Optimized ore blending method based on sintering-pelletizing-ironmaking linkage

A technology for sintering ore and pellets, which is applied in the fields of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems such as the inability to feedback the cost of molten iron to optimize the proportion of iron ore, and it is difficult to effectively reduce the cost of iron making, so as to optimize the raw materials. The effect of proportioning, reducing the cost of iron making, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

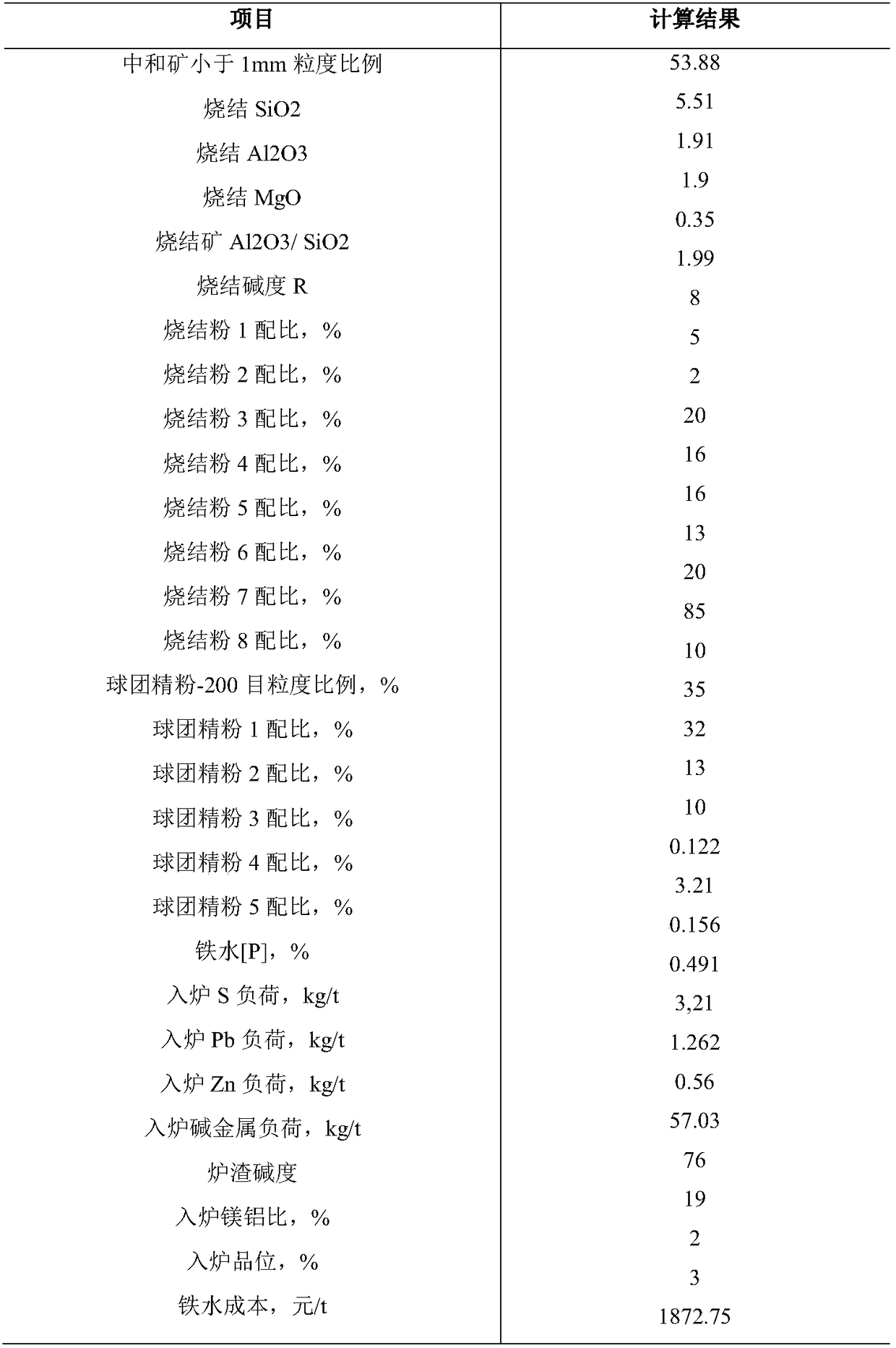

Embodiment 1

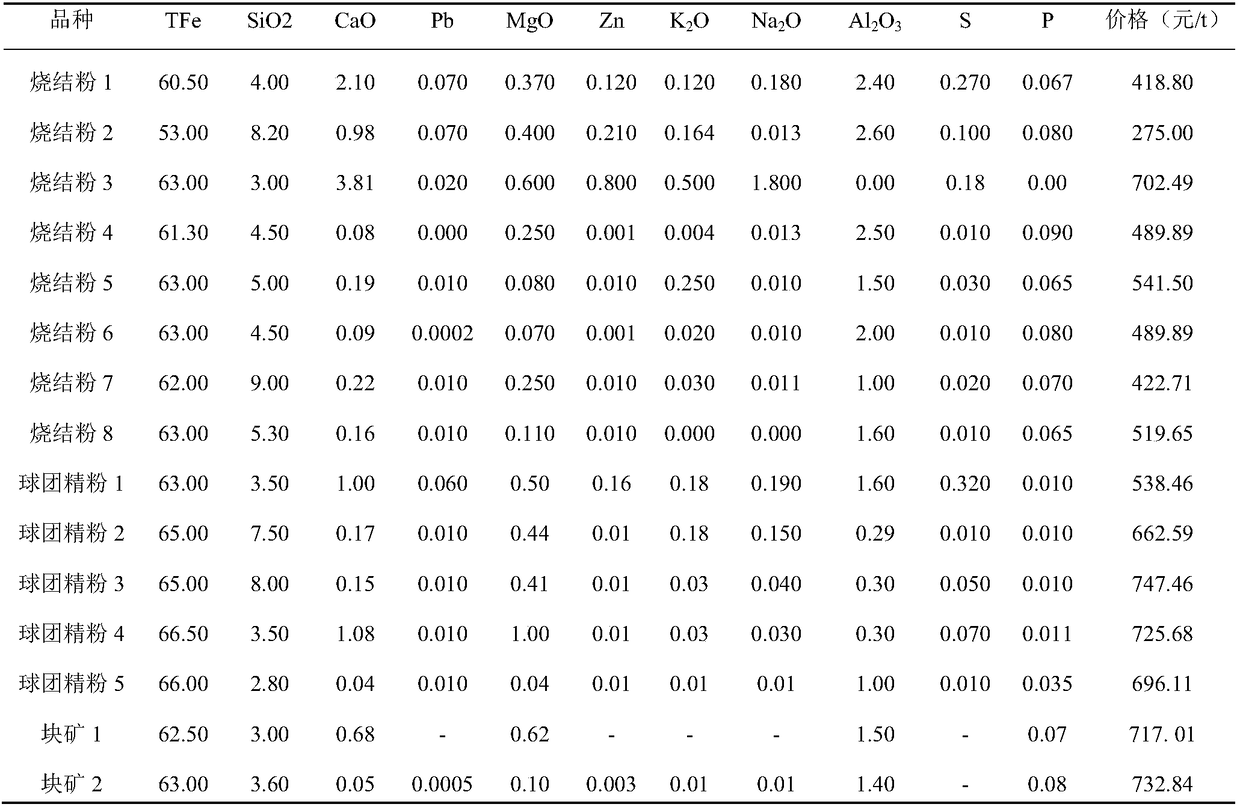

[0034] Based on the sintering-pellet-ironmaking linkage ore distribution module, it can better guide procurement and make procurement serve production. Therefore, a sintering-pelletizing-ironmaking linkage optimization ore blending model was subsequently developed to realize the simultaneous optimization of sintering batching, pelletizing batching, and blast furnace batching.

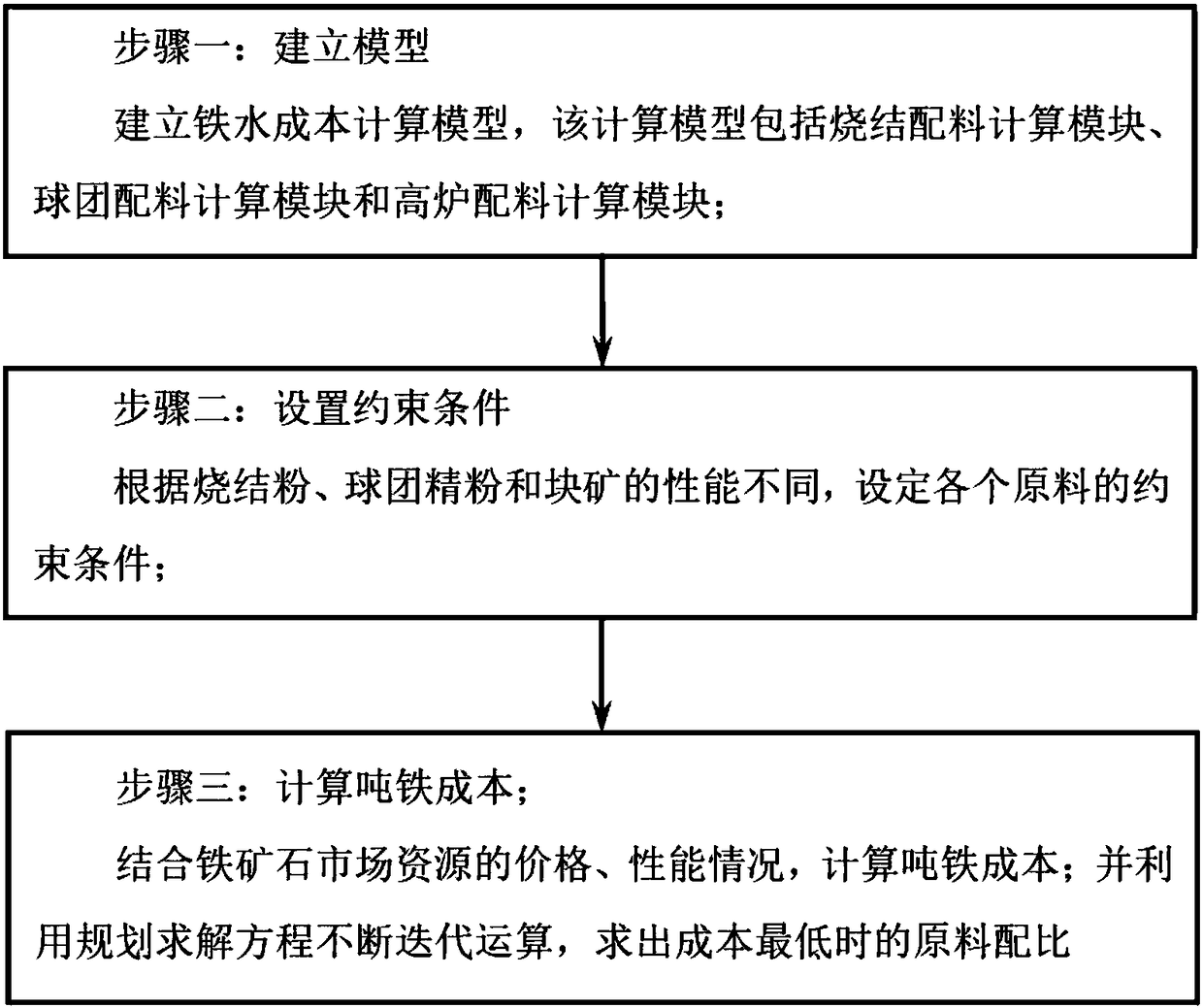

[0035] An optimized ore blending method based on sintering-pellet-ironmaking linkage of the present invention, the specific steps are as follows:

[0036] Step 1: Build a model

[0037]Establish a molten iron cost calculation model, which includes a sinter batch calculation module, a pellet batch calculation module, and a blast furnace batch calculation module;

[0038] Step 2: Set constraints

[0039] According to the different properties of sinter powder, pellet powder and lump ore, set the constraints of each raw material; guide by years of experience data, combined with market resource conditions,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com