Method for re-selecting vanadium titanomagnetite concentrate by alkali leaching, classification and magnetic gravity

A technology of vanadium-titanium magnetite concentrate and magnetic-gravity combination, which is applied in chemical instruments and methods, solid separation, wet separation, etc., to achieve the effects of reducing emissions, reducing ironmaking costs, and improving comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

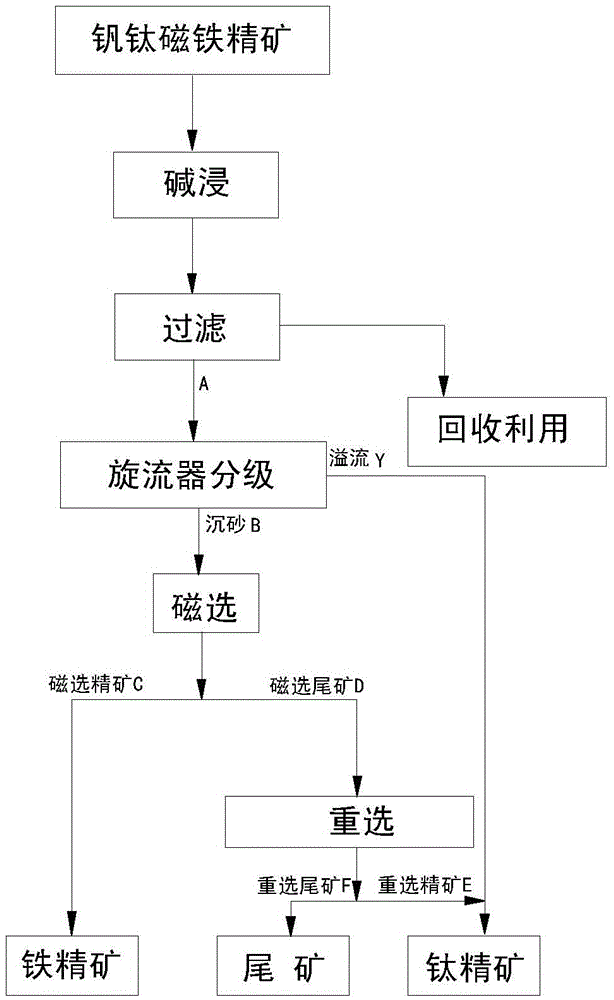

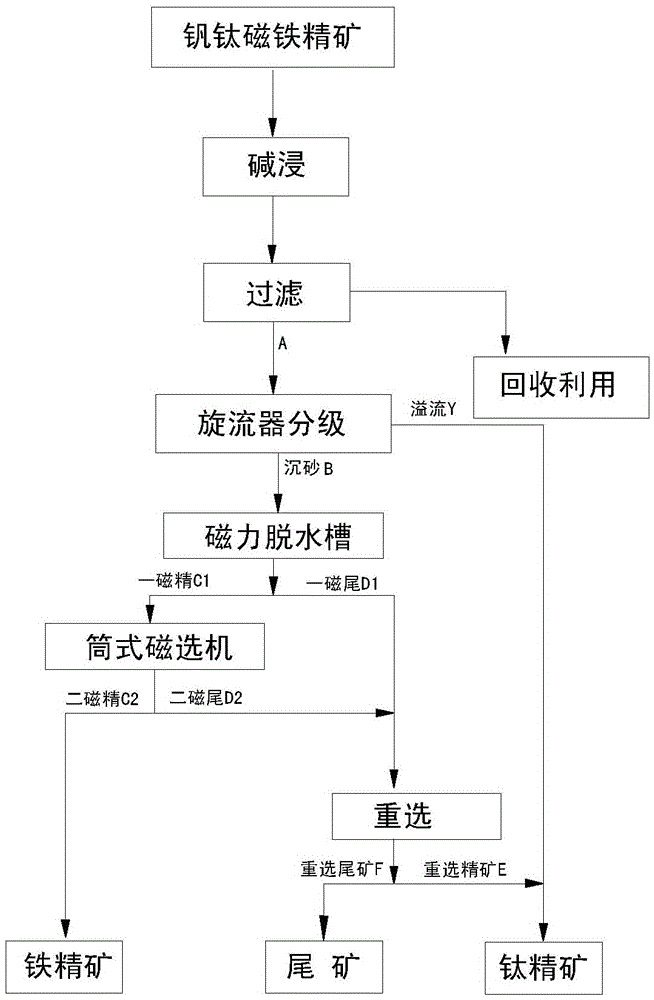

[0037] Such as figure 1 shown.

[0038] 1) Alkaline leaching

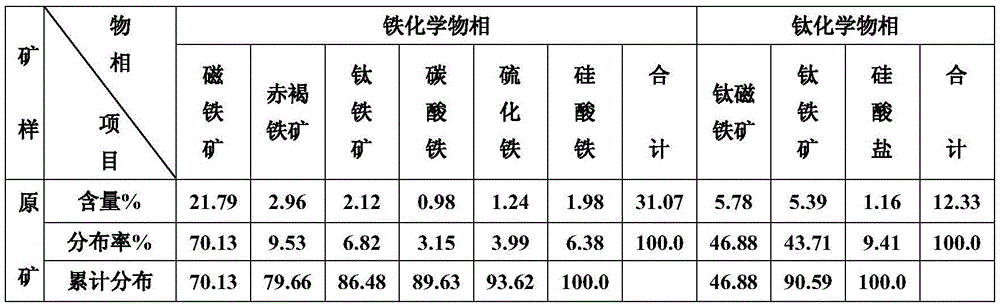

[0039] The TFe content is 52.8%, TiO 2 content of 12.5%, SiO 2 The content is 4.75%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.90% and a S content of 0.78% was placed in an 8% NaOH alkali solution, subjected to alkali leaching reaction at a temperature of 300°C for 5 hours, and the reactant was filtered to obtain the filtrate and Alkali leaching filter cake A, NaOH consumption 81kg / t is fed to ore, and described filtrate is fed into recovery treatment system, and its chemical reaction formula is:

[0040]

[0041]

[0042]

[0043]

[0044]

[0045] 2) Grading

[0046] Add water to the alkali leaching filter cake A in step 1) to form an ore slurry with a mass concentration of 20% and feed it into a cyclone for classification, and classify the grit B and overflow Y.

[0047] 3) Combined magnetic gravity beneficiation

[0048] Adding water to the sand settling B i...

Embodiment 2

[0051] Such as figure 1 shown.

[0052] 1) Alkaline leaching

[0053] The TFe content is 51.2%, TiO 2 content of 11.1%, SiO 2 The content is 4.75%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.82% and a S content of 0.81% is placed in a NaOH alkali solution with a mass concentration of 15%, and is subjected to alkali leaching reaction at a temperature of 290° C. for 4 hours, and the reactant is filtered to obtain the filtrate and Alkali leaching filter cake A, NaOH consumption 81kg / t feeds ore, and described filtrate feeds recovery processing system, and its chemical reaction formula is the same as embodiment 1.

[0054] 2) Grading

[0055] Add water to the alkali leaching filter cake A in step 1) to form an ore slurry with a mass concentration of 21% and feed it into a cyclone for classification, and classify the grit B and overflow Y.

[0056] 3) Combined magnetic gravity beneficiation

[0057] Add water to the grit B in step 2) to make a ...

Embodiment 3

[0060] Such as figure 1 shown.

[0061] 1) Alkaline leaching

[0062] The TFe content is 50.8%, TiO 2 content of 14.5%, SiO 2 The content is 4.65%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.72% and a S content of 0.66% is placed in a NaOH alkali solution with a mass concentration of 22%, and is subjected to alkali leaching reaction at a temperature of 310° C. for 3 hours, and the reactant is filtered to obtain a filtrate and Alkali leaching filter cake A, NaOH consumption 80kg / t is fed to ore, and described filtrate is fed into recovery treatment system, and its chemical reaction formula is the same as embodiment 1.

[0063] 2) Grading

[0064] Add water to the alkali leaching filter cake A in step 1) to form an ore slurry with a mass concentration of 22% and feed it into a cyclone for classification, and classify the grit B and overflow Y.

[0065] 3) Combined magnetic gravity beneficiation

[0066] Add water to the grit B in step 2) to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com