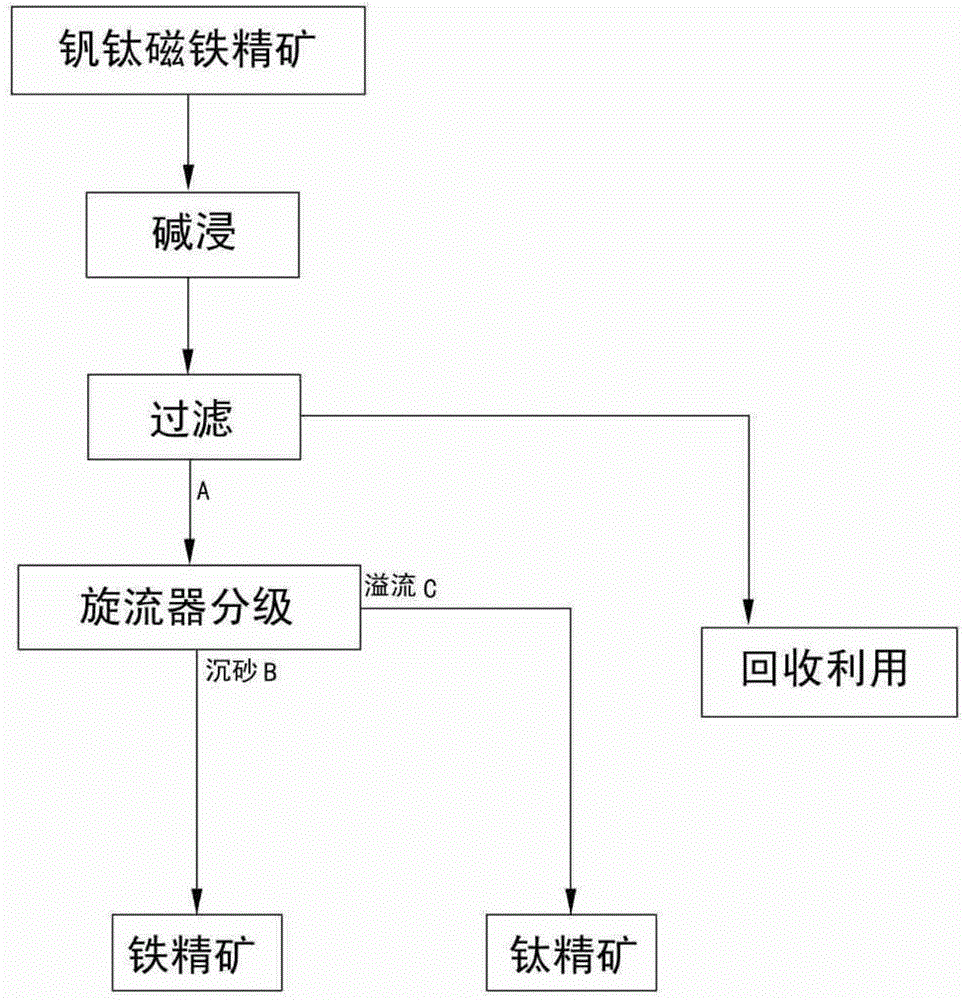

Method for recleaning vanadium-titanium magnetite concentrate by using alkaline leaching and grading

A technology of vanadium-titanium magnetite concentrate and alkali leaching, which is applied in blast furnaces, furnace types, furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

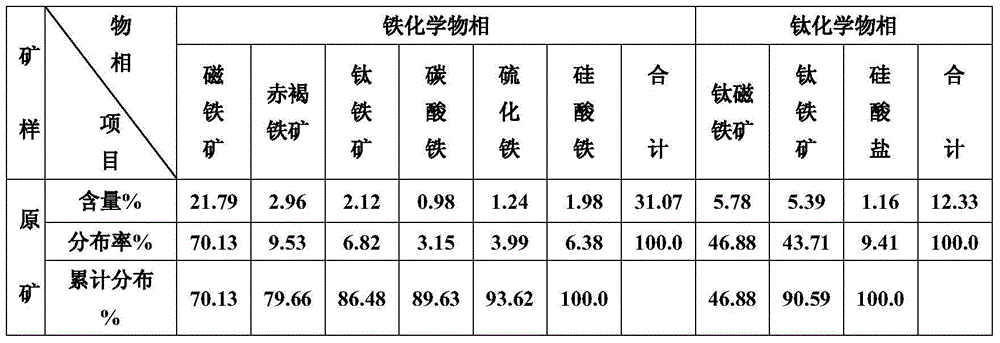

[0029]1) Alkaline leaching

[0030] The TFe content is 50.9%, TiO 2 content of 14.5%, SiO 2 The content is 3.62%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.40% and a S content of 0.58% is placed in a NaOH alkali solution with a mass concentration of 20%, and is subjected to alkali leaching reaction at a temperature of 280° C. for 4.0 hours, and the reactant is filtered to obtain a filtrate and Alkali leaching filter cake A, NaOH consumption 79kg / t feeds ore, and described filtrate is fed into recovery treatment system, and its chemical reaction formula is:

[0031]

[0032]

[0033]

[0034]

[0035]

[0036] 2) Grading

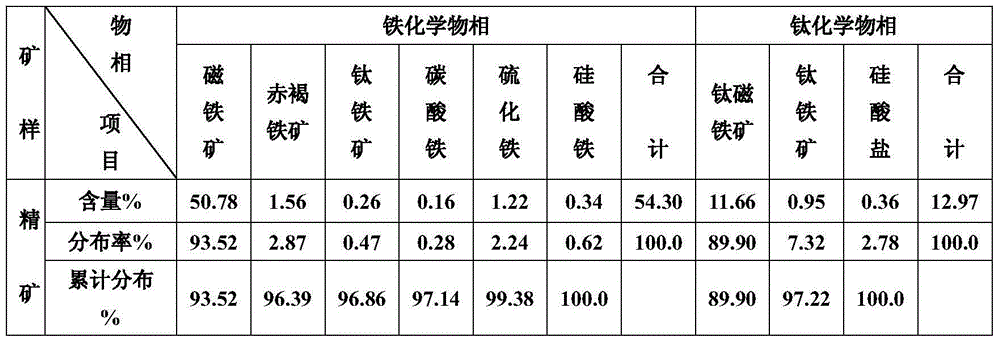

[0037] Add water to the alkali leaching filter cake A in step 1) to form an ore slurry with a mass concentration of 20% and feed it into the cyclone for classification, and classify the grit B and overflow C, and the grit B is the final iron concentrate with a TFe content of 60.2%. (SiO 2 The content is 0.80...

Embodiment 2

[0039] 1) Alkaline leaching

[0040] The TFe content is 53.5%, TiO 2 content of 11.3%, SiO 2 The content is 3.56%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 5.50% and a S content of 0.72% was placed in an 8% NaOH alkali solution, subjected to alkali leaching reaction at a temperature of 310° C. for 3.5 hours, and the reactant was filtered to obtain the filtrate and Alkali leaching filter cake A, NaOH consumption 75kg / t feeds ore, and described filtrate feeds recovery processing system, and its chemical reaction formula is the same as embodiment 1.

[0041] 2) Grading

[0042] Add water to the alkali leaching filter cake A in step 1) to form an ore slurry with a mass concentration of 21% and feed it into the cyclone for classification, and classify the grit B and overflow C, and the grit B is the final iron concentrate with a TFe content of 63.1%. (SiO 2 The content is 0.53%, Al 2 o 3 content of 1.86%, S content of 0.01%), the overflow C is ...

Embodiment 3

[0044] 1) Alkaline leaching

[0045] The TFe content is 52.5%, TiO 2 content of 12.3%, SiO 2 The content is 3.95%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 5.48% and a S content of 0.69% is placed in a concentration of 30% N a In OH alkali solution, carry out alkali leaching reaction at 300°C for 2.5 hours, filter the reactants to obtain filtrate and alkali leaching filter cake A, the NaOH consumption is 80kg / t to feed the ore, and the filtrate is fed to the recovery treatment system , its chemical reaction formula is with embodiment 1.

[0046] 2) Grading

[0047] Add water to the alkali leaching filter cake A in step 1) to form an ore slurry with a mass concentration of 22% and feed it into the cyclone for classification, and classify the grit B and overflow C, and the grit B is the final iron concentrate with a TFe content of 64.5%. (SiO 2 The content is 0.52%, Al 2 o 3 content of 1.84%, S content of 0.01%), the overflow C is concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com