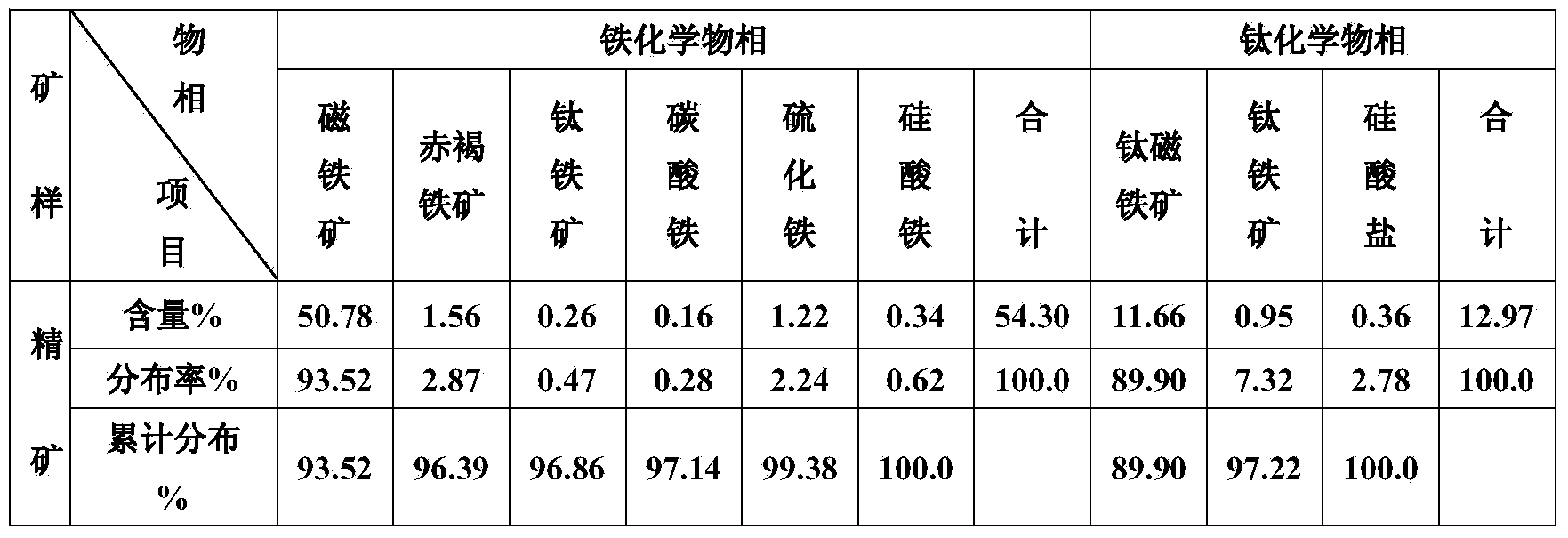

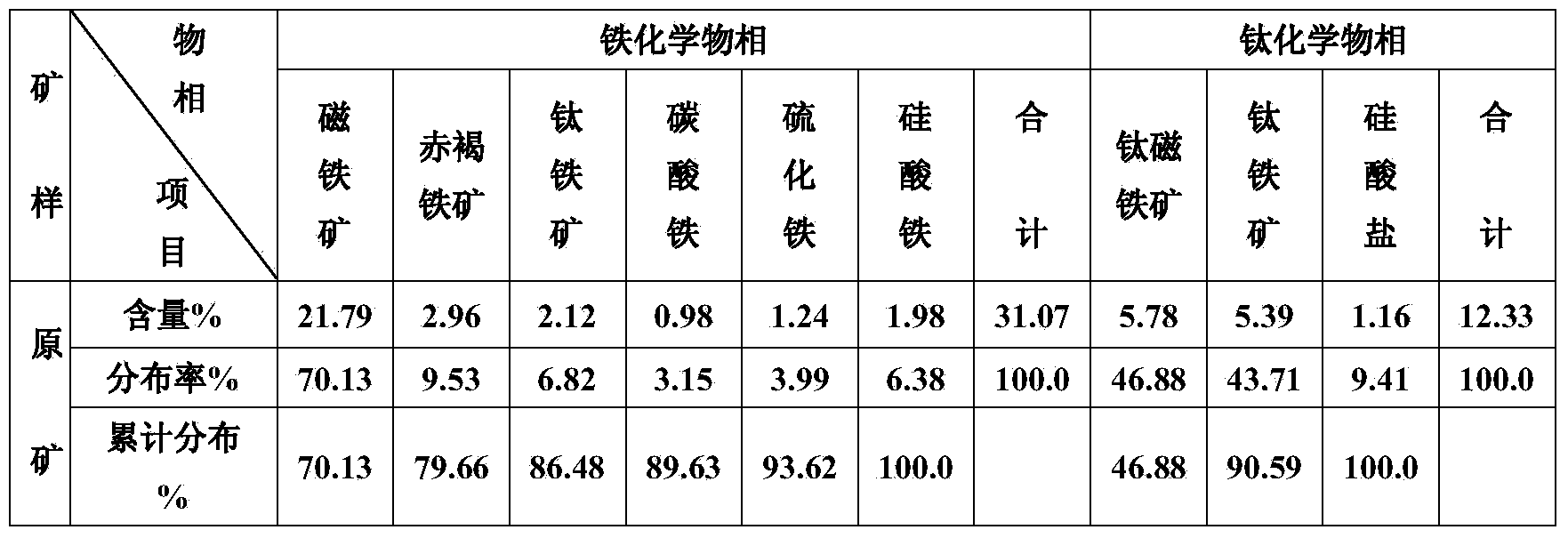

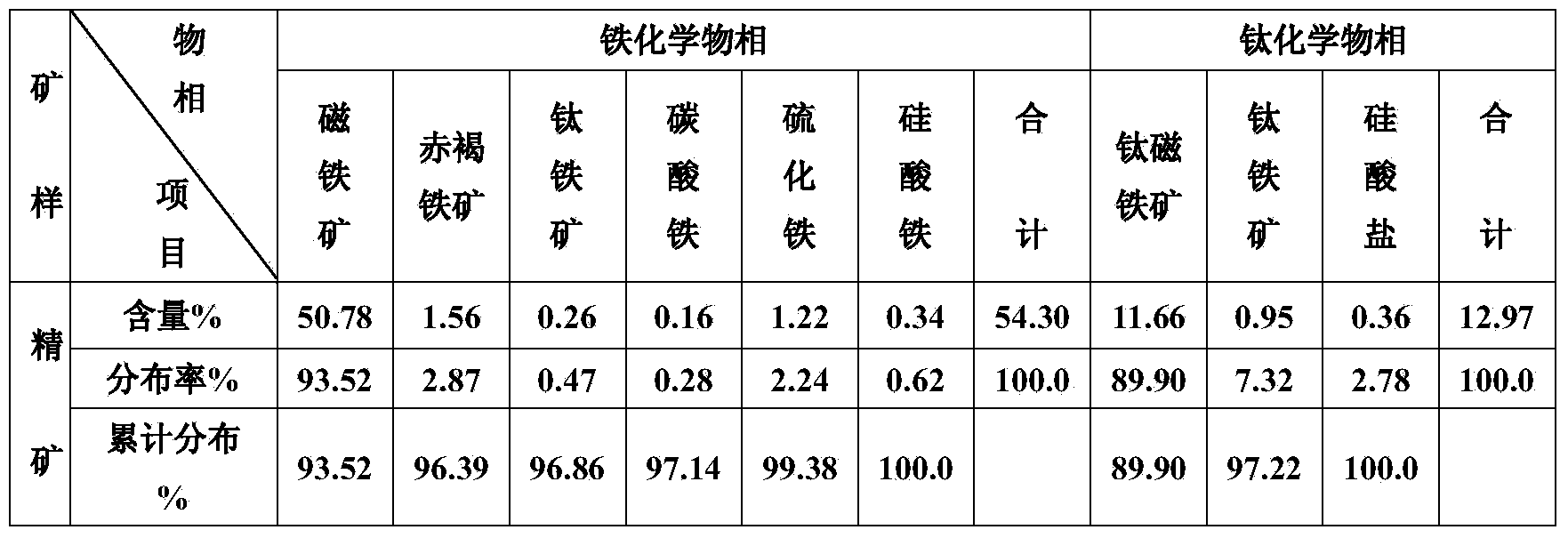

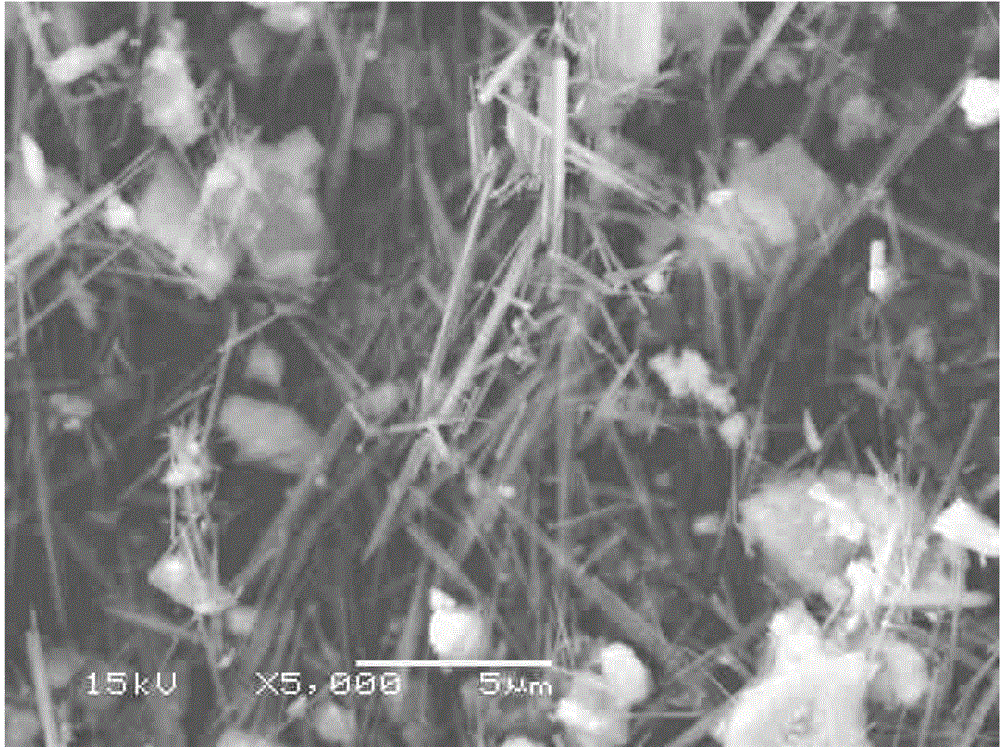

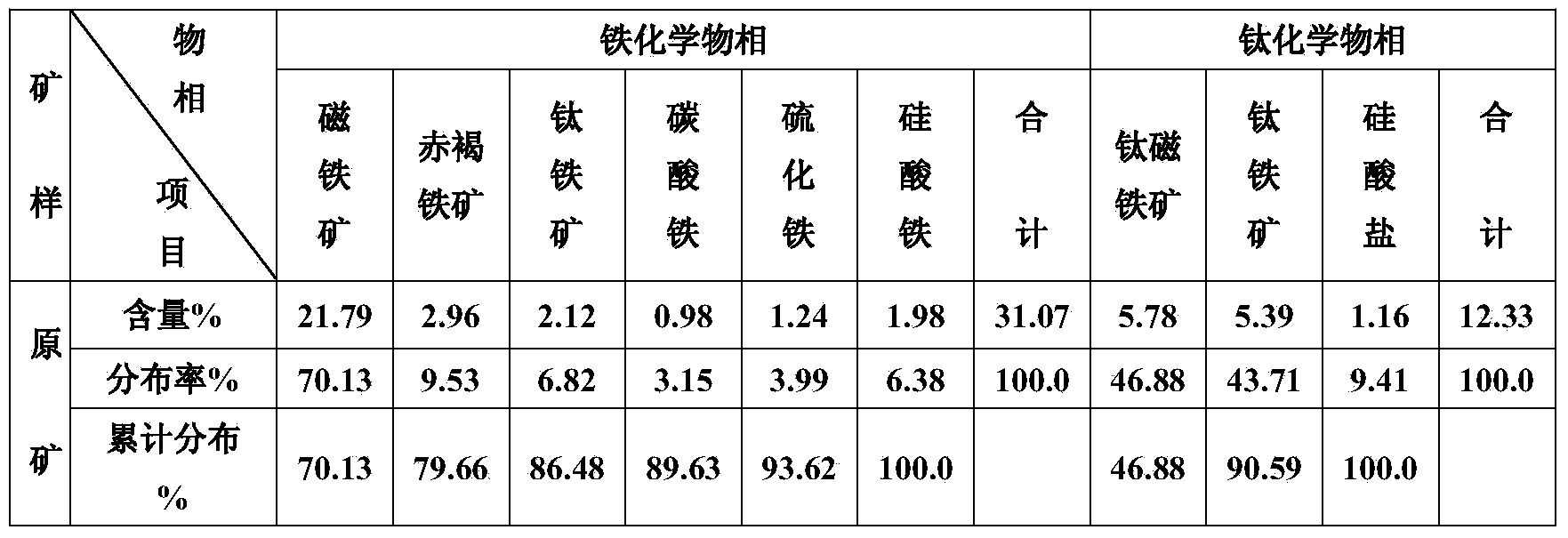

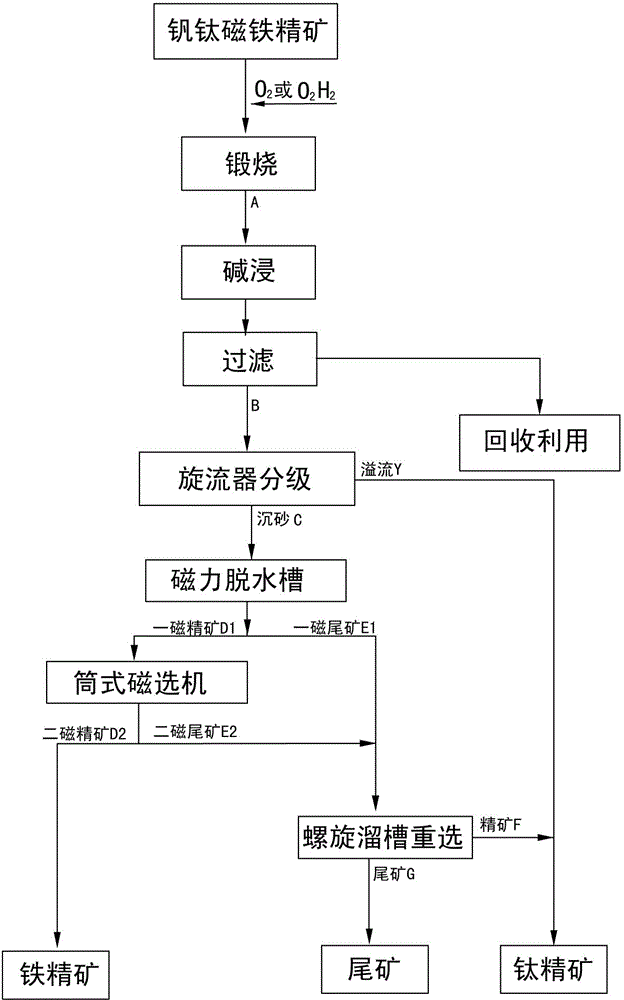

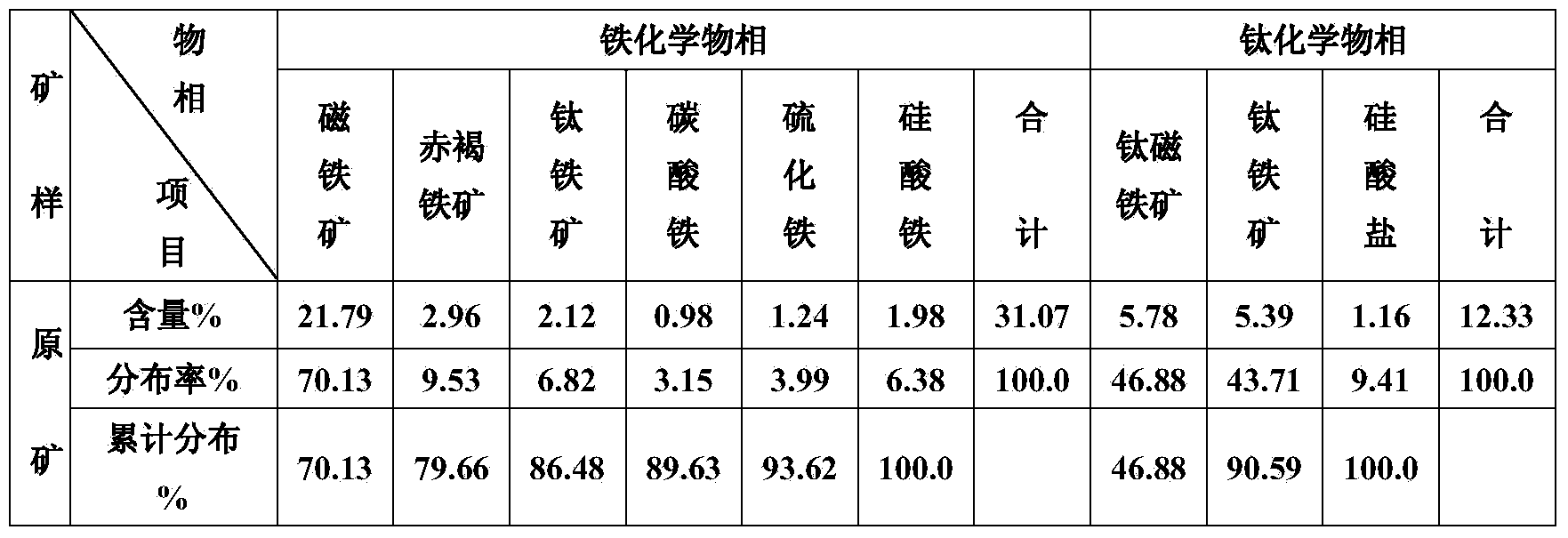

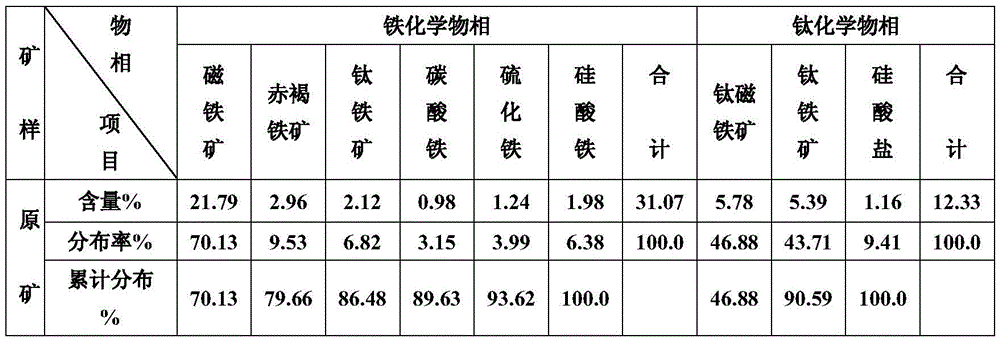

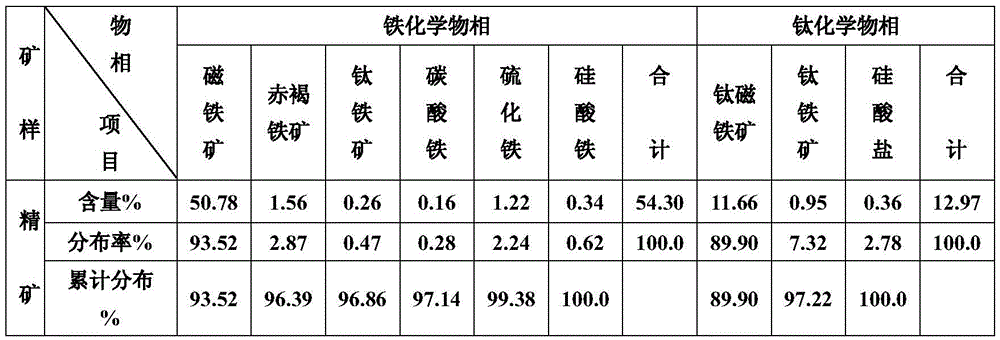

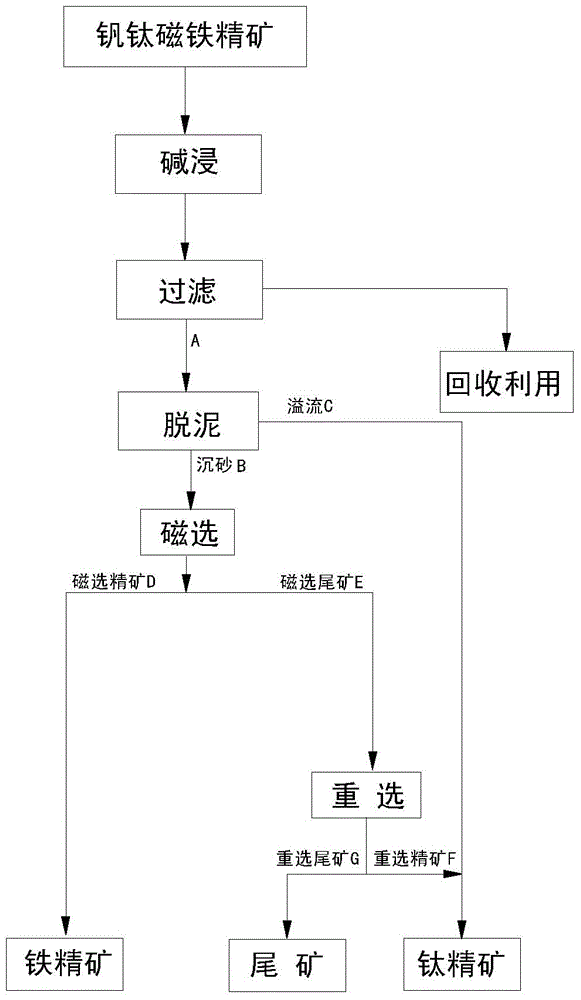

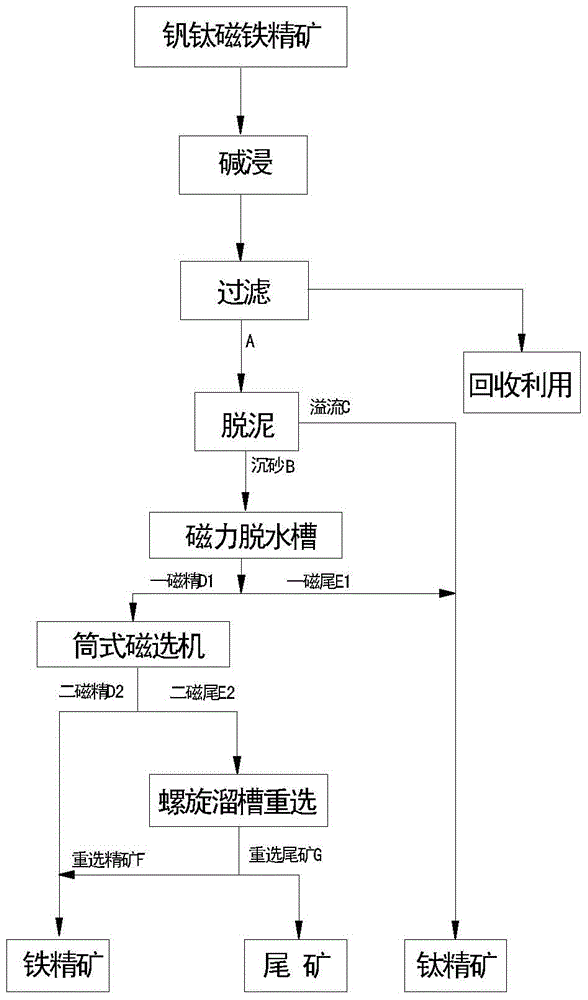

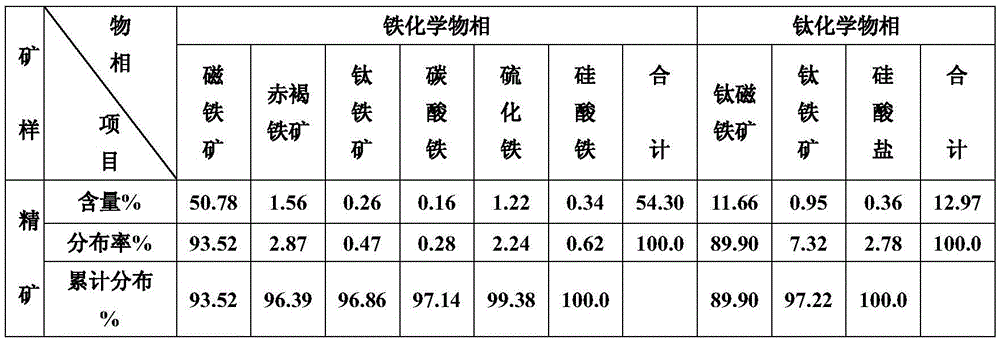

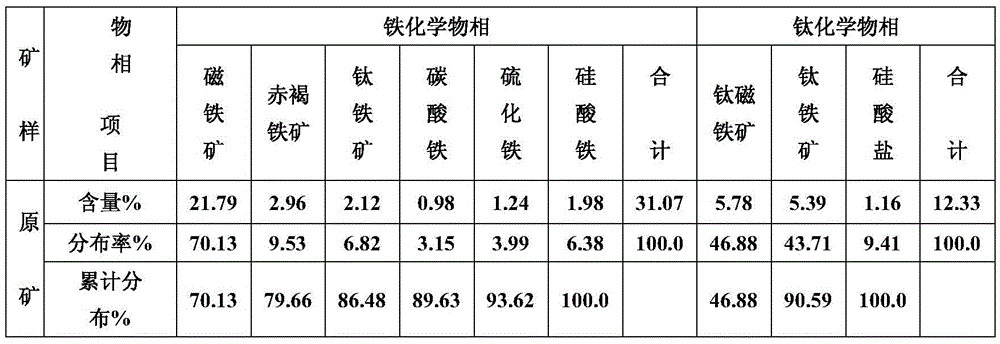

The invention discloses a vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, classification and combined magnetic-gravity separation. The method comprises the steps of placing vanadium-titanium magnetite concentrate in aqueous alkali with a mass concentration of 5%-52% for alkaline leaching reaction at a temperature between 280 DEG C and 370 DEG C for 0.5 h - 5 h and conducting filtering to obtain a filtrate and an alkaline leached filter cake A; adding water into A to form pulp with a mass concentration of 20%-25%, and feeding the pulp into a cyclone for classification to obtain effused flow and set sand B; adding water into the set sand B to obtain pulp with a mass concentration of 30%-41%, and conducting magnetic separation and gravity separation to obtain iron ore concentrate with the TFe content ranging from 63% to 68% and titanium concentrate with the TiO2 content ranging from 50% to 70%. The method has the advantages that efficient sorting of the vanadium-titanium magnetite concentrate is realized, alkali consumption is low, the content of impurities such as Al and Si entering a blast furnace is reduced, the content of detrimental impurities TiO2 and S is reduced especially, the utilization coefficient of the blast furnace is increased, blast furnace slag emission is reduced, iron-making cost is reduced, the problems of high S content and severe pollution in the smelting process are solved, and the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

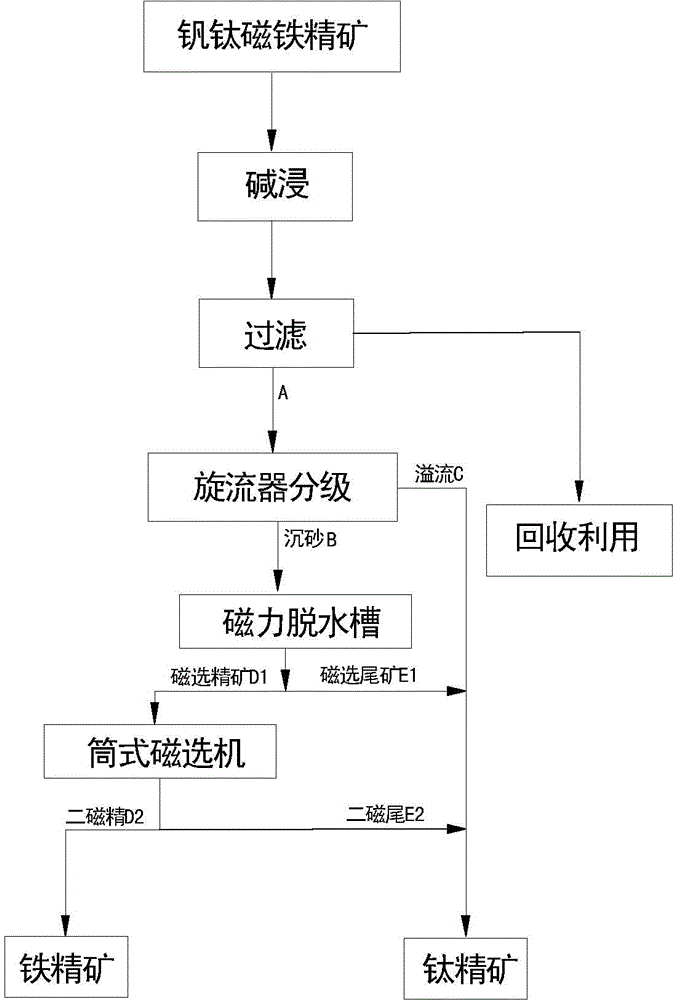

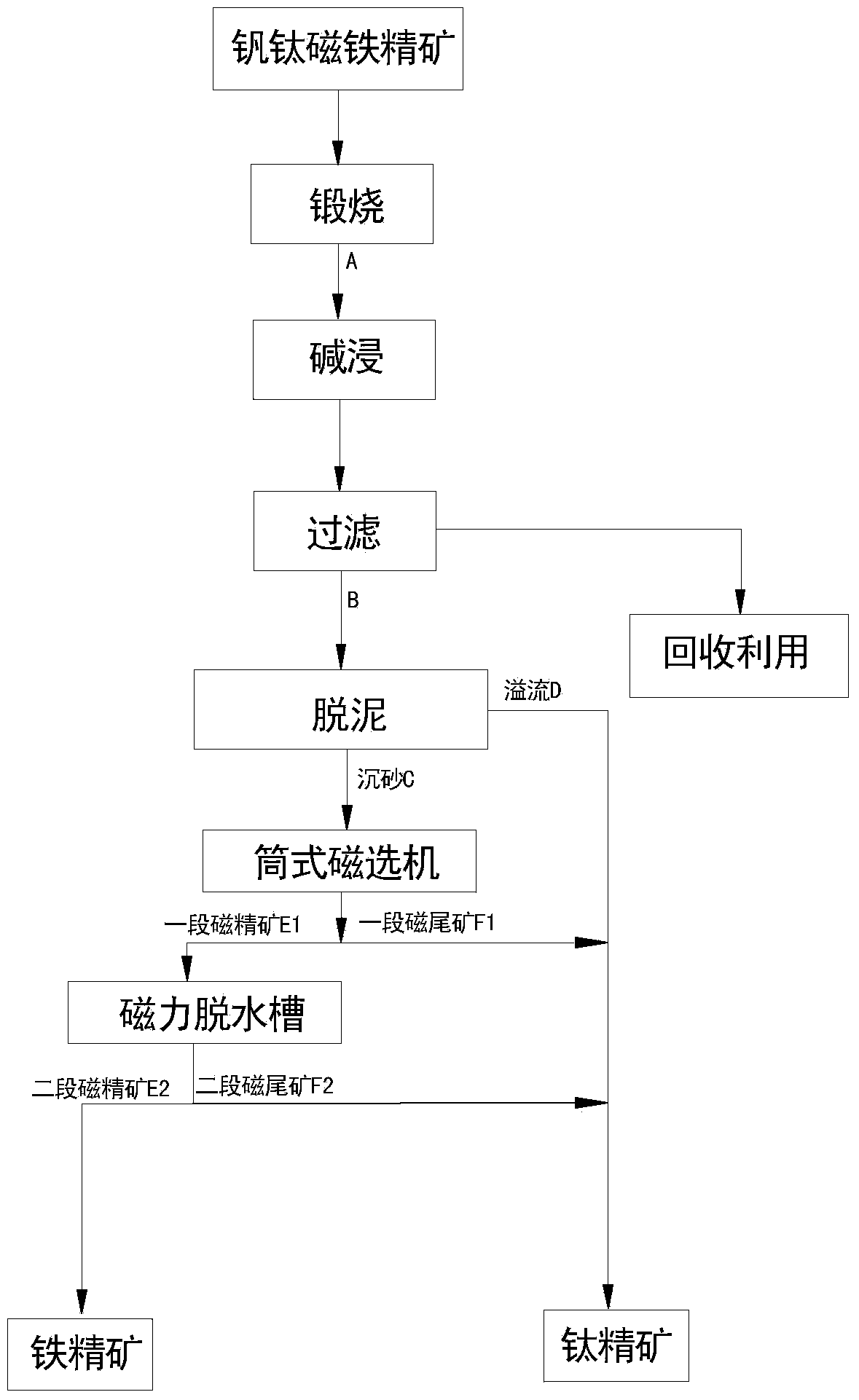

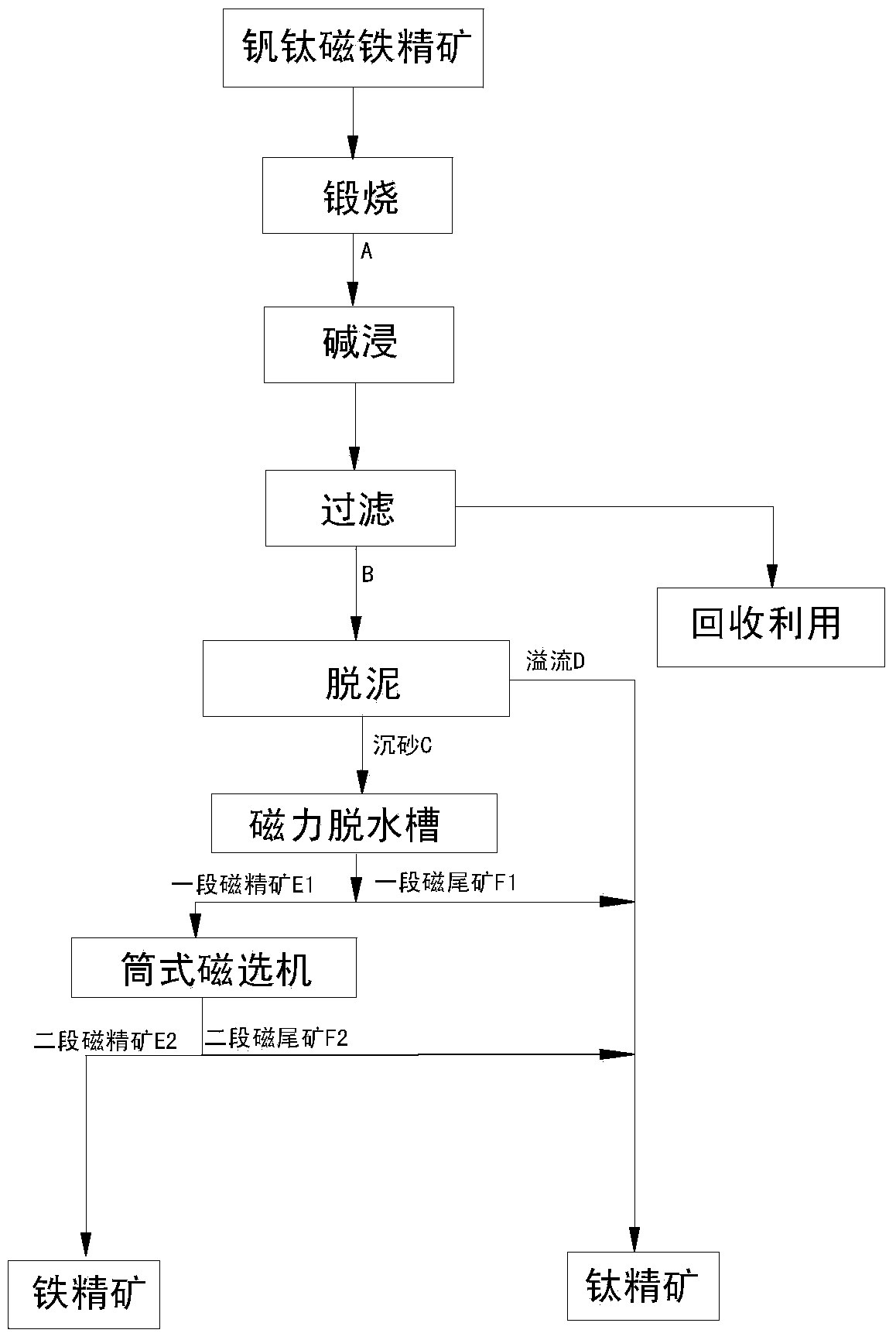

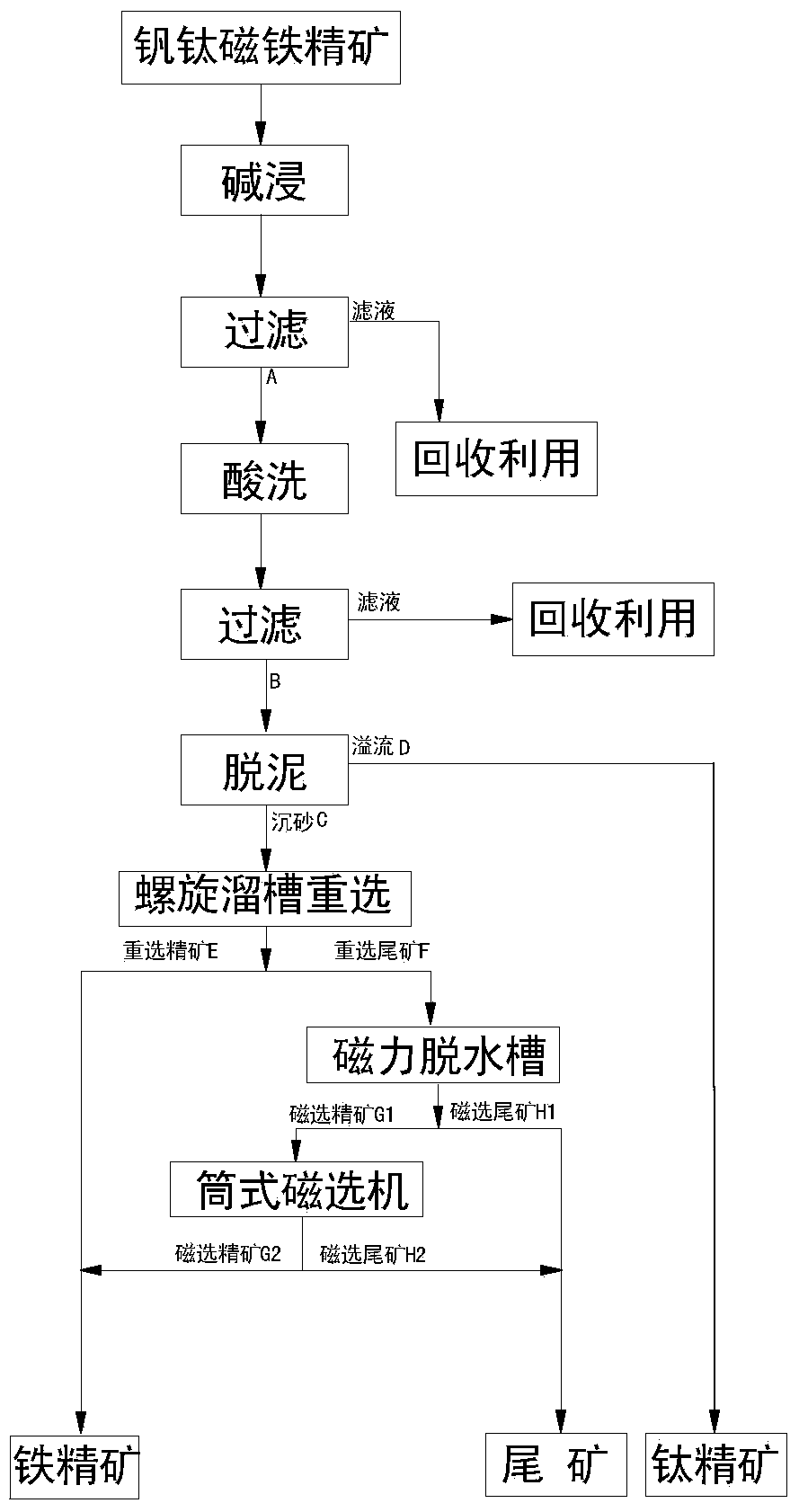

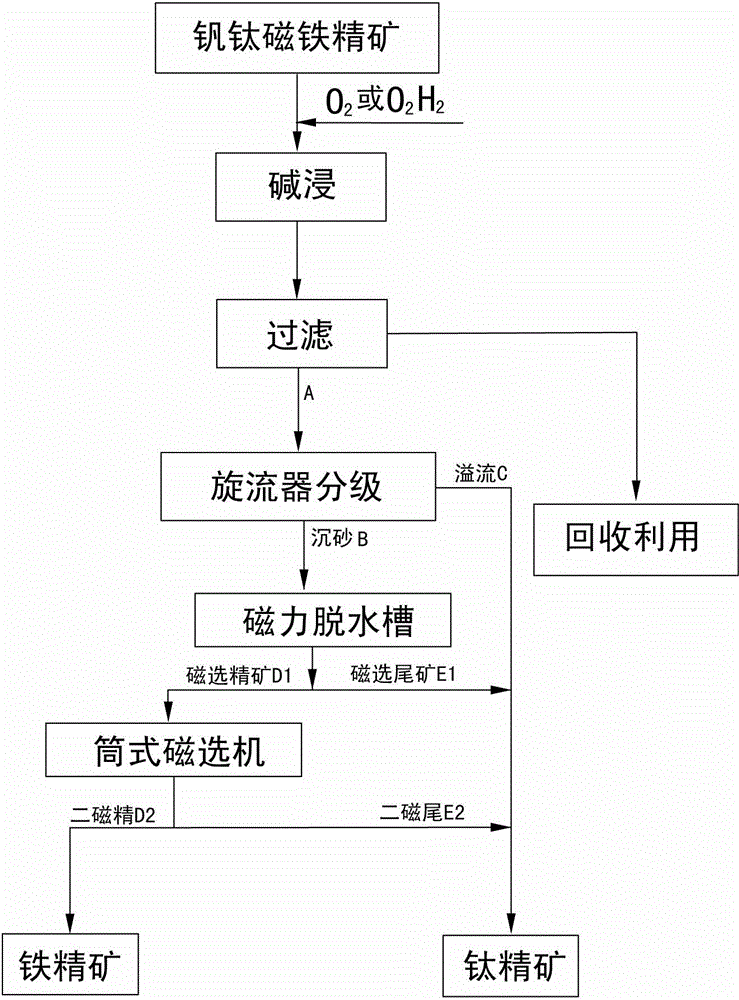

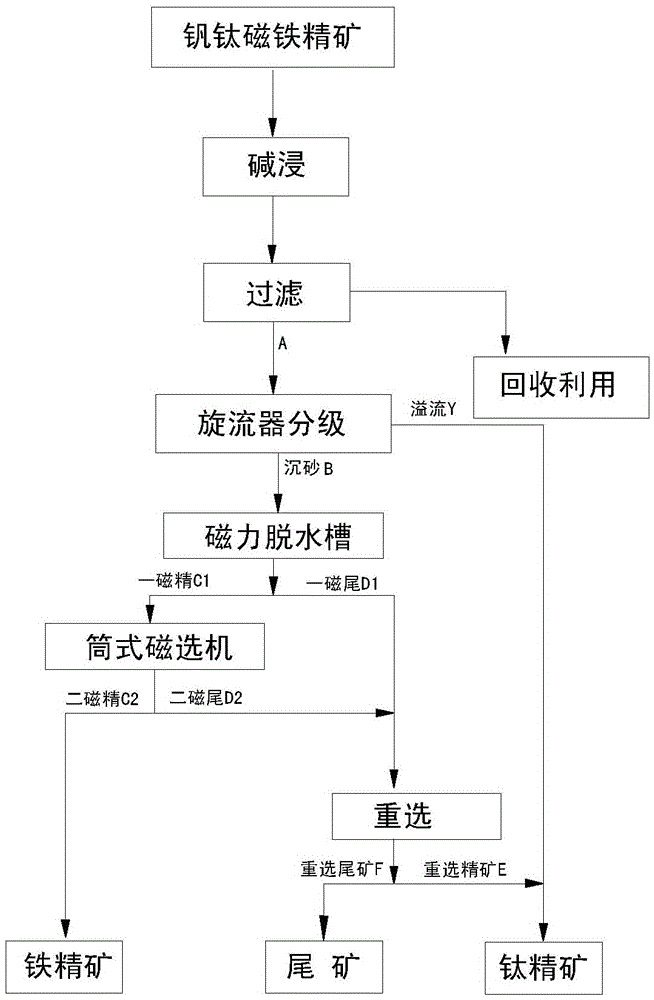

Method for recleaning of vanadium-titanium magnetite concentrate by using alkaline leaching, grading and magnetic separation

ActiveCN103949335AEfficient separationLow S contentMagnetic separationWet separationMagnetiteImpurity

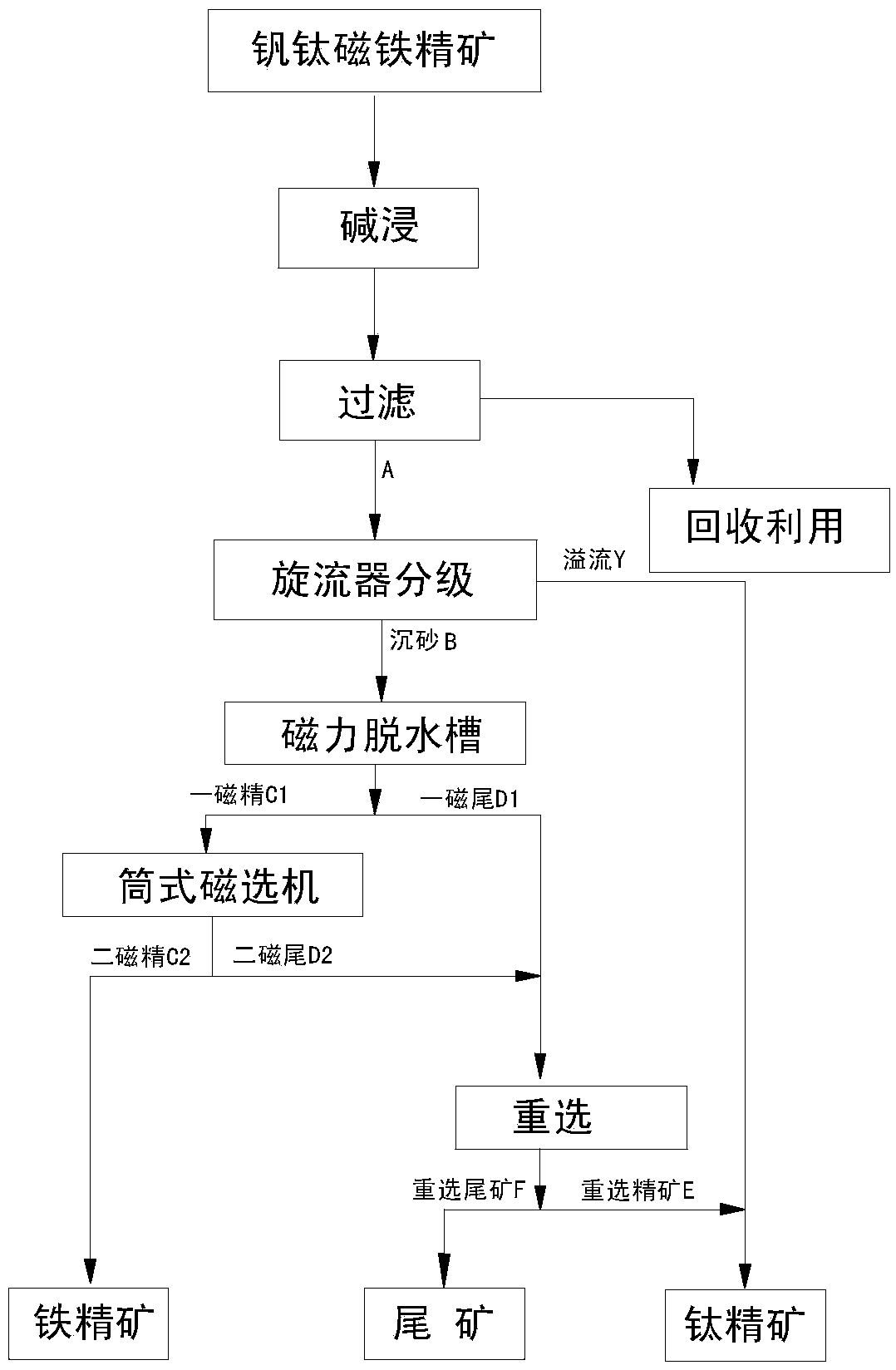

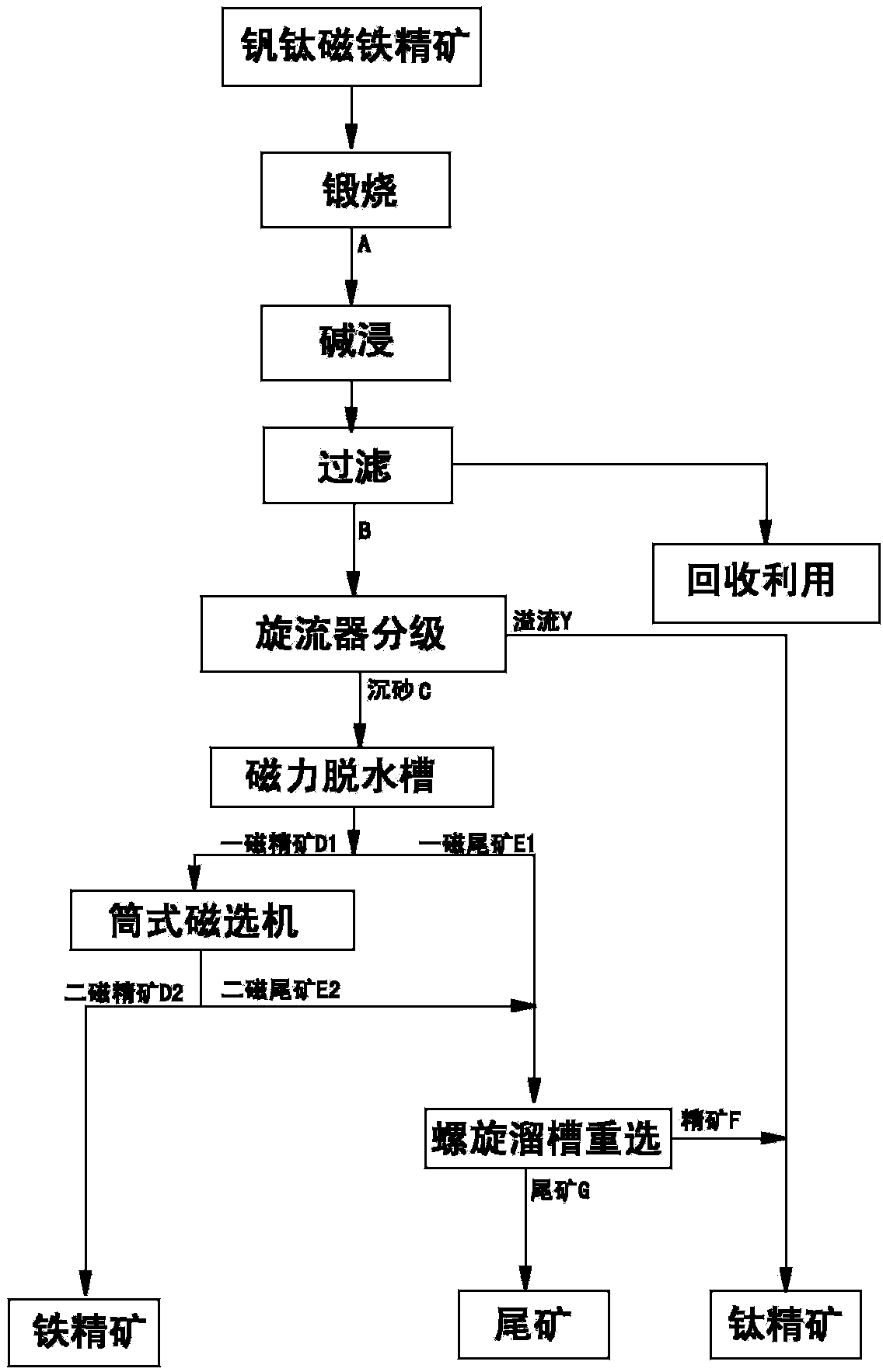

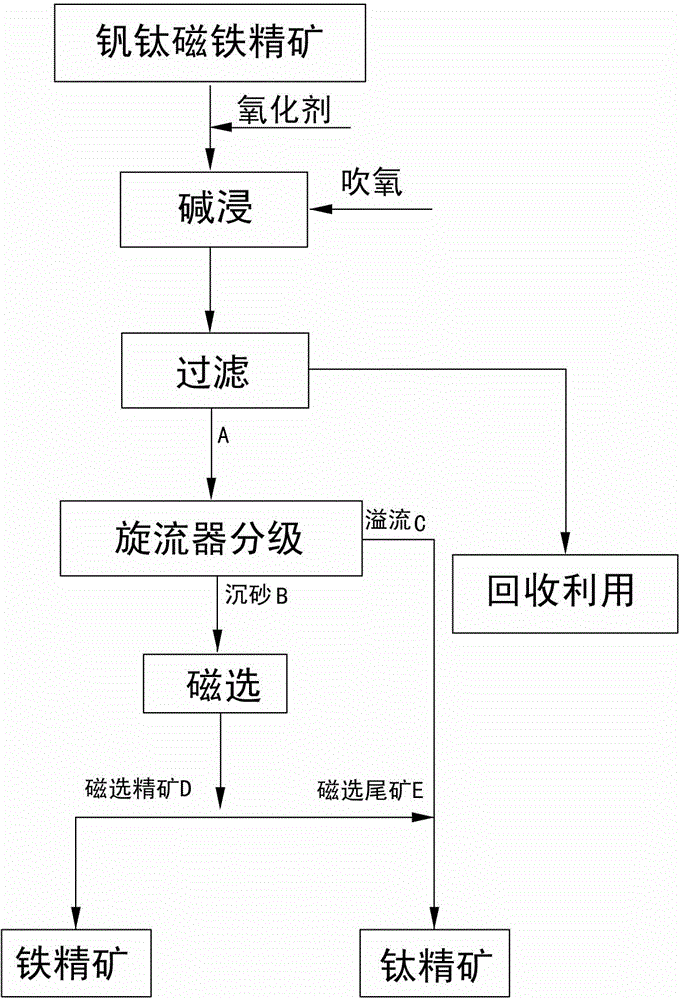

The invention discloses a method for recleaning of a vanadium-titanium magnetite concentrate by using alkaline leaching, grading and magnetic separation. The method comprises the following steps of placing the vanadium-titanium magnetite concentrate into alkali solution with the mass concentration of 5-52%, reacting for 0.5-5 hours in an alkaline leaching mode at 280-370 DEG C, and filtering to obtain filtrate and an alkaline leaching filter cake A; adding water into A to make mine pulp with the mass concentration of 20-25% and feeding into a swirler for grading to obtain overflows and setting sand B; adding water into B to make mine pulp with the mass concentration of 30-36% and performing magnetic separation to obtain final iron ore concentrate with the TFe content range being 63-68% and final titanium concentrate with the TiO2 content range being 35-50%. The method has the advantages that the efficient separation for the vanadium-titanium magnetite concentrate is realized, the alkaline consumption is low, the contents of impurities such as Al and Si, particularly harmful impurities of TiO2 and S, which enter a blast furnace are reduced, the use coefficient of the blast furnace is improved, the discharge of blast furnace slag is reduced, the puddling cost is reduced, and the problems of high S content and severe pollution in the smelting process are solved; the comprehensive use rate of the titanium resources is improved.

Owner:ANSTEEL GRP MINING CO LTD

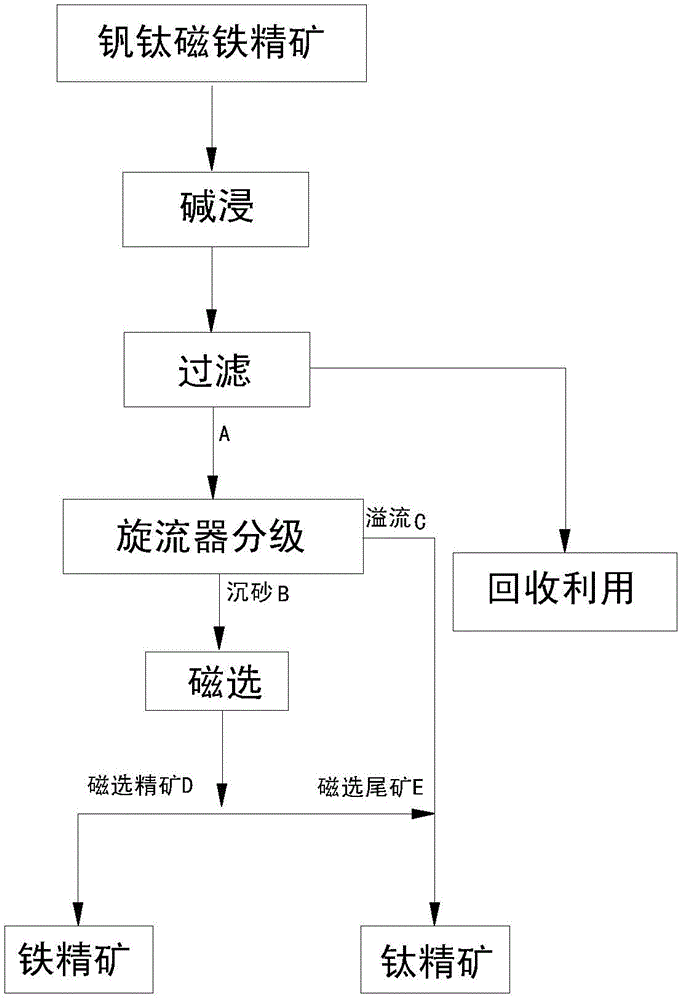

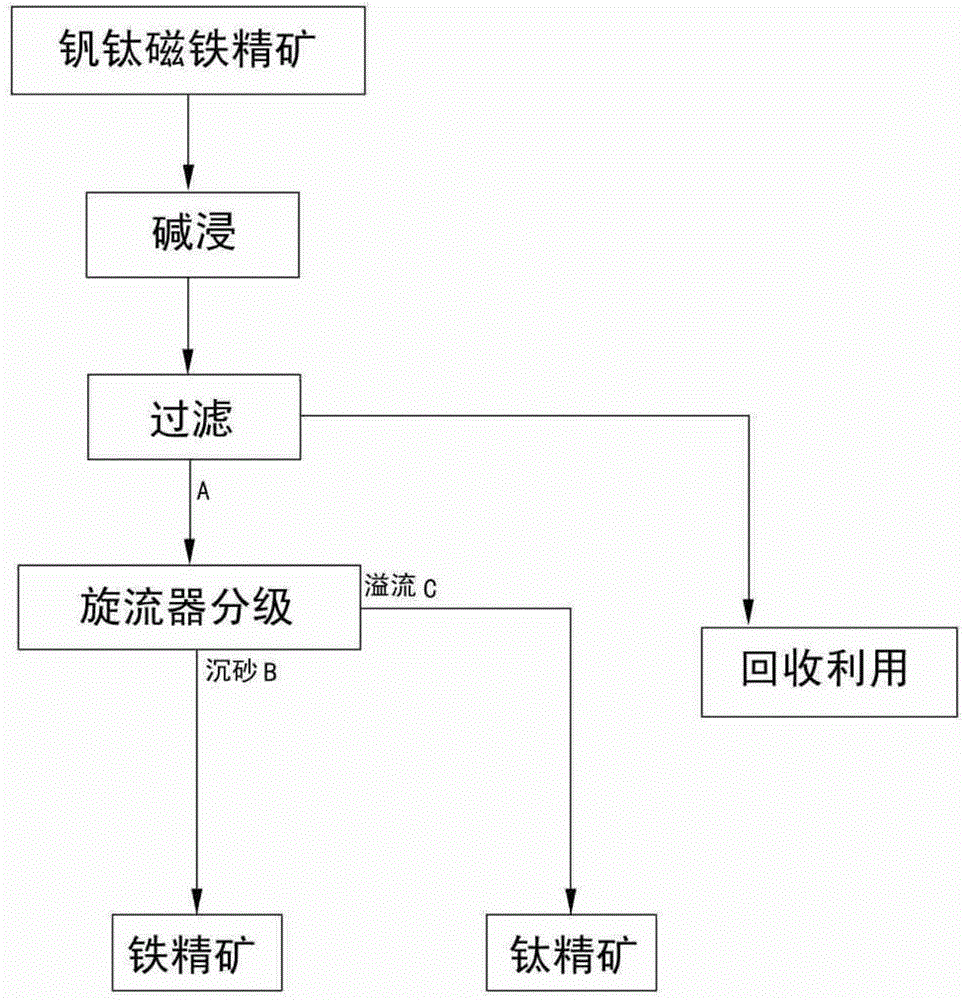

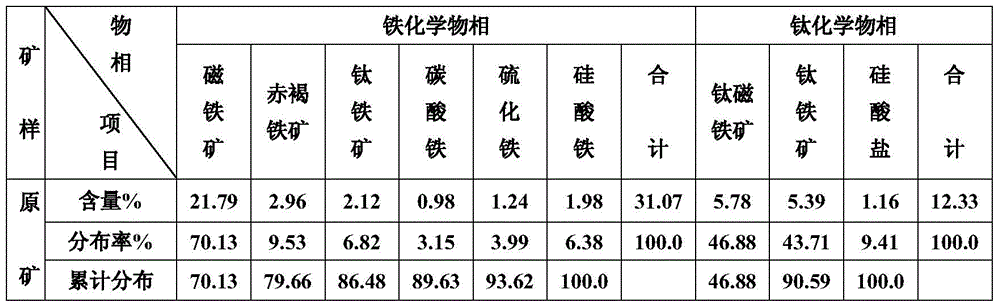

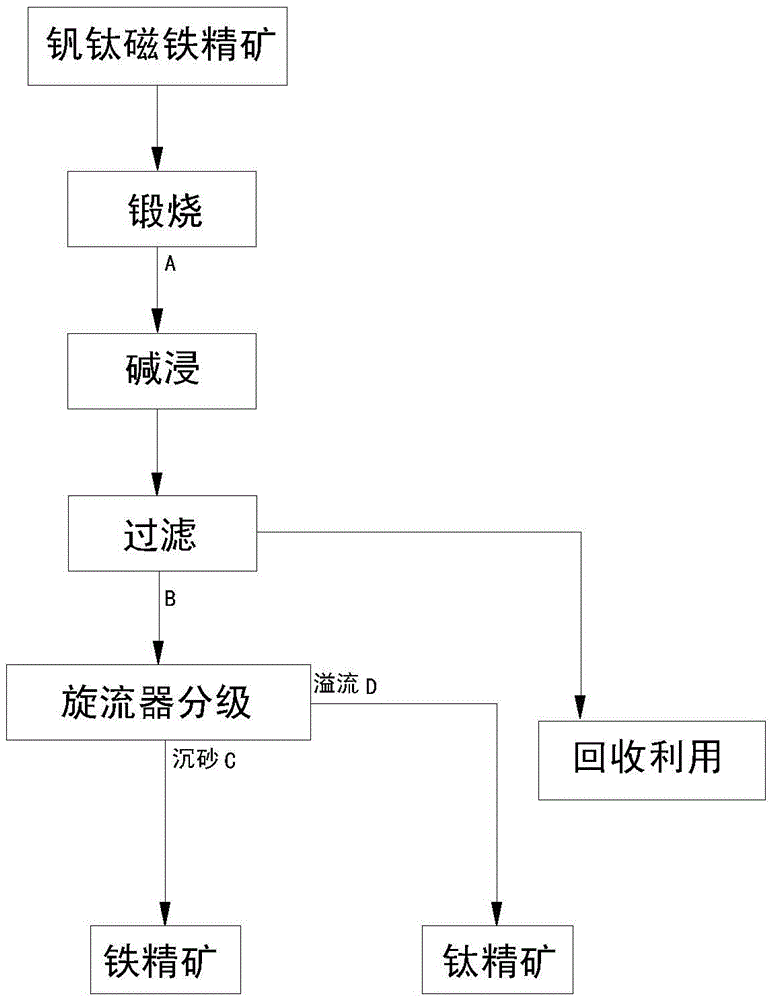

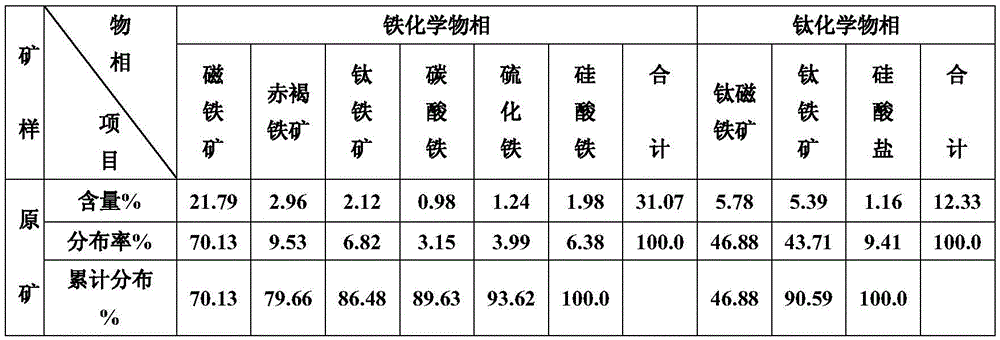

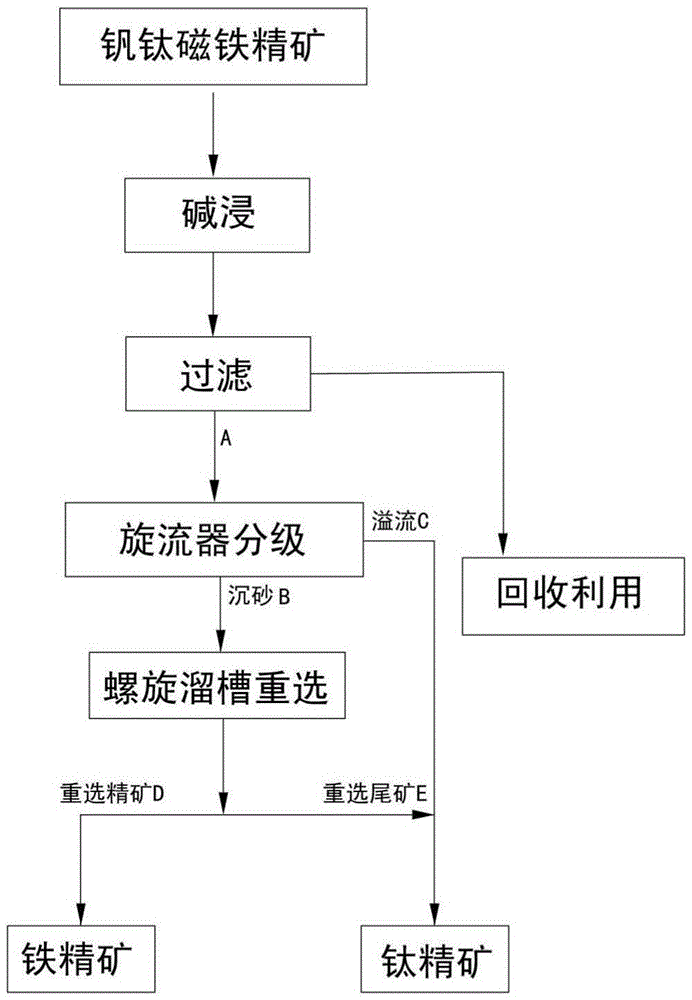

Method for recleaning vanadium-titanium magnetite concentrate by using alkaline leaching and grading

The invention discloses a method for recleaning vanadium-titanium magnetite concentrate by using alkaline leaching and grading. The method comprises the following steps: putting the vanadium-titanium magnetite concentrate in aqueous alkali with the mass concentration of 5-52%, carrying out alkaline leaching reaction at the temperature of 280-370 DEG C for 0.5-5 hours, and filtering so as to obtain filtrate and alkaline leaching filter cakes A; adding water to the alkaline leaching filter cakes A so as to prepare ore pulp with the mass concentration of 20%-25%, feeding the ore pulp into a hydrocyclone, and grading so as to respectively obtain iron ore concentrate with the TFe content of 60-68% and the titanium concentrate with the TiO2 content of 35-50%. The method has the advantages that the high-efficiency grading of the vanadium-titanium magnetite concentrate is realized, the alkali consumption is low, the content of impurities such as Al and Si entering a blast furnace is reduced, especially, the content of detrimental impurities such as TiO2 and S is reduced, the utilization coefficient of the blast furnace is increased, the discharge amount of blast furnace slag is reduced, the iron smelting cost is reduced, the problems of high S content and serious pollution in a smelting process are solved, and meanwhile, the compressive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

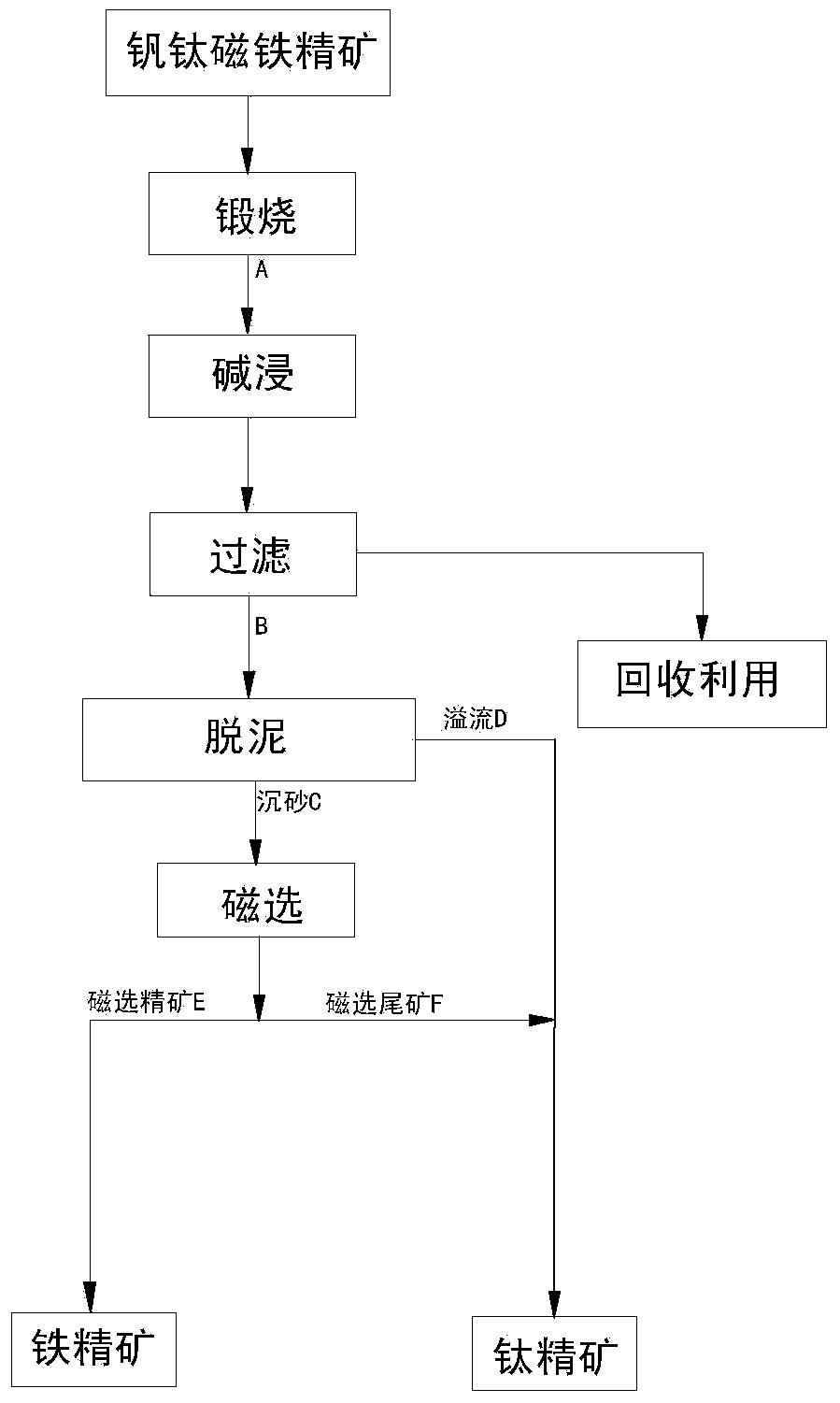

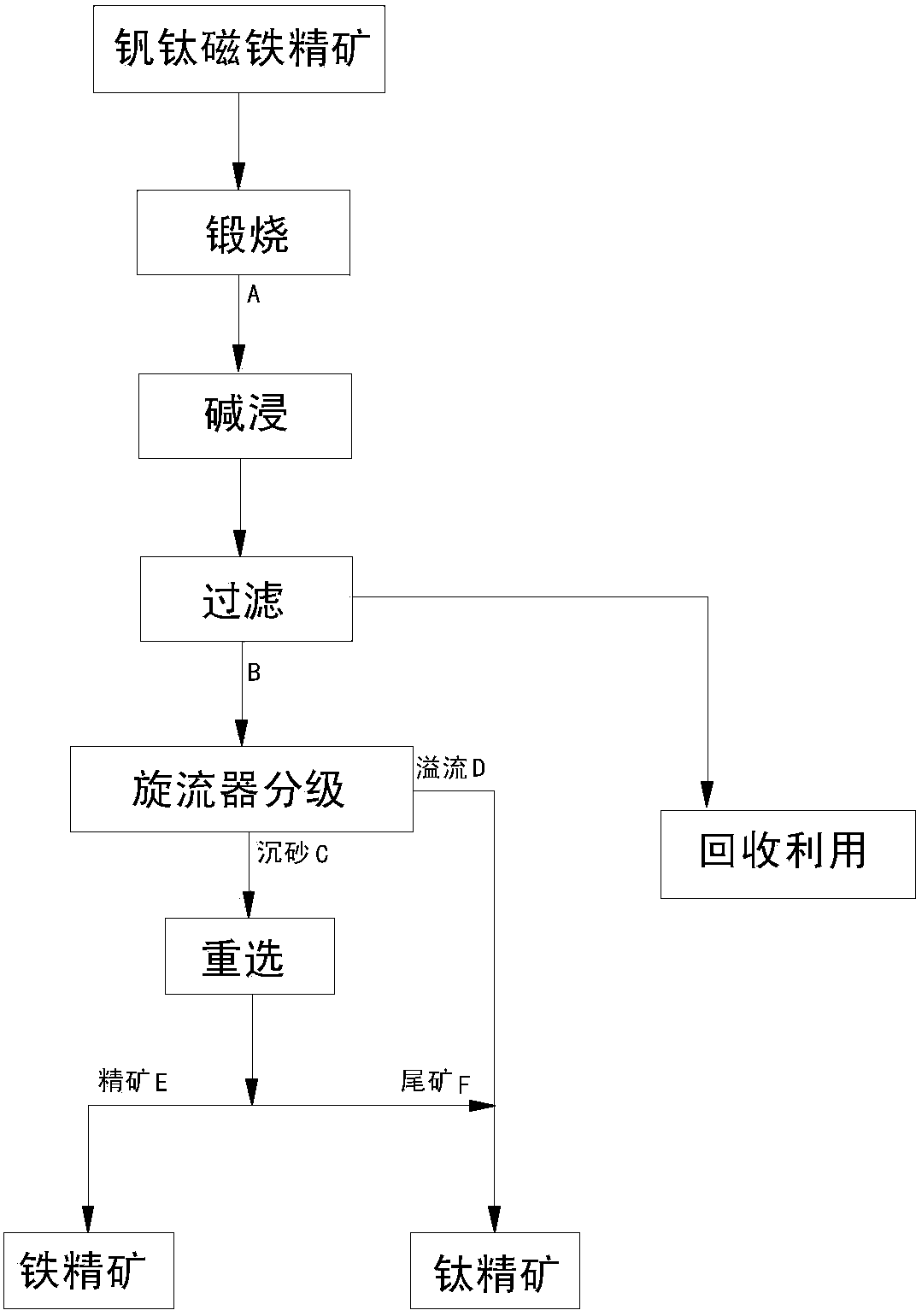

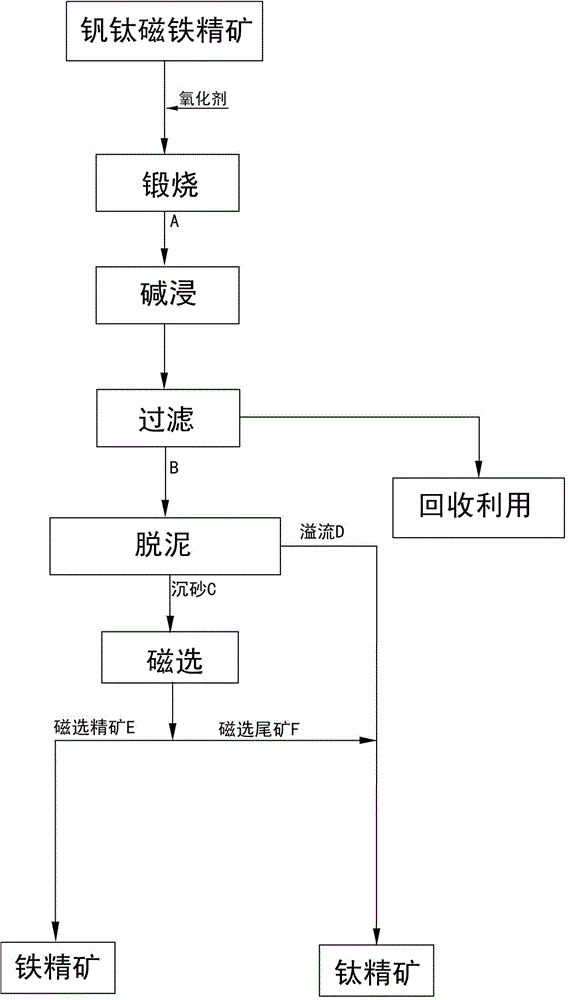

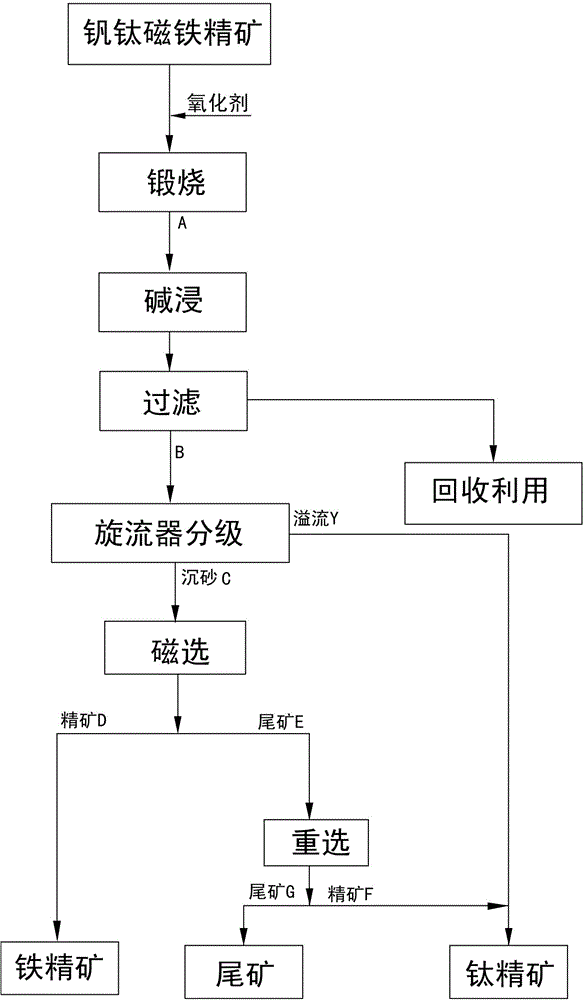

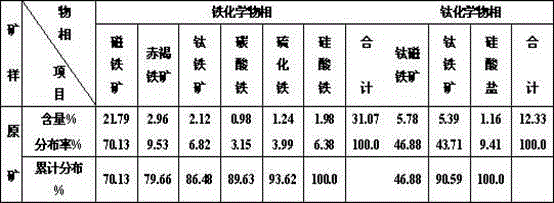

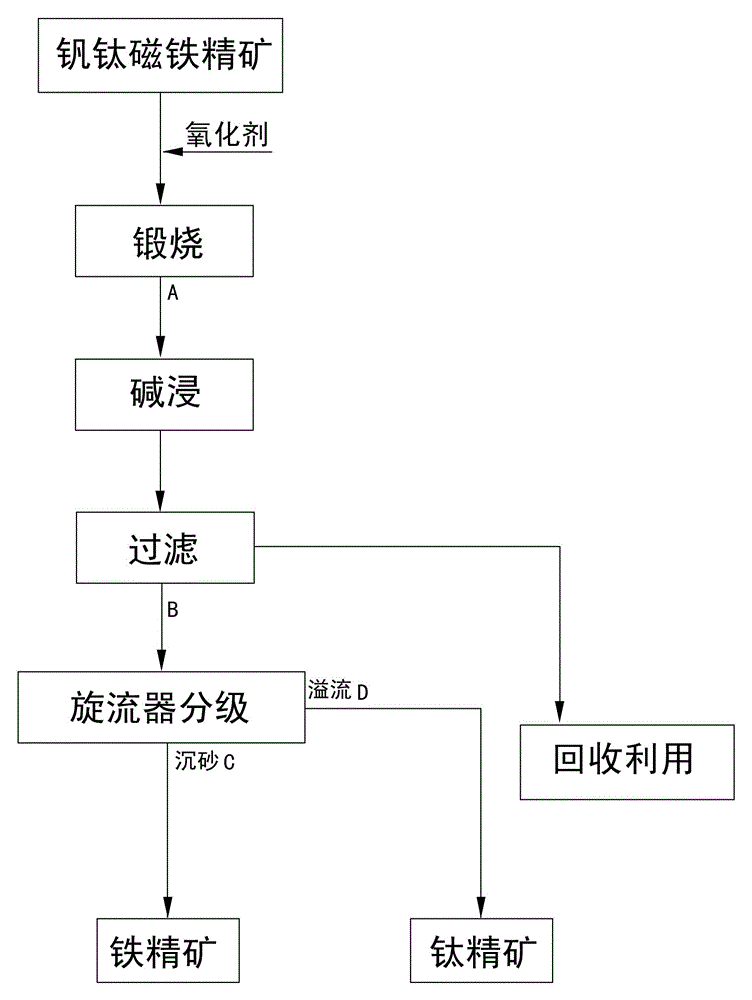

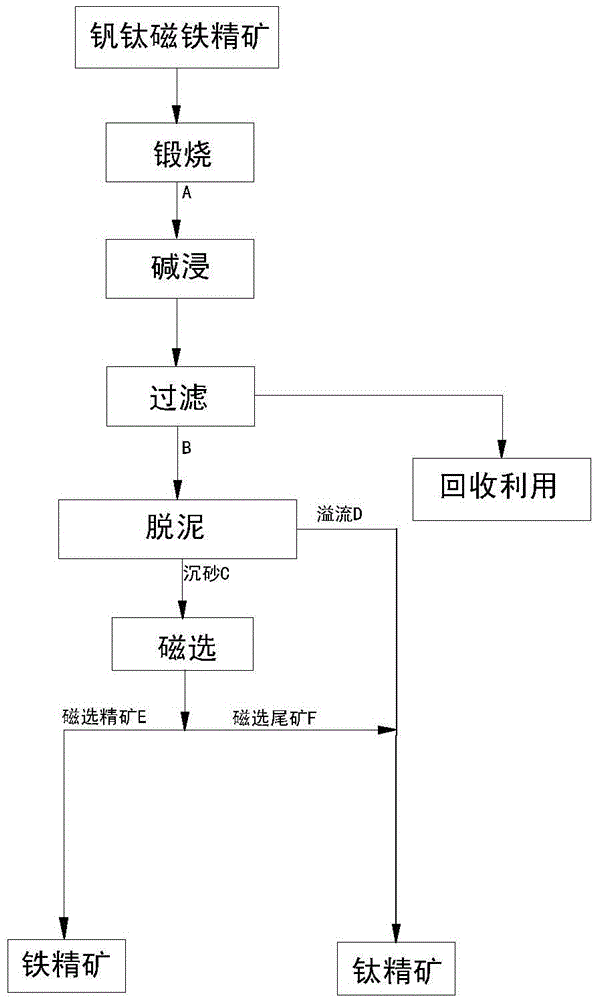

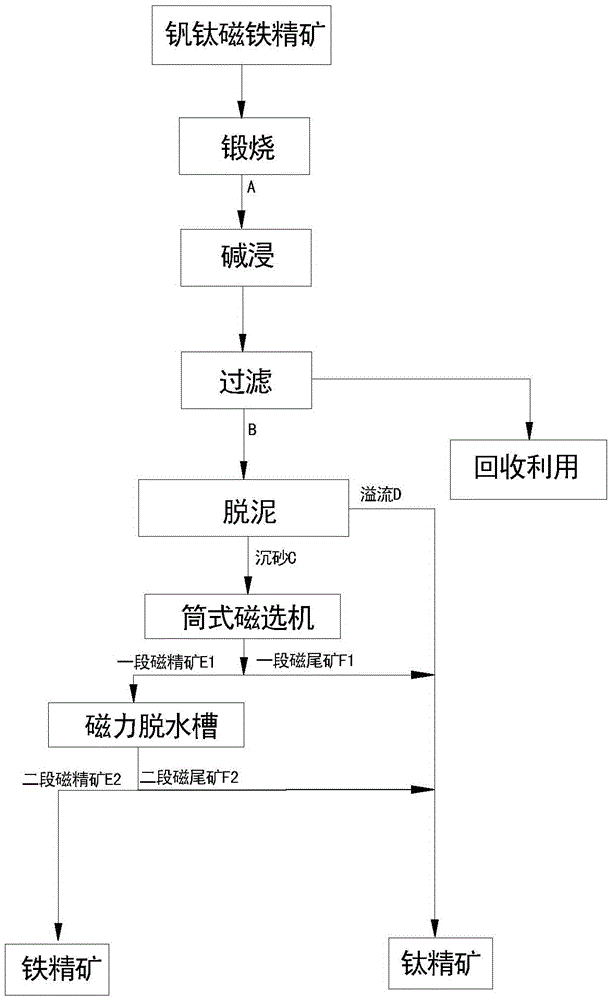

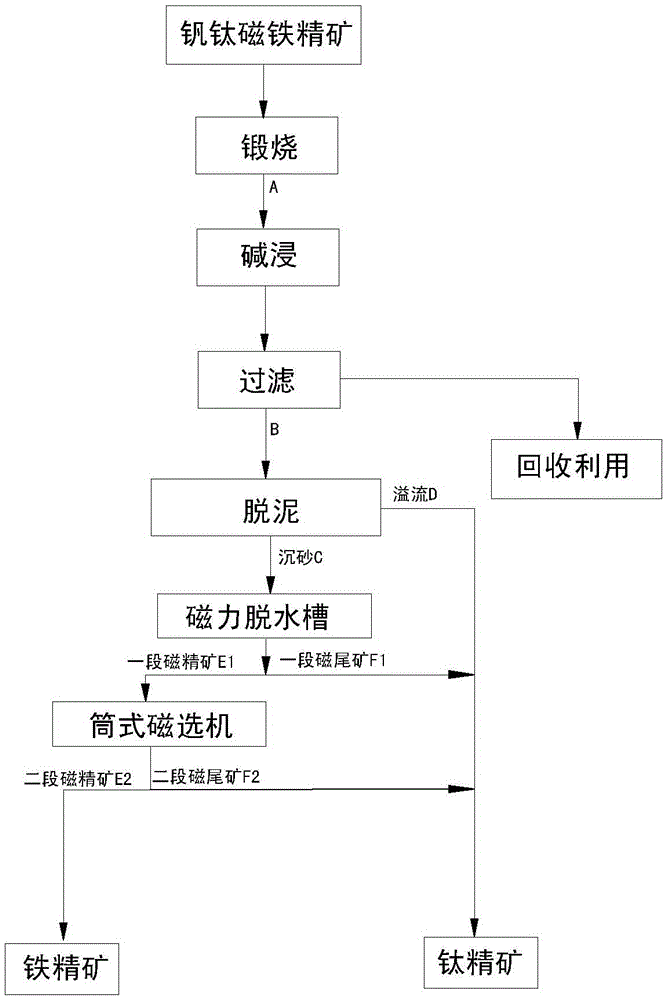

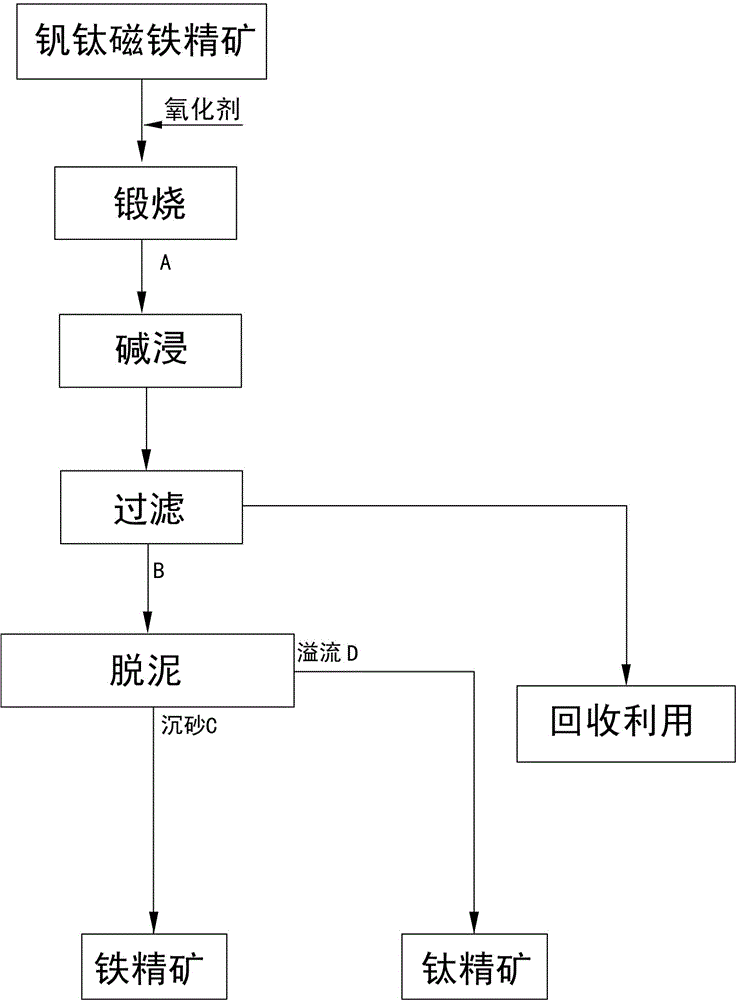

Method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching, desliming and magnetic separation

The invention discloses a method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching, desliming and magnetic separation. The method comprises the following steps that CaO is added to the vanadium-titanium magnetite concentrates, the mixture is calcined for 20 to 60 minutes at the temperature ranging from 800 DEG C to 1400 DEG C, and therefore a calcined product A is formed; the product A is placed in an alkaline solution, an alkaline leaching reaction is conducted for 0.5 to 5 hours at the temperature ranging from 300 DEG C to 370 DEG C, and filtrate and an alkaline leaching filter cake B are obtained through filtration; water is added to the alkaline leaching filter cake B, so that ore pulp is prepared and fed for desliming operation, and settling sand C and overflow D are obtained; water is added to the settling sand C, so that ore pulp is prepared for magnetic separation, and final iron ore concentrates with the TFe content ranging from 63% to 68% and final titanium concentrates with the TiO2 content ranging from 35% to 50% are screened. The method has the advantages that consumption of NaOH or KOH is reduced, the vanadium-titanium magnetite concentrates are efficiently screened, alkali consumption is low, the content of impurities such as Al and Si which enter a blast furnace is reduced, the blast furnace use coefficient is increased, the problems of the high S content and serious pollution in the smelting process are solved, and meanwhile the comprehensive use rate of titanium resources is improved.

Owner:ANSTEEL GRP MINING CO LTD

Method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching, classification and combination of magnetic separation and gravity concentration

ActiveCN103962229AEfficient separationLow S contentMagnetic separationWet separationMagnetitePollution

Owner:ANSTEEL GRP MINING CO LTD

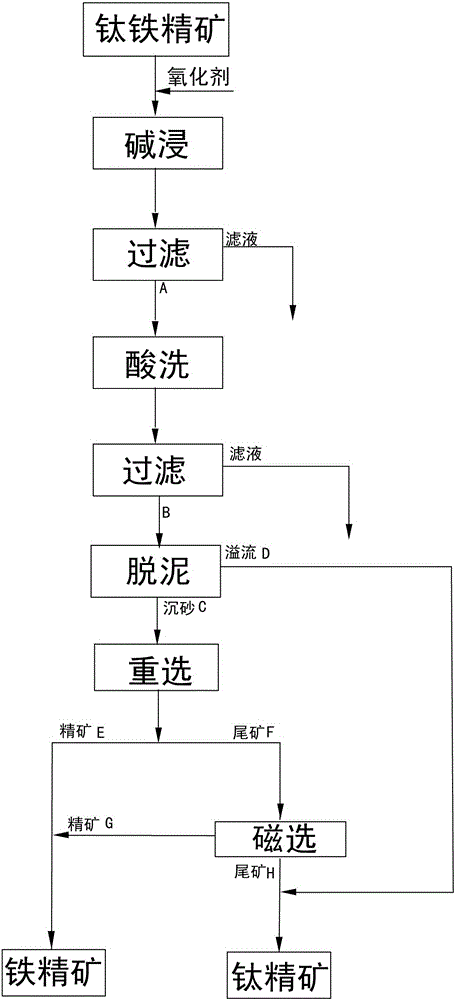

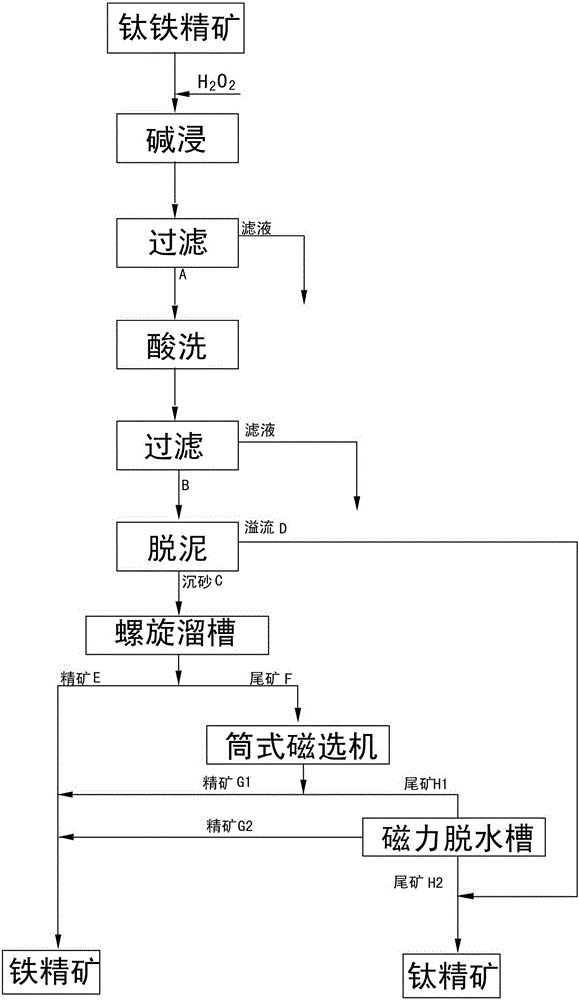

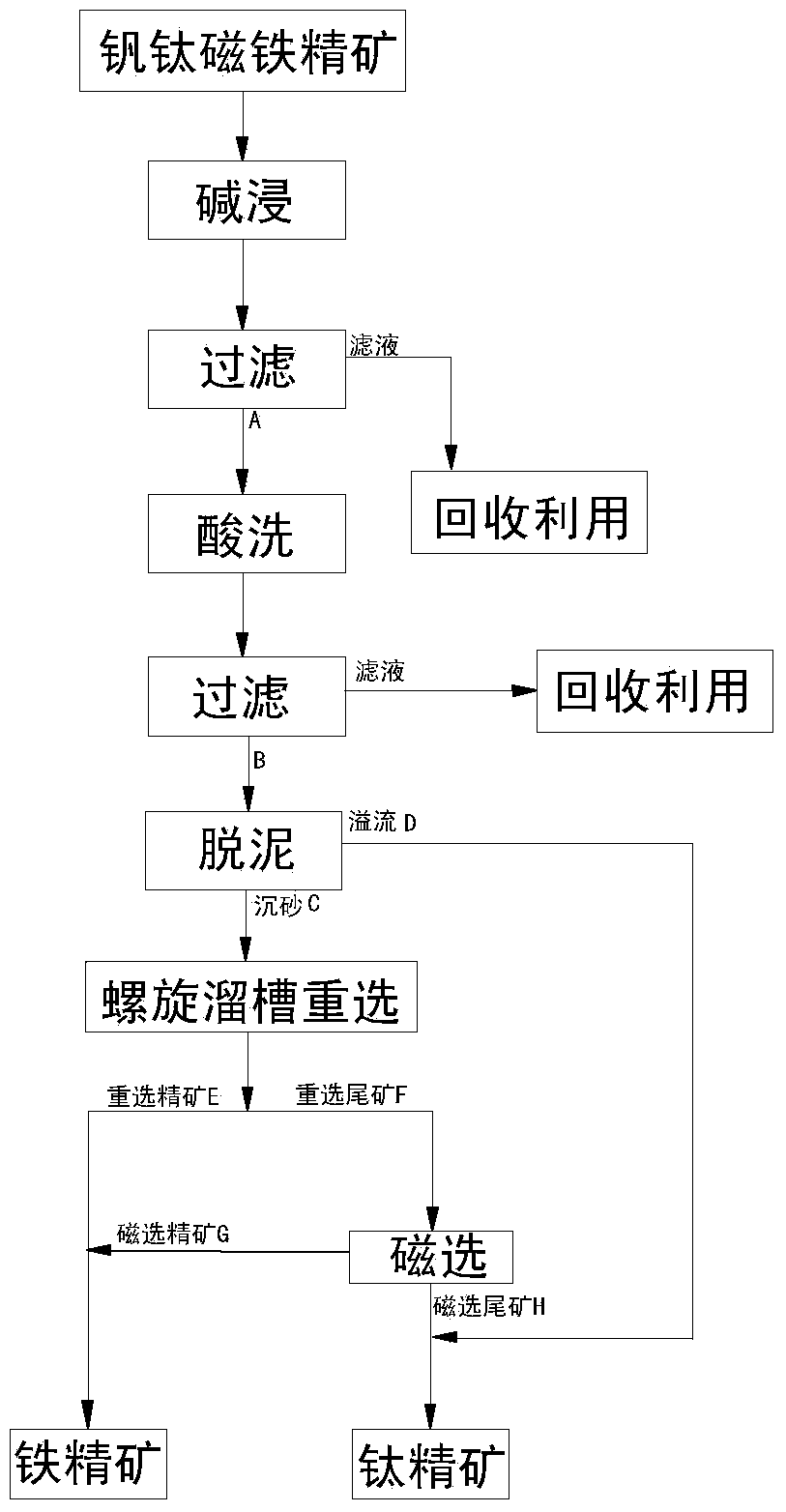

Vanadium-titanium magnetite concentrate re-concentration method achieved through oxidation alkaline leaching, acid pickling, desliming and gravity and magnetism

InactiveCN105013608AMild reaction conditionsEquipment corrosion is smallMagnetic separationTitaniumMineralogy

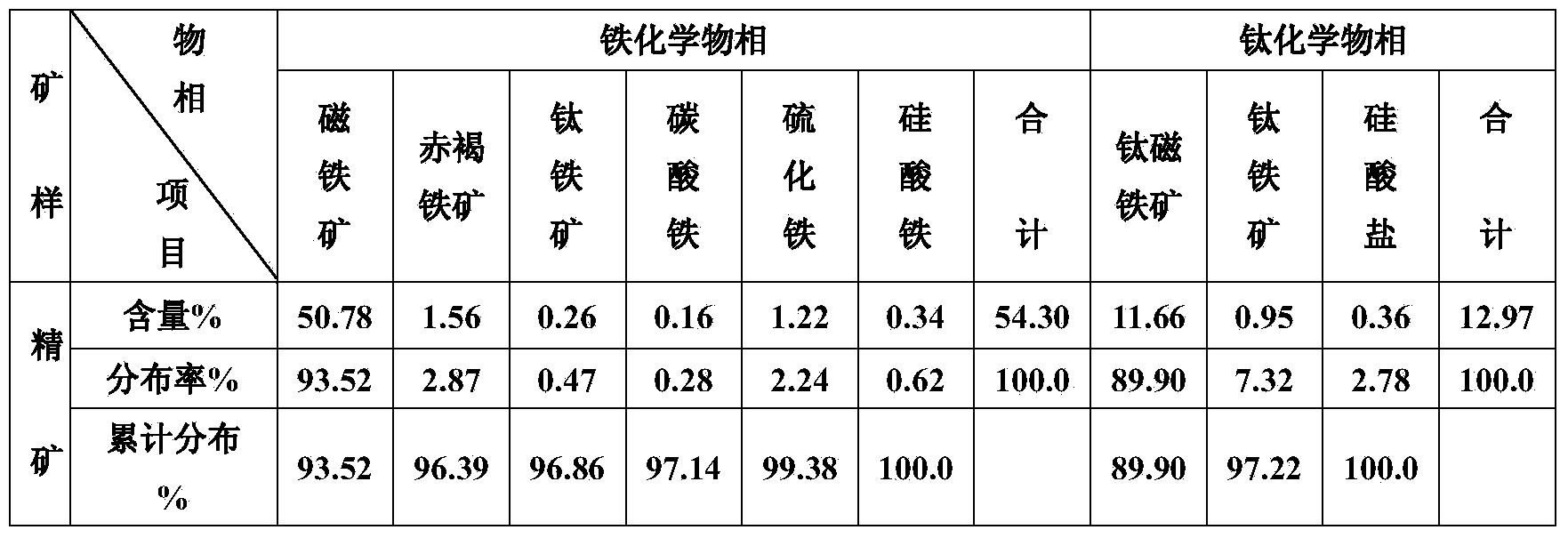

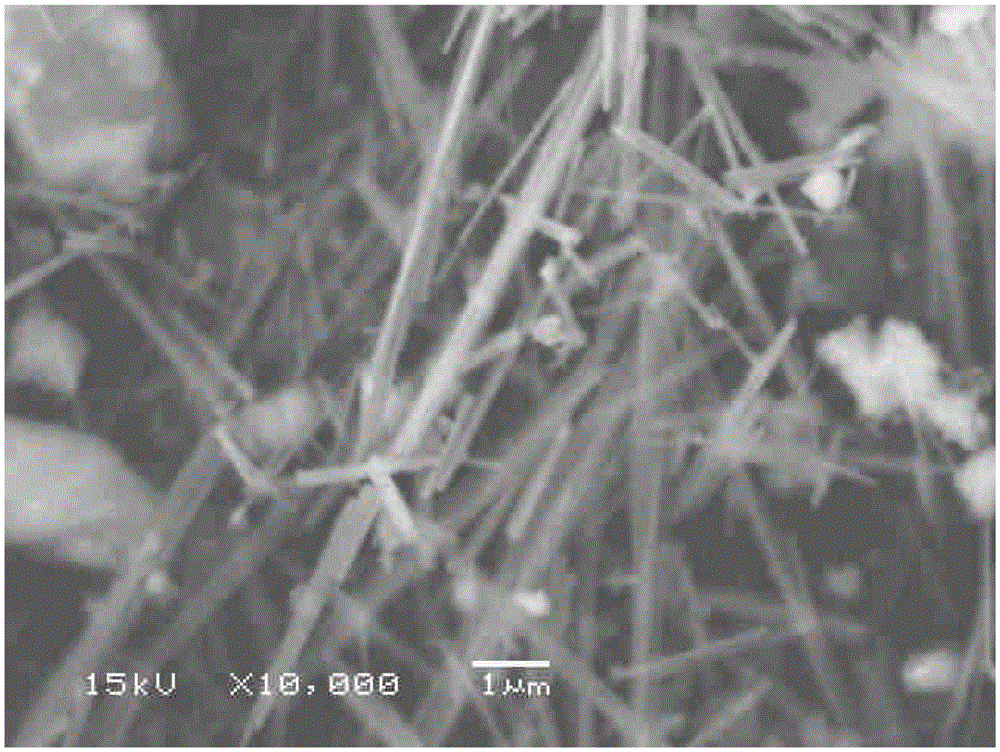

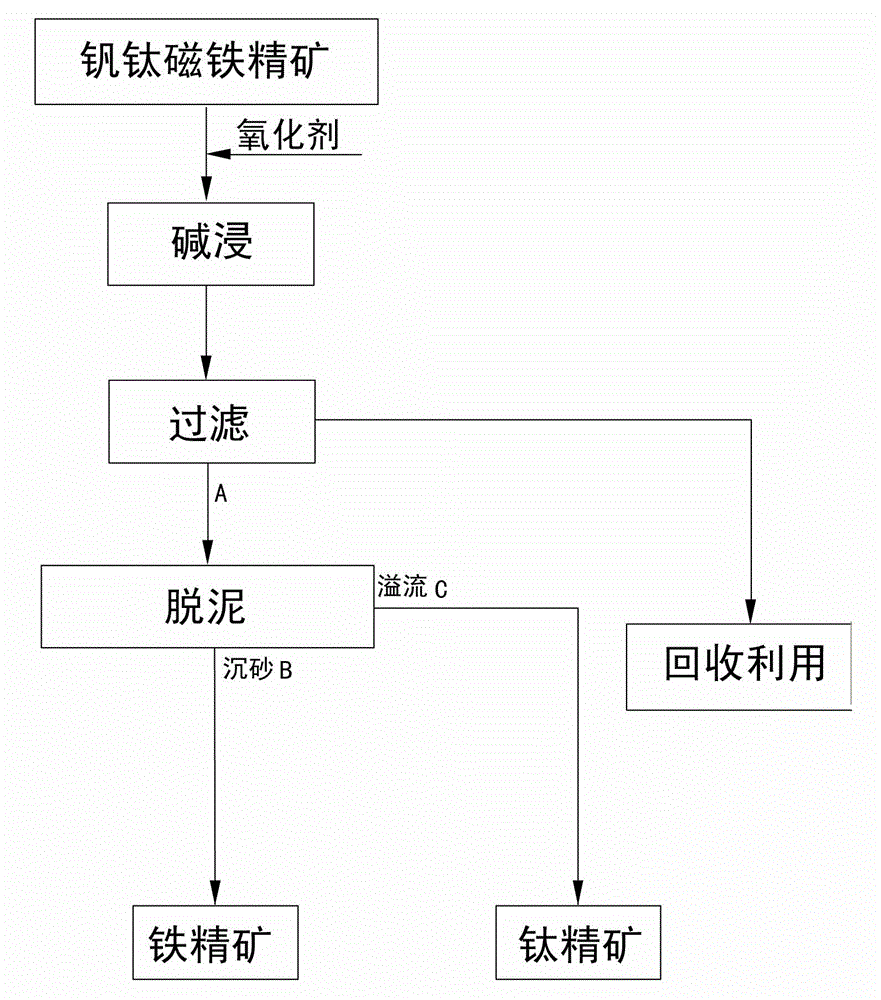

The invention relates to a vanadium-titanium magnetite concentrate re-concentration method achieved through oxidation alkaline leaching, acid pickling, desliming and gravity and magnetism. The method is characterized by including the following steps that oxidation alkaline leaching is performed on vanadium-titanium magnetite concentrate, and the vanadium-titanium magnetite concentrate is placed in an alkaline solution; oxidization agents are added; then, an alkaline leaching reaction lasts for 0.5-2 h at the temperature of 220-330 DEG C; filtration is performed, and then filter liquor and alkaline leached filter cakes A are obtained; water is added in the alkaline leached filter cakes A, and ore pulp is prepared; then, the ore pulp is placed in a H2SO4 solution, and acid pickling is performed for 5-60 min at the temperature of 50-90 DEG C; filtration is performed, and filter liquor and acid leached filter cakes B are obtained; water is added into B, and ore pulp with the mass concentration being 30-35% can be prepared; and desliming and gravity and magnetism combined re-concentration is performed, and iron concentrate with the TFe content being 64-70% and titanium concentrate with the TiO2 content being 60-82% can be obtained respectively. The method has the beneficial effects that due to introduction of O2 or H2O2 during oxidation alkaline leaching, S compounds can be oxidized, the reaction is accelerated, the reaction temperature is lowered, the reaction time is shortened, and energy consumption and equipment investment are greatly reduced.

Owner:ANSTEEL GRP MINING CO LTD

Method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching, classification and gravity concentration

The invention discloses a method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching, classification and gravity concentration. The method comprises the following steps that CaO is added to the vanadium-titanium magnetite concentrates, the mixture is calcined for 20 to 60 minutes at the temperature ranging from 800 DEG C to 1400 DEG C, and therefore a calcined product A is formed; the product A is placed in an alkaline solution, an alkaline leaching reaction is conducted for 0.5 to 5 hours, and filtrate and an alkaline leaching filter cake B are obtained through filtration; water is added to the alkaline leaching filter cake B, so that ore pulp is prepared and fed into a hydrocyclone for classification, and settling sand C and overflow D are obtained through classification; gravity concentration is conducted on the settling sand C, so that gravity concentrates E and gravity tailings F are obtained, the gravity concentrates E are final iron ore concentrates with the TFe content ranging from 63% to 68%, and the gravity tailings F are combined with the overflow D of the hydrocyclone, so that final titanium concentrates with the TiO2 content ranging from 50% to 60% are obtained. The method has the advantages that consumption of NaOH or KOH is reduced, the vanadium-titanium magnetite concentrates are efficiently screened, alkali consumption is low, the content of impurities such as Al and Si which enter a blast furnace is reduced, the problems of the high S content and serious pollution in the smelting process are solved, and meanwhile the comprehensive use rate of titanium resources is improved.

Owner:ANSTEEL GRP MINING CO LTD

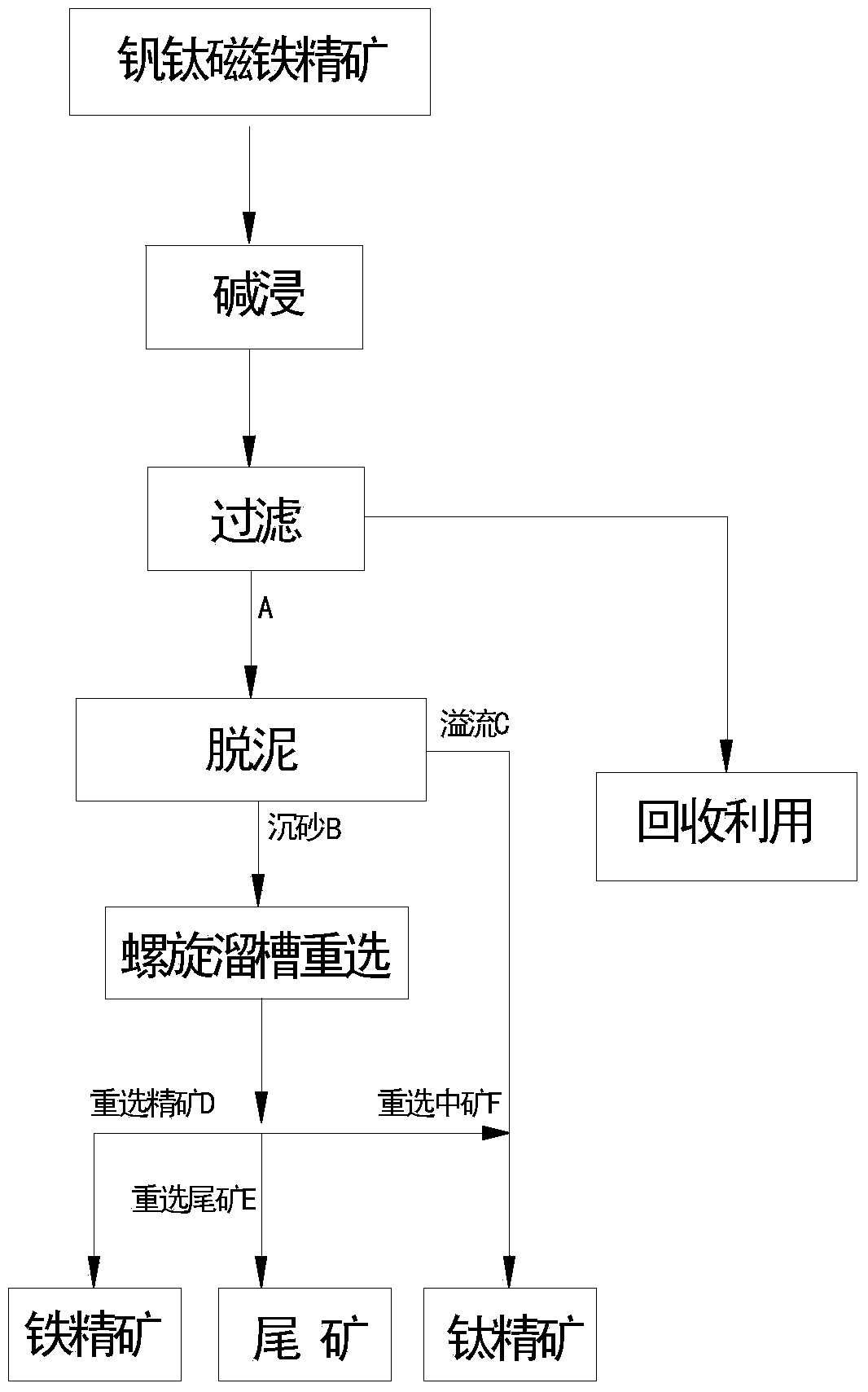

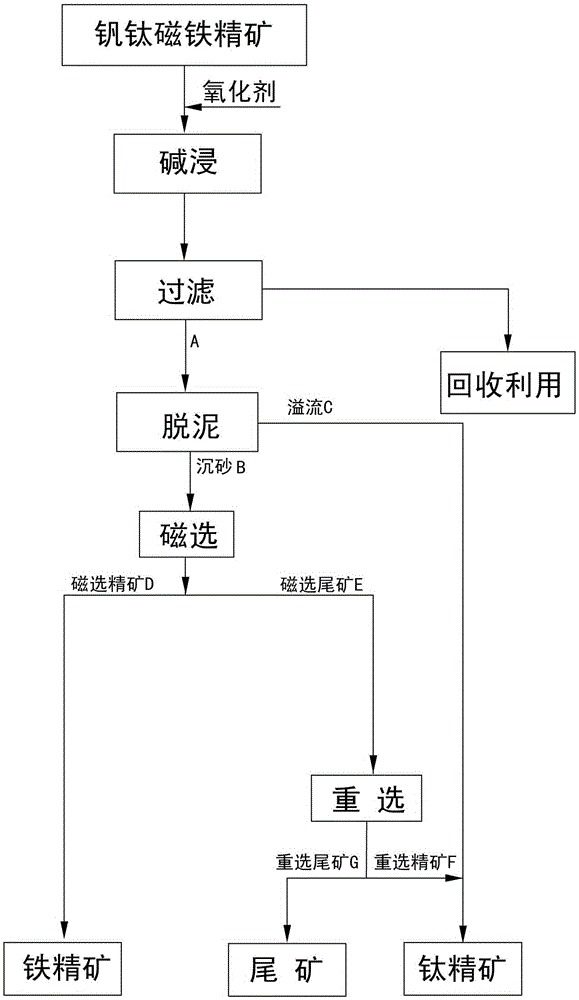

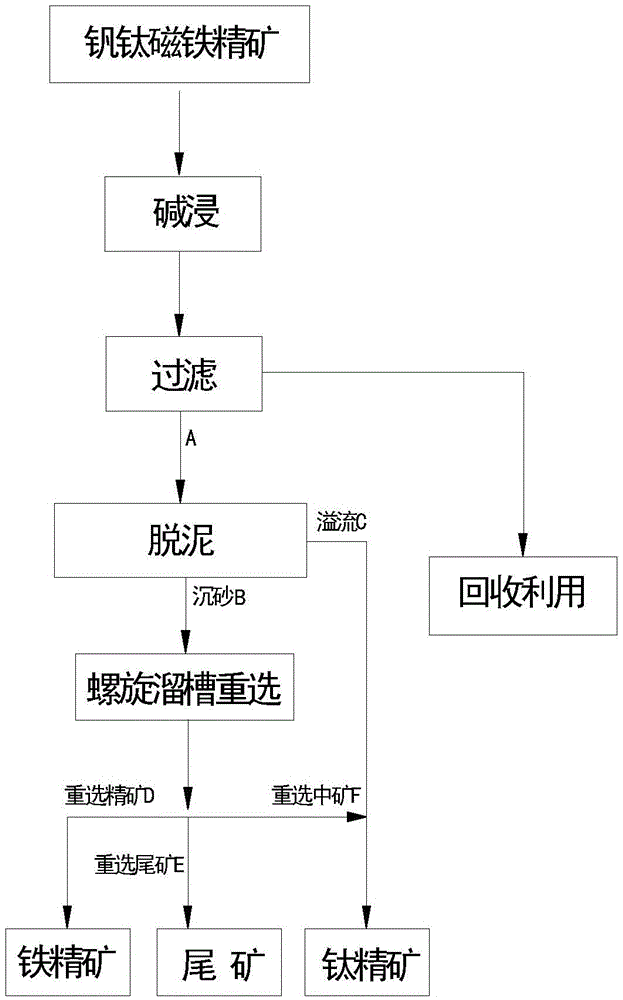

Vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, desliming and gravity separation

The invention discloses a vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, desliming and gravity separation. The method comprises the steps of placing vanadium-titanium magnetite concentrate in aqueous alkali with a mass concentration of 5%-52% for alkaline leaching reaction at a temperature between 260 DEG C and 370 DEG C for 0.5 h - 5 h and conducting filtering to obtain a filtrate and an alkaline leached filter cake A; adding water into A to obtain pulp with the mass concentration of 21%-25%, and conducting desliming to obtain set sand B and effused flow C; adding water into B to obtain pulp with a mass concentration of 35%-40%, and conducting gravity separation to obtain iron ore concentrate with the TFe content ranging from 63% to 68% and titanium concentrate with the TiO2 content ranging from 50% to 75%. The method has the advantages that efficient sorting of the vanadium-titanium magnetite concentrate is realized, alkali consumption is low, the content of impurities such as Al and Si entering a blast furnace is reduced, the content of detrimental impurities TiO2 and S is reduced especially, the utilization coefficient of the blast furnace is increased, blast furnace slag emission is reduced, iron-making cost is reduced, the problems of high S content and severe pollution in the smelting process are solved, and the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

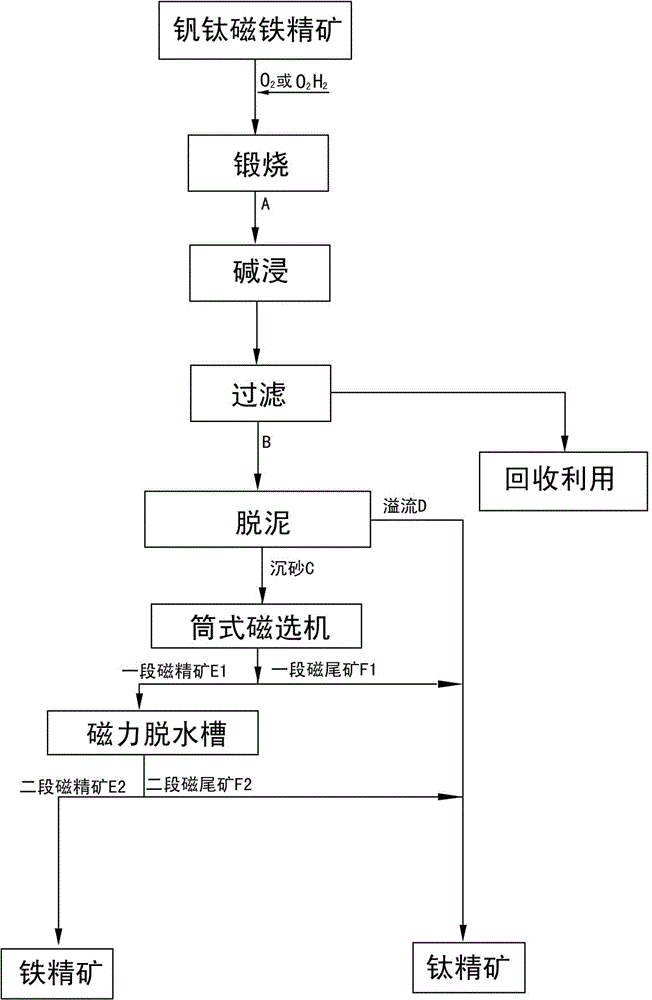

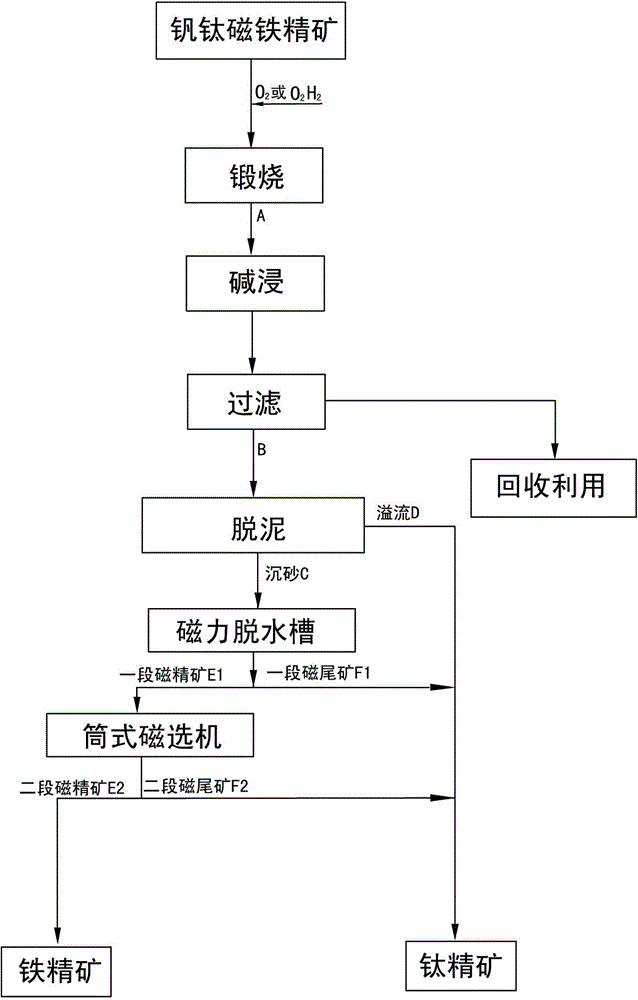

Method for magnetic separation of vanadium-titanium magnetite concentrate through forging, oxidative alkaline leaching and de-sliming

InactiveCN104962730AReduce contentEmission reductionMagnetic separationReaction temperatureMagnetite

The invention relates to a method for magnetic separation of vanadium-titanium magnetite concentrate through forging, oxidative alkaline leaching and de-sliming. The method includes the following steps that CaO is added into the vanadium-titanium magnetite concentrate according to the weight proportion of 1 to 0.1-0.2, and forging is performed at the temperature ranging from 800 DEG C to 1400 DEG C; the forged product A is placed in an alkaline solution with the mass concentration being 5-52%; an oxidizing agent is added, then an alkaline leaching reaction is carried out for 0.5-2.0 hours at the temperature of 220-330 DEG C, and filtered liquid and an alkaline leaching filter cake B are obtained; and the filter cake B is de-slimed and magnetically separated. The method has the advantages that a compound containing S is oxidized by introducing O2 or H2O2 during oxidative alkaline leaching, the reaction is accelerated, the reaction temperature is lowered, and the reaction time is shortened; besides, iron concentrate with the content of TFe being 64-69% and titanium concentrate with the content of TiO2 being 36-52% are graded, the content of impurities, such as TiO2, S, Si and Al, entering a blast furnace is reduced, the utilization coefficient of the blast furnace is increased, and meanwhile the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

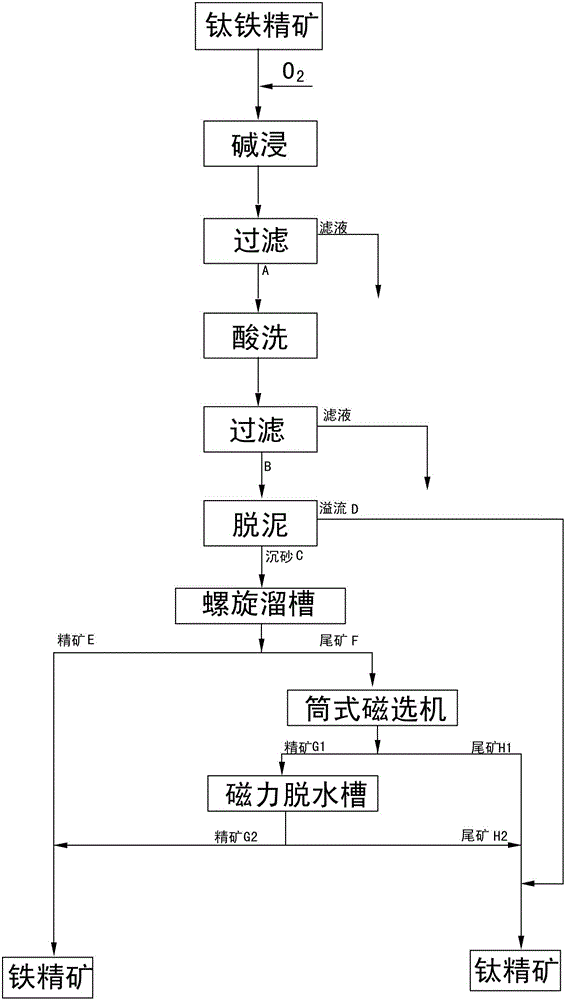

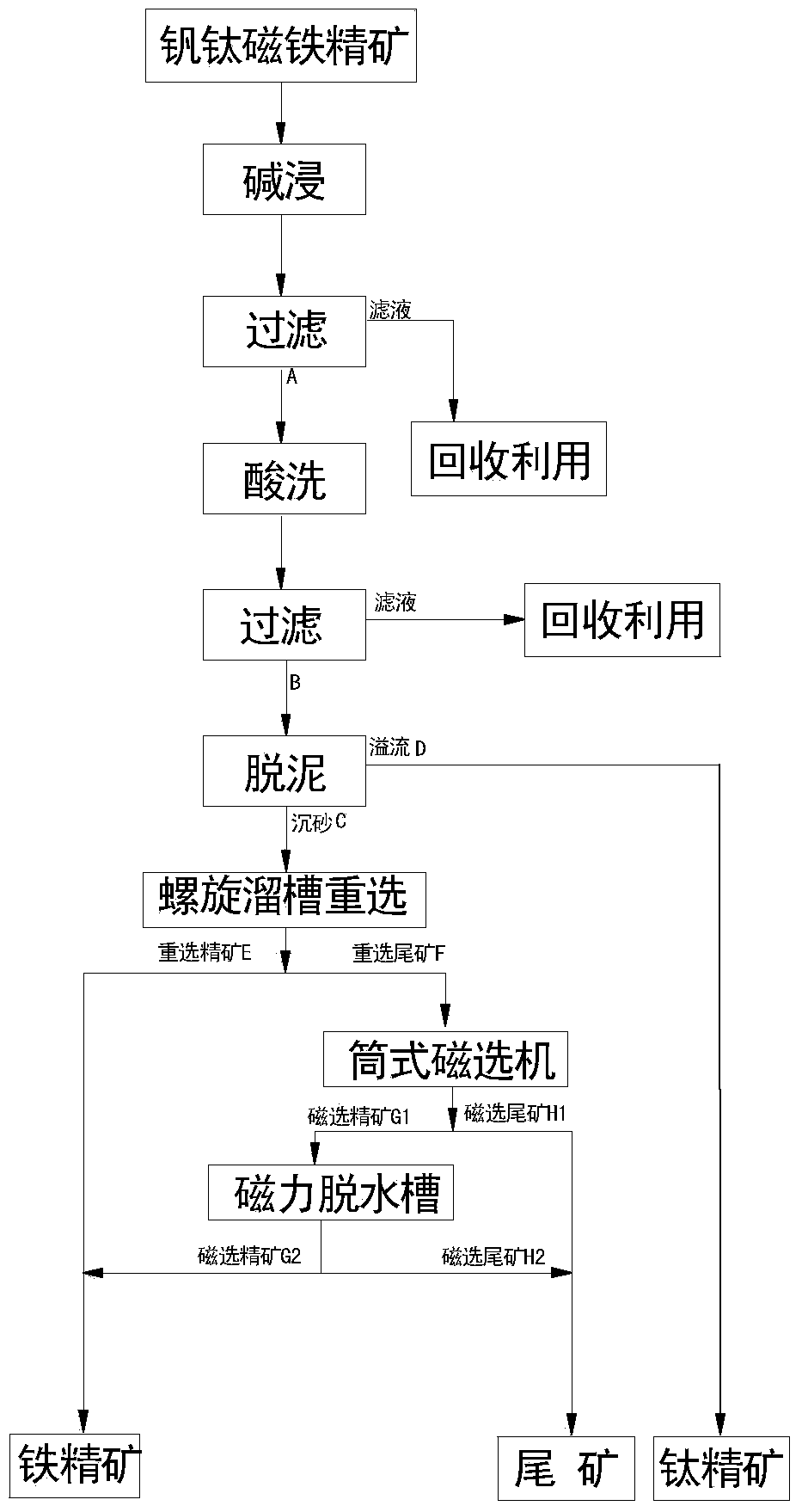

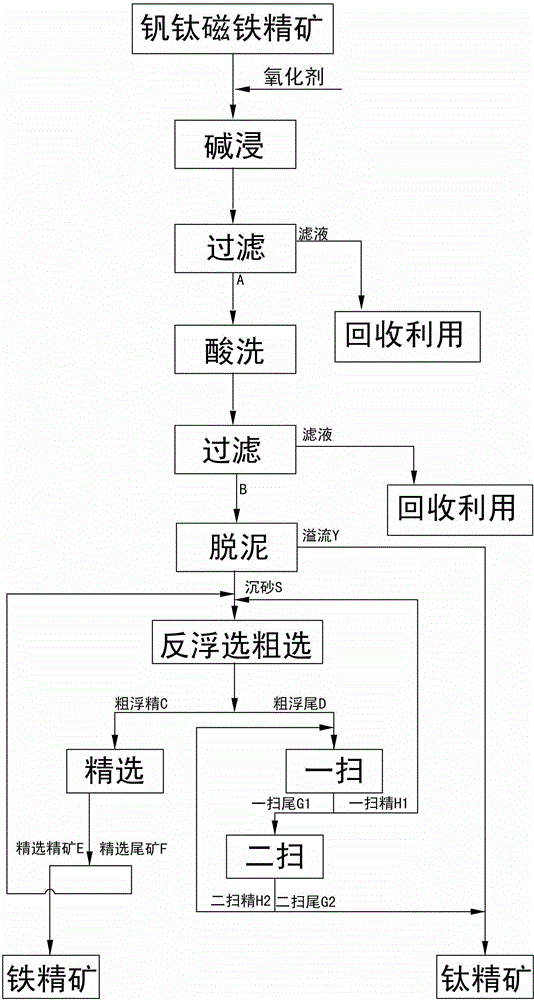

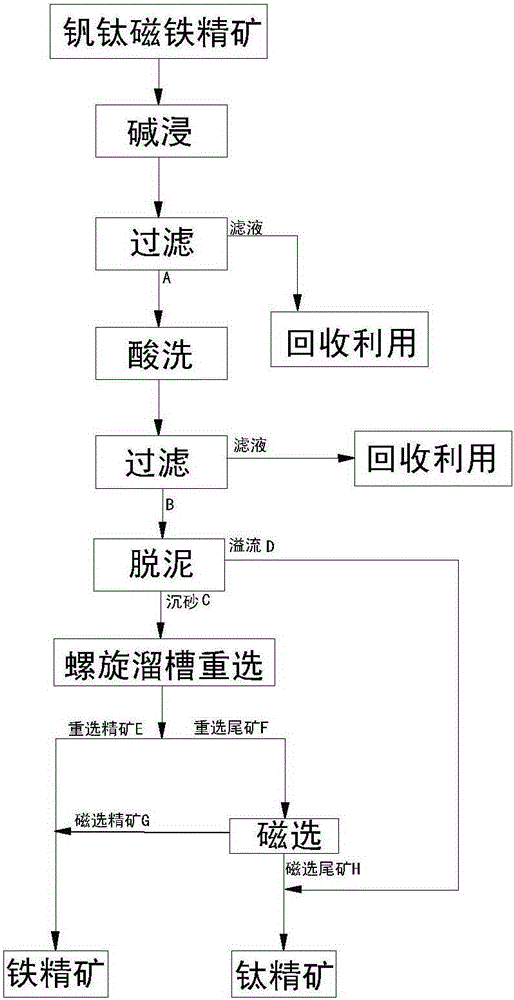

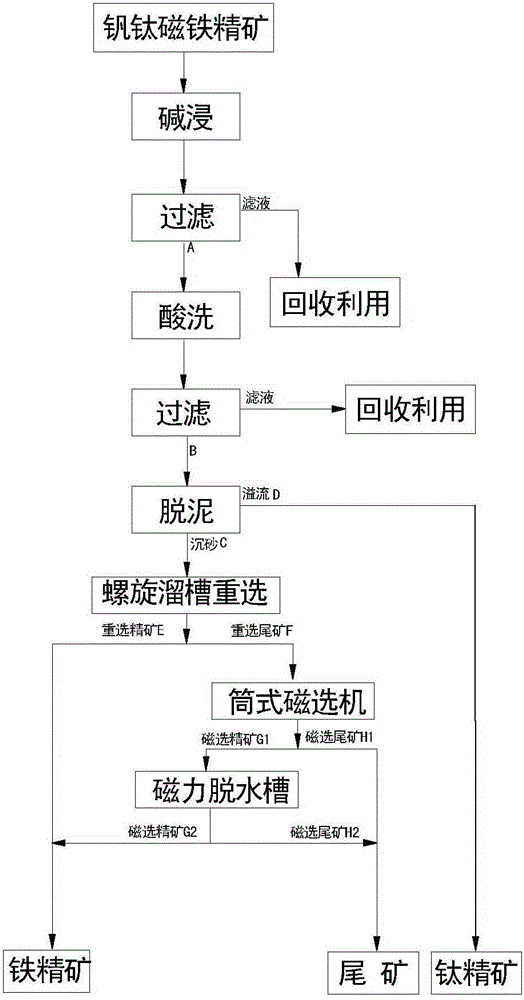

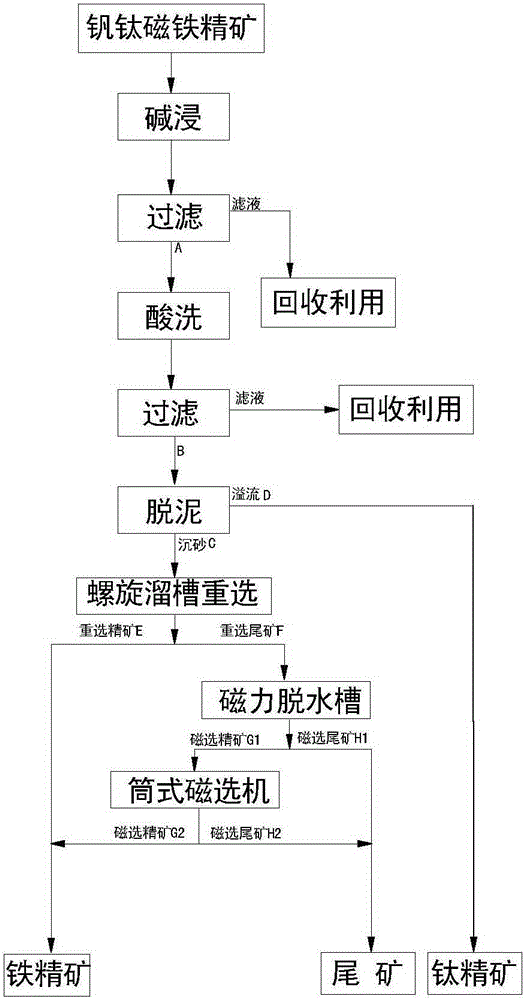

Vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, acid pickling, desliming and combined gravity-magnetic separation

The invention discloses a vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, acid pickling, desliming and combined gravity-magnetic separation. The method comprises the steps of placing vanadium-titanium magnetite concentrate in aqueous alkali with a mass concentration of 5%-52% for alkaline leaching reaction at a temperature between 280 DEG C and 370 DEG C for 0.5 h - 5 h and conducting filtering to obtain a filtrate and an alkaline leached filter cake A; adding water into A to obtain pulp with the mass ratio of solid to liquid of 1:1-10, placing the pulp into an H2SO4 solution, conducting acid pickling for 5 min - 60 min at a temperature between 50 DEG C and 90 DEG C, and conducting filtering to obtain a filtrate and an acid leached filter cake B; conducting desliming on the acid leached filter cake B to obtain set sand C and effused flow D, adding water into the set sand C to obtain pulp with a mass concentration of 30%-41%, and conducting combined gravity-magnetic separation to obtain final iron ore concentrate with the TFe content ranging from 63% to 69% and titanium concentrate with the TiO2 content ranging from 60% to 82%. The method has the advantages that efficient sorting of the vanadium-titanium magnetite concentrate is realized, the content of impurities such as Al and Si entering a blast furnace is reduced, the utilization coefficient of the blast furnace is increased, and the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

Method for utilizing oxidation alkaline leaching and desliming to re-concentrate vanadium-titanium magnetite concentrates

InactiveCN104878221AReduce contentEmission reductionBlast furnace detailsProcess efficiency improvementMagnetiteReaction temperature

The invention relates to a method for utilizing oxidation alkaline leaching and desliming to re-concentrate vanadium-titanium magnetite concentrates. The method comprises the steps of arranging the vanadium-titanium magnetite concentrates in aqueous alkali, adding an oxidizing agent, performing alkaline leaching reaction at the temperature ranging from 220 DEG C to 330 DEG C for 0.5-2 hours, filtering a reactant to obtain a filtrate and an alkaline leaching filter cake A, adding water into the alkaline leaching filter cake A to prepare ore pulp to perform desliming and re-concentrating operations. The method has the advantages that O2 or H2O2 introduced in alkaline leaching enables an S compound to be oxidized, reaction is accelerated, reaction time is shortened, reaction temperature, energy consumption and device investment are reduced, sorted iron ore concentrates contain 65%-70% of iron content, and titanium concentrates contain 50%-75% of TiO2 content, efficient titanium-iron separation in the vanadium-titanium magnetite concentrates is achieved, the content of impurities including TiO2, S, Si, Al and the like fed into a shaft furnace is decreased, the utilization coefficient of the shaft furnace is improved, and the comprehensive utilization rate of TiO2 resources is improved.

Owner:ANSTEEL GRP MINING CO LTD

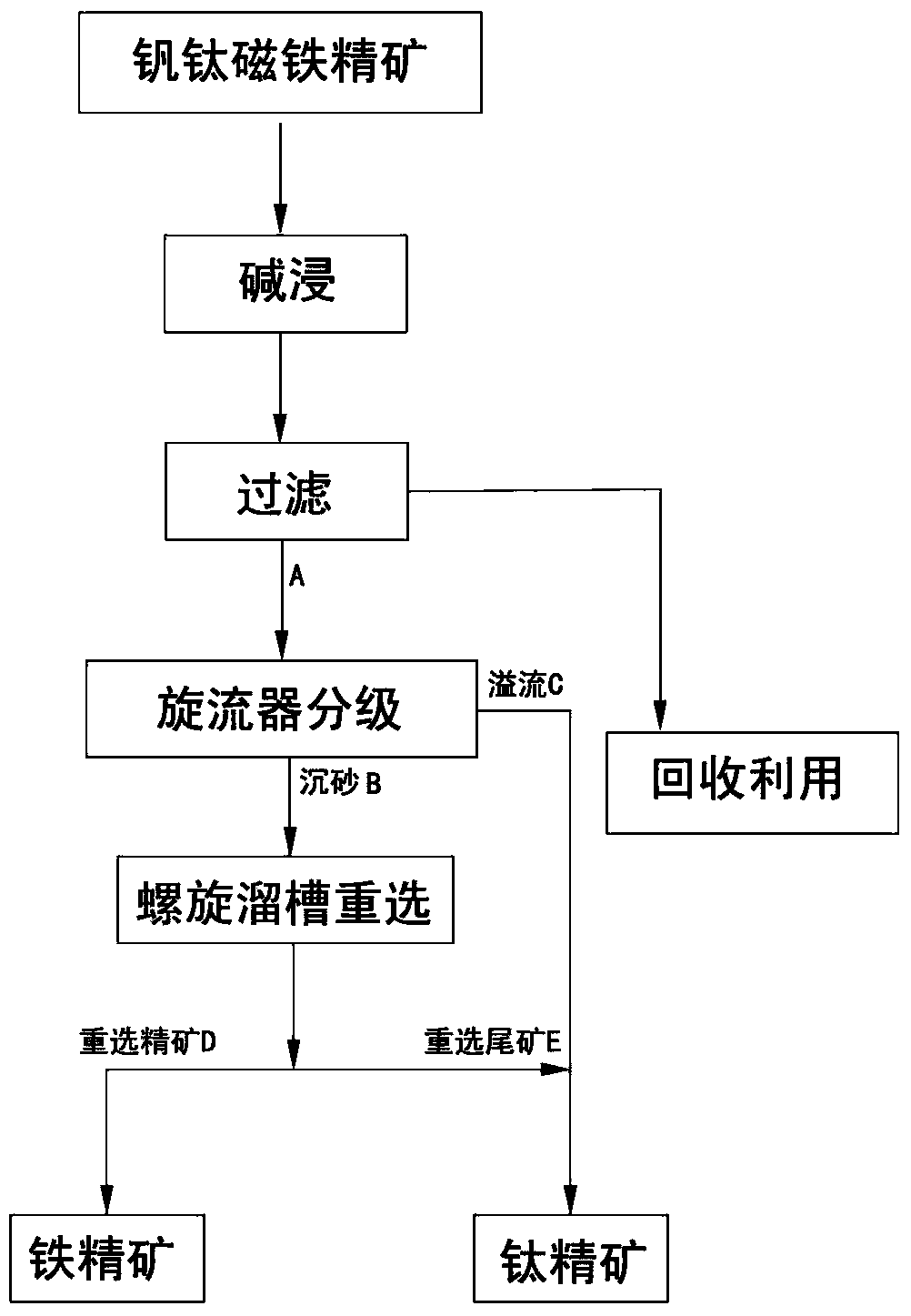

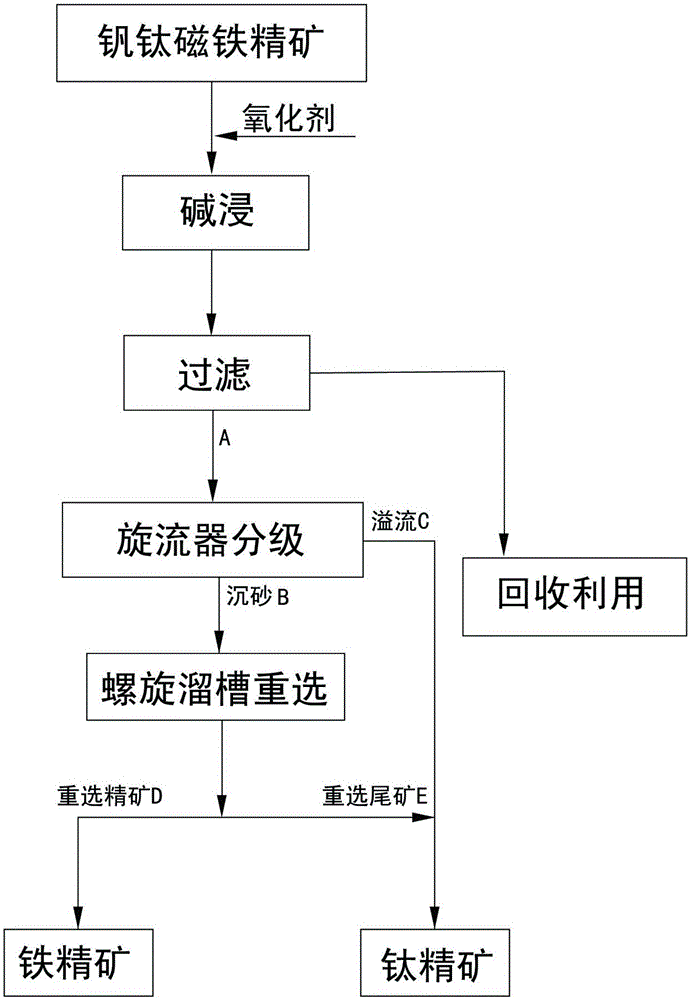

Vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, classification and gravity separation

The invention discloses a vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, classification and gravity separation. The method comprises the steps of placing vanadium-titanium magnetite concentrate in aqueous alkali with a mass concentration of 5%-52% for alkaline leaching reaction at a temperature between 260 DEG C and 370 DEG C for 0.5 h - 5 h and conducting filtering to obtain a filtrate and an alkaline leached filter cake A; adding water into A and feeding the mixture into a cyclone for classification to obtain set sand B and effused flow C; adding water into B to obtain pulp with a mass concentration of 35%-40%, and conducting gravity separation to obtain iron ore concentrate with the TFe content ranging from 63% to 68% and titanium concentrate with the TiO2 content ranging from 50% to 60%. The method has the advantages that efficient sorting of the vanadium-titanium magnetite concentrate is realized, alkali consumption is low, the content of impurities such as Al and Si entering a blast furnace is reduced, the content of detrimental impurities TiO2 and S is reduced especially, the utilization coefficient of the blast furnace is increased, blast furnace slag emission is reduced, iron-making cost is reduced, the problems of high S content and severe pollution in the smelting process are solved, and the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

Method for recleaning vanadium-titanium magnetite concentrates by using oxidation and alkaline leaching, desliming and combined magneto-gravity separation

InactiveCN105296752AEfficient separationReduce contentMagnetic separationWet separationReaction temperatureTitanium

The invention relates to a method for recleaning vanadium-titanium magnetite concentrates by using oxidation and alkaline leaching, desliming and combined magneto-gravity separation. The method comprises the following steps: vanadium-titanium magnetite concentrates are put into an alkaline solution and an oxidizing agent is added; then an alkaline leaching reaction lasts for 0.5-2 hours at the temperature of 220 DEG C-330 DEG C; reactants are filtered, so that a filtrate and an alkaline leaching filter cake A are obtained; and the filter cake A is added with water, and the mixture is prepared into ore pulp for desliming and combined magneto-gravity recleaning. The method has the advantages as follows: due to the introduction of O2 or H2O2 during oxidation and alkaline leaching, compounds containing S are oxidized, the reaction is accelerated, and the reaction temperature and the energy consumption are reduced. Besides, an iron ore concentrate with the TFe content of 65 %-70 % and a titanium concentrate with the TiO2 content of 50 %-70 % are screened, so that efficient separation of titanium and iron in vanadium-titanium magnetite concentrates is achieved, the content of impurities entering a blast furnace, such as TiO2, S, Si, Al and the like is reduced, the utilization coefficient of blast furnace is increased, and the comprehensive utilization ratio of titanium resources is increased as well.

Owner:ANSTEEL GRP MINING CO LTD

Vanadium-titanium magnetite concentrate method by using calcinations, oxidation by alkaline leaching, grading and magnetic gravitational reselection

InactiveCN104888937AEfficient separationReduce contentProcess efficiency improvementWet separationMagnetiteReaction temperature

The invention relates to a vanadium-titanium magnetite concentrate method by using calcinations, oxidation by alkaline leaching, grading and magnetic gravitational reselection. The method comprises the following steps: adding vanadium-titanium magnetite concentrate into CaO (Calcium Oxide) according to the weight ratio of 1: (0.1-0.2), calcining at 800-1400 DEG C, placing a calcined product A into aqueous alkali of which the mass concentration is 5-52%, adding an oxidant, carrying out alkaline leaching reaction for 0.5-2.0 hours at 220-330 DEG C to obtain a filtrate and an alkaline leaching filter cake B, and carrying out grading and magnetic gravitational reselection on the filter cake B. The method provided by the invention has the advantages that either O2 (Oxygen) or H2O2 (Hydrogen Peroxide), during the process of oxidation by alkaline leaching, is introduced so that the oxidation reaction of an S (Sulfur)-containing compound is accelerated, therefore the reaction temperature can be reduced and the reaction time can be shortened; furthermore, iron ore concentrate, of which TFe (Tetrafluoroethylene) content is 63-69% and TiO2 (Titanium Oxide) content is 50-72%, can be selected so that the contents of TiO2, S, Si (Silicon), Al (Aluminum) and other impurities which enter a blast furnace can be reduced, the capacity factor of the blast furnace can be improved, and the rate of multipurpose utilization of a titanium resource can be improved.

Owner:ANSTEEL GRP MINING CO LTD

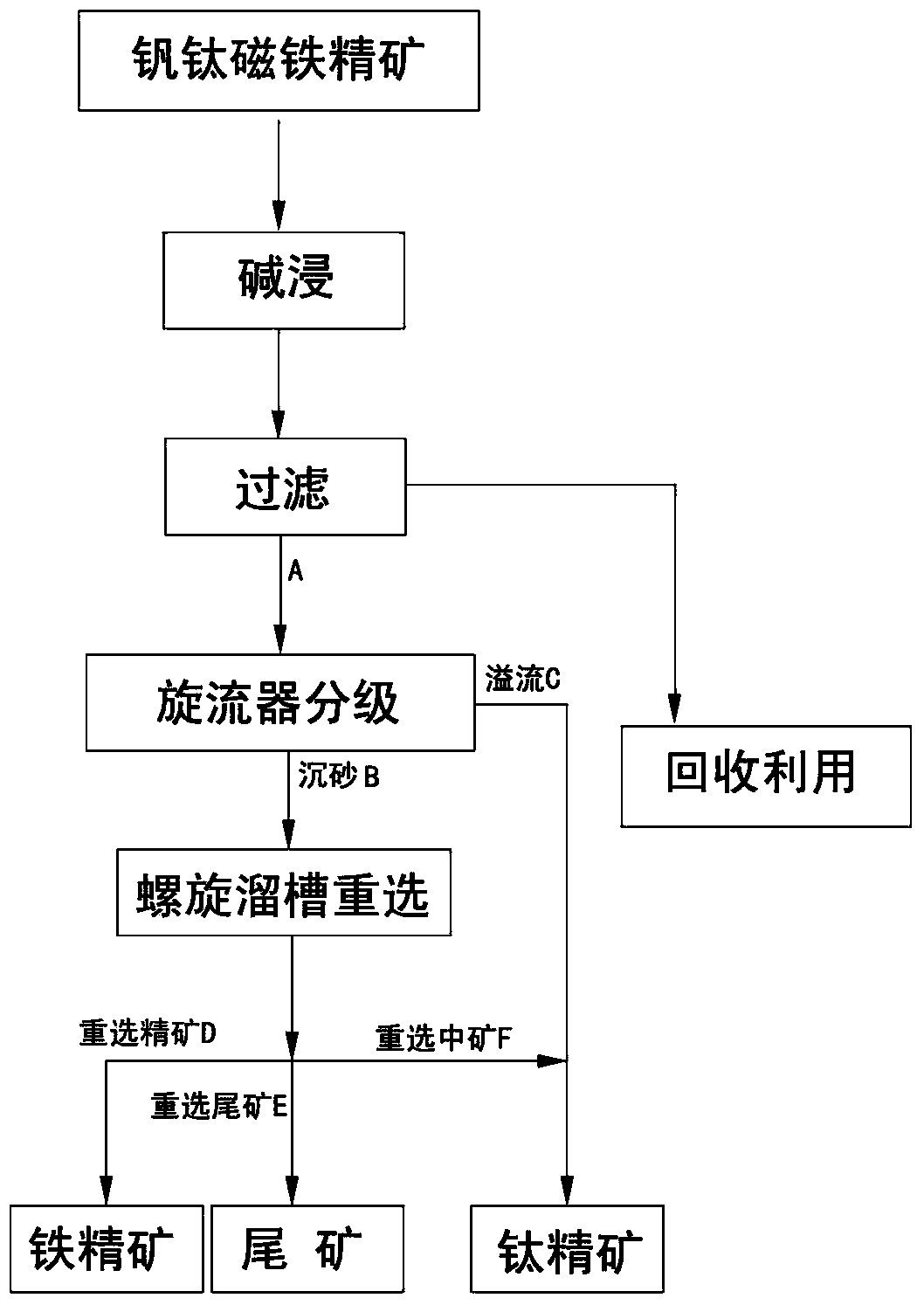

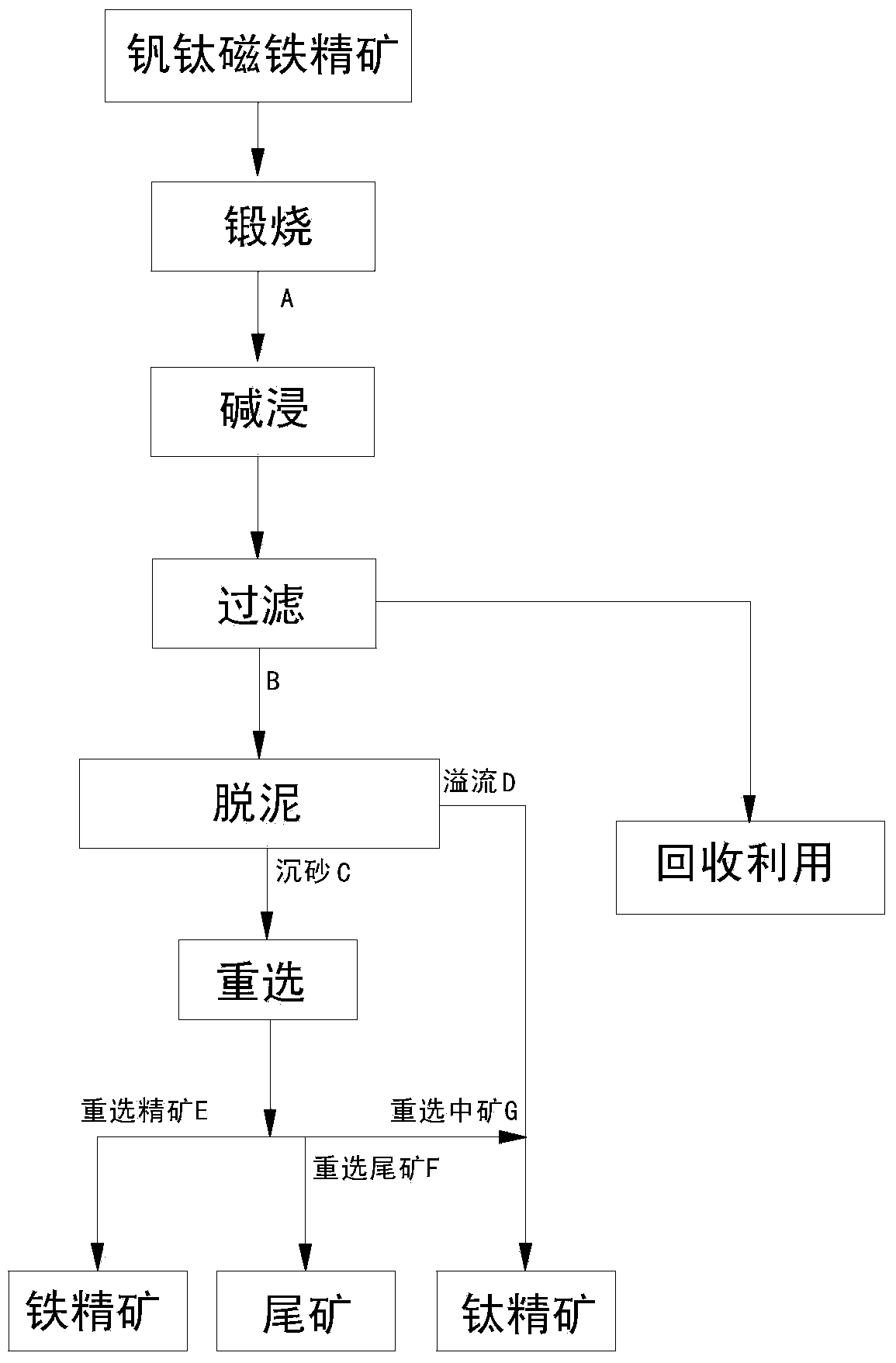

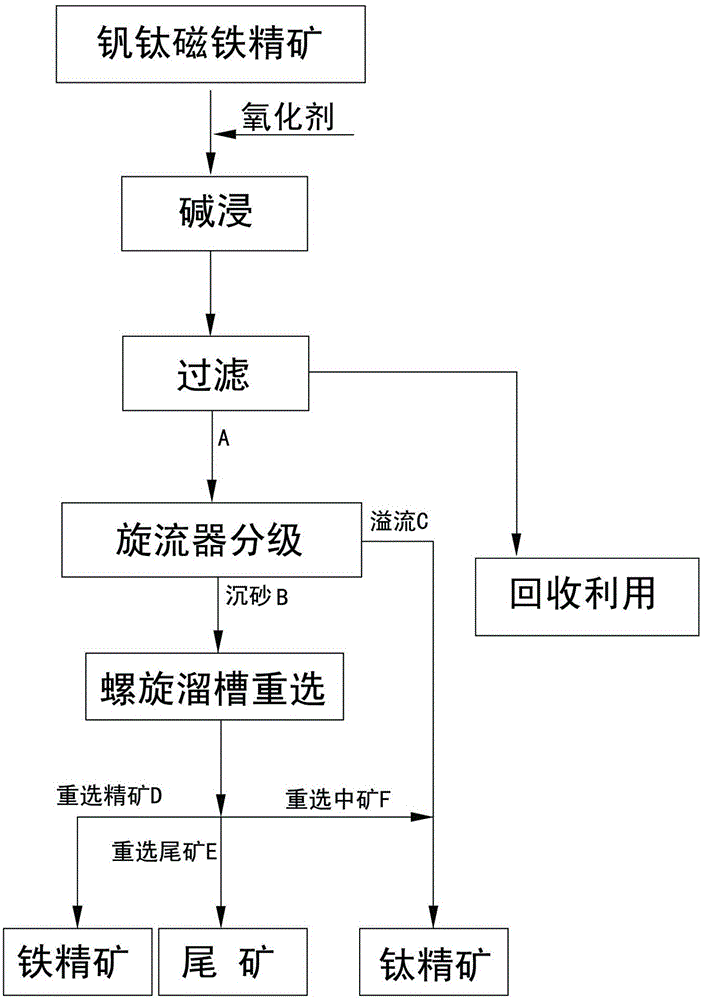

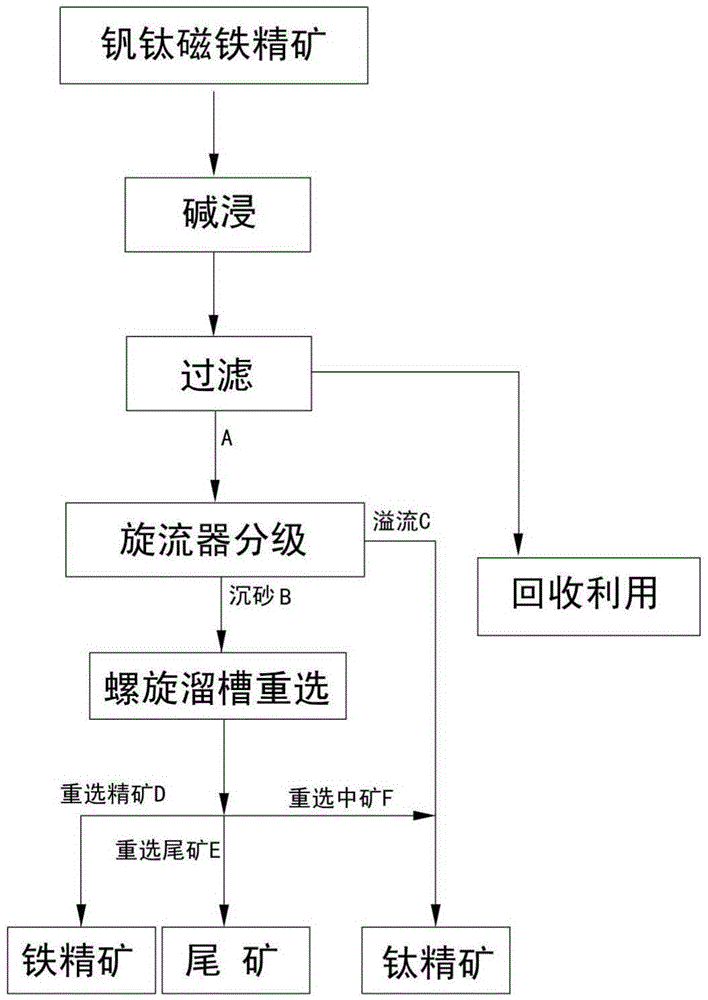

Method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching, desliming and gravity concentration

The invention discloses a method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching, desliming and gravity concentration. The method comprises the following steps that CaO is added to the vanadium-titanium magnetite concentrates, the mixture is calcined for 20 to 60 minutes at the temperature ranging from 800 DEG C to 1400 DEG C, and therefore a calcined product A is formed; the product A is placed in an alkaline solution with the mass concentration ranging from 5% to 52%, an alkaline leaching reaction is conducted for 0.5 to 5 hours, and filtrate and an alkaline leaching filter cake B are obtained through filtration; water is added to the alkaline leaching filter cake B, so that ore pulp is prepared and fed for desliming operation, and settling sand C and overflow D are obtained; water is added to the settling sand C, so that ore pulp is prepared for gravity concentration, gravity concentrates E, gravity tailings F and gravity middlings G are respectively obtained, the gravity concentrates E are final iron ore concentrates, the gravity tailings F are final tailings, and final titanium concentrates are obtained by combining the gravity middlings G with the overflow D. The method has the advantages that consumption of NaOH or KOH is reduced, the vanadium-titanium magnetite concentrates are efficiently screened, alkali consumption is low, the content of impurities such as Al and Si which enter a blast furnace is reduced, the blast furnace use coefficient is increased, and meanwhile the comprehensive use rate of titanium resources is improved.

Owner:ANSTEEL GRP MINING CO LTD

Method for vanadium-titanium magnetite concentrate by using oxidization alkaline leaching, acid washing, desliming and reverse flotation

The invention relates to a method for a vanadium-titanium magnetite concentrate by using oxidization alkaline leaching, acid washing, desliming and reverse flotation. The method is characterized by comprising the following steps: the oxidization alkaline leaching is to put the vanadium-titanium magnetite concentrate into alkaline solution; an oxidizing agent is added to perform the alkaline leaching reaction for 0.5-2 hours, and is filtered to obtain filtrate and an alkaline leaching filter cake A; the alkaline leaching filter cake A is added with water to prepare pulp, is put in H2SO4 solution to wash by acid for 5-60 minutes at a temperature of 50-90 DEG C, and is filtered to obtain filtrate and acid leaching filter cake B; and the B is added with water to prepare pulp with the mass concentration of 30-35% for desliming and reverse flotation reselection to obtain an iron ore concentrate with the TFe content of 65-70% and a titanium ore concentrate with the TiO2 content of 60-75%. The method has the following advantages: the introduction of O2 or H2O2 in the oxidization alkaline leaching enables an S-contained compound to be oxidized, so that the reaction is accelerated, the reaction temperature is lowered, the reaction time is shortened, and the energy consumption and the equipment investment are largely reduced.

Owner:ANSTEEL GRP MINING CO LTD

Method for processing vanadium-titanium magnetite concentrate by utilizing calcination, oxidation alkaline leaching, grading and gravity concentration

InactiveCN105039680AReduce consumptionReduce manufacturing costProcess efficiency improvementWet separationReaction temperatureMagnetite

The invention relates to a method for processing vanadium-titanium magnetite concentrate by utilizing calcination, oxidation alkaline leaching, grading and gravity concentration. The method comprises the following steps: adding vanadium-titanium magnetite concentrate in CaO in a weight proportion of the vanadium-titanium magnetite concentrate to the CaO being 1:0.1-0.2 so as to obtain a mixture; calcinating the mixture under the temperature of 800-1400DEG C so as to obtain a calcination product A; placing the calcination product A in an alkaline solution of which the mass concentration is 5-52% so as to obtain a mixed solution; adding an oxidizing agent in the mixed solution; performing an alkaline leaching reaction on the oxidizing agent and the mixed solution under the temperature of 220-330DEG C so as to obtain a filtrate and an alkaline leaching filter cake B; grading the filter cake B; and performing gravity concentration on the graded filter cake B. The method disclosed by the invention has the advantages that through the introduction of O2 or H2O2 in oxidation alkaline leaching, a compound containing S is oxidized, the reaction is accelerated, the reaction temperature is lowered, and the reaction time is shortened; the iron concentrate containing 63-69% of TFe, and the titanium concentrate containing 53-62% of TiO2 are obtained through mineral separation; the content of impurities, such as TiO2, S, Si and Al, entering a blast furnace is reduced; the utilization coefficient of the blast furnace is increased; besides, the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

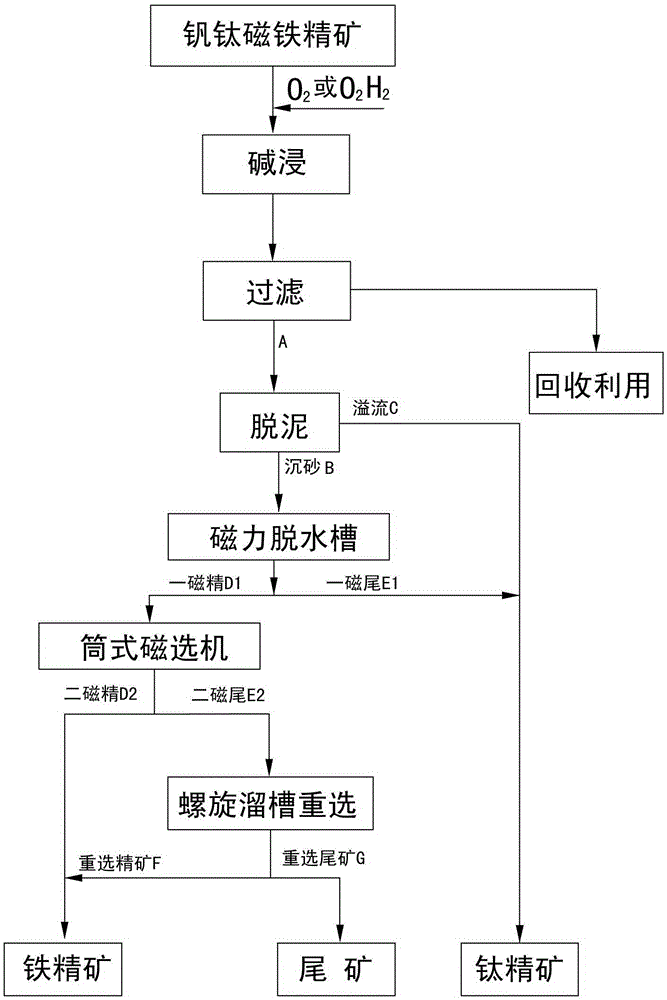

Method for recleaning vanadium-titanium magnetite concentrates by oxidation alkaline leaching, grading and magnetic separation

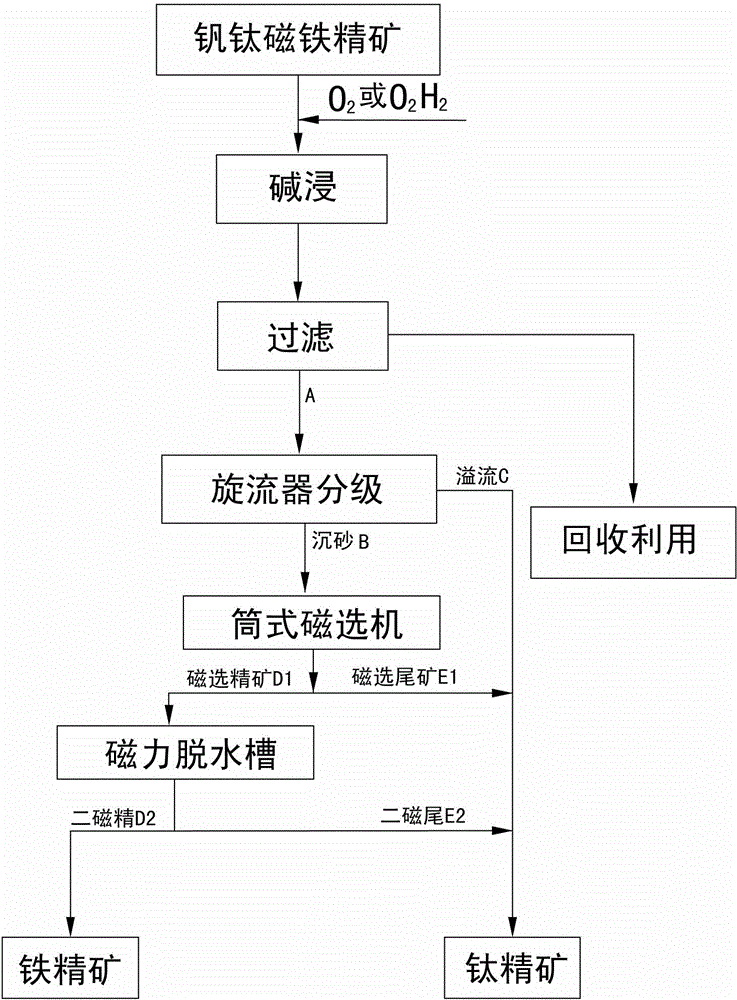

The invention relates to a method for recleaning vanadium-titanium magnetite concentrates by oxidation alkaline leaching, grading and magnetic separation. The method comprises the following steps: putting the vanadium-titanium magnetite concentrates into an aqueous alkali, adding an oxidizing agent therein, then alkaline leaching for 0.5-2 hours under a temperature of 220 degrees centigrade to 330 degrees centigrade, filtering the reactant to obtain a filtrate and an alkaline leached filter cake A; adding water into the leached filter cake A to prepare an ore pulp which is sent into a hydrocyclone for being graded and magnetically separated therein. The method has the advantages that the introduction of O2 or H2O2 in the oxidation alkaline leaching allows the compound containing S to be oxidized, thereby accelerating the reaction, shortening the reaction time, and reducing the reaction temperature, the energy consumption and the equipment investment; moreover, the iron ore concentrate containing 63%-69% of TFe and the titanium concentrate containing 35%-50% of TiO2 are respectively separated out, thereby achieving the efficient separation of titanium and iron in the vanadium-titanium magnetite concentrates, reducing the content of impurities such as TiO2, S, Si, and Al entering the blast furnace, increasing the utilization ratio of the blast furnace, and also increasing the comprehensive utilization ratio of the titanium resource.

Owner:ANSTEEL GRP MINING CO LTD

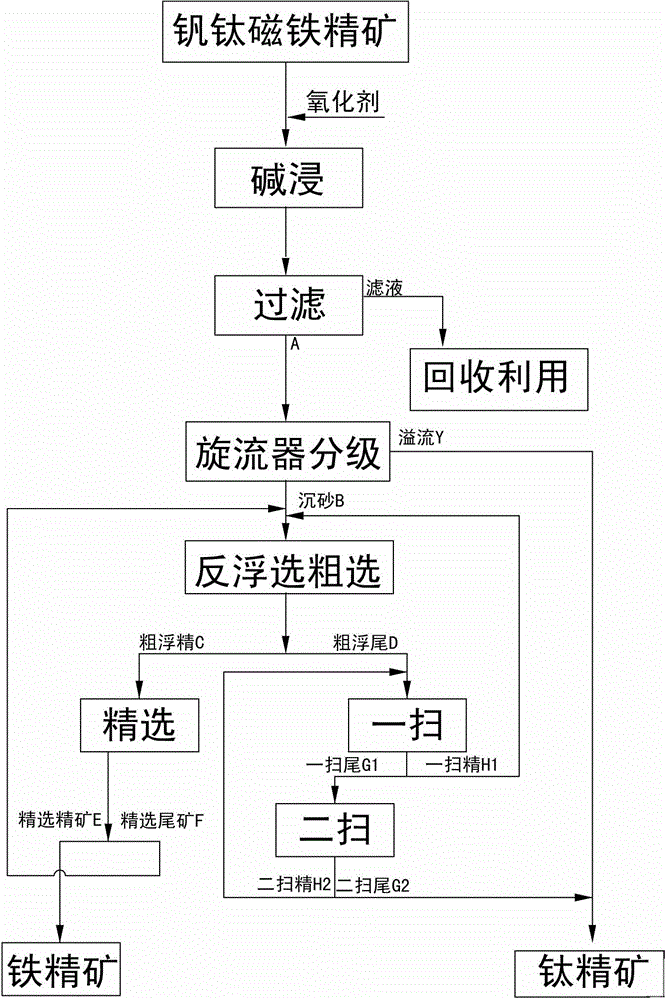

Method for reselecting vanadium-titanium magnetite concentrate by using oxidization alkaline leaching, classification and reverse flotation

InactiveCN104959217AReduce alkali consumptionRapid responseProcess efficiency improvementWet separationMagnetiteReaction temperature

The invention relates to a method for reselecting a vanadium-titanium magnetite concentrate by using oxidization alkaline leaching, classification and reverse flotation. The method comprises the following steps: the vanadium-titanium magnetite concentrate is put into alkaline solution; an oxidizing agent is added to perform the alkaline leaching reaction for 0.5-2 hours at a temperature of 220-330 DEG C; a reactant is filtered to obtain filtrate and an alkaline leaching filter cake A; and the alkaline leaching filter cake A is added with water to prepare pulp to perform the classification and the reverse flotation reselection operation. The method has the following advantages: the introduction of O2 or H2O2 in the oxidization alkaline leaching enables an S-contained compound to be oxidized, so that the reaction is accelerated, the reaction time is shortened, and the reaction temperature, the energy consumption and the equipment investment are reduced; and as an iron ore concentrate with the TFe content of 65-70% and a titanium ore concentrate with the TiO2 content of 50-70% are selected out, the high-efficiency titanium and iron separation of the vanadium-titanium magnetite concentrate is realized, the contents of such impurities as TiO2, S, Si and Al entering a blast furnace are reduced, the utilization coefficient of the blast furnace is increased, and the comprehensive utilization rate of a titanium resource is improved.

Owner:ANSTEEL GRP MINING CO LTD

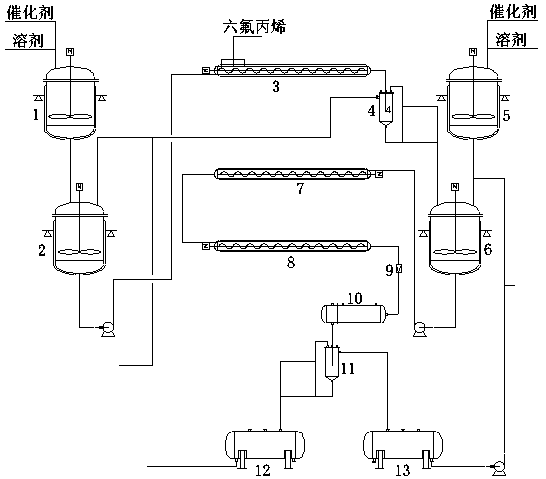

A kind of industrialized production method and production device of perfluoro-2-methyl-2-pentene

ActiveCN105837398BPoor compatibilityHigh selectivityHalogenated hydrocarbon preparationIsomerizationHexafluoropropylene

The invention provides an industrial production method and production apparatus for perfluoro-2-methyl-2-pentene, belonging to the technical field of chemical preparation of organic fluorine. The industrial production method comprises the following steps: with hexafluoropropene as a main raw material, carrying out a continuous gas-liquid phase oligomerization reaction at 0 to 60 DEG C in the presence of a main catalyst to produce dimer perfluoro-4-methyl-2-pentene hexafluoropropylene biopolymer, wherein reaction retention time is 10 to 600 s; and subjecting the obtained perfluoro-4-methyl-2-pentene hexafluoropropylene biopolymer to a continuous liquid-phase catalytic isomerization reaction in an organic solvent in the presence of the main catalyst so as to convert the biopolymer into perfluoro-2-methyl-2-pentene, wherein reaction temperature is 70 to 200 DEG C, reaction pressure is 0.3 to 1.8 MPa, and reaction retention time is 180 to 3000 s. The objective of the invention is to provide the industrial production method with the advantages of simple operation, a high automation degree and capacity of inhibiting or reducing generation of by-products, improving the usage efficiency of equipment and reducing emission of waste gas, waste water and industrial residues.

Owner:浙江诺亚氟化工有限公司

Method for re-selecting vanadium-titanium-magnetite concentrate by calcination, alkali leaching, desliming and magnetic separation

The invention discloses a method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching, desliming and magnetic separation. The method comprises the following steps that CaO is added to the vanadium-titanium magnetite concentrates, the mixture is calcined for 20 to 60 minutes at the temperature ranging from 800 DEG C to 1400 DEG C, and therefore a calcined product A is formed; the product A is placed in an alkaline solution, an alkaline leaching reaction is conducted for 0.5 to 5 hours at the temperature ranging from 300 DEG C to 370 DEG C, and filtrate and an alkaline leaching filter cake B are obtained through filtration; water is added to the alkaline leaching filter cake B, so that ore pulp is prepared and fed for desliming operation, and settling sand C and overflow D are obtained; water is added to the settling sand C, so that ore pulp is prepared for magnetic separation, and final iron ore concentrates with the TFe content ranging from 63% to 68% and final titanium concentrates with the TiO2 content ranging from 35% to 50% are screened. The method has the advantages that consumption of NaOH or KOH is reduced, the vanadium-titanium magnetite concentrates are efficiently screened, alkali consumption is low, the content of impurities such as Al and Si which enter a blast furnace is reduced, the blast furnace use coefficient is increased, the problems of the high S content and serious pollution in the smelting process are solved, and meanwhile the comprehensive use rate of titanium resources is improved.

Owner:ANSTEEL GRP MINING CO LTD

Method for re-selecting vanadium titanomagnetite concentrate by alkali leaching, classification and magnetic gravity

The invention discloses a vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, classification and combined magnetic-gravity separation. The method comprises the steps of placing vanadium-titanium magnetite concentrate in aqueous alkali with a mass concentration of 5%-52% for alkaline leaching reaction at a temperature between 280 DEG C and 370 DEG C for 0.5 h - 5 h and conducting filtering to obtain a filtrate and an alkaline leached filter cake A; adding water into A to form pulp with a mass concentration of 20%-25%, and feeding the pulp into a cyclone for classification to obtain effused flow and set sand B; adding water into the set sand B to obtain pulp with a mass concentration of 30%-41%, and conducting magnetic separation and gravity separation to obtain iron ore concentrate with the TFe content ranging from 63% to 68% and titanium concentrate with the TiO2 content ranging from 50% to 70%. The method has the advantages that efficient sorting of the vanadium-titanium magnetite concentrate is realized, alkali consumption is low, the content of impurities such as Al and Si entering a blast furnace is reduced, the content of detrimental impurities TiO2 and S is reduced especially, the utilization coefficient of the blast furnace is increased, blast furnace slag emission is reduced, iron-making cost is reduced, the problems of high S content and severe pollution in the smelting process are solved, and the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

Method for re-selecting vanadium titanomagnetite concentrate by alkali leaching, desliming and gravity separation

Owner:ANSTEEL GRP MINING CO LTD

The method of re-selecting vanadium-titanium magnetite concentrate by alkali leaching, desliming and magnetic gravity

Owner:ANSTEEL GRP MINING CO LTD

The method of re-selecting vanadium-titanium magnetite concentrate by calcination, alkali leaching and classification

The invention discloses a method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching and classification. The method comprises the following steps that CaO is added to titaniferous iron concentrates according to the weight ratio of 1: 0.1 to 0.2, the mixture is calcined for 20 to 60 minutes at the temperature ranging from 800 DEG C to 1400 DEG C, and therefore a calcined product A is formed; the product A is placed in an alkaline solution, an alkaline leaching reaction is conducted for 0.5 to 5 hours at the temperature ranging from 300 DEG C to 370 DEG C, and filtrate and an alkaline leaching filter cake B are obtained through filtration; water is added to the alkaline leaching filter cake B, so that ore pulp is prepared and fed into a hydrocyclone for classification, and settling sand C and overflow D are obtained through classification; the settling sand C is final iron ore concentrates with the TFe content ranging from 60% to 68%, and the overflow D is concentrated to be titanium concentrates with the TiO2 content ranging from 35% to 50%. The method has the advantages that consumption of NaOH or KOH is reduced, the vanadium-titanium magnetite concentrates are efficiently screened, alkali consumption is low, the content of impurities such as Al and Si which enter a blast furnace is reduced, the blast furnace use coefficient is increased, iron manufacture cost is reduced, and meanwhile the comprehensive use rate of titanium resources is improved.

Owner:ANSTEEL GRP MINING CO LTD

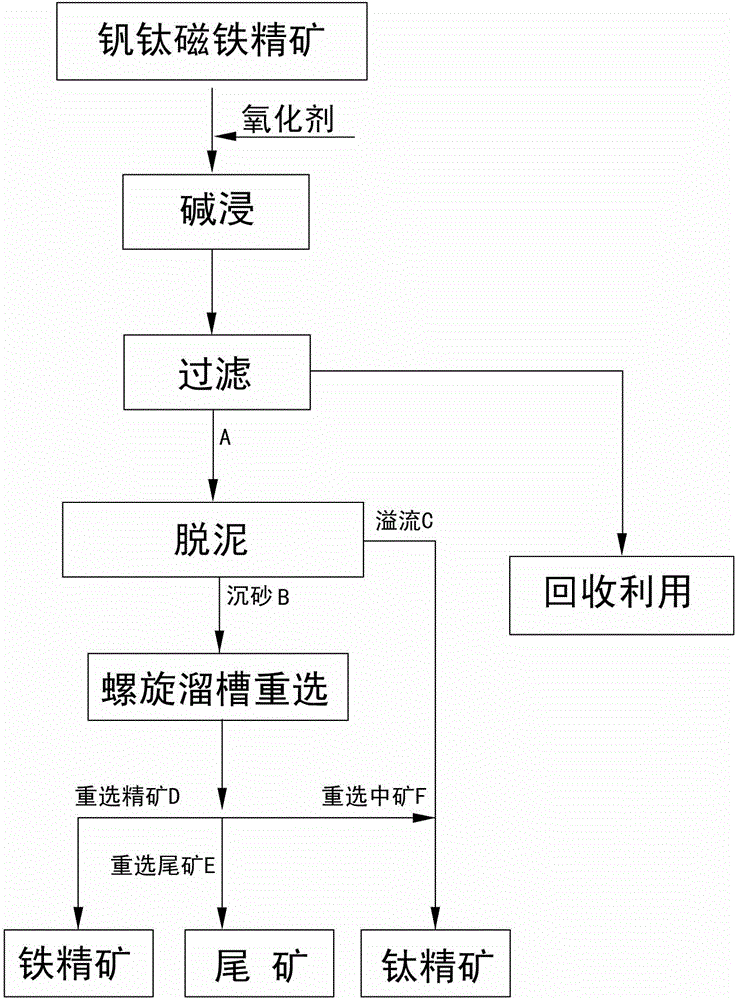

Vanadium-titanium magnetite concentrate re-concentration method achieved through oxidation alkaline leaching, classification and reselection

The invention relates to a vanadium-titanium magnetite concentrate re-concentration method achieved through oxidation alkaline leaching, classification and reselection. The method includes the following steps that vanadium-titanium magnetite concentrate is placed in an alkaline solution; oxidization agents are added, and then, an alkaline leaching reaction lasts for 0.5-2 h at the temperature of 220-330 DEG C; reactants are filtered, and then filter liquor and alkaline leached filter cakes A are obtained; water is added in the alkaline leached filter cakes A, and ore pulp is prepared; and the ore pulp is fed into a hydrocyclone for classification and reselection. The method has the beneficial effects that due to introduction of O2 or H2O2 during oxidation alkaline leaching, S compounds can be oxidized, the reaction is accelerated, the reaction time is shortened, the reaction temperature is lowered, and energy consumption and equipment investment are reduced; iron concentrate with the TFe content being 65-70% and titanium concentrate with the TiO2 content being 50-60% can be selected; titanium and iron of the vanadium-titanium magnetite concentrate are efficiently separated; the content of the TiO2, S, Si, Al and other impurities entering a blast furnace is reduced; the utilizing coefficient of the blast furnace is increased; and meanwhile, the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

Method for re-selecting vanadium-titanium magnetite concentrate by alkali leaching, pickling, desliming and gravity-magnetism

The invention discloses a vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, acid pickling, desliming and combined gravity-magnetic separation. The method comprises the steps of placing vanadium-titanium magnetite concentrate in aqueous alkali with a mass concentration of 5%-52% for alkaline leaching reaction at a temperature between 280 DEG C and 370 DEG C for 0.5 h - 5 h and conducting filtering to obtain a filtrate and an alkaline leached filter cake A; adding water into A to obtain pulp with the mass ratio of solid to liquid of 1:1-10, placing the pulp into an H2SO4 solution, conducting acid pickling for 5 min - 60 min at a temperature between 50 DEG C and 90 DEG C, and conducting filtering to obtain a filtrate and an acid leached filter cake B; conducting desliming on the acid leached filter cake B to obtain set sand C and effused flow D, adding water into the set sand C to obtain pulp with a mass concentration of 30%-41%, and conducting combined gravity-magnetic separation to obtain final iron ore concentrate with the TFe content ranging from 63% to 69% and titanium concentrate with the TiO2 content ranging from 60% to 82%. The method has the advantages that efficient sorting of the vanadium-titanium magnetite concentrate is realized, the content of impurities such as Al and Si entering a blast furnace is reduced, the utilization coefficient of the blast furnace is increased, and the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

The method of re-selecting vanadium-titanium magnetite concentrate by alkali leaching, classification and gravity separation

The invention discloses a vanadium-titanium magnetite concentrate recleaning method realized through alkaline leaching, classification and gravity separation. The method comprises the steps of placing vanadium-titanium magnetite concentrate in aqueous alkali with a mass concentration of 5%-52% for alkaline leaching reaction at a temperature between 260 DEG C and 370 DEG C for 0.5 h - 5 h and conducting filtering to obtain a filtrate and an alkaline leached filter cake A; adding water into A and feeding the mixture into a cyclone for classification to obtain set sand B and effused flow C; adding water into B to obtain pulp with a mass concentration of 35%-40%, and conducting gravity separation to obtain iron ore concentrate with the TFe content ranging from 63% to 68% and titanium concentrate with the TiO2 content ranging from 50% to 60%. The method has the advantages that efficient sorting of the vanadium-titanium magnetite concentrate is realized, alkali consumption is low, the content of impurities such as Al and Si entering a blast furnace is reduced, the content of detrimental impurities TiO2 and S is reduced especially, the utilization coefficient of the blast furnace is increased, blast furnace slag emission is reduced, iron-making cost is reduced, the problems of high S content and severe pollution in the smelting process are solved, and the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

Method for recleaning vanadium-titanium magnetite concentrate through oxidative alkaline leaching and de-sliming

The invention relates to a method for recleaning vanadium-titanium magnetite concentrate through oxidative alkaline leaching and de-sliming. The method includes the following steps that the vanadium-titanium magnetite concentrate is added into an alkaline solution, an oxidizing agent is added, and then an alkaline leaching reaction is carried out for 0.5-2 hours at the temperature of 220-330 DEG C; the reactant is filtered, and the filtered liquid and an alkaline leaching filter cake A are obtained; and water is added into the filter cake A to be mixed into slurry for de-sliming. The method has the advantages that a compound containing S is oxidized by introducing O2 or H2O2 during oxidative alkaline leaching, the reaction is accelerated, the reaction time is shortened, the reaction temperature is lowered, and energy consumption and equipment investment are reduced; besides, iron concentrate with the content of TFe being 62-70% and titanium concentrate with the content of TiO2 being 40-50% are graded, efficient separation of titanium and iron in the vanadium-titanium magnetite concentrate is achieved, the content of impurities, such as TiO2, S, Si and Al, entering a blast furnace is reduced, the utilization coefficient of the blast furnace is increased, and meanwhile the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

Method for recleaning vanadium-titanium magnetite concentrate through forging, oxidative alkaline leaching and de-sliming

The invention relates to a method for recleaning vanadium-titanium magnetite concentrate through forging, oxidative alkaline leaching and de-sliming. The method includes the following steps that CaO is added into the vanadium-titanium magnetite concentrate according to the weight proportion of 1 to 0.1-0.2, and forging is performed at the temperature ranging from 800 DEG C to 1400 DEG C; the forged product A is placed in an alkaline solution with the mass concentration being 5-52%; an oxidizing agent is added, then an alkaline leaching reaction is carried out for 0.5-2.0 hours at the temperature of 220-330 DEG C, and filtered liquid and an alkaline leaching filter cake B are obtained; and the filter cake B is de-slimed and recleaned. The method has the advantages that a compound containing S is oxidized by introducing O2 or H2O2 during oxidative alkaline leaching, the reaction is accelerated, the reaction temperature is lowered, and the reaction time is shortened; besides, iron concentrate with the content of TFe being 60-69% and titanium concentrate with the content of TiO2 being 42-50% are graded, the content of impurities, such as TiO2, S, Si and Al, entering a blast furnace is reduced, the utilization coefficient of the blast furnace is increased, and meanwhile the comprehensive utilization rate of titanium resources is increased.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com