Lump coal pyrolysis experimental method for melting gasification furnace

A technology of melter gasifier and test method, which is used in coke ovens, special forms of dry distillation, instruments, etc., can solve the problems of poor differentiation, small heat storage of muffle furnaces, easy to burst, etc. The effect of poor differentiation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

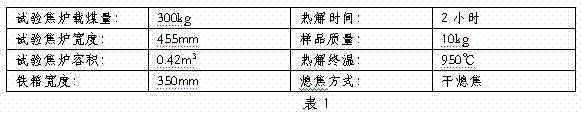

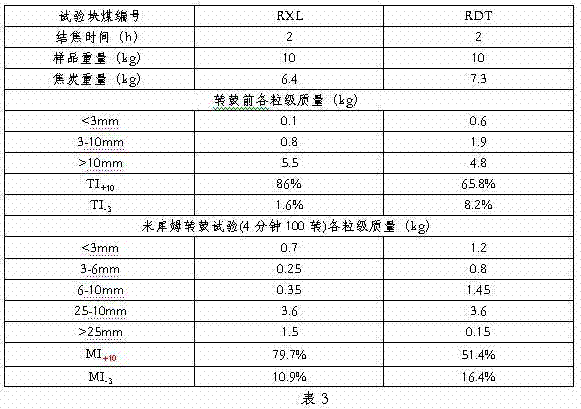

[0024] A test method for pyrolysis of lump coal for melting and gasification furnaces, including three parts: lump coal mechanical strength test, lump coal coking characteristic test and lump coal semi-coke strength test;

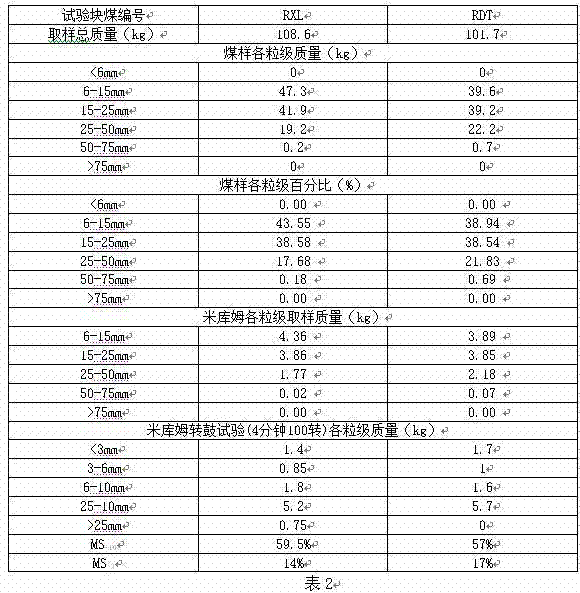

[0025] 1. At the beginning, make samples first, sieve the lump coal samples to be tested, and classify them with 6mm, 15mm, 25mm, 50mm, and 75mm sieves respectively, record the weights of all levels in the obtained coal samples, and select coals with particle size above 6mm Calculate the proportion of each particle size, and then mix the coal samples larger than 6mm into 5-20kg samples according to the above-mentioned ratio of particle size;

[0026] 2. Then use the samples to carry out lump coal mechanical strength test, lump coal coking characteristic test and lump coal semi-coke strength test respectively;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com