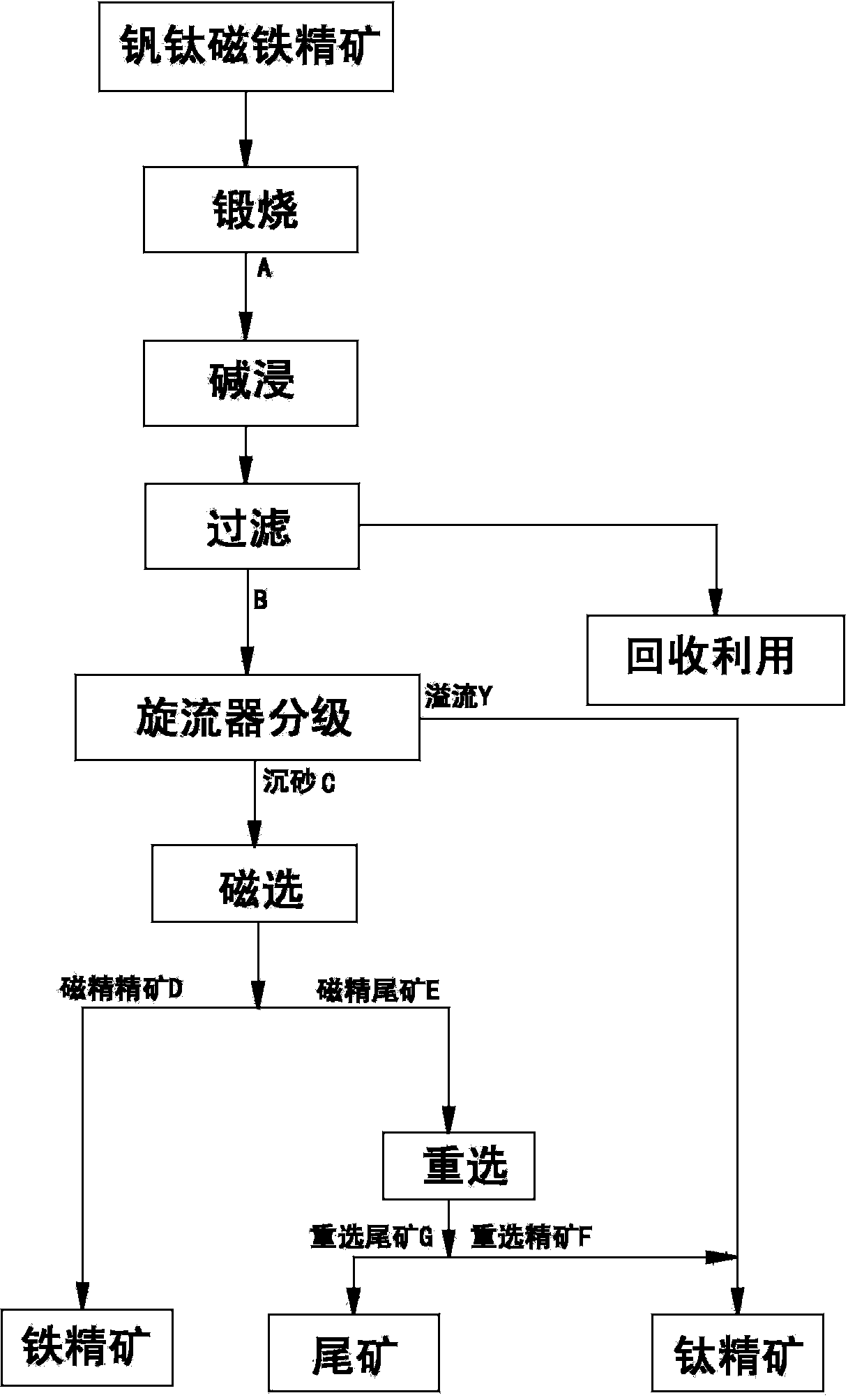

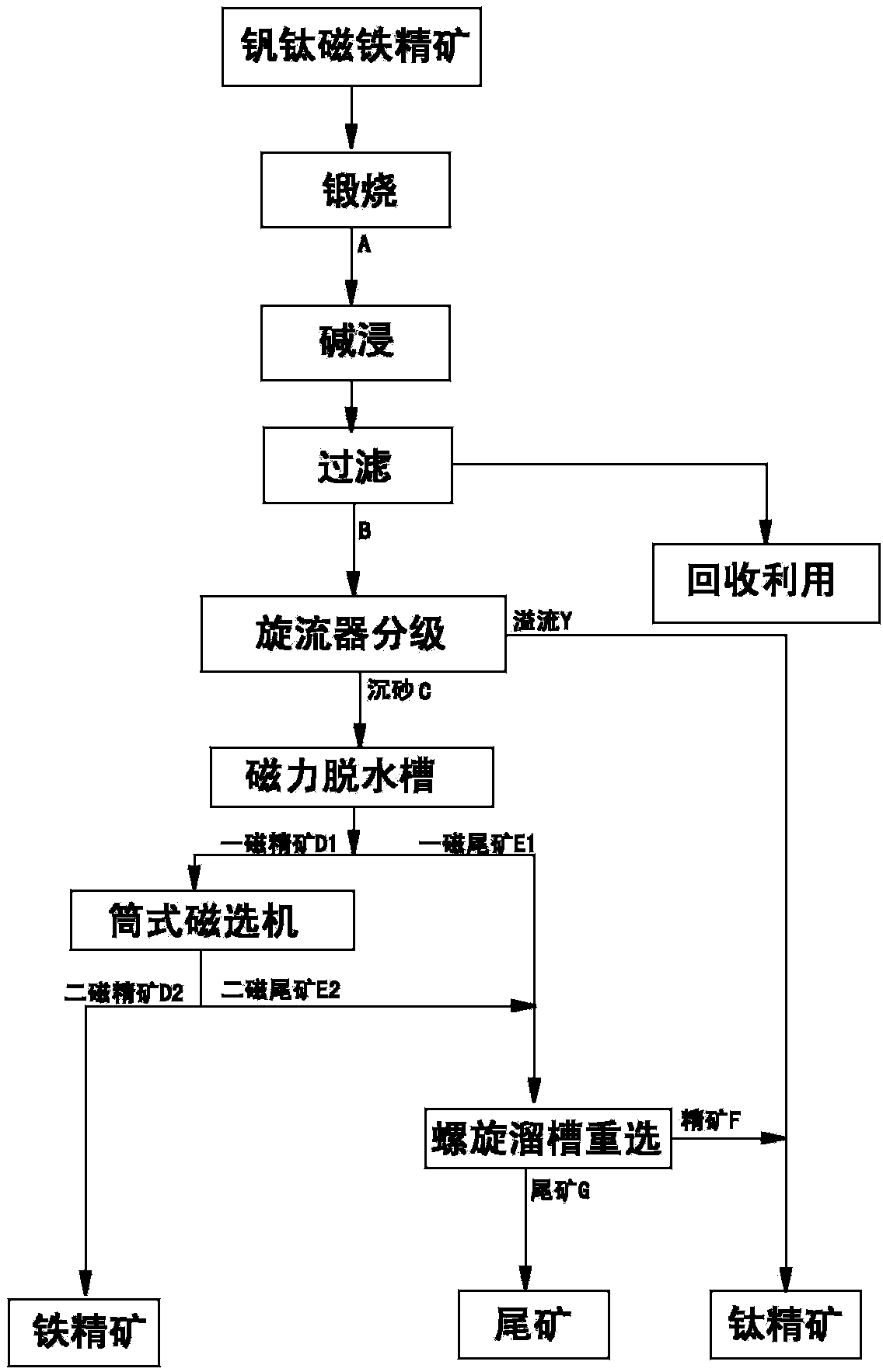

Method for recleaning of vanadium-titanium magnetite concentrates through calcination, alkaline leaching, classification and combination of magnetic separation and gravity concentration

A technology of vanadium-titanium magnetite concentrate and magnetic gravity combination, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Calcination

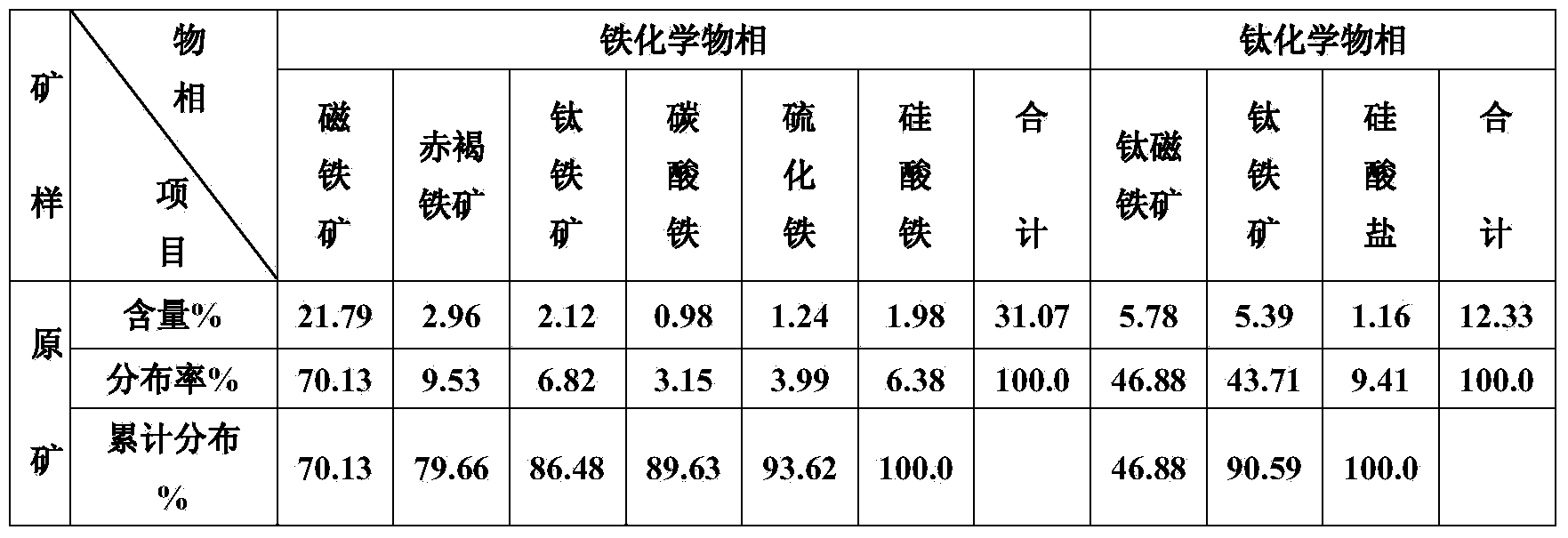

[0041] The TFe content is 53.2%, TiO 2 content of 12.9%, SiO 2 The content is 4.49%, Al 2 o 3 Vanadium-titanium magnetite concentrate with a content of 4.56% and a S content of 0.84% is added with CaO at a ratio of 1:0.12 by weight, and calcined at a temperature of 1350°C for 20 minutes to form a calcined product A. The chemical reaction formula is:

[0042]

[0043] 2) Alkaline leaching

[0044] The calcined product A in step 1) is placed in a NaOH alkali solution with a mass concentration of 10%, and the alkali leaching reaction is carried out at a temperature of 310° C. for 4.5 hours, and the reactant is filtered to obtain the filtrate and the alkali leaching filter cake B, NaOH Consumption of 47kg / t is fed to the ore, and the filtrate is fed into the recovery treatment system, and its chemical reaction formula is:

[0045]

[0046]

[0047] 3) Grading

[0048] Add water to the alkali leaching filter cake B in step 2) to form an ore ...

Embodiment 2

[0053] 1) Calcination

[0054] The TFe content is 51.9%, TiO 2 content of 12.1%, SiO 2 The content is 4.55%, Al 2 o 3 Vanadium-titanium magnetite concentrate with a content of 4.67% and a S content of 0.75% was added with CaO at a ratio of 1:0.13 by weight, and calcined at a temperature of 1300°C for 25 minutes to form a calcined product A, whose chemical reaction formula is the same as in Example 1 .

[0055] 2) Alkaline leaching

[0056] The calcined product A in step 1) is placed in a NaOH alkali solution with a mass concentration of 15%, and the alkali leaching reaction is carried out at a temperature of 320° C. for 3.5 hours, and the reactant is filtered to obtain the filtrate and the alkali leaching filter cake B, NaOH Consumption 46.5kg / t feeds ore, and described filtrate feeds recovery processing system, and its chemical reaction formula is the same as embodiment 1.

[0057] 3) Grading

[0058] Add water to the alkali leaching filter cake B in step 2) to form an...

Embodiment 3

[0063] 1) Calcination

[0064] The TFe content is 51.6%, TiO 2 content of 14.0%, SiO 2 The content is 4.25%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.27% and a S content of 0.64% was added with CaO at a ratio of 1:0.13 by weight, and calcined at a temperature of 1200° C. for 35 minutes to form a calcined product A, whose chemical reaction formula is the same as in Example 1 .

[0065] 2) Alkaline leaching

[0066] The calcined product A in step 1) is placed in a NaOH alkali solution with a mass concentration of 21%, and the alkali leaching reaction is carried out at a temperature of 330° C. for 3.0 hours, and the reactant is filtered to obtain the filtrate and the alkali leaching filter cake B, NaOH Consumption 47.2kg / t feeds ore, and described filtrate feeds recovery processing system, and its chemical reaction formula is the same as embodiment 1.

[0067] 3) Grading

[0068] Add water to the alkali leaching filter cake B in step 2) to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com